Fixing a car's fuel gauge can be a straightforward process if you follow the right steps. The fuel gauge is a critical component that provides drivers with an accurate indication of their vehicle's fuel level. Over time, the gauge may malfunction due to various reasons, such as sensor issues, wiring problems, or even a faulty gauge itself. This guide will provide a comprehensive overview of the process, including identifying the cause of the issue, gathering the necessary tools and parts, and following a step-by-step repair procedure. Whether you're a seasoned mechanic or a DIY enthusiast, this guide will equip you with the knowledge to get your fuel gauge working properly again.

What You'll Learn

- Identify the Problem: Check for loose connections, faulty sensors, or damaged wiring

- Locate the Gauge: Access the fuel gauge module, often under the dashboard

- Test the Sensor: Use a multimeter to test the fuel level sensor for continuity

- Replace the Gauge: If faulty, replace the fuel gauge with a new one

- Calibrate the System: Reset the gauge by draining the fuel tank and refilling

Identify the Problem: Check for loose connections, faulty sensors, or damaged wiring

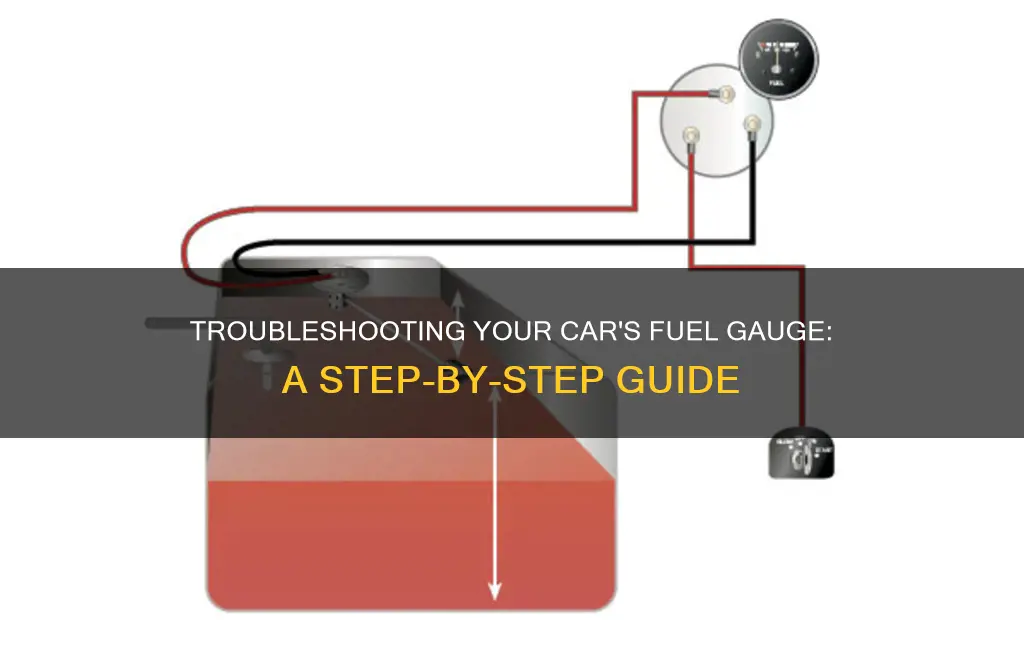

When your car's fuel gauge is acting erratically or not working at all, the first step is to identify the root cause of the issue. This involves a systematic check of the various components involved in the fuel gauge system. One of the most common reasons for a faulty fuel gauge is a problem with the electrical connections. Over time, these connections can loosen due to vibration or corrosion, leading to erratic readings or a complete failure of the gauge. Start by inspecting the fuel gauge sender unit, which is usually located in the fuel tank. This unit has a small float that rises and falls with the fuel level, and it sends this information to the gauge via a series of wires. Carefully check the connections at the sender unit and the gauge itself. Ensure that all wires are securely plugged into their respective ports and that there is no visible damage or corrosion. If you find any loose connections, tighten them gently but firmly.

Moving on, the fuel gauge sensor itself can also be at fault. This sensor, often a small float-type mechanism, is responsible for providing the actual fuel level data to the gauge. If it is faulty, the gauge may not accurately reflect the fuel level. Inspect the sensor for any signs of damage or wear. It should be clean and free of debris. In some cases, the sensor might need to be replaced, especially if it has become stuck or is not functioning properly.

Wiring issues are another potential cause of a malfunctioning fuel gauge. The wiring harness that connects the sender unit to the gauge can become damaged or corroded over time. Check for any visible signs of damage, such as frayed or burnt-out wires. Also, look for any signs of moisture or corrosion around the wiring connections. If you find any damaged wiring, it may need to be replaced. Ensure that you use the correct gauge and color of wire when making any repairs to maintain the integrity of the electrical system.

In addition to these checks, it's also worth considering the overall health of the fuel tank and its components. Over time, fuel can accumulate sediment or contaminants that can interfere with the sender unit's performance. If the fuel gauge is still not working after addressing the electrical connections and sensors, it might be worth draining and cleaning the fuel tank to ensure that no debris is affecting the sender unit's operation.

Identifying the problem early on is crucial to avoiding more extensive and costly repairs. By systematically checking for loose connections, faulty sensors, and damaged wiring, you can often resolve the issue and get your fuel gauge working correctly again. If, after these checks, the problem persists, it may be best to consult a professional mechanic who can provide further diagnosis and repair services.

The Efficiency of Fuel Cell Cars: A Comprehensive Review

You may want to see also

Locate the Gauge: Access the fuel gauge module, often under the dashboard

To begin the process of fixing your car's fuel gauge, you'll need to locate the gauge itself. The fuel gauge is typically found under the dashboard, often in a compartment that houses various dashboard components. This compartment is usually accessible by removing the dashboard trim or the center console cover. Once you've located the general area, you can start the process of accessing the fuel gauge module.

The fuel gauge module is a small electronic component that houses the sensors and wiring connected to the fuel gauge. It is often a rectangular or square-shaped box, and its exact location can vary depending on the make and model of your car. Some vehicles may have the module integrated into the dashboard itself, while others might have it mounted separately. Carefully inspect the dashboard and surrounding areas to identify the correct module.

Carefully remove any trim panels or covers that might be obstructing your view or access to the module. This might involve prying off small clips or screws that hold the panels in place. Take your time and be gentle to avoid causing any damage. Once the panels are removed, you should be able to see the fuel gauge module clearly.

With the module now accessible, you can proceed to the next steps of diagnosing and fixing the fuel gauge issue. This may involve checking the wiring connections, inspecting the sensors, or replacing any faulty components. It's important to have a basic understanding of car mechanics and electronics or to consult a repair manual specific to your vehicle to ensure you perform the necessary repairs correctly.

Maximizing Your Car's Fuel Capacity: A Comprehensive Guide

You may want to see also

Test the Sensor: Use a multimeter to test the fuel level sensor for continuity

Testing the fuel level sensor with a multimeter is a crucial step in diagnosing fuel gauge issues. This method allows you to check for continuity, ensuring the sensor functions properly. Here's a detailed guide on how to perform this test:

Gather the Tools:

You'll need a multimeter, preferably one with a range suitable for measuring ohms (Ω). A basic multimeter with a continuity test function will also work. Ensure you have a set of test leads with probes for connecting to the sensor.

Locate the Sensor:

Accessing the fuel level sensor can vary depending on your vehicle's make and model. Consult your car's manual or online resources to locate the sensor. It is typically found near the fuel tank, often attached to the fuel pump or along the fuel lines.

Prepare the Multimeter:

Set your multimeter to the ohms setting. Ensure it is in good working condition and properly calibrated. Adjust the multimeter's dial to a suitable range, usually in the hundreds of ohms (Ω) or kilohms (kΩ) range.

Test for Continuity:

- Disconnect the negative terminal of the battery to prevent any accidental short circuits.

- Locate the sensor's wiring harness or connector. It will have multiple wires connected to it.

- Set one multimeter probe on the sensor's ground wire (usually a black or brown wire).

- Touch the other probe to each of the sensor's signal wires (typically white, yellow, or green) in turn. The multimeter should display a low resistance reading (a few ohms or less) when the probe is touching a good signal wire. If the resistance is infinite (no continuity), it indicates a faulty sensor or wiring.

- Repeat the process for each signal wire to ensure all connections are functioning.

Interpret the Results:

- A low resistance reading (a few ohms or less) indicates a healthy sensor with good continuity.

- Infinite resistance or a high resistance reading (above 10kΩ) suggests a broken sensor, damaged wiring, or a faulty multimeter connection.

Troubleshooting:

If the sensor test reveals a problem, further investigation is required. Check for loose connections, corroded terminals, or damaged wiring. Ensure all connections are clean and secure. If the issue persists, consider consulting a professional mechanic or referring to online repair guides specific to your vehicle model.

Remember, this test is a diagnostic tool to identify potential sensor issues. Further troubleshooting may be necessary to pinpoint the exact cause of the fuel gauge malfunction.

Ethanol Fuel: Friend or Foe for Your Car's Health?

You may want to see also

Replace the Gauge: If faulty, replace the fuel gauge with a new one

If your fuel gauge is not working correctly and you've tried the basic troubleshooting steps, it might be time to replace the gauge itself. This process can vary slightly depending on the make and model of your car, but here's a general guide to help you through the replacement process.

Step 1: Purchase a New Gauge

Start by sourcing a replacement fuel gauge that is compatible with your vehicle. You can find these at auto parts stores or online retailers. Ensure you have the correct gauge for your specific car model, as different vehicles may have varying gauge requirements.

Step 2: Disconnect the Old Gauge

Locate the fuel gauge on your dashboard. It is usually connected to the fuel sending unit via a series of wires. Carefully disconnect these wires, taking note of their positions and connections. You may need to remove the gauge cluster or have access to the dashboard to reach the gauge.

Step 3: Remove the Old Gauge

With the wires disconnected, you can now remove the old fuel gauge. This might involve unscrewing or releasing clips that hold the gauge in place. Be gentle to avoid damaging the surrounding dashboard components.

Step 4: Install the New Gauge

Place the new fuel gauge in the same position as the old one. Ensure it is aligned correctly and secure it in place. Reconnect the wires, making sure they are connected to the corresponding terminals on the new gauge. Double-check all connections to avoid any short circuits.

Step 5: Test and Calibrate

Once the new gauge is installed, start the vehicle and test the fuel level indication. Check if the gauge reads accurately and responds to changes in fuel levels. If necessary, you may need to calibrate the new gauge by adjusting it to match the actual fuel levels. This process can often be done by pressing and holding certain buttons on the gauge or using a diagnostic tool.

Remember, if you are unsure about any step or encounter complex issues, it is best to consult a professional mechanic who can provide specialized assistance for your car's make and model.

Prepaying for Fuel: JTR's Rental Car Policy

You may want to see also

Calibrate the System: Reset the gauge by draining the fuel tank and refilling

Calibrating the fuel gauge system by draining and refilling the fuel tank is a method often employed to reset the gauge and restore its accuracy. This process is particularly useful when the fuel gauge is reading incorrectly or showing an empty tank when there is still fuel left. Here's a step-by-step guide to help you through this calibration process:

- Prepare the Vehicle: Ensure the car is parked on a level surface and the engine is turned off. It is crucial to have a safe and stable environment to work on the vehicle.

- Locate the Fuel Tank Drain: Find the fuel tank drain valve, which is typically located at the bottom of the fuel tank. This valve allows you to drain the fuel from the tank. It might be a small screw or a dedicated drain port.

- Drain the Fuel Tank: Place a suitable container under the drain valve to catch the fuel as it drains out. Open the drain valve and allow the fuel to flow out until the tank is nearly empty. This step ensures that the gauge reads zero when the tank is drained. Be cautious and take necessary safety precautions when handling fuel.

- Refill the Fuel Tank: Once the tank is drained, carefully refill it with the appropriate fuel type. Ensure you add enough fuel to reach the desired level, considering the gauge's markings. It is essential to have a clear understanding of the gauge's scale to determine the correct fuel level.

- Start the Engine and Check the Gauge: After refilling, start the car's engine and monitor the fuel gauge. The gauge should now accurately reflect the fuel level in the tank. If the gauge still shows incorrect readings, you may need to repeat the process or consider other potential issues with the gauge or sensor.

- Repeat if Necessary: If the gauge doesn't respond correctly, you might need to repeat the calibration process. This could involve further draining and refilling until the gauge stabilizes and provides accurate readings.

Remember, this method is a temporary fix and might not address underlying issues with the fuel gauge or the vehicle's fuel system. If the problem persists, it is advisable to consult a professional mechanic to diagnose and resolve any potential technical faults.

Mastering Fuel Pressure: A Guide to Connecting the Regulator

You may want to see also

Frequently asked questions

A faulty fuel gauge can be identified by discrepancies between the gauge's reading and the actual fuel level in the tank. If you fill up your tank and the gauge doesn't reflect the expected amount, or if the needle jumps or fluctuates erratically, it could indicate a problem.

Common issues include damaged or worn-out gauge wiring, a faulty sending unit (which measures fuel level and sends the signal to the gauge), or a defective gauge itself. Sometimes, the problem can be as simple as a loose connection or a blown fuse.

Simple issues like a blown fuse or a loose connection can often be resolved by the vehicle owner. However, for more complex problems, especially if you're unsure about your mechanical skills, it's best to consult a professional mechanic. They have the tools and expertise to diagnose and repair the issue accurately.

Replacing the sending unit typically involves draining the fuel tank, removing the old unit, and installing the new one. This process can be complex and requires a good understanding of car mechanics. It's recommended to follow a detailed guide or seek professional assistance to ensure the job is done correctly.

In some cases, a temporary fix might involve checking and securing loose connections, cleaning the gauge and sending unit contacts, or even using a different gauge to test the wiring. However, these solutions are only temporary, and a proper diagnosis and repair are necessary for a long-term solution.