Disconnecting fuel pump lines is a crucial step in any vehicle maintenance or repair process, ensuring a safe and efficient workflow. This guide will provide a step-by-step approach to disconnecting fuel pump lines, covering essential safety precautions and techniques to ensure a smooth and successful disconnection. By following these instructions, you can effectively isolate the fuel system, making it safer to work on the vehicle's engine and other components.

What You'll Learn

Locate the fuel pump lines under the hood

To locate the fuel pump lines under the hood, you'll need to inspect the engine compartment carefully. Here's a step-by-step guide to help you identify the correct areas:

Start by opening the hood of your vehicle. Locate the engine, and you'll likely see a network of hoses and wires connected to various components. The fuel pump lines are typically responsible for supplying fuel from the tank to the engine. These lines can vary in appearance, but they often have a distinct color or marking to indicate their purpose. Common colors include black, blue, or red, and they might have a fuel symbol or label attached.

Look for the fuel tank, which is usually located at the front or rear of the vehicle, depending on the model. The fuel pump lines will extend from the tank, often running along the frame or near the engine. They might be secured with clamps or brackets to keep them in place. Carefully examine the area around the fuel tank and engine bay to find the lines.

In some cases, the fuel pump lines might be hidden behind other components or under insulation. If you can't see them clearly, try moving any accessible parts or using a flashlight to illuminate the area. The lines might also have a slight bend or angle to follow the engine's contours.

Remember to be cautious when handling these lines, as they can be delicate. Take note of their positions and any connections or fasteners they might have. If you need to disconnect them, ensure you have the necessary tools and a clear understanding of the process to avoid any damage.

Mastering Fuel Line Maintenance: Spring Decoupling Tool Techniques

You may want to see also

Identify the lines with fuel pump connectors

When it comes to disconnecting fuel pump lines, identifying the correct lines with fuel pump connectors is a crucial step. This process requires careful observation and understanding of your vehicle's fuel system. Here's a detailed guide to help you through this task:

Locate the fuel pump, which is typically found in the engine compartment, often near the fuel tank. The pump is responsible for delivering fuel from the tank to the engine. Once you've located the pump, you'll need to inspect the lines connected to it. These lines are usually made of rubber or plastic and have connectors that secure them to the pump and other components.

The fuel pump lines are often color-coded or marked with identifiers to differentiate them. Common colors include black, blue, and green. Look for these colors on the lines leading from the pump to the fuel filter, fuel pressure regulator, and the engine itself. Alternatively, some vehicles may have labels or tags attached to the lines, clearly indicating their destinations.

Pay close attention to the connectors. These are small, often plastic or metal, and can be found at the ends of the lines. The connectors typically have a locking mechanism that secures the line to the pump or another component. Carefully inspect each connector to ensure it is properly attached and locked.

It's important to note that the fuel pump lines are designed to be disconnected without causing any damage to the pump or the fuel system. However, be cautious not to force anything, as this can lead to damage. If a line is difficult to disconnect, ensure you have the correct tools, such as a fuel pump disconnect tool, and follow the manufacturer's instructions.

By carefully identifying the lines with fuel pump connectors, you'll be well-prepared to safely disconnect the fuel pump lines for maintenance or repairs. Remember, always exercise caution when working with fuel systems to avoid any potential hazards.

Unraveling the Mystery: What's Beneath the Fuel Line in Elite: Dangerous

You may want to see also

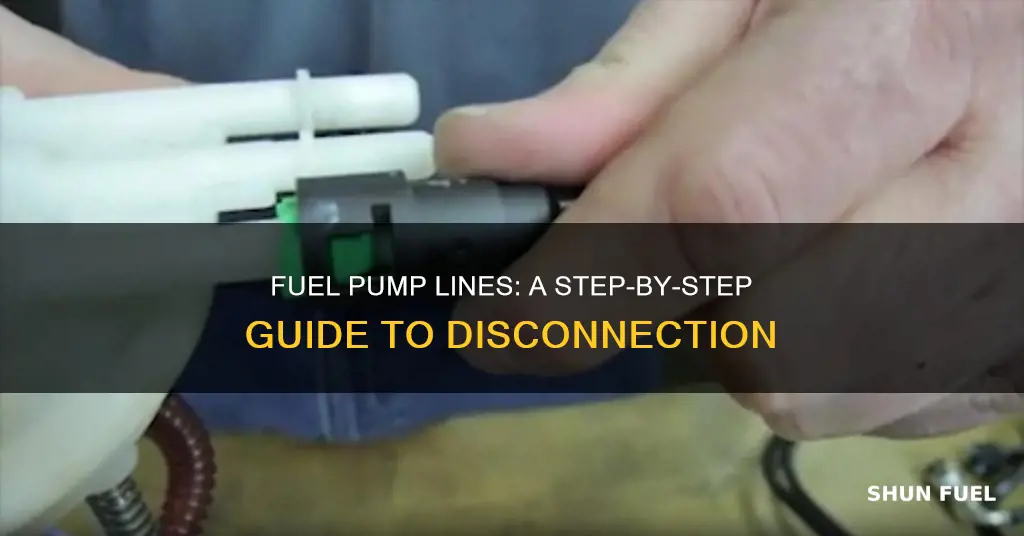

Disconnect the lines by removing the connectors

To disconnect the fuel pump lines, you'll need to locate the connectors that attach the lines to the fuel pump and the engine. These connectors are typically located near the fuel pump, often within the engine compartment. Start by identifying the specific connectors for the lines you want to disconnect. These connectors are usually made of plastic or metal and may have a locking mechanism to secure the lines in place.

Once you've identified the connectors, use the appropriate tools to remove them. The tools required will depend on the type of connector. For example, if the connectors have a bayonet or quick-release mechanism, you may need a small flathead screwdriver or a specialized tool to release the lock. For other types of connectors, you might need a pair of pliers or a fuel line disconnect tool. Carefully insert the tool into the connector and apply gentle force to release the connection. Ensure you do not force the tool, as this can damage the connector or the fuel line.

After releasing the connector, you should be able to pull the fuel line away from the fuel pump and the engine. Take note of the position of the line to ensure you can reconnect it correctly later. It's a good practice to clean the connectors and the surrounding area to remove any dirt or debris that may have accumulated. This ensures a proper connection when you reattach the lines.

Remember to handle the fuel lines with care, as they can be fragile. Avoid kinking or damaging the lines during the disconnection process. If you encounter any resistance or difficulty, double-check your tools and technique to ensure you are using the correct method. Once you have disconnected all the desired lines, you can proceed with the next steps of your project or maintenance routine.

Quick Fix: Temporary Solutions for Leaky Fuel Lines

You may want to see also

Ensure no fuel leaks before reassembling

Before you begin the process of disconnecting the fuel pump lines, it is crucial to ensure that you are working in a safe and controlled environment. Fuel leaks can be dangerous and cause environmental hazards, so taking the necessary precautions is essential. Start by identifying the fuel pump lines and their connections. These lines are typically located near the fuel tank and may be connected to the pump, the engine, or both. Locate the fuel pump module, which is often a small box-like component. It houses the pump and its associated wiring. Carefully inspect the lines for any signs of damage, cracks, or corrosion. If you notice any issues, it is best to replace the affected lines to prevent potential leaks.

Once you have identified the lines and ensured they are in good condition, proceed with the disconnection process. Locate the fuel pump relay, which is usually a small black box with multiple terminals. It controls the power to the fuel pump. Turn off the engine and disconnect the negative terminal of the battery to ensure the system is not energized. Now, carefully disconnect the fuel pump lines. Start with the line that connects the fuel pump to the engine. Loosen the clamp or fitting holding the line in place and carefully pull it away from the connection. Repeat this process for the other line, ensuring you do not force anything to avoid damage.

As you disconnect the lines, inspect the fittings and connections for any signs of fuel. If you notice any fuel seeping or dripping, it is a clear indication of a potential leak. In such cases, you may need to tighten the fittings or replace the affected lines. Take your time and be methodical to avoid missing any potential issues. Once all the lines are disconnected, place them in a secure location to prevent accidental re-attachment.

Before reassembling, it is essential to double-check for any fuel leaks. Apply a small amount of diesel fuel or a suitable fuel leak detector solution to the disconnected lines and fittings. Allow a few minutes for the product to work, then inspect the area for any signs of fuel. If you detect any leaks, you may need to tighten connections or replace damaged components. Ensure that all surfaces are clean and dry before proceeding.

After confirming that there are no fuel leaks, you can begin reassembling the fuel pump lines. Follow the reverse process of disconnection, ensuring that you reconnect the lines securely and tightly. Double-check each connection to guarantee a proper seal. Once reassembled, start the engine and check for any unusual noises or vibrations. Monitor the fuel gauge and ensure it reads correctly. If everything is functioning as expected, you can now proceed with the rest of your vehicle maintenance or repair tasks, knowing that the fuel pump lines are secure and leak-free.

Where to Find 5/16 Fuel Line: A Comprehensive Guide

You may want to see also

Test the fuel system after disconnecting the lines

After disconnecting the fuel pump lines, it's crucial to test the fuel system to ensure there are no leaks and that the system is functioning correctly. Here's a step-by-step guide on how to test the fuel system:

Step 1: Prepare the Vehicle

Before starting the test, ensure the vehicle is parked on a level surface and the engine is cool. Turn off the ignition and disconnect the negative battery terminal to prevent any accidental electrical discharges.

Step 2: Inspect the Lines

Visually inspect the disconnected fuel pump lines for any signs of damage, cracks, or leaks. Check for any visible signs of fuel leakage around the connections and fittings. If any issues are found, address them before proceeding with the test.

Step 3: Test for Fuel Pressure

Use a fuel pressure gauge to measure the pressure in the fuel lines. Connect the gauge to the fuel rail or the line where the pump connects. Turn the ignition to the 'on' position but do not start the engine. The gauge should read the expected fuel pressure, which can vary depending on the vehicle's specifications. If the pressure is significantly lower than expected, it may indicate a problem with the fuel pump or the pressure regulator.

Step 4: Check for Vacuum Leaks

Use a vacuum gauge to check for vacuum leaks in the fuel system. Connect the gauge to the intake manifold and create a vacuum by slightly raising the hood and opening the throttle body or air cleaner. The gauge should read a steady vacuum level. If the reading fluctuates or drops, it suggests a leak in the fuel system, such as a cracked fuel line or a faulty fuel tank vent.

Step 5: Start the Engine (Optional)

If you have access to a fuel pressure tester or a diagnostic tool, you can start the engine and monitor the fuel pressure while it runs. This will help identify any issues with the fuel injection system or the pump's operation.

Step 6: Document and Troubleshoot

Record the readings and observations from each test. If any issues are detected, you can further investigate and troubleshoot the problem. This may involve checking the fuel filter, inspecting the fuel injectors, or consulting the vehicle's manual for specific troubleshooting steps.

Remember, testing the fuel system requires caution and attention to detail. If you are unsure about any step, consult a professional mechanic or refer to the vehicle's manual for guidance.

Fuel Line Installation: A Guide to Running Lines on Your Poulan Chainsaw

You may want to see also

Frequently asked questions

Disconnecting fuel pump lines requires caution and a systematic approach to avoid any accidents or fuel leaks. First, ensure the engine is off and the vehicle is parked on a level surface. Locate the fuel pump module, which is usually found near the engine compartment. Use a fuel pump disconnect tool or a flathead screwdriver to carefully pry open the fuel pump access cover. Once the cover is open, you'll see the fuel pump lines. Loosen the nuts or clips securing the lines to the fuel pump and the fuel tank. Gently pull the lines apart, ensuring you do not twist or kink them. If the lines are difficult to separate, consider using a fuel pump disconnect kit, which provides the necessary tools and adapters.

Yes, having the right tools can make the process easier and safer. You will typically need a fuel pump disconnect tool, which is a specialized device designed to release the pressure and safely disconnect the fuel pump lines. These tools often include a handle and a set of jaws or prongs that grip the fuel lines. Alternatively, a flathead screwdriver can be used as a temporary solution, but it's important to be gentle and avoid applying excessive force. Additionally, having a set of wrenches or pliers might be useful for loosening any nuts or clips holding the lines in place.

Fuel leaks can be dangerous and should be addressed immediately. If you notice any fuel dripping or leaking during the disconnection, stop the process and locate the source of the leak. Ensure the engine is off and the vehicle is in a well-ventilated area. Use a rag or absorbent material to catch any spills and prevent contamination. Tighten any loose connections or replace damaged lines to stop the leak. If the leak persists or you are unsure about the cause, it is best to consult a professional mechanic who can safely resolve the issue and reconnect the fuel pump lines.