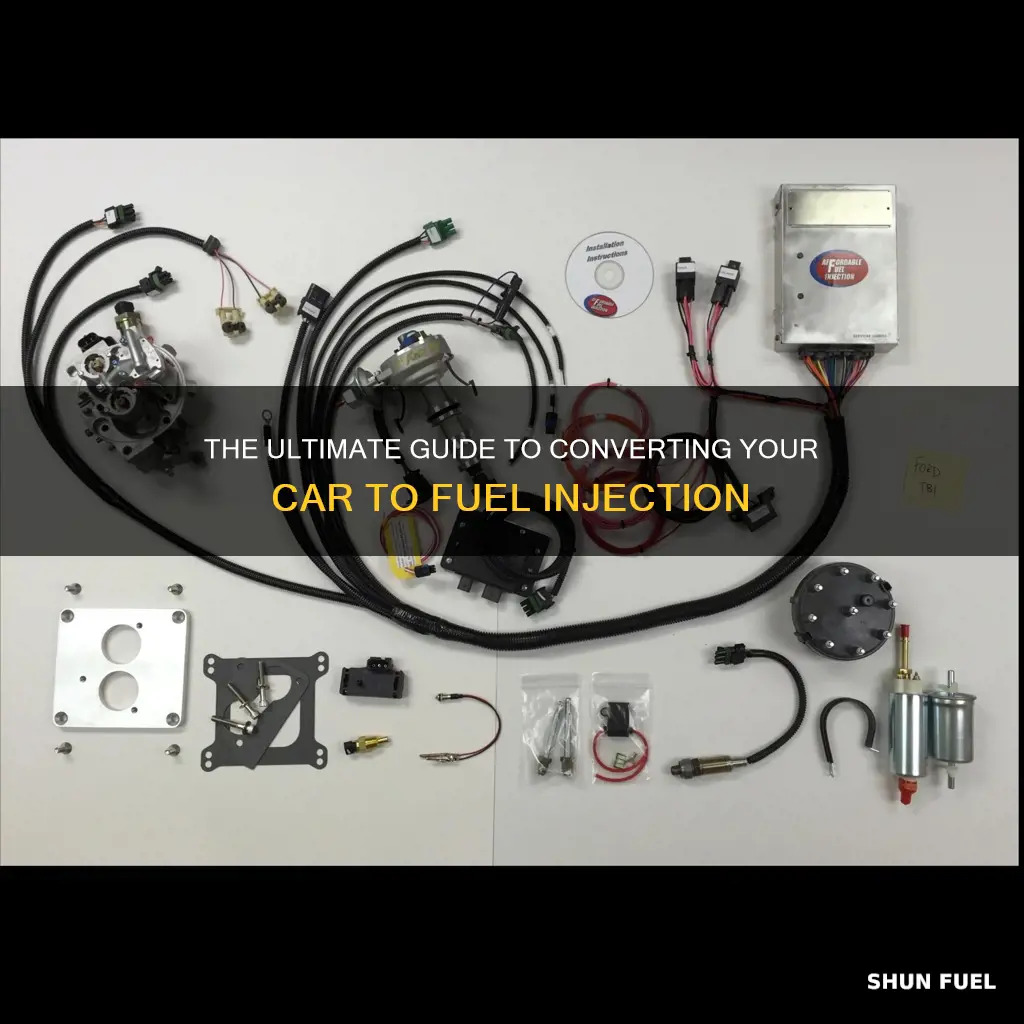

Converting a car to fuel injection can significantly enhance its performance and efficiency. This process involves replacing the traditional carburetor system with an electronic fuel injection (EFI) setup, which precisely controls the fuel-air mixture for optimal combustion. The conversion requires careful planning and technical expertise to ensure compatibility with the vehicle's engine and electrical systems. It involves replacing the carburetor, installing an EFI controller, and calibrating the system to match the engine's requirements. This guide will provide a comprehensive overview of the steps involved, offering a detailed roadmap for enthusiasts looking to upgrade their vehicles for improved power and fuel economy.

What You'll Learn

- Fuel Injection Basics: Understand the principles and components of fuel injection systems

- Diagnosing Issues: Learn to identify problems with the car's fuel injection system

- Fuel Pump Replacement: Guide to replacing the fuel pump for optimal performance

- Sensor Calibration: Adjust sensors to ensure precise fuel injection control

- Engine Management System: Explore the role of the engine control unit in fuel injection

Fuel Injection Basics: Understand the principles and components of fuel injection systems

Fuel injection is a sophisticated technology that optimizes engine performance by precisely managing the fuel-air mixture. It offers a more efficient and powerful alternative to traditional carburetors. The process begins with the fuel injection system, which is responsible for delivering the correct amount of fuel to the engine at the right time. This system consists of several key components, each playing a crucial role in the overall functionality.

At the heart of the fuel injection system is the fuel pump, which is designed to deliver fuel at a precise pressure to ensure optimal atomization. This pump is typically driven by a small electric motor, providing a consistent and reliable fuel supply. The fuel then travels through a series of fuel lines, which are carefully routed to maintain pressure and direct the fuel to the injectors.

The injectors are the next critical component. These small, precise nozzles are strategically positioned in the engine's intake manifold or directly into the cylinders. When activated, they spray a fine mist of fuel into the engine, creating a homogeneous mixture with air. This process is highly controlled, ensuring that the fuel is injected at the correct timing and in the right amount, optimizing combustion.

The electronic control unit (ECU) is the brain of the fuel injection system. It receives input from various sensors, such as the engine's temperature, speed, and load, and uses this data to calculate the precise fuel injection requirements. The ECU then sends signals to the injectors, controlling the timing and amount of fuel delivered. This electronic control allows for dynamic adjustments, ensuring the engine operates efficiently under various conditions.

Understanding the principles of fuel injection is essential for anyone considering a conversion. The system's ability to provide a precise and controlled fuel-air mixture results in improved performance, better fuel efficiency, and reduced emissions. By grasping the role of each component, from the fuel pump to the ECU, enthusiasts can make informed decisions during the conversion process, ensuring a successful and powerful upgrade.

Brazil's Sugar-Powered Revolution: Unlocking the Potential of Biofuel

You may want to see also

Diagnosing Issues: Learn to identify problems with the car's fuel injection system

The fuel injection system is a complex component of a vehicle's engine, and diagnosing issues with it can be a challenging task. Here's a guide to help you identify and troubleshoot problems:

Engine Performance and Response: One of the most common indicators of fuel injection system issues is a noticeable change in engine performance. If you observe that the engine is running rough, losing power, or having difficulty starting, it could be a sign of a problem. Pay attention to any unusual noises, such as backfires or a misfiring sound, as these can also suggest fuel injection system malfunctions.

Check Engine Light: Modern vehicles are equipped with an onboard computer that monitors various systems, including fuel injection. If the check engine light illuminates, it is a warning sign that something is amiss. This light can be triggered by a variety of issues, such as a faulty sensor, a clogged fuel filter, or a problem with the fuel pump. It is essential to address this warning promptly to prevent further complications.

Fuel Pressure and Flow: Monitoring the fuel pressure and flow rates is crucial for diagnosing fuel injection problems. You can use a fuel pressure gauge to check if the system is delivering the correct amount of fuel. Insufficient fuel pressure or inconsistent flow can lead to poor engine performance. If you notice a significant drop in pressure or inconsistent fuel delivery, it may indicate a clogged fuel filter, a faulty pump, or a problem with the injectors.

Sensor Malfunctions: The fuel injection system relies on various sensors to provide accurate data for engine management. These include the mass airflow sensor, manifold absolute pressure sensor, and oxygen sensors. If any of these sensors malfunction, it can result in incorrect fuel-air mixture calculations. Symptoms may include erratic engine behavior, poor fuel economy, or the check engine light coming on.

Visual Inspection: Regular visual inspections of the fuel injection system can help identify potential issues. Check for any signs of damage, corrosion, or leaks in the fuel lines and hoses. Inspect the fuel injectors for blockages or debris. Over time, carbon deposits can build up on the injectors, leading to reduced performance. Cleaning or replacing clogged injectors can often restore engine power and efficiency.

When diagnosing fuel injection problems, it's important to remember that each vehicle may have unique characteristics. Consulting the vehicle's service manual and using specialized diagnostic tools can provide valuable insights. Additionally, seeking professional assistance from a qualified mechanic is recommended for complex issues to ensure accurate diagnosis and repair.

Jump-Starting a Car: Fuel Pump Issues and Solutions

You may want to see also

Fuel Pump Replacement: Guide to replacing the fuel pump for optimal performance

Fuel pumps are essential components in any vehicle's fuel injection system, responsible for delivering the required amount of fuel to the engine at the right pressure. Over time, these pumps can wear out or fail, leading to performance issues and potential engine damage. Replacing the fuel pump is a crucial task for car owners, ensuring their vehicle operates efficiently and reliably. Here's a step-by-step guide to help you through the process:

Preparation and Safety: Before you begin, ensure you have the necessary tools and safety equipment. This task requires a certain level of mechanical skill and knowledge, so it's important to be prepared. Gather the required tools, including a new fuel pump, a fuel filter, and any necessary adapters or seals. Additionally, wear protective gear, such as gloves and safety goggles, to safeguard against potential fuel spills and splashes.

Locate the Fuel Pump: The fuel pump is typically located near the fuel tank or in the engine compartment, depending on the vehicle's design. Consult your vehicle's service manual to identify the exact location. It is often secured with brackets or clips, so carefully remove these fasteners to access the pump. Take note of the wiring connections and any other components that need to be disconnected.

Remove the Old Pump: Start by disconnecting the electrical connections and any hoses or lines attached to the fuel pump. Carefully lift the pump out of its mounting position, ensuring you don't damage any surrounding components. Take this opportunity to inspect the old pump for any signs of wear or damage. Clean the mounting surface and prepare it for the new pump.

Install the New Fuel Pump: Carefully position the new fuel pump into the mounting location, ensuring it is aligned correctly. Secure it with the provided fasteners, making sure they are tight and secure. Reconnect all the electrical wiring and hoses, double-checking for proper connections. Verify that all components are functioning correctly by starting the engine and monitoring for any leaks or unusual noises.

Final Checks and Testing: After the installation, perform a few crucial checks. Ensure that all connections are secure and there are no fuel leaks. Start the engine and monitor its performance, checking for any signs of hesitation or rough idling, which could indicate a faulty installation. Test-drive the vehicle to ensure the fuel pump is functioning optimally and that the engine operates smoothly.

Remember, fuel pump replacement is a specialized task, and if you're unsure about any step, it's best to consult a professional mechanic. Proper maintenance and timely replacements can ensure your vehicle's fuel injection system operates efficiently, providing optimal engine performance and longevity.

Turning Plastic into Gas: A Sustainable Fuel Revolution

You may want to see also

Sensor Calibration: Adjust sensors to ensure precise fuel injection control

Sensor calibration is a critical step in the process of converting a car to fuel injection, as it ensures that the fuel injection system operates efficiently and precisely. This process involves adjusting various sensors to optimize the fuel-air mixture, which is essential for improved performance, fuel efficiency, and reduced emissions. Here's a detailed guide on how to approach sensor calibration:

- Identify the Sensors: Begin by understanding the different sensors involved in the fuel injection system. These typically include the mass airflow (MAF) sensor, manifold absolute pressure (MAP) sensor, oxygen (O2) sensors, and temperature sensors. Each sensor plays a unique role in measuring various parameters related to the engine's operating conditions. For instance, the MAF sensor measures the amount of air entering the engine, while O2 sensors monitor the oxygen levels in the exhaust.

- Sensor Location and Access: Locate the sensors and familiarize yourself with their positions. Some sensors might be easily accessible, while others may require removing certain engine components to gain access. Understanding the sensor's location is crucial for proper adjustment. For example, the MAP sensor is usually located near the intake manifold, and its position is vital for accurate calibration.

- Sensor Adjustment Techniques: Calibration involves fine-tuning the sensors to provide accurate readings. Here are some common methods:

- MAF Sensor Calibration: Adjust the MAF sensor by comparing its output with a known accurate sensor. You can use a dynamometer or a fuel flow meter to measure the actual fuel flow and compare it with the sensor's reading. Adjust the sensor's position or wiring if necessary to ensure optimal performance.

- MAP Sensor Calibration: The MAP sensor measures engine load. You can calibrate it by adjusting its position or using a MAP simulator. This ensures that the sensor provides accurate readings at various engine speeds and loads.

- O2 Sensor Calibration: O2 sensors require careful calibration to ensure they provide precise oxygen level measurements. This often involves using a specialized tool to adjust the sensor's heater control or wiring. Proper calibration ensures accurate lean and rich mixture detection.

- Testing and Verification: After making adjustments, it's crucial to test the system thoroughly. Start the engine and monitor its performance using a scan tool or an OBDII reader. Check for any error codes related to the fuel injection system. Drive the vehicle under various conditions (city driving, highway, acceleration) to ensure the sensors provide consistent and accurate data.

- Fine-Tuning and Iterative Process: Sensor calibration might require multiple iterations to achieve optimal results. Fine-tune the sensors by making small adjustments and re-testing. This process ensures that the fuel injection system delivers the correct amount of fuel for different driving conditions.

Remember, sensor calibration is a precise task, and small adjustments can significantly impact engine performance. It is recommended to consult the vehicle's service manual or seek guidance from experienced mechanics to ensure accurate calibration. Proper sensor calibration will result in a well-balanced fuel-air mixture, leading to improved engine performance and overall driving experience.

Helicopter vs. Car: Fuel Efficiency Battle

You may want to see also

Engine Management System: Explore the role of the engine control unit in fuel injection

The Engine Control Unit (ECU) is the brain of a fuel-injected engine, playing a pivotal role in optimizing performance, fuel efficiency, and emissions. This sophisticated microcomputer receives input from various sensors and uses this data to precisely manage the fuel injection process.

At the heart of the ECU's function is its ability to calculate the ideal air-fuel mixture for combustion. It considers factors like engine speed, load, temperature, and ambient conditions to determine the precise amount of fuel required. This calculation is crucial for achieving optimal power output while minimizing harmful emissions.

The ECU communicates with the fuel injectors via electrical signals, instructing them to deliver the calculated amount of fuel at the right time. This process is highly precise, ensuring that the air-fuel mixture is neither too rich (wasting fuel and producing excessive emissions) nor too lean (leading to inefficient combustion and potential engine damage).

Beyond fuel injection, the ECU also manages other critical engine functions. It controls spark timing, adjusts idle speed, monitors engine temperature, and implements various diagnostic routines. This comprehensive control ensures that the engine operates efficiently, reliably, and within safe parameters.

In the context of converting a car to fuel injection, understanding the ECU's role is essential. It's not just about replacing the carburetor with fuel injectors. The ECU needs to be programmed and calibrated to work effectively with the new fuel injection system. This involves setting up fuel maps, adjusting timing, and fine-tuning various parameters to ensure optimal performance and compatibility with the existing engine management system.

Hydrogen Fuel Cell Cars: The Future is Now

You may want to see also

Frequently asked questions

Fuel injection is a system that delivers fuel to the engine more efficiently than traditional carburetors. It provides precise control over the fuel-air mixture, resulting in improved performance, better fuel economy, and reduced emissions. Converting to fuel injection can offer a significant performance boost for enthusiasts and racers.

Not all vehicles are compatible with fuel injection conversion. It depends on the car's make, model, and engine design. Some older cars may require extensive modifications to accommodate fuel injection. It's essential to research your specific vehicle and consult with experts to determine feasibility.

The cost of conversion can vary widely. Basic kits for simple conversions can range from $500 to $1500, while more complex setups with high-performance components can cost several thousand dollars. Labor costs for professional installation should also be considered, typically ranging from $500 to $1000 or more, depending on the complexity of the job.

Fuel injection offers several advantages. It provides more accurate fuel delivery, resulting in better engine performance and responsiveness. Fuel injection can also improve fuel economy by ensuring the engine always receives the correct amount of fuel. Additionally, it reduces emissions by optimizing the combustion process, making it an environmentally friendly choice.

While fuel injection offers numerous benefits, there are a few potential drawbacks. Initial setup and calibration can be complex and time-consuming. Some engines may require specialized tools and knowledge for proper tuning. Additionally, the cost of conversion can be a significant factor, especially for high-performance builds. Proper maintenance and regular servicing are also essential to ensure the system's longevity.