Checking the fuel line on a dirt bike is an essential maintenance task to ensure optimal performance and prevent potential issues. This guide will provide a step-by-step process to inspect the fuel line, covering the necessary tools, safety precautions, and visual checks to identify any leaks, damage, or blockages. By following these instructions, riders can maintain their dirt bikes' reliability and longevity, ensuring a smooth and enjoyable riding experience.

What You'll Learn

- Visual Inspection: Check for cracks, leaks, and damage to the fuel line

- Pressure Test: Use a gauge to ensure the line holds pressure

- Fuel Flow: Verify that fuel is flowing to the engine

- Fuel Pump: Inspect the pump for proper operation and flow rate

- Hose Connections: Ensure all connections are tight and secure

Visual Inspection: Check for cracks, leaks, and damage to the fuel line

A visual inspection is a crucial step in maintaining and ensuring the safety of your dirt bike's fuel system. It is a simple yet effective way to identify potential issues with the fuel line before they become major problems. Here's a detailed guide on how to perform this inspection:

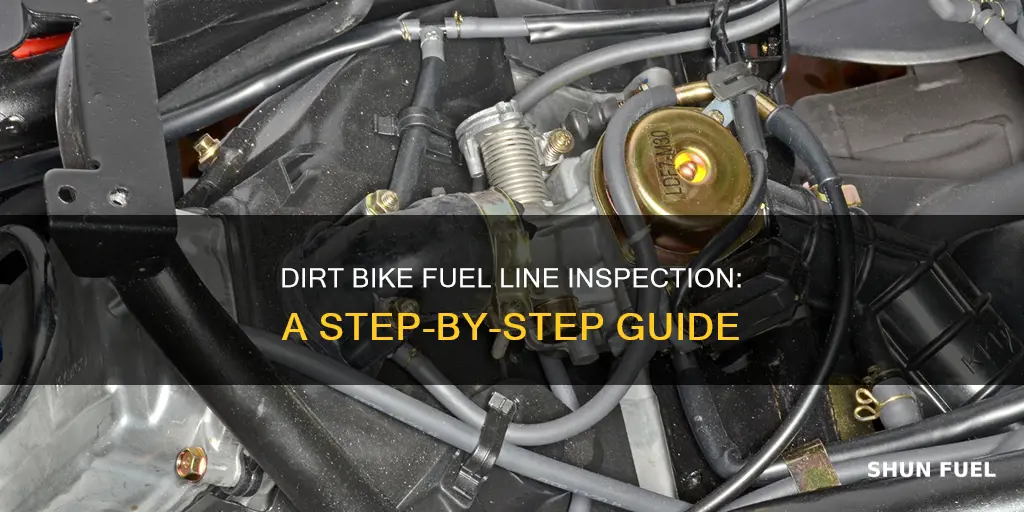

Start by locating the fuel line, which is typically a flexible tube that runs from the fuel tank to the engine. It is often black or dark in color and can be found along the frame of the bike. Carefully examine the fuel line for any visible signs of damage or deterioration. Look for cracks, splits, or punctures along the length of the line. These defects can be caused by various factors, such as age, wear and tear, or impact damage from the bike's movement during operation. Inspect the connections between the fuel line and the tank, as well as where it attaches to the engine, for any signs of leakage or corrosion. Even a small crack can lead to fuel leaks, which can cause engine misfires, reduced performance, and potential safety hazards.

Pay attention to the flexibility of the fuel line. Over time, the line can become brittle and less flexible, making it more susceptible to damage. If you notice any stiffness or rigidity in the line, it may indicate that it needs to be replaced. Additionally, check for any signs of fuel accumulation or residue around the fuel line. If the line is not properly maintained, fuel can accumulate and cause blockages or corrosion inside the line.

During your inspection, also look for any signs of damage to the fuel tank and its surrounding area. Small holes or punctures in the tank can lead to fuel leaks, which, as mentioned earlier, can have serious consequences. Ensure that the tank is intact and secure, with no visible signs of damage.

Remember, a thorough visual inspection can help you identify issues early on, allowing for timely repairs or replacements. Regular maintenance checks are essential to keep your dirt bike in optimal condition and ensure its longevity.

Choosing the Right Fuel Line for Small Gas Engines: A Guide

You may want to see also

Pressure Test: Use a gauge to ensure the line holds pressure

When it comes to maintaining a dirt bike, ensuring the fuel system is in top shape is crucial. One essential aspect of this maintenance is checking the fuel line for any potential issues. A pressure test is a simple yet effective method to verify the integrity of the fuel line and its ability to deliver fuel efficiently. Here's a step-by-step guide on how to perform this test:

Gather the Necessary Tools:

You'll need a fuel pressure gauge, which can be purchased from most motorcycle or automotive supply stores. This gauge measures the pressure in the fuel line and provides an accurate reading. Additionally, ensure you have a source of fuel, such as a fuel pump or a fuel can, to simulate the fuel flow.

Locate the Fuel Line:

Identify the fuel line on your dirt bike. It is typically a rubber or plastic hose that runs from the fuel tank to the engine. Locate the point where the fuel line connects to the engine, as this is where you will attach the pressure gauge.

Prepare for the Test:

Park your dirt bike on a level surface and ensure it is in a secure position. Turn off the engine and allow it to cool down if it has been running. This step is important to ensure safety and accurate readings.

Connect the Gauge:

Attach the fuel pressure gauge to the fuel line, ensuring a tight and secure connection. Make sure the gauge is positioned so that it can accurately measure the pressure. You might need to adjust the gauge's position slightly to get the best reading.

Simulate Fuel Flow:

Using your fuel source, start the flow of fuel through the line. This can be done by activating the fuel pump or opening a fuel can's valve. As the fuel flows, the pressure gauge will display the pressure reading. A healthy fuel line should maintain a steady pressure within the recommended range, typically between 40-60 psi (pounds per square inch) for dirt bikes.

Record and Analyze:

Take note of the pressure reading. If the pressure drops significantly or fluctuates, it may indicate a problem with the fuel line, such as a leak or a restricted flow. If the pressure is below the recommended range, it could suggest a faulty fuel pump or a clogged fuel filter. This test is a valuable tool for diagnosing fuel system issues and ensuring your dirt bike's performance remains optimal.

Remember, regular maintenance and checks like this can help prevent unexpected breakdowns and keep your dirt bike running smoothly.

Revive Your Furnace: A Guide to Restarting After Fuel Line Maintenance

You may want to see also

Fuel Flow: Verify that fuel is flowing to the engine

To ensure your dirt bike's engine receives the necessary fuel, it's crucial to verify the fuel flow. Here's a step-by-step guide to help you check the fuel flow:

- Locate the Fuel Line: Start by identifying the fuel line, which is typically a rubber or plastic hose that runs from the fuel tank to the engine. It's important to locate the point where the fuel line connects to the engine's fuel injection system or carburetor.

- Remove the Fuel Line (Optional): In some cases, you might need to temporarily remove the fuel line to access the engine's fuel system. Carefully detach the fuel line from the engine and any other connections to ensure you can inspect the system thoroughly.

- Check for Clogs or Restrictions: Inspect the fuel line for any signs of damage, cracks, or blockages. Even a small obstruction can disrupt the fuel flow. Look for any clumps of dirt, debris, or contaminants that might be present in the line. If you notice any issues, consider cleaning or replacing the fuel line to ensure optimal performance.

- Use a Fuel Pressure Gauge: A fuel pressure gauge is a valuable tool for this step. Connect the gauge to the fuel line, ensuring a secure connection. Turn on the engine and observe the fuel pressure reading. A healthy fuel flow should result in a stable and consistent pressure. If the pressure fluctuates or drops significantly, it indicates a potential issue with the fuel system, such as a restricted line or a problem with the fuel pump.

- Test the Fuel Pump: With the engine running, listen for the fuel pump's operation. The pump should be audible, creating a humming or whirring sound as it draws fuel from the tank. If you don't hear the pump, it could be faulty and in need of replacement. Additionally, check for any leaks or excessive fuel spray around the pump area, as this might indicate a problem with the fuel delivery system.

- Inspect the Fuel Tank: While you have the engine running, it's a good idea to check the fuel tank for any signs of contamination or low fuel levels. Ensure that the tank is clean and free from debris. If the fuel level is low, refill the tank to maintain optimal performance.

By following these steps, you can effectively verify the fuel flow to your dirt bike's engine, ensuring it receives the required fuel for efficient operation. Regular maintenance and checks on the fuel system will help prevent issues and keep your bike running smoothly.

Finding the Perfect Fuel Line for Your 1993 Toyota 4Runner

You may want to see also

Fuel Pump: Inspect the pump for proper operation and flow rate

When it comes to maintaining your dirt bike, ensuring the fuel pump is functioning correctly is crucial for optimal performance. Here's a step-by-step guide on how to inspect the fuel pump for proper operation and flow rate:

- Access the Fuel Pump: Start by locating the fuel pump, which is typically mounted near the fuel tank or along the fuel line. It is important to consult your dirt bike's manual to identify the exact location. You might need to remove certain panels or components to gain access, so have the necessary tools ready.

- Check for Visual Signs: Inspect the fuel pump for any visible damage or signs of wear. Look for cracks, corrosion, or any debris that might have accumulated around the pump. Ensure that all connections and wiring are secure and free from any signs of deterioration.

- Measure Flow Rate: The flow rate of the fuel pump is a critical aspect of its performance. You can measure it using a fuel flow meter or by using a calibrated container to measure the fuel output over a specific time period. Compare the measured flow rate with the manufacturer's specifications to ensure it meets the required standards. If the flow rate is significantly lower than expected, it may indicate a clogged or faulty pump.

- Listen for Operation: While the bike is running, listen to the fuel pump's operation. It should produce a steady, rhythmic sound, indicating that it is pumping fuel correctly. If you hear any unusual noises, such as rattling or a high-pitched whine, it could suggest an issue with the pump or its mounting.

- Test for Power: Ensure that the fuel pump is receiving the correct voltage and power supply. You can use a multimeter to check the voltage at the pump's terminals. If the voltage is inconsistent or absent, it may indicate a problem with the electrical system or a faulty pump.

- Consider Replacement: If you find any issues during the inspection, such as significant wear, damage, or inconsistent performance, it might be time to consider replacing the fuel pump. Regular maintenance and timely replacements can prevent fuel-related problems and ensure your dirt bike runs smoothly.

Understanding the 3/8 Fuel Line: A Comprehensive Guide

You may want to see also

Hose Connections: Ensure all connections are tight and secure

When it comes to maintaining a dirt bike, paying attention to the fuel system is crucial, especially when it comes to the hose connections. These connections are vital to ensure a continuous and efficient fuel supply to the engine, and any looseness or damage can lead to performance issues or even engine failure. Here's a detailed guide on how to check and secure the hose connections:

Start by locating the fuel lines, which are typically made of rubber or flexible plastic. These lines carry fuel from the tank to the carburetor or fuel injection system. Identify the connections where the fuel lines are attached to the fuel pump, the carburetor, and any other components in your bike's fuel system. Each connection should have a secure clamp or fitting to hold the hose in place.

The first step in ensuring tightness is to inspect each connection for any signs of damage or wear. Look for cracks, tears, or any deformation in the hose material. Over time, hoses can degrade due to heat, fuel contamination, or physical impact. If you notice any damage, it's crucial to replace the affected hose immediately. Even a small tear can lead to fuel leaks, which can be dangerous and cause engine misfires.

To check the tightness of the connections, gently pull on the fuel lines to ensure they are securely attached. You should feel some resistance, but the hose should not come loose easily. If you find any loose connections, tighten the clamps or fittings by hand first. Then, use a wrench or a specialized fuel line tool to apply firm pressure and ensure the connections are snug. Tight connections prevent fuel leaks and ensure the fuel system operates optimally.

It's also a good practice to lubricate the connections with a small amount of fuel line sealant or silicone grease, especially if the connections are made of metal. This simple step can help prevent hose deterioration and ensure a longer lifespan for your fuel lines. Additionally, regular maintenance and inspections will help identify any potential issues before they become major problems.

Remember, proper hose connections are essential for the overall performance and longevity of your dirt bike's fuel system. By following these steps, you can ensure that your bike's fuel lines remain secure and efficient, providing reliable power to your engine.

Motorized Bikes: Understanding Fuel Line Dimensions

You may want to see also

Frequently asked questions

It is recommended to inspect the fuel line at least once a month or before major rides to ensure optimal performance and safety. Regular checks are essential, especially if you ride in harsh conditions or notice any issues with the bike's performance.

Look out for symptoms like reduced engine performance, difficulty starting the bike, or inconsistent idling. If you notice any leaks, cracks, or bends in the fuel line, it's crucial to address the issue promptly to prevent further damage.

You can perform a basic visual inspection yourself. Start by ensuring the bike is on a level surface and the engine is cool. Check for any visible damage, corrosion, or debris around the fuel line. If you're unsure or the damage seems extensive, consulting a professional mechanic is advisable.

Locate the fuel tank and identify the fuel line, which is typically a rubber or plastic hose connected to the fuel pump and the carburetor. You might need to remove some panels or access panels to get a clear view and reach the fuel line for inspection.

A simple flashlight or headlamp is useful for illuminating dark areas. You might also consider using a fuel line inspection mirror to get a better view of hard-to-reach areas. Additionally, having a small brush or compressed air can help clean and clear any debris from the fuel line.