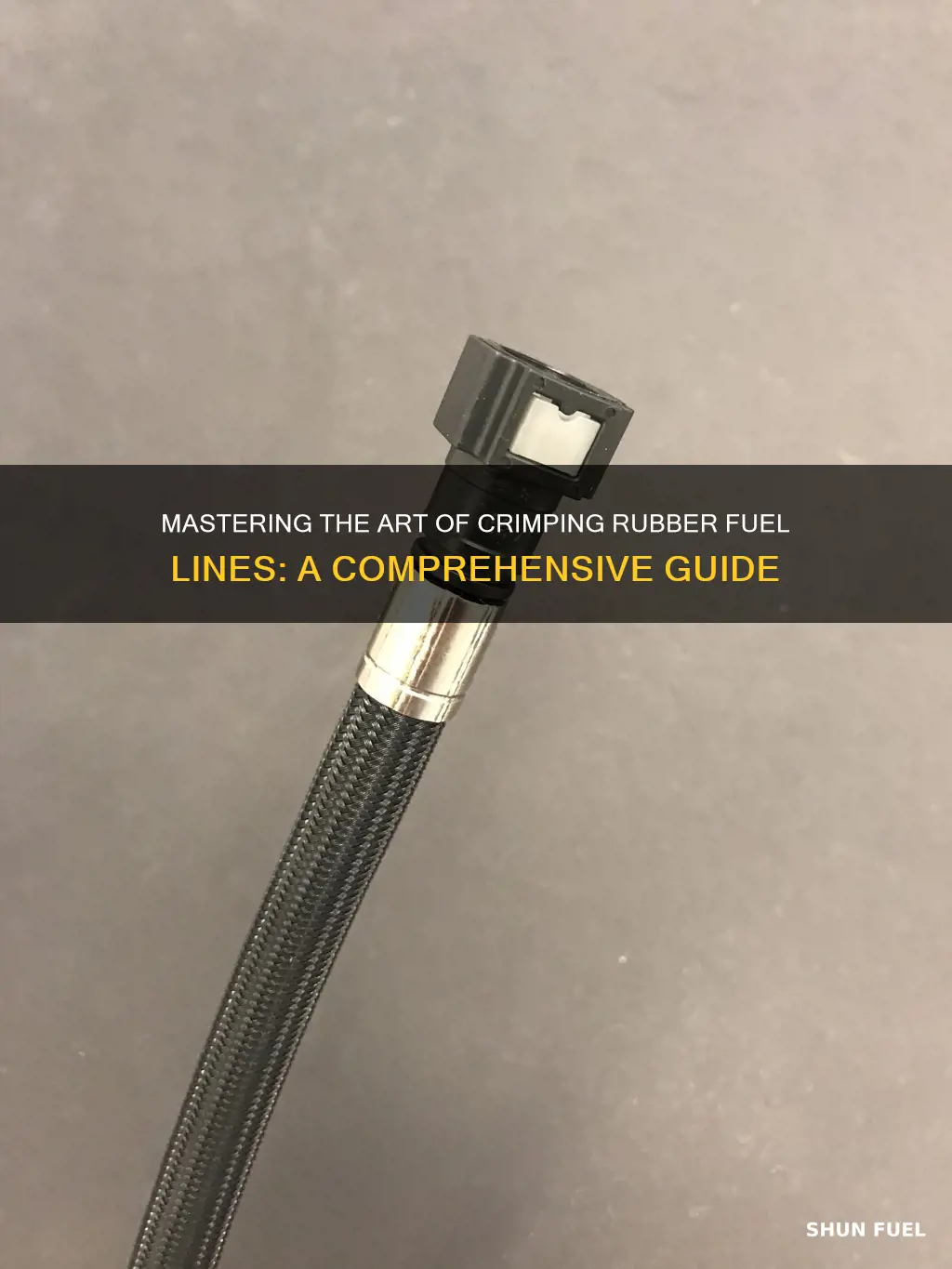

Crimping rubber fuel lines is a crucial skill for anyone working on vehicles, especially those with high-performance engines. This process involves connecting the fuel line to the fuel pump or tank using specialized tools and techniques to ensure a secure and leak-free seal. It requires precision and attention to detail to avoid damage to the fuel line or the crimping tool. This guide will provide a step-by-step process for crimping rubber fuel lines, including the necessary tools, safety precautions, and best practices to ensure a successful and reliable connection.

What You'll Learn

- Prepare Tools: Gather crimping tools, fuel line, and cleaning supplies

- Clean Line: Remove dirt and debris from the fuel line using a brush and solvent

- Measure Crimp: Mark the line with a ruler and crimping gauge for accurate bends

- Crimp Technique: Use a crimping tool to apply pressure to the marked areas

- Test Connection: Ensure a secure connection by checking for leaks and proper fit

Prepare Tools: Gather crimping tools, fuel line, and cleaning supplies

To begin the process of crimping a rubber fuel line, it is crucial to have the right tools and materials ready. First and foremost, you will need a crimping tool specifically designed for this purpose. These tools come in various types, such as manual crimpers, power crimpers, or hydraulic crimpers, each with its own advantages depending on the project's scale and complexity. Ensure you select a tool that matches the size and type of crimp required for your fuel line.

Gathering the appropriate fuel line is essential as well. Check the specifications of your vehicle or equipment to determine the correct size and type of fuel line needed. Rubber fuel lines are commonly used due to their flexibility and durability. Make sure to inspect the new fuel line for any defects or damage before proceeding with the installation.

In addition to the fuel line, you should also have cleaning supplies readily available. This includes a suitable solvent or cleaner designed for removing contaminants from the fuel line. It is important to clean the fuel line to ensure a proper crimp connection. You might also need a small brush or air compressor to blow away any debris or old fuel line residue.

Other necessary tools include a pair of pliers for gripping and holding the fuel line during the crimping process, a tape measure to ensure accurate measurements, and a sharp knife or cutting tool for any necessary adjustments or cuts. Having all these tools and materials prepared beforehand will make the crimping process more efficient and less stressful.

Challenger RT Fuel Lines: A 1970s Classic's Fuel System Breakdown

You may want to see also

Clean Line: Remove dirt and debris from the fuel line using a brush and solvent

To ensure a clean and efficient fuel line, it's crucial to remove any dirt and debris that may have accumulated over time. This process is essential for maintaining optimal performance and preventing potential issues. Here's a step-by-step guide on how to effectively clean the fuel line using a brush and solvent:

Preparation: Begin by gathering the necessary tools and materials. You'll need a suitable solvent, such as a fuel line cleaner or a mixture of gasoline and vinegar, a small brush with firm bristles (a toothbrush can be a good option), and a container for the solvent. Ensure you have adequate ventilation in your workspace to avoid inhaling any fumes.

Cleaning Process: Start by disconnecting the fuel line from the fuel tank and any other connected components. This step is crucial for safety and allows easy access to the fuel line for cleaning. Once disconnected, use the brush to gently scrub the interior of the fuel line. Work your way along the length of the line, removing any visible dirt, rust, or debris. Pay close attention to bends and tight spaces, as these areas can accumulate more contaminants. After brushing, rinse the fuel line with clean water to remove any remaining solvent and debris.

Solvent Application: For stubborn deposits or to ensure a thorough clean, apply the solvent. Dip the brush into the solvent and carefully wipe the interior walls of the fuel line. Allow the solvent to sit for a few minutes to loosen any remaining dirt. Then, use the brush to scrub again, ensuring you cover all areas. The solvent will help dissolve and lift away any contaminants.

Rinsing and Drying: After cleaning, thoroughly rinse the fuel line with clean water to remove any traces of the solvent. Ensure no residue remains, as it could attract more dirt. Once rinsed, allow the fuel line to air dry completely. You can use a towel to speed up the process, but ensure it's not too rough to avoid damaging the rubber.

Reassembly and Testing: Once the fuel line is dry, carefully reassemble it, ensuring all connections are secure. Test the fuel line by filling the tank with fuel and checking for any leaks. This final step confirms that the cleaning process was successful and that the fuel line is ready for use.

Upgrading Your 2001 Silverado's Fuel Pump: A Step-by-Step Guide to Line Replacement

You may want to see also

Measure Crimp: Mark the line with a ruler and crimping gauge for accurate bends

When working with rubber fuel lines, ensuring precise bends is crucial to maintaining the integrity of the fuel system. The 'Measure Crimp' technique is a fundamental step in this process, allowing you to create accurate bends that will withstand the rigors of the fuel line's journey through the vehicle's engine bay. Here's a detailed guide on how to execute this step effectively:

Measuring and Marking: Begin by carefully measuring the length of the fuel line that needs bending. Use a flexible ruler or a measuring tape to get an accurate reading. It's essential to measure twice to ensure precision. Once you have the correct length, mark this measurement on the fuel line using a permanent marker or a piece of chalk. This mark will serve as your guide for the bend.

Using a Crimping Gauge: Invest in a good-quality crimping gauge, which is a specialized tool designed for creating crimps. This gauge will help you achieve consistent and accurate bends. Place the marked end of the fuel line into the crimping gauge, ensuring that the gauge's jaws are aligned with the mark. Apply gentle but firm pressure to the gauge, following the manufacturer's instructions for the specific model. The goal is to create a clean, precise bend without damaging the fuel line.

Creating the Bend: After the crimp is made, carefully bend the fuel line to the desired angle. Use your hands or a pair of pliers to shape the line, ensuring that the bend is smooth and free from any sharp edges. The bend should be long enough to provide a secure connection but not so sharp that it causes stress on the material.

Practice and Precision: The Measure Crimp technique requires practice and attention to detail. Take your time to get the measurements and bends just right. Inconsistent bends can lead to fuel leaks or damage to the fuel line over time. Remember, the goal is to create a professional-looking installation that will function reliably.

By following these steps, you'll be able to create precise bends in your rubber fuel lines, ensuring a secure and long-lasting installation. This technique is a cornerstone of automotive fuel system maintenance and repair, contributing to the overall performance and safety of your vehicle.

Chevy S10 '92 Fuel Line Location: A Quick Guide

You may want to see also

Crimp Technique: Use a crimping tool to apply pressure to the marked areas

To ensure a secure and reliable connection when crimping a rubber fuel line, it's crucial to follow a precise technique using a crimping tool. This methodical approach guarantees a tight and leak-free seal, which is essential for maintaining the integrity of your fuel system. Here's a step-by-step guide to mastering the crimp technique:

Step 1: Preparation

Before you begin, ensure you have the right tools and materials. You'll need a crimping tool specifically designed for the type of fuel line you're working with. Mark the rubber fuel line at the designated areas where the crimp will be applied. These marks should be aligned with the corresponding crimping tool settings. It's important to double-check the markings to avoid any mistakes.

Step 2: Positioning the Tool

Place the crimping tool over the marked area of the fuel line. Ensure that the tool's jaws are positioned correctly, matching the shape and size of the crimping area. The tool should be firmly held in place, providing a stable base for the upcoming crimping process.

Step 3: Applying Pressure

Now, the crucial part: applying pressure. Use the crimping tool to exert a firm and consistent force onto the marked area. Apply pressure in a smooth, controlled motion, ensuring that the tool's jaws make full contact with the fuel line. The goal is to create a tight, secure crimp without causing any damage to the rubber or the underlying metal reinforcement. Take your time and apply steady pressure until the crimp is formed.

Step 4: Crimping Force and Quality

The force applied during the crimping process is critical. You want to achieve a crimp that is neither too tight, which could damage the fuel line, nor too loose, which would compromise the seal. Aim for a moderate to firm pressure, ensuring that the crimp is visible and distinct. A well-executed crimp should have a uniform appearance, with no visible gaps or uneven edges.

Step 5: Repeat and Verify

If you're crimping multiple areas, repeat the process for each marked location. After completing the crimps, inspect the work to ensure all connections are secure. Check for any signs of leakage or damage to the fuel line. If everything looks good, your crimping job is successful, and you can proceed with the rest of the fuel line installation or repair.

Mastering the crimp technique using a crimping tool is an essential skill for anyone working with fuel lines. It ensures a professional and reliable connection, contributing to the overall safety and performance of your vehicle's fuel system. Remember, practice makes perfect, and with time, you'll develop a keen eye for achieving precise and secure crimps.

Cold Weather Fuel Line Freezing: A Risk for Airplanes?

You may want to see also

Test Connection: Ensure a secure connection by checking for leaks and proper fit

When you've finished installing the rubber fuel line, it's crucial to test the connection to ensure it's secure and leak-free. This step is often overlooked, but it's essential to verify that the fuel line is properly connected to avoid potential issues down the line. Here's a detailed guide on how to test the connection:

- Gather the Necessary Tools: Before you begin, ensure you have the required tools for this task. You'll need a fuel line connector kit, which typically includes various sizes of crimping tools, dies, and possibly a torque wrench. Having the right tools will make the process more efficient and accurate.

- Inspect the Connection: Start by visually inspecting the connection. Check for any signs of damage, such as tears or cracks in the rubber fuel line. Ensure that the crimping tool has been applied evenly and that there are no sharp edges or uneven surfaces where the line connects. A proper connection should appear smooth and seamless.

- Perform a Leak Test: The primary purpose of this test is to ensure there are no leaks. You can use a simple method by applying a small amount of diesel fuel or a suitable diesel fuel line sealant to the connection. Then, use a rag or a piece of cloth to cover the connection and gently press it. If there's a leak, fuel will start to appear on the rag. If no fuel is visible after a few minutes, the connection is likely secure.

- Check for Proper Fit: Ensure that the fuel line is correctly aligned and fits snugly into the connector. It should not be loose or wobbly. A proper fit ensures that the fuel line doesn't restrict flow or cause unnecessary pressure, which could lead to potential issues.

- Use a Pressure Test (Optional): For added assurance, you can perform a pressure test. This involves attaching a pressure gauge to the fuel line and applying a small amount of pressure. If the connection is secure, the pressure should hold, and no leaks should occur.

Remember, taking the time to thoroughly test the connection will provide peace of mind and help prevent potential fuel system failures. It's a critical step in the process of installing a rubber fuel line, ensuring the safety and efficiency of your vehicle's fuel system.

The Fuel Tank's Double Line: A Safety Feature Explained

You may want to see also

Frequently asked questions

Crimping a rubber fuel line is a crucial step in plumbing or repairing fuel systems. It involves using a specialized tool to create a secure and leak-proof connection between the fuel line and a fitting or another fuel line. This process ensures a tight seal, preventing fuel leaks and potential hazards.

To crimp a rubber fuel line, you will need a few essential tools. These include a crimping tool or die set, which comes in various sizes depending on the fitting and line diameter. You'll also require a pair of pliers for holding the line in place, a fuel line cutter for precise cuts, and a source of heat to soften the rubber slightly before crimping.

Before crimping, ensure the rubber fuel line is clean and free of any debris or contaminants. Cut the line to the desired length using the fuel line cutter, making sure to leave a small excess for the crimp. Soften the rubber slightly by applying heat, typically using a heat gun or a flame, being careful not to overheat or burn the material. This step helps the line conform to the crimping tool.

Crimp fittings come in various sizes and types to accommodate different fuel line diameters. Common sizes include 1/4", 3/8", and 1/2" diameters, each with its own set of crimping tools and dies. The most standard types are the 15-degree, 30-degree, and 45-degree elbow fittings, and straight fittings. It's essential to select the appropriate fitting and crimping tool for the specific fuel line size to ensure a proper connection.