Fuel cell cars are an innovative and eco-friendly alternative to traditional internal combustion engine vehicles. These cars run on electricity generated through a chemical reaction between hydrogen and oxygen, producing only water as a byproduct. To power these vehicles, you need to understand the process of fueling, which involves supplying compressed hydrogen gas into the fuel cell stack. This process is similar to refueling a conventional car but requires specialized equipment and stations that can provide high-pressure hydrogen gas. The efficiency and environmental benefits of fuel cell cars make them a promising technology for the future of sustainable transportation.

What You'll Learn

- Fuel Cell Basics: Understand the core technology behind fuel cells and their role in powering vehicles

- Hydrogen Storage: Learn about methods to safely store hydrogen for fuel cell cars

- Fuel Cell Design: Explore the engineering of fuel cell systems for optimal performance and efficiency

- Refueling Process: Discover the steps involved in refueling a fuel cell car, including hydrogen dispensing

- Environmental Impact: Assess the environmental benefits of fuel cell vehicles compared to traditional combustion engines

Fuel Cell Basics: Understand the core technology behind fuel cells and their role in powering vehicles

Fuel cells are innovative devices that offer a clean and efficient way to power vehicles, providing an alternative to traditional internal combustion engines. At its core, a fuel cell is a device that generates electricity through a chemical reaction, specifically the electrochemical reaction of hydrogen and oxygen. This process produces electricity, water, and heat, making fuel cells a highly efficient and environmentally friendly power source.

The basic principle behind fuel cells is simple yet powerful. They consist of two electrodes, an anode and a cathode, separated by an electrolyte. When a fuel, typically hydrogen, is supplied to the anode, it undergoes a reaction with oxygen from the air, producing water and releasing electrons. These electrons flow through an external circuit, creating an electric current that can be used to power a vehicle's electrical systems. The electrolyte facilitates the movement of ions between the electrodes, ensuring the continuity of the reaction.

The beauty of fuel cells lies in their ability to produce electricity directly from a chemical reaction, eliminating the need for complex mechanical components like engines. This results in higher efficiency compared to conventional vehicles, as most of the energy in the fuel is converted into electricity, with minimal waste heat. Additionally, fuel cells produce no harmful emissions, only water vapor and warm air, making them an environmentally friendly choice for transportation.

One of the key advantages of fuel cell technology is its flexibility in terms of fuel options. While hydrogen is the most common fuel, fuel cells can also utilize other fuels like natural gas, methanol, or even organic liquids. This adaptability allows for a wide range of potential fuel sources, making fuel cell vehicles accessible and convenient for various applications.

In the context of powering vehicles, fuel cells offer a promising solution for sustainable transportation. They provide a continuous and stable source of power, ensuring a smooth and efficient driving experience. As the technology advances, fuel cell vehicles are becoming more practical and accessible, offering a cleaner and more efficient alternative to conventional cars, buses, and even heavy-duty vehicles.

Leaking Fuel Line: Safe Driving or Disaster in the Making?

You may want to see also

Hydrogen Storage: Learn about methods to safely store hydrogen for fuel cell cars

Hydrogen storage is a critical aspect of fuel cell technology, especially for vehicles powered by hydrogen fuel cells. The challenge lies in finding safe and efficient ways to store hydrogen, as it is a highly flammable and reactive gas. Several methods have been developed to overcome this hurdle, ensuring that hydrogen fuel cell cars can be practical and widely adopted.

One of the primary methods for hydrogen storage is through compression. Hydrogen gas is compressed to a high pressure, typically above 5,000 pounds per square inch (psi), which significantly reduces its volume. This high-pressure storage allows for a compact design, making it feasible to install hydrogen tanks in vehicles without compromising interior space. The compressed hydrogen is stored in specialized tanks made from advanced materials like carbon fiber composites, ensuring both strength and safety. These tanks are designed to withstand extreme conditions, including high pressure and temperature, to prevent any potential hazards.

Another approach is to store hydrogen in a liquid state. This method involves cooling hydrogen gas to extremely low temperatures, causing it to turn into a liquid. The liquid hydrogen is then stored in insulated tanks, which maintain the low temperature required to keep it in a liquid state. This technique offers a higher energy density compared to compressed hydrogen, allowing for longer driving ranges. However, it requires sophisticated cooling systems and specialized infrastructure for handling and refueling.

Metal-hydride storage is a unique method where hydrogen is absorbed into a metal-hydride compound. This process involves a chemical reaction between the metal-hydride material and hydrogen gas, resulting in the storage of hydrogen within the compound. Metal-hydride storage systems are often used in stationary fuel cell applications but have shown promise for mobile applications as well. The advantage of this method is its ability to release hydrogen at relatively low temperatures and pressures, making it safer for on-board storage.

Additionally, chemical hydrogen storage materials, such as ammonia borane (AB), are being explored. These materials can store hydrogen in a stable form and release it when needed. The process involves chemical reactions that can be triggered by heat or catalysts, providing a potential solution for safe and efficient hydrogen storage. However, this method is still under development and requires further research to ensure reliability and performance.

In summary, hydrogen storage for fuel cell cars involves various techniques, each with its own advantages and challenges. Compression, liquid storage, metal-hydride absorption, and chemical storage methods are all being investigated to find the most suitable solution for practical and widespread adoption of hydrogen fuel cell vehicles. The focus is on ensuring safety, efficiency, and convenience, making hydrogen fuel cell cars a viable alternative to traditional internal combustion engine vehicles.

Unleashing Flexibility: Understanding the Mechanics of Flex Fuel Cars

You may want to see also

Fuel Cell Design: Explore the engineering of fuel cell systems for optimal performance and efficiency

Fuel cell technology is a promising alternative to traditional internal combustion engines, offering a clean and efficient power source for vehicles. The design of fuel cell systems is a complex engineering challenge, requiring careful consideration of various factors to ensure optimal performance and efficiency. Here's an overview of the key aspects involved in fuel cell design:

- Electrolyte Membrane Selection: The heart of a fuel cell is the electrolyte membrane, which facilitates the movement of protons (H+) while blocking electrons. This membrane is crucial for the efficient transport of reactants and products. Engineers must choose the right material, such as perfluorosulfonic acid (PFSA) or sulfonated polyetheretherketone (SPEEK), considering factors like conductivity, stability, and tolerance to operating conditions. The membrane's thickness and porosity also play a role in optimizing gas diffusion and overall cell performance.

- Catalysts and Electrode Design: Catalysts are essential for facilitating the electrochemical reactions at the anode and cathode. Common catalysts include platinum, palladium, and their alloys. The design involves optimizing catalyst loading, particle size, and distribution to maximize reaction rates. Electrode design is critical, as it provides a large surface area for the reactions to occur. Engineers aim to create a thin, highly conductive electrode with a uniform catalyst distribution to minimize resistance and maximize efficiency.

- System Integration and Optimization: Fuel cell systems consist of multiple components, including fuel tanks, pumps, humidifiers, and control units. Efficient system integration is vital. Engineers must ensure proper fluid and gas management, including fuel supply, cooling, and humidity control, to maintain optimal operating conditions. The design should also consider the overall size, weight, and packaging of the fuel cell stack to meet vehicle requirements.

- Thermal and Mechanical Management: Fuel cells operate optimally within specific temperature ranges. Effective thermal management is essential to maintain performance and longevity. Engineers employ various techniques, such as liquid or air cooling, to dissipate heat generated during operation. Mechanical design also focuses on structural integrity, vibration resistance, and the ability to withstand the rigors of vehicle operation.

- Fuel Processing and Storage: The design of fuel cell vehicles involves considerations for fuel storage and processing. Hydrogen, the most common fuel, requires high-pressure tanks or advanced storage materials. Engineers must ensure safe and efficient fuel supply, including fuel purification, compression, and delivery systems. The overall goal is to provide a reliable and convenient refueling experience while maintaining system efficiency.

In summary, fuel cell design is a multifaceted engineering endeavor. It involves meticulous selection of materials, optimization of component design, and careful system integration to achieve high performance and efficiency. By addressing these aspects, engineers can contribute to the development of fuel cell vehicles that offer a sustainable and environmentally friendly transportation solution.

Hydrogen Fuel Cell Safety: Myth vs. Reality

You may want to see also

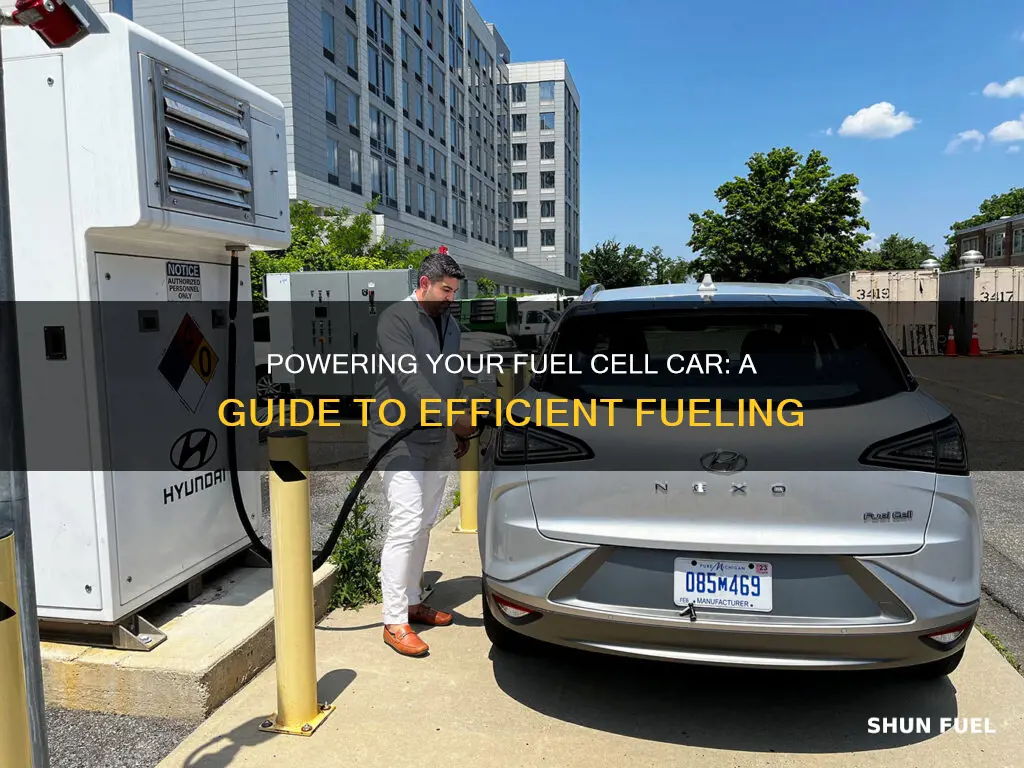

Refueling Process: Discover the steps involved in refueling a fuel cell car, including hydrogen dispensing

The refueling process for a fuel cell car is a straightforward procedure, but it involves specialized equipment and knowledge of hydrogen dispensing. Here's a step-by-step guide to understanding how to refuel these vehicles:

Location and Preparation: Fuel cell cars are typically refueled at dedicated hydrogen stations, which are becoming more common in many regions. Before refueling, ensure that the vehicle is parked in a well-ventilated area, and follow any safety instructions provided by the station staff. It is essential to have the necessary safety gear, such as protective clothing and equipment, as hydrogen is a highly flammable gas.

Hydrogen Dispensing: The refueling process begins with the dispensing of hydrogen gas. Hydrogen stations use specialized equipment to compress and store hydrogen in various forms, such as compressed gas or liquid. The dispensing process involves connecting the vehicle's fueling port to the hydrogen supply using a high-pressure hose. This hose is designed to handle the extreme pressures required to fill the vehicle's fuel tank efficiently. The dispensing rate is carefully controlled to ensure the vehicle's tank is filled to the appropriate level, which may take a few minutes depending on the vehicle's capacity.

Filling the Fuel Tank: As hydrogen is dispensed, it fills the vehicle's fuel tank, which is typically located under the floor or in the trunk. Modern fuel cell cars have sophisticated systems that monitor the filling process, ensuring the tank is filled to the correct pressure and volume. The vehicle's onboard computer system may provide real-time updates on the refueling progress, allowing drivers to know when the process is complete.

Post-Refueling Checks: After refueling, it is essential to perform a few checks. Ensure that the fueling port is properly sealed to prevent any hydrogen leaks. Conduct a visual inspection of the vehicle for any signs of damage or contamination. Additionally, some vehicles may have a post-refueling procedure, such as a brief driving cycle, to ensure the fuel cell system operates optimally after refueling.

Refueling a fuel cell car is a precise and controlled process, ensuring the vehicle's efficient operation and safety. With the increasing availability of hydrogen stations, the convenience of refueling these vehicles is improving, making fuel cell technology an attractive alternative to traditional internal combustion engines.

Fuel Injector Cleaner: Too Much of a Good Thing?

You may want to see also

Environmental Impact: Assess the environmental benefits of fuel cell vehicles compared to traditional combustion engines

The environmental advantages of fuel cell vehicles (FCVs) over traditional combustion engine vehicles are significant and offer a promising path towards a more sustainable transportation future. One of the most notable benefits is the reduction of greenhouse gas emissions. Fuel cells produce electricity through a chemical reaction between hydrogen and oxygen, resulting in the only byproduct being water vapor and warm air, making FCVs a zero-emission vehicle in terms of tailpipe emissions. This is in stark contrast to conventional internal combustion engines (ICEs), which burn fossil fuels and release a multitude of pollutants, including carbon dioxide, nitrogen oxides, and particulate matter, contributing to air pollution and climate change.

In addition to zero tailpipe emissions, fuel cell vehicles also contribute to a cleaner environment by reducing the demand for fossil fuels. Hydrogen, when used as a fuel, can be produced from renewable sources such as wind or solar power, or through the electrolysis of water using renewable electricity. This process of hydrogen production is crucial as it allows for the displacement of conventional fossil fuel-based energy production, which is a major source of carbon emissions. By utilizing renewable energy for hydrogen generation, FCVs can significantly lower the carbon footprint of the transportation sector.

The environmental impact of FCVs extends beyond their own operation. The infrastructure required to support these vehicles is also becoming increasingly sustainable. Hydrogen refueling stations, for instance, can be powered by renewable energy sources, further reducing the overall environmental impact. Moreover, the development of fuel cell technology encourages the use of sustainable materials and manufacturing processes, which can have a positive effect on the environment throughout the vehicle's lifecycle.

Comparing FCVs to ICEs, the former offer a more efficient and environmentally friendly alternative. While ICEs convert only about 20-30% of the energy in fuel to power, fuel cells can achieve efficiencies of up to 60%, making them more energy-efficient. This higher efficiency means less energy is wasted, and consequently, fewer resources are consumed, leading to a reduced environmental impact.

In summary, fuel cell vehicles present a compelling case for a greener transportation system. Their ability to produce zero tailpipe emissions, the potential for renewable hydrogen production, and the overall efficiency gains make them a significant step forward in mitigating the environmental impact of the transportation sector. As technology advances and infrastructure develops, FCVs could play a crucial role in reducing our reliance on fossil fuels and combating climate change.

Unleash Your Ride: A Guide to Finding Your Car's Fuel Tank Capacity

You may want to see also

Frequently asked questions

Fuel cell cars typically use hydrogen as their primary fuel source. The hydrogen is stored in high-pressure tanks or as a compressed gas, and it is then fed into the fuel cell stack.

The fuel cell's electrochemical process combines hydrogen and oxygen (from the air) to produce electricity, water, and heat. This reaction occurs at the anode and cathode within the fuel cell stack. The hydrogen fuel is oxidized at the anode, releasing electrons, while oxygen is reduced at the cathode. This process creates a flow of electrons, generating electricity, and the byproducts are harmless water vapor and warm air.

No, fuel cell cars are designed to run on hydrogen fuel only. Gasoline or diesel engines use internal combustion to generate power, which is fundamentally different from the electrochemical process of fuel cells. Hydrogen fuel cells are a clean and efficient alternative to traditional combustion engines, producing zero direct emissions.