Cleaning the fuel line on a carrier is an important maintenance task to ensure optimal performance and longevity of the vehicle's fuel system. Over time, fuel lines can accumulate dirt, debris, and contaminants, leading to reduced fuel efficiency, engine performance issues, and potential safety hazards. This guide will provide a step-by-step process to effectively clean the carrier fuel line, covering the necessary tools, safety precautions, and techniques to ensure a thorough and safe cleaning process.

What You'll Learn

- Prepare the Tools: Gather cleaning supplies like a fuel line cleaner, brush, and compressed air

- Remove Clogged Areas: Identify and clear blockages using a brush or compressed air

- Apply Cleaner: Spray fuel line cleaner and let it sit for the recommended time

- Rinse Thoroughly: Use compressed air or a hose to flush out the cleaner

- Test for Leaks: Inspect for any leaks and ensure the line is dry

Prepare the Tools: Gather cleaning supplies like a fuel line cleaner, brush, and compressed air

Before you begin the process of cleaning your carrier fuel line, it's essential to have the right tools and supplies ready. This preparation will ensure an efficient and effective cleaning process. Here's a step-by-step guide on what you need to gather:

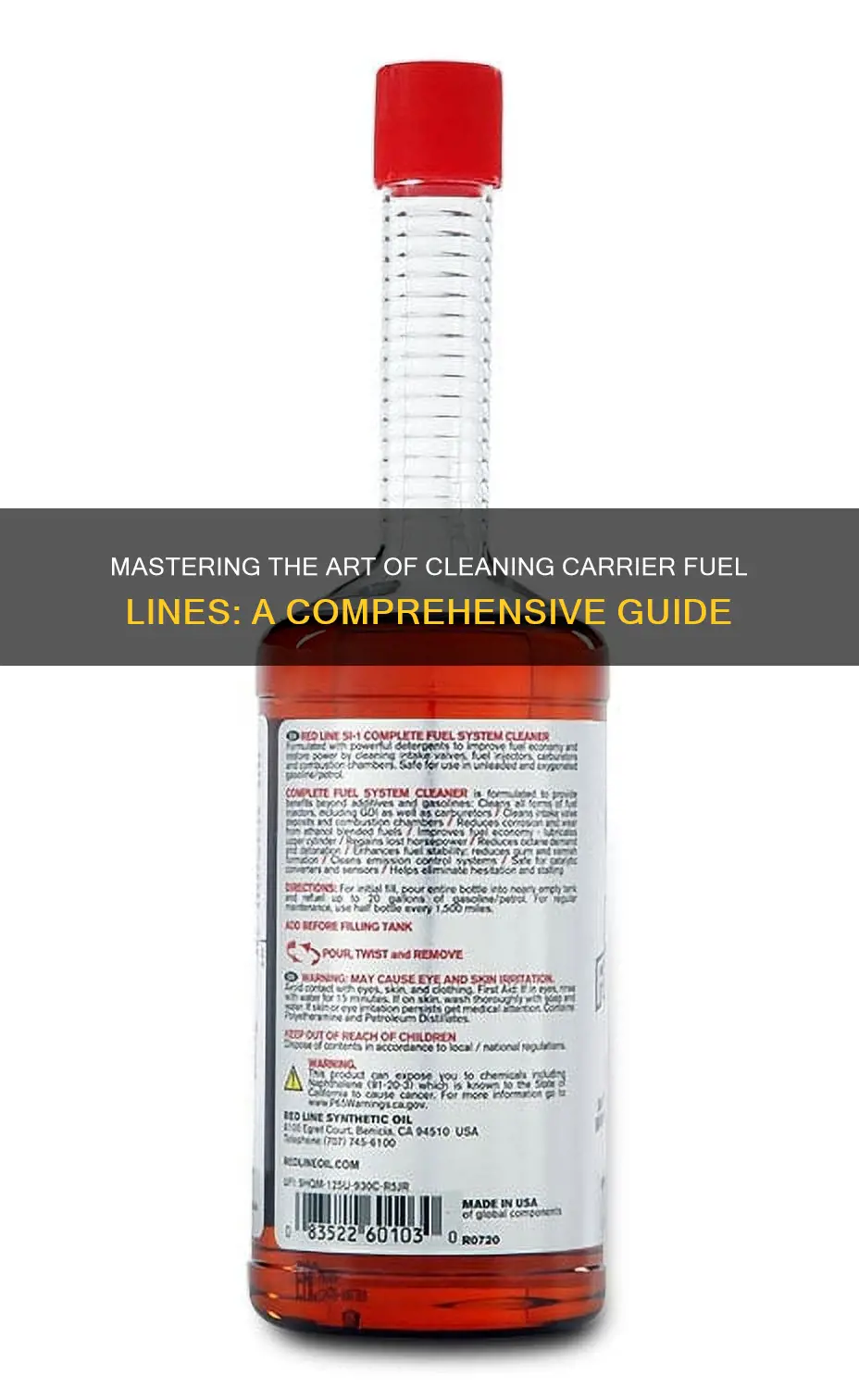

Fuel Line Cleaner: Start by acquiring a high-quality fuel line cleaner. This product is specifically designed to dissolve and remove contaminants from fuel lines. Look for a cleaner that is compatible with your fuel type and the materials used in your fuel system. There are various brands available, so choose one that is reputable and suitable for your needs.

Brush: A small brush, preferably with firm bristles, will be your tool for scrubbing and removing any built-up deposits. Ensure the brush is the right size to fit into the fuel line comfortably. You want a brush that can reach all areas of the line without causing damage.

Compressed Air: Compressed air cans are an excellent way to blow out any remaining debris or cleaner from the fuel line. This step ensures that you've effectively removed all contaminants. Make sure to use compressed air that is food-grade and safe for use in fuel systems.

Additionally, consider having some rags or paper towels on hand to wipe down the fuel line and surrounding areas. These simple yet essential tools will make the cleaning process much more manageable and thorough. By gathering these supplies beforehand, you'll be well-prepared to tackle the cleaning of your carrier fuel line, ensuring optimal performance and longevity.

Upgrading Your TD42 Fuel Return Line: A Comprehensive Guide

You may want to see also

Remove Clogged Areas: Identify and clear blockages using a brush or compressed air

When dealing with a clogged fuel line, it's crucial to identify and address the blocked areas to ensure a thorough cleaning process. Start by inspecting the fuel line for any visible blockages, such as debris, dirt, or clumps of fuel residue. These blockages can accumulate over time, leading to reduced fuel flow and potential performance issues. Look for any signs of narrowing or constriction in the fuel line, as these areas are prime candidates for blockages.

One effective method to clear these clogged areas is by using a brush. Select a brush with soft bristles to avoid damaging the fuel line. Insert the brush into the fuel line, ensuring it reaches the blocked section. Gently move the brush back and forth to dislodge any built-up residue or debris. Take care not to apply excessive force, as this can potentially damage the fuel line. If the blockage is particularly stubborn, consider using a flexible brush with a longer handle to provide better access and control.

For more stubborn blockages or in cases where the fuel line is difficult to reach, compressed air can be a powerful tool. Compressed air cans are readily available and can be used to blow out any debris or residue. Hold the can upright and direct the stream of compressed air into the fuel line, aiming for the clogged area. The high-pressure air can dislodge and remove blockages effectively. Ensure you hold the can at a safe distance to avoid any potential damage to the fuel line or surrounding components.

It's important to note that when using compressed air, be cautious of any potential fuel leaks or spills. Always work in a well-ventilated area and wear protective gear if necessary. Additionally, consider using a fuel line cleaner or a fuel system flush to further enhance the cleaning process and ensure optimal performance.

By employing these methods, you can effectively identify and clear clogged areas within the fuel line, promoting better fuel flow and overall engine performance. Remember to exercise caution and follow safety guidelines when working with fuel lines to ensure a successful and safe cleaning process.

Duramax Fuel Line Pressure: Testing and Troubleshooting Guide

You may want to see also

Apply Cleaner: Spray fuel line cleaner and let it sit for the recommended time

To effectively clean your carrier fuel line, it's crucial to follow a systematic approach. One of the most important steps is applying a suitable fuel line cleaner. Here's a detailed guide on how to do this:

Step 1: Prepare the Cleaner

Start by acquiring a high-quality fuel line cleaner. These products are specifically designed to dissolve and remove deposits, corrosion, and contaminants from fuel lines. You can find them at auto parts stores or online. Ensure you choose a cleaner that is compatible with your fuel system and vehicle type.

Step 2: Spray the Cleaner

Once you have the cleaner, it's time to apply it. Locate the fuel lines on your carrier. These are typically found running from the fuel tank to the engine. Using a spray bottle or a dedicated fuel line cleaner applicator, spray the cleaner directly onto the fuel lines. Make sure to cover the entire length of the lines, paying extra attention to any areas with visible deposits or corrosion.

Step 3: Let it Sit

After spraying, it's essential to allow the cleaner to work its magic. Follow the instructions on the cleaner's packaging regarding the recommended contact time. This time can vary, typically ranging from 10 to 30 minutes. During this period, the cleaner will penetrate the fuel line walls, dissolving and loosening any built-up contaminants.

Step 4: Rinse and Flush

After the recommended time has passed, it's time to rinse and flush the fuel lines. Use a garden hose or a dedicated fuel line flush kit to run water through the lines, flushing out the cleaner and any dislodged contaminants. Ensure you have a container to catch any debris or contaminants that come out of the lines.

Step 5: Reassemble and Test

Once you've thoroughly rinsed the fuel lines, reassemble any disconnected parts and ensure a proper connection. Start the engine and let it run, checking for any leaks or unusual noises. This final test ensures that the cleaning process has been successful and that your fuel system is now clean and ready for optimal performance.

Carburetor Fuel Line Pressure: The Ideal Range for Optimal Performance

You may want to see also

Rinse Thoroughly: Use compressed air or a hose to flush out the cleaner

When it comes to cleaning a carrier fuel line, the process of rinsing thoroughly is an essential step to ensure a complete and effective clean. This step helps to remove any remaining cleaner and debris, leaving the fuel line clean and ready for use. Here's a detailed guide on how to perform this crucial rinse:

Start by ensuring you have the necessary tools: compressed air or a powerful hose with a spray nozzle. Compressed air is ideal for reaching tight spaces and ensuring a thorough rinse, while a hose with a spray setting can provide a high-pressure flow of water. The goal is to create a strong, controlled stream of water or air to flush out any contaminants.

Begin the rinsing process by applying the compressed air or water spray directly into the fuel line. Focus on the areas where the cleaner has been applied, ensuring that every inch of the fuel line is covered. Use steady, consistent pressure to create a strong flow that can dislodge any particles or residue. For tight spaces or corners, you might need to adjust the angle and pressure of the air or water to ensure a complete flush.

As you rinse, pay attention to the flow of the cleaner and water. You should see a clear, clean stream exiting the fuel line, indicating that the cleaning process is effective. If you notice any residue or debris, continue the rinsing process until it is completely removed. This step is crucial to ensure that no cleaner or contaminants remain, as it can lead to potential issues with the fuel system's performance and longevity.

For an even more thorough rinse, consider using a combination of both compressed air and water. After flushing with air, you can use the hose to provide a final, high-pressure rinse. This two-step approach ensures that the fuel line is not only cleaned but also well-rinsed, leaving no room for any lingering cleaner or debris.

Remember, taking the time to rinse thoroughly is an important part of the cleaning process, as it ensures the fuel line is ready for its intended use, free from any potential contaminants that could impact performance.

Unveiling the Milwaukee Fuel Line: Powering Your Projects

You may want to see also

Test for Leaks: Inspect for any leaks and ensure the line is dry

When it comes to maintaining your aircraft's fuel system, one crucial step is identifying and addressing any potential leaks. This process is essential to ensure the safety and efficiency of your aircraft's operations. Here's a detailed guide on how to inspect for leaks and keep the fuel line dry:

Inspecting for Leaks:

Start by visually examining the fuel line for any signs of damage, cracks, or corrosion. Look for any visible leaks or drips around the connections, fittings, and where the line joins the fuel tank and engine. Even a small leak can lead to significant issues over time, so it's essential to be thorough. Check for any signs of fuel accumulation or moisture, as this could indicate a breach in the system. Pay close attention to the areas where the fuel line bends or where it is secured with clamps or brackets, as these spots are more susceptible to damage.

Use a soapy water solution to perform a more comprehensive leak test. Apply the solution to the fuel line, focusing on the connections and fittings. If there are any leaks, you'll likely see bubbles forming around the affected areas. This simple test can help you identify even minor leaks that might not be visible to the naked eye. Ensure you test the line under various conditions, including when the aircraft is stationary and during operation, to account for different pressure variations.

Ensuring the Line is Dry:

Moisture in the fuel line can lead to corrosion and contamination, which can severely impact engine performance. To ensure the line is dry, you can use a few methods. One approach is to run the aircraft's fuel system through a drying cycle. This involves operating the engine and allowing it to run for an extended period, ensuring that any moisture in the system is burned off. Alternatively, you can use a fuel line drying kit, which typically includes a specialized solvent that absorbs moisture. Follow the manufacturer's instructions for the chosen method to effectively eliminate any excess moisture.

Regularly check the fuel line for any signs of water accumulation, especially after operations in humid conditions. If you notice any water, it's crucial to address it promptly to prevent potential issues. In some cases, you might need to consider using a fuel line desiccant to keep moisture at bay, especially during long periods of storage or non-use.

By following these steps, you can effectively test for leaks and ensure that your aircraft's fuel line remains in optimal condition, contributing to the overall safety and performance of your carrier's operations. Remember, regular maintenance and inspections are key to preventing costly repairs and ensuring the longevity of your aircraft's systems.

Is Nickel-Copper Alloy Safe for Fuel Storage?

You may want to see also

Frequently asked questions

It is recommended to clean your fuel line at least once a year or every 10,000 miles to maintain optimal performance and prevent fuel-related issues.

A thorough cleaning can be done by flushing the system with a fuel line cleaner. This process involves attaching the cleaner to the fuel line and running it through the system, dissolving and removing any deposits or contaminants.

No, regular car cleaners are not designed for fuel lines and may contain harsh chemicals that can damage the internal components. It's crucial to use a product specifically formulated for fuel line maintenance.

Yes, some common indicators include reduced engine performance, frequent stalling, difficulty starting the engine, or a noticeable decrease in fuel efficiency. If you experience any of these issues, it's advisable to have your fuel line inspected and cleaned.

Regular maintenance, including fuel line cleaning, is essential. Additionally, using high-quality fuel and ensuring proper fuel storage can help prevent contamination and keep your fuel line in good condition.