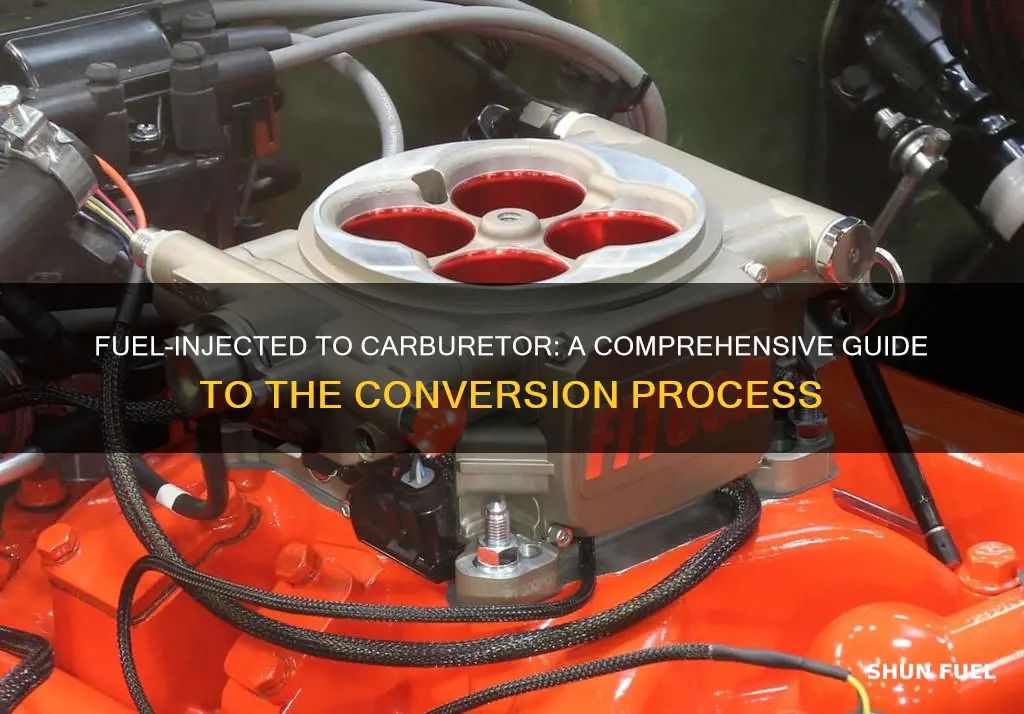

Converting a fuel-injected car to a carburetor system can be a complex and challenging project, but it can also be a rewarding one for those who are passionate about classic car restoration or performance enhancement. This process involves replacing the fuel injection system, which is responsible for precise fuel metering and delivery, with a carburetor, a simpler and more traditional system. The conversion requires careful planning and execution, as it involves modifying the engine's fuel supply and combustion process. It's essential to understand the mechanics of both systems and the specific requirements of the vehicle to ensure a successful and safe conversion.

What You'll Learn

- Engine Compatibility: Ensure the engine can accommodate a carburetor conversion

- Fuel Injection Removal: Carefully remove the fuel injection system

- Carburetor Installation: Fit a suitable carburetor for optimal performance

- Fuel System Adjustments: Fine-tune the fuel system for efficient operation

- Testing and Tuning: Calibrate for optimal power and fuel efficiency

Engine Compatibility: Ensure the engine can accommodate a carburetor conversion

When considering a carburetor conversion for a fuel-injected engine, engine compatibility is a critical factor that cannot be overlooked. The success of the conversion heavily relies on the engine's design and its ability to accommodate the changes required for a carburetor setup. Here's a detailed guide on how to ensure engine compatibility for a carburetor conversion:

Engine Design and Architecture: Begin by understanding the engine's architecture. Different engine designs have varying intake systems, valve layouts, and cylinder configurations. For a carburetor conversion to be feasible, the engine should ideally have a suitable intake manifold that can accommodate the carburetor. Look for engines with a single or double overhead camshaft design, as these often provide better access to the intake ports, making the conversion process more manageable.

Intake Manifold and Throttle Body: The intake manifold plays a crucial role in directing air and fuel to the engine's cylinders. In a carburetor conversion, the intake manifold may need to be modified or replaced to accommodate the carburetor's requirements. Check if the existing intake manifold has enough space for the carburetor and if it can be modified to suit the new setup. Additionally, ensure that the throttle body, which controls the air flow, is compatible with the carburetor's needs. Some engines may require a throttle body that can be adjusted to match the carburetor's performance.

Engine Block and Cylinder Head: The engine block and cylinder head should be examined for any potential issues. The cylinder head's valve train and valve sizes might need adjustments to work optimally with a carburetor. Ensure that the engine block has sufficient space for the carburetor's components, especially the carburetor body and the float bowl, if applicable. In some cases, engine block modifications might be necessary to accommodate the larger carburetor components.

Engine Performance and Modifications: Consider the engine's performance characteristics and any existing modifications. Fuel-injected engines are often tuned for optimal fuel-air mixture and performance. When converting to a carburetor, the engine's power output, fuel consumption, and overall performance may change. It is essential to understand the potential impact on the engine's performance and make necessary modifications to maintain or improve its efficiency. This might include adjusting the camshaft timing, valve sizes, and other engine components to ensure proper carburetor operation.

Consultation with Experts: Given the complexity of engine compatibility, consulting with experienced mechanics or engine specialists is highly recommended. They can provide valuable insights into the specific engine's capabilities and limitations. These experts can guide you through the conversion process, ensuring that the engine remains intact and functional throughout the modifications.

By carefully evaluating the engine's design, architecture, and performance, you can make an informed decision about the feasibility of a carburetor conversion. Engine compatibility is a crucial aspect that will determine the success and efficiency of the conversion process.

Leased Cars: Fuel Coverage Explained

You may want to see also

Fuel Injection Removal: Carefully remove the fuel injection system

The process of converting a fuel-injected car to a carburetor system requires careful and methodical work, especially when it comes to removing the fuel injection setup. Here's a step-by-step guide to ensure a successful conversion:

Step 1: Gather the Necessary Tools and Parts

Before you begin, ensure you have all the required tools and replacement parts. This includes a new carburetor, fuel lines, and any necessary adapters or brackets to accommodate the carburetor setup. Having everything ready will make the removal process smoother.

Step 2: Disconnect the Fuel Injection System

Locate the fuel injectors, which are typically mounted near the engine's intake manifold. Carefully disconnect the electrical connections and hoses attached to each injector. Take note of the wiring harness and ensure you understand which wires are connected to which components. This step is crucial to avoid any electrical issues during the conversion.

Step 3: Remove the Injector Mounting

Carefully detach the injector mounting brackets or clips that hold the injectors in place. This might require some prying or careful leverage, especially if the brackets are rusted or tightly secured. Once removed, set aside the brackets and the injectors themselves.

Step 4: Unplug and Remove the Fuel Pump

The fuel pump, which is responsible for supplying fuel to the injectors, needs to be disconnected and removed. Locate the fuel pump module, which is usually mounted near the fuel tank or under the car's front end. Carefully unplug the electrical connections and detach any hoses or lines connected to the pump. Then, remove the pump module from its mounting position.

Step 5: Disconnect the Fuel Rails (if applicable)

In some fuel-injected systems, there are fuel rails that distribute fuel to the injectors. If your car has this setup, carefully disconnect the fuel rails from the injectors and the fuel pump. This might involve removing additional brackets or clips to access the connections.

Step 6: Finalize the Removal

With all the major components disconnected and removed, you can now carefully take out the fuel injection system as a whole. This step may vary depending on the car's make and model, but generally, you'll lift out the system from its mounting points. Ensure you handle the components with care to avoid any damage.

Viscosity's Impact: Unlocking Fuel Efficiency in Your Engine

You may want to see also

Carburetor Installation: Fit a suitable carburetor for optimal performance

When converting a fuel-injected car to a carburetor system, one of the most critical steps is selecting and installing a suitable carburetor. This process requires careful consideration to ensure optimal performance and compatibility with the vehicle's engine. Here's a step-by-step guide to help you through the carburetor installation process:

Step 1: Research and Compatibility Check: Begin by researching the specific carburetor models that are compatible with your car's engine. Different engines have varying requirements, and it's essential to choose a carburetor that matches the displacement and specifications of your vehicle. Consider factors such as the engine's cubic capacity, compression ratio, and the desired power output. Online resources, automotive forums, and specialist websites can provide valuable insights and recommendations.

Step 2: Prepare the Engine: Before installation, ensure that your engine is properly prepared. This may involve removing the existing fuel injection system, which could include fuel rails, injectors, and related wiring. Carefully document the process and take notes on the location and connections of each component to ensure an easier reinstallation later. Cleaning the engine bay and removing any debris or old fuel system parts is also crucial for a smooth installation.

Step 3: Choose the Right Carburetor: Select a carburetor that suits your performance goals. Carburetors come in various types, such as side-mount, top-mount, or downdraft designs, each with its own advantages. For high-performance applications, consider a high-flow carburetor that can handle increased fuel demands. Ensure the chosen carburetor has the necessary jetting and vacuum ports to accommodate your engine's requirements.

Step 4: Installation Process: With the compatible carburetor in hand, proceed with the installation. Start by mounting the carburetor in the designated location, typically where the fuel-injected system was previously housed. Secure it using the provided fasteners or brackets. Connect the carburetor's fuel line to the engine's fuel supply, ensuring a tight and leak-free connection. Adjust the carburetor's idle and mixture screws to optimize performance, referring to the manufacturer's guidelines for the correct settings.

Step 5: Testing and Fine-Tuning: After installation, start the engine and perform a thorough test. Check for any leaks and ensure the carburetor is functioning correctly. Adjust the carburetor's idle speed and mixture as needed to achieve a smooth and stable running condition. Fine-tuning may require additional adjustments to the carburetor's jets and vacuum ports to match the engine's characteristics.

Remember, converting a fuel-injected car to a carburetor system is a complex process, and each vehicle may have unique requirements. It is recommended to seek professional guidance or consult detailed manuals specific to your car model for a successful conversion.

Flex Fuel Flexibility: Can Your Car Run on Regular Gas?

You may want to see also

Fuel System Adjustments: Fine-tune the fuel system for efficient operation

When converting a fuel-injected car to a carburetor setup, fine-tuning the fuel system is crucial to ensure optimal performance and efficient operation. Here are some key adjustments to consider:

Fuel Pump and Pressure Regulation: One of the primary modifications involves the fuel pump. Carburetor systems typically require a lower fuel pressure compared to fuel injection. Adjust the fuel pump to deliver a controlled amount of fuel at a reduced pressure. This might involve reducing the pump's output or using a smaller-sized pump suitable for carburetor applications. Proper pressure regulation is essential to prevent excessive fuel flow and ensure a balanced air-fuel mixture.

Jetting and Carburetor Components: Carburetors rely on precise jetting and carefully designed components. You'll need to adjust the carburetor's jets, such as the main jet, pilot jet, and accelerator pump jet, to match the engine's requirements. These jets control the fuel-air mixture's richness and volatility. Fine-tune the jet sizes based on the engine's power output and desired performance characteristics. Additionally, inspect and clean the carburetor's passages, throttle body, and other internal components to ensure proper fuel flow and atomization.

Air Intake and Induction System: The air intake system plays a vital role in fuel system efficiency. Ensure that the air filter is properly sized and positioned to provide a clean air supply. Consider modifying the air intake manifold or using a performance air filter to improve airflow. A well-designed induction system can enhance the engine's performance and fuel efficiency.

Fuel Delivery and Return System: Modify the fuel return system to accommodate the new carburetor setup. This may involve adjusting the fuel bowl's design, adding a fuel-level sensor, or implementing a fuel-level management system. Proper fuel return ensures that any excess fuel is recycled, preventing engine flooding and maintaining a balanced fuel-air mixture.

During the conversion process, it's essential to test and adjust the fuel system iteratively. Use a fuel pressure gauge and a fuel flow meter to monitor the system's performance. Fine-tuning the fuel system requires patience and a methodical approach, but it will result in a well-balanced and efficient engine operation with the new carburetor setup.

Does Idling Your Car Waste Gas? Uncover the Truth

You may want to see also

Testing and Tuning: Calibrate for optimal power and fuel efficiency

The process of converting a fuel-injected car to a carburetor system requires careful testing and tuning to ensure optimal performance and fuel efficiency. Here's a detailed guide on how to approach this calibration process:

Testing and Tuning Process:

- Initial Assessment: Begin by evaluating the current performance of your fuel-injected vehicle. This includes measuring power output, fuel consumption, and overall drivability. Take note of any specific issues or areas of improvement needed. Understanding the baseline performance is crucial for effective calibration.

- Carburetor Selection: Choose a suitable carburetor for your engine. Consider factors such as engine displacement, desired power output, and the specific requirements of your vehicle. Different carburetors have varying jetting and venturi configurations, so selecting the right one is essential for proper air-fuel mixture management.

- Jetting and Needle Adjustments: Fine-tune the carburetor's jetting and needle settings. This involves adjusting the main jet, pilot jet, and needle valve to optimize the air-fuel ratio. You'll need to refer to the carburetor's specifications and consult technical manuals for guidance. The goal is to achieve a balanced mixture that provides efficient combustion while maintaining power output.

- Idle and Acceleration Testing: Conduct thorough testing at various engine speeds and loads. Start with idle speed, ensuring it is stable and within the desired range. Then, gradually increase the engine speed to test acceleration and power delivery. Make adjustments to the carburetor settings as needed to fine-tune the performance. Pay attention to any unusual noises or engine behavior during this process.

- Fuel Efficiency Calibration: Focus on optimizing fuel efficiency without compromising power. Adjust the carburetor's throttle plate and fuel-air mixture settings to find the sweet spot. Fine-tune the idle speed and load to ensure the engine operates efficiently at different operating conditions. Proper calibration will result in better fuel economy without sacrificing performance.

- Performance Monitoring: Continuously monitor the vehicle's performance during the tuning process. Use diagnostic tools to log engine data, including RPM, temperature, and fuel consumption. This data will provide valuable insights into the engine's behavior and help you make informed adjustments. Regularly test and re-evaluate the vehicle to ensure it meets your performance and efficiency goals.

- Fine-Tuning and Iterative Process: Carburetor conversion is an iterative process. You may need to make multiple adjustments and re-test the vehicle to achieve the optimal balance. Fine-tune the settings gradually, making small changes and observing the results. This iterative approach ensures that you fine-tune the system for the specific characteristics of your engine and driving conditions.

Remember, converting a fuel-injected system to a carburetor requires patience and a systematic approach. It's essential to have a good understanding of engine mechanics and access to the necessary tools and resources for accurate calibration. Proper testing and tuning will result in a well-performing, efficient engine that meets your desired specifications.

Auntie Ifeoma's Car Fuel: A Family Secret Revealed

You may want to see also

Frequently asked questions

Fuel injection and carburetors are both methods of delivering fuel to an engine, but they operate differently. Fuel injection is an electronic system that precisely meters and injects fuel directly into the engine's intake manifold or cylinders. It offers better fuel efficiency, higher performance, and more accurate control over the fuel-air mixture. Carburetors, on the other hand, mix air and fuel in a chamber and then meter the mixture to the engine. They are simpler and more mechanical but can be less efficient and less responsive.

Converting a fuel-injected car to a carburetor is a significant modification and is typically done for specific reasons. Some enthusiasts prefer the simplicity and reliability of a carburetor, as it can be more forgiving in terms of tuning and maintenance. Carburetors also offer a unique driving experience with a distinct engine sound and character. However, it's important to note that this conversion is complex and may require specialized knowledge and skills, as well as potential modifications to the engine and exhaust system.

Yes, there are several considerations and potential issues. Firstly, the performance and efficiency of the engine may be compromised, as fuel injection is generally more advanced and efficient. The conversion process can be time-consuming and costly, requiring specialized tools and expertise. Additionally, the modified engine may not meet emissions standards, and there could be legal implications in some regions. It's crucial to thoroughly research and understand the specific requirements and challenges of the conversion before proceeding.