Fixing a fuel sensor in a car can be a complex task, but with the right tools and knowledge, it is possible to resolve the issue. The fuel sensor, also known as the fuel level sensor, plays a crucial role in monitoring the amount of fuel in the tank and providing accurate readings to the car's computer system. If the sensor is faulty, it can lead to inaccurate fuel gauge readings, engine performance issues, and even prevent the car from starting. This guide will provide a step-by-step approach to diagnosing and repairing the fuel sensor, covering common problems, troubleshooting techniques, and the necessary tools and procedures to get your car running smoothly again.

What You'll Learn

- Diagnose Sensor Issues: Check for error codes, test sensor output, and inspect wiring

- Clean or Replace Sensor: Use a cleaner or replace if damaged

- Test Fuel Level Accuracy: Verify sensor readings with actual fuel levels

- Check Electrical Connections: Ensure all wires are secure and free of corrosion

- Seek Professional Help: Consult a mechanic for complex sensor repairs

Diagnose Sensor Issues: Check for error codes, test sensor output, and inspect wiring

When dealing with a fuel sensor in a car, the first step in diagnosing any issues is to check for error codes. Modern vehicles are equipped with onboard diagnostic systems (OBD) that can detect and store trouble codes related to various components, including the fuel sensor. You can access these error codes using a diagnostic scanner or code reader, which is a tool that connects to the OBD port of your car. By retrieving the error codes, you can identify specific problems with the sensor or its related circuitry. For example, a common error code related to fuel sensors is P0489, which indicates a malfunction in the fuel level sensor circuit. Understanding these codes is crucial as they provide valuable insights into the nature of the sensor issue.

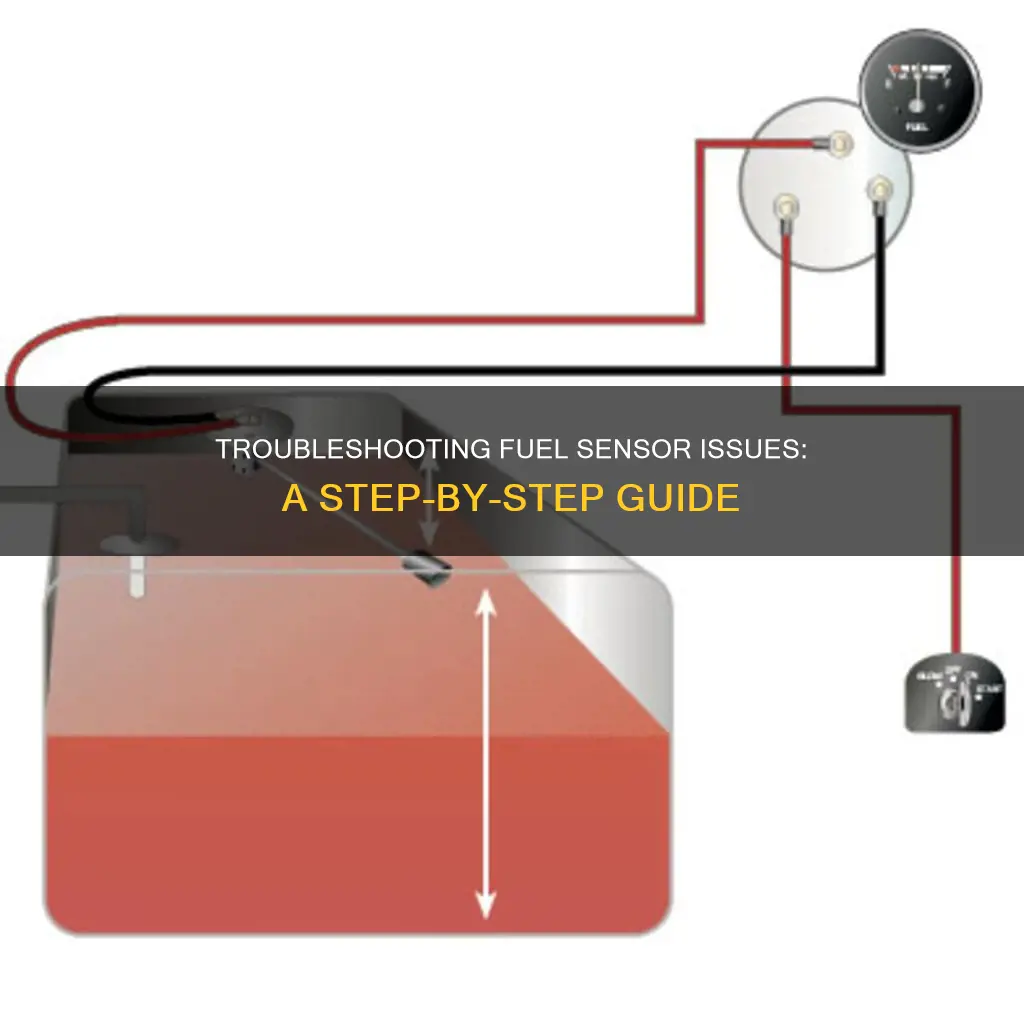

Once you have the error codes, the next step is to test the sensor's output. Fuel sensors typically convert the fuel level or quality into an electrical signal that the engine control unit (ECU) can interpret. You can use a multimeter or a specialized fuel sensor tester to measure the sensor's output voltage or current. Compare the readings with the expected values for a healthy sensor. If the sensor's output is outside the normal range, it may indicate a faulty sensor. For instance, if the sensor is supposed to output a specific voltage when the fuel tank is full, and it consistently reads lower, it could suggest a malfunctioning sensor.

In addition to testing the sensor's output, it is essential to inspect the wiring connected to the fuel sensor. Over time, wiring can become damaged due to wear, corrosion, or exposure to harsh conditions. Start by checking the wiring harness for any visible signs of damage, such as frayed or exposed wires, burn marks, or loose connections. Ensure that all wiring connections are secure and free from corrosion. If you find any issues with the wiring, you may need to repair or replace it. It's also a good idea to check for any loose connections at the sensor itself and ensure that the ground wire is properly attached.

Furthermore, pay attention to the sensor's mounting and ensure it is securely attached to the fuel tank or related components. A loose sensor can lead to inaccurate readings and potential damage during vehicle operation. If the sensor is accessible, gently rock it back and forth to ensure it moves freely within its housing. This simple test can help identify any internal sensor issues or obstructions. Remember, proper wiring and secure mounting are crucial for accurate sensor performance.

By following these steps, you can systematically diagnose sensor issues in a car. Checking for error codes provides a starting point, while testing the sensor's output and inspecting the wiring offer further insights into the problem. This approach allows for a more accurate identification of the fuel sensor's condition, enabling you to take the necessary steps for repair or replacement.

Unveiling the Fuel Cell Car's Range: A Comprehensive Guide

You may want to see also

Clean or Replace Sensor: Use a cleaner or replace if damaged

When dealing with a faulty fuel sensor in your car, the first step is to assess whether cleaning or replacing the sensor is the appropriate solution. Cleaning the sensor can often resolve issues caused by dirt, debris, or corrosion, while replacement is necessary if the sensor is damaged beyond repair. Here's a step-by-step guide to help you decide and take action:

Cleaning the Fuel Sensor:

- Start by ensuring you have the necessary tools, including a fuel sensor cleaner, which is typically a specialized cleaning solution. You can find these at auto parts stores or online.

- Locate the fuel sensor, which is usually positioned near the fuel tank or along the fuel lines. It is often a small, cylindrical device with electrical connections.

- Carefully disconnect the sensor's electrical connections to avoid any short circuits. Take note of the sensor's position to facilitate reattachment.

- Apply the cleaner to the sensor, following the manufacturer's instructions. This process may involve soaking the sensor in the cleaner or spraying it directly onto the sensor's surface. Allow the cleaner to work for the recommended time, which can vary depending on the product.

- After cleaning, rinse the sensor thoroughly with water to remove any residual cleaner. Ensure no cleaning solution remains inside the sensor.

- Once cleaned, reattach the sensor to its original position, ensuring all connections are secure.

When to Replace the Sensor:

- If cleaning the sensor does not resolve the issue, or if you notice visible signs of damage such as cracks, corrosion, or a burnt smell, it is time to consider replacement.

- Over time, sensors can degrade due to exposure to fuel contaminants, heat, or mechanical stress. If the sensor is old and consistently failing, replacement might be necessary.

- When replacing the sensor, ensure you purchase a compatible part from a reputable source. Follow the manufacturer's instructions for proper installation.

- After replacing the sensor, test the vehicle's fuel system to ensure the new sensor is functioning correctly. This can often be done using a diagnostic tool or by checking for error codes.

Remember, regular maintenance and cleaning of the fuel sensor can prevent many common issues. However, if the sensor is damaged or beyond repair, replacement is the only way to ensure optimal fuel system performance and avoid potential engine problems. Always consult a professional mechanic if you are unsure about any step or if the issue persists after attempting these solutions.

Coasting in Gear: Fuel Efficiency and Engine Behavior

You may want to see also

Test Fuel Level Accuracy: Verify sensor readings with actual fuel levels

To ensure the accuracy of your fuel sensor, it's crucial to periodically verify its readings against the actual fuel levels in your vehicle. This process helps identify any potential issues with the sensor or the fuel gauge, ensuring you have an accurate representation of your fuel status. Here's a step-by-step guide on how to test the fuel level accuracy:

- Prepare the Vehicle: Park your car on a level surface and ensure it's in a stationary position. Turn off the engine and allow it to cool down if it has been running. This step is important to ensure the fuel level doesn't fluctuate due to engine operation.

- Check the Fuel Gauge: Start by checking the fuel gauge. Note the reading and make a mental or written record of the current fuel level. This will serve as your reference point for comparison. Modern vehicles often have digital displays, while older models might have analog gauges.

- Remove the Fuel Tank Cap: Carefully remove the fuel tank cap to access the fuel level sensor. The location of this cap varies depending on the vehicle make and model. Some cars have it on the side of the fuel tank, while others might require opening the hood. Be cautious as fuel vapor can be hazardous.

- Measure the Fuel Level: Using a measuring stick or a similar tool, carefully insert it into the fuel tank to measure the actual fuel level. Ensure the tool reaches the bottom of the tank to get an accurate reading. Record this measurement, as it represents the true fuel level.

- Compare Readings: Now, compare the fuel gauge reading with the actual fuel level you measured. If the sensor reading is significantly different from the measured value, it may indicate a malfunction. For instance, if the gauge shows a full tank but the measurement shows only a quarter of fuel, there could be an issue with the sensor or the gauge itself.

- Repeat for Different Fuel Levels: It's essential to test the sensor's accuracy at various fuel levels. When the tank is nearly empty, full, and at various stages in between, you can get a comprehensive understanding of the sensor's performance. This will help identify any discrepancies across the entire fuel range.

- Troubleshooting: If you consistently find discrepancies between the sensor readings and the actual fuel levels, it's time to troubleshoot. Check for any visible damage to the sensor or wiring. Ensure the sensor is properly seated and connected. If issues persist, consider consulting a professional mechanic for further diagnosis and potential sensor replacement.

By following these steps, you can ensure that your fuel sensor provides accurate readings, helping you make informed decisions about your vehicle's fuel status and maintenance needs. Regular testing is an essential part of vehicle maintenance to avoid unexpected breakdowns due to fuel-related issues.

AC Fan Speed: Fuel Efficiency Impact Explained

You may want to see also

Check Electrical Connections: Ensure all wires are secure and free of corrosion

When dealing with a faulty fuel sensor in your car, one of the most common issues is related to the electrical connections. Over time, these connections can loosen, corrode, or even break, leading to inaccurate readings or complete failure of the sensor. Here's a step-by-step guide on how to check and address these electrical connections:

- Locate the Fuel Sensor: Start by identifying the fuel sensor in your vehicle. The location can vary depending on the car model, but it is typically found near the fuel tank or along the fuel lines. Refer to your car's manual if you're unsure about the exact location.

- Inspect the Wiring: Carefully examine the wires connected to the fuel sensor. Look for any signs of damage, such as frayed or exposed insulation. Check for any loose connections where the wires are attached to the sensor and the vehicle's wiring harness. Ensure that the wires are securely plugged into their respective terminals.

- Tighten Connections: If you find any loose wires, gently tighten the connections. Use a wrench or a small tool to secure the wires, ensuring they are snug and won't come loose during driving. Make sure not to overtighten, as this can damage the wires or the sensor.

- Clean Corroded Connections: Corrosion can build up over time, especially in harsh weather conditions. If you notice any corrosion around the connections, carefully clean it. You can use a small brush or a cotton swab dipped in isopropyl alcohol to remove the corrosion. Ensure that all traces of corrosion are gone before proceeding.

- Check for Short Circuits: Sometimes, corrosion or damaged insulation can lead to short circuits. Inspect the wires for any signs of melting or burning, which could indicate a short circuit. If you find any, it's best to replace the affected wires to prevent further damage.

- Test the Sensor: After ensuring the connections are secure and clean, test the fuel sensor to see if it's functioning correctly. You can use a multimeter to check for continuity and proper voltage readings. If the sensor still doesn't work, you may need to consider other potential issues or consult a professional mechanic.

By following these steps, you can often resolve electrical connection problems with your fuel sensor, ensuring it provides accurate fuel level readings. Regular maintenance and inspection of these connections can help prevent future issues.

Emptying Your Car's Fuel Tank: A Step-by-Step Guide

You may want to see also

Seek Professional Help: Consult a mechanic for complex sensor repairs

While it's tempting to try and tackle car sensor issues yourself, especially with the wealth of online resources available, certain repairs, like fixing a fuel sensor, are best left to the professionals. Here's why:

Complexity: Fuel sensors are intricate components, often located in hard-to-reach places within your engine bay. They require specialized knowledge and tools to diagnose and repair accurately. A mechanic has the experience to pinpoint the exact cause of the sensor malfunction, whether it's a faulty wiring connection, a damaged sensor element, or an issue with the sensor's mounting.

Safety Considerations: Working with car sensors involves dealing with electricity and potentially hazardous engine components. A professional mechanic understands the safety protocols and can ensure your vehicle is properly isolated and secured during the repair process, minimizing the risk of accidents or further damage.

Diagnostic Expertise: Diagnosing sensor problems can be tricky. A qualified mechanic will use advanced diagnostic equipment to identify the specific issue with the fuel sensor. This might involve scanning the vehicle's computer system for error codes, testing sensor output signals, or even removing and testing the sensor itself. Their expertise allows for a more accurate and efficient resolution.

Warranty and Longevity: Attempting complex repairs yourself may void your vehicle's warranty. Additionally, improper repairs can lead to further complications and potentially shorten the lifespan of other engine components. A professional repair ensures your fuel sensor is fixed correctly, restoring optimal engine performance and potentially saving you money in the long run by preventing additional repairs.

Remember, while DIY repairs can be rewarding, some tasks are best handled by professionals. Consulting a qualified mechanic for fuel sensor repairs is a wise investment in your vehicle's health and your safety.

Fuel Pump Replacement: Cost Guide for Older Cars

You may want to see also

Frequently asked questions

Common signs of a faulty fuel sensor include erratic engine performance, hard starting, stalling, or frequent "Check Engine" lights. If you notice any of these symptoms, it's best to have the sensor inspected by a professional mechanic.

While some basic troubleshooting can be done by car owners, replacing a fuel sensor often requires specialized tools and knowledge. It's recommended to consult a qualified mechanic to ensure proper diagnosis and repair.

Fuel sensors can fail due to various reasons, including contamination of the fuel, sensor degradation over time, electrical issues, or physical damage. Regular maintenance and fuel system cleaning can help prevent sensor failure.

The cost of replacing a fuel sensor varies depending on the make and model of your car, as well as the location of the sensor. On average, it can range from $100 to $300, but it's best to get a quote from a local mechanic for an accurate estimate.

Temporary solutions are not recommended as they may provide short-term relief but can lead to more serious issues. It's crucial to address the problem permanently by replacing the sensor or resolving any underlying causes.