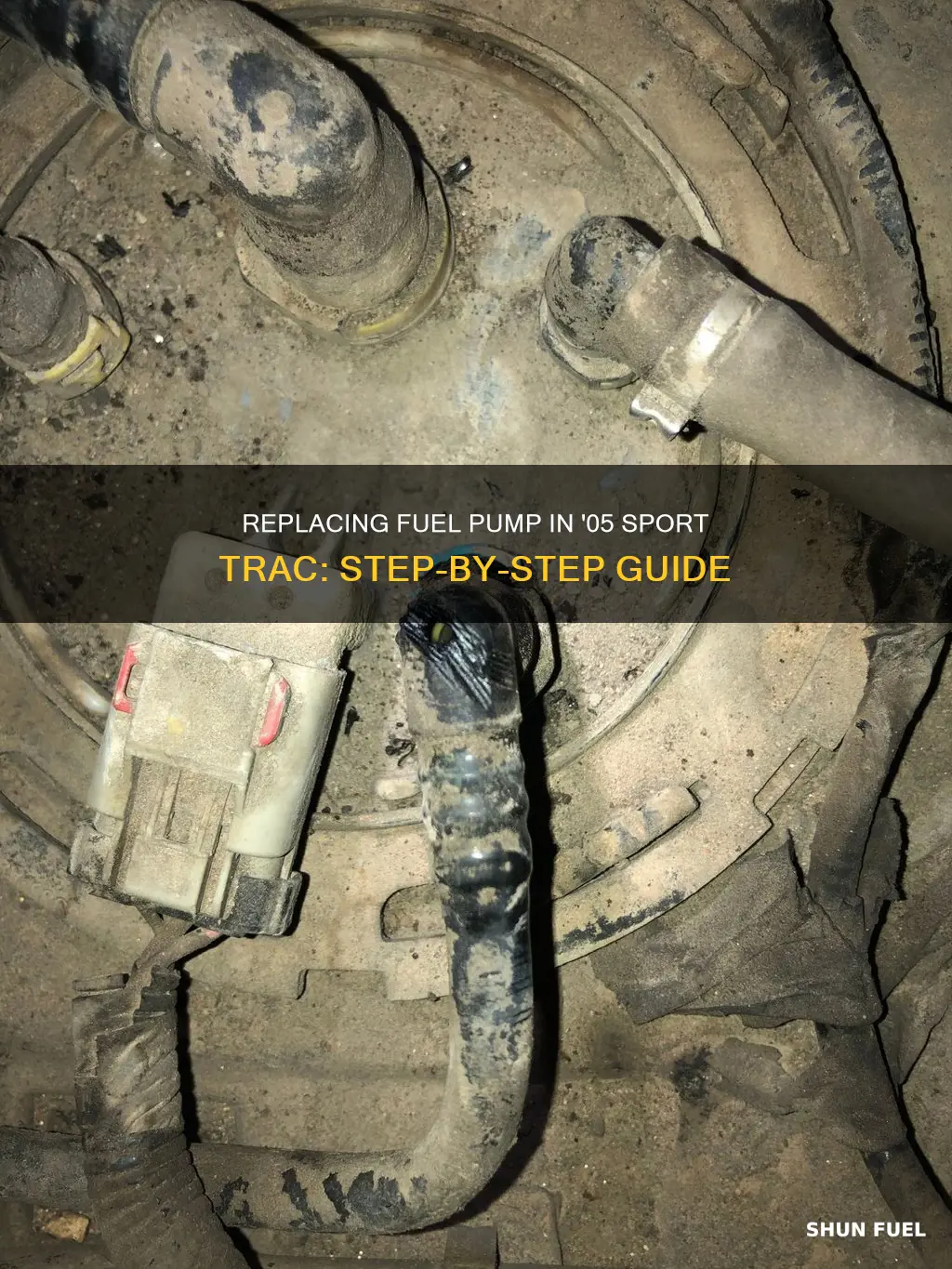

Changing the fuel pump in a 2005 Sport Trac is a complex task that requires careful attention to multiple steps. It is important to note that this job may be challenging to do alone, and it is recommended to have an assistant to help with certain steps. The first step is to disconnect the battery and release the fuel pressure. Next, remove the left rear wheel and fender liner, and loosen the hose clamps on the filler and breather tube at the tank end. Spray between the hose and tube with window spray or lubricant, and twist the hose. Now, the fuel can be siphoned out. After removing the tank shield and loosening the tank bolts, the tank can be supported at the rear with a jack and plywood. With the rear of the tank lowered, disconnect the fuel lines and wiring. Finally, remove the remaining bolts at the front, and carefully lower the tank, sliding it out from under the truck.

| Characteristics | Values |

|---|---|

| Vehicle | 2005 Ford Explorer Sport Trac |

| Fuel pump replacement cost | $250 (NAPA fuel pump) |

| Labor cost | $1100 (Ford dealership) |

| Fuel pump relay location | Under hood fuse box |

| Fuel tank removal | Disconnect battery, release fuel pressure, jack up rear of vehicle, remove left rear wheel and fender liner, remove filler pipe hose, etc. |

| Fuel pump access | Cut access hole in floor from front of passenger rear seat to back of passenger front seat |

| Fuel pump lock ring | Requires special tool for removal |

What You'll Learn

Check the fuel inertia switch

To check the fuel inertia switch on a 2005 Sport Trac, begin by locating the switch on the passenger side under the dashboard. Push down on the switch—if it clicks, it has been tripped. If it doesn't click, check for 12v reaching it. There is a fuel pump relay that feeds it in the under-hood fuse box.

The fuel inertia switch is activated or deactivated by G-forces, similar to how a crash sensor works in an airbag system. It has a very low failure rate, so you don't need to worry about it. However, if it keeps tripping for no apparent reason, you should consider replacing it.

To reset the fuel inertia switch, simply push the button back down.

If you are experiencing issues with your fuel pump, it is worth checking the fuel inertia switch before attempting to replace the pump.

Changing Fuel Filters: A Guide for Ford Bronco Owners

You may want to see also

Check for 12v reaching the fuel pump

To check for 12v reaching the fuel pump, you can perform a voltage test. Here is a step-by-step guide:

Step 1: Prepare the Settings

Connect a digital multimeter to the positive and negative terminals of the fuel pump. Ensure there are no broken circuits between the fuel pump and relay.

Step 2: Switch Ignition

Insert the key into the ignition and turn it on without starting the engine. If the pump is functioning, you should hear a soft whirl sound, indicating it is ready to pump fuel.

Step 3: Test Negative Terminals

Split the circuit in half, with the ground phase on one side and the positive on the other. Use a jumper wire to power the fuel circuit and energize the pump. Now, connect the digital multimeter to the battery and the pump, both on their negative terminals. Conduct the tests using a live circuit wire. If the meter shows a reading of more than 0.1, this indicates a loss of voltage power due to damaged harness connectors or poor wiring.

Step 4: Test Positive Terminals

Connect the digital multimeter to the positive terminals of the pump and the battery. Also, test the output terminal of the fuel pump to ensure it is functioning correctly. If the voltage drop is greater than 0.1 volts, this confirms that the harness connectors or wiring is faulty.

Step 5: Testing Pump Relay

Locate the fuel pump relay, usually on the dashboard or engine compartment. Remove the relay and have an assistant switch on the ignition without starting the engine. Check for voltage at the relay connector using a digital multimeter.

Step 6: Test the Pump

If possible, remove the fuel pump from the vehicle and place it on a flat surface. Use jumper wires connected to the battery to test for voltage. If the pump is challenging to remove, take your battery to the back of the vehicle and connect the jumper wires to the battery and fuel pump to test for voltage, being careful not to cause sparking.

Additionally, you can apply 12v directly to the fuel pump through the diagnostic connector. Locate the G terminal in the diagnostic connector and connect the positive lead of an external 12v battery to it. However, this is not recommended as a permanent solution. Instead, testing and replacing the relay is advised.

Changing Fuel Filter on Hyundai Santa Fe: Step-by-Step Guide

You may want to see also

Drain the fuel tank

To drain the fuel tank of your 2005 Sport Trac, you will need to insert a suitable fuel drain tube into the fuel tank filler pipe until it reaches the fuel tank inlet spout. This will remove approximately 1/8 of the fuel from the tank. Attach a fuel storage tanker to the drain tube and remove the residual fuel from the filler pipe.

Next, release the fuel tank filler pipe hose clamp and disconnect the hose from the tank. Insert the fuel drain tube into the fuel tank inlet spout. When the tank is completely full, this will drain most of the fuel from the right-hand side of the tank and partially drain the left-hand side due to the siphoning effect. Attach the fuel storage tanker to the drain tube and drain the fuel from the right-hand side of the tank.

It is also possible to siphon the fuel tank without removing it, but this is very difficult due to the bends in the fuel filler line. To do this, remove the spare tire to access the hose clamp for the filler line. You will need a 7/32 socket to remove the clamp.

If you are still unable to siphon the fuel, you can lower the tank with fuel still in it. Use a floor jack and a friend to support the tank while lowering.

Replacing Fuel Filter in 2006 Ford Expedition: Step-by-Step Guide

You may want to see also

Disconnect the fuel tank filler pipe hose

Disconnecting the fuel tank filler pipe hose on a 2005 Sport Trac can be a challenging task, but with the right tools and approach, it can be accomplished. Here is a detailed guide to help you through the process:

Before beginning, make sure you have the necessary tools, such as a hose hook, a floor jack, and a helper. You will also need to place a floor jack and a plank of plywood underneath your vehicle for support.

First, remove the spare tire and the inner fender. This will provide you with the necessary room to work and access the hose hook. Next, pour boiling water over the hose connection to soften it and make it easier to remove. Use the hose hook to pry against the spout and loosen the hose. Twist the hose while prying to further aid in its removal.

At this point, you may need to remove the driver's side rear wheel to gain better access to the hose connection. With the wheel removed, you can try using a cotter pin puller to slip between the hose and the nipple, twisting and pulling the hose off.

If the hose is still difficult to remove, you can try using a combination of the previously mentioned methods. For example, you can spray lubricant between the hose and the neck of the tank, twist the hose, and then use the hose hook to pry it off.

Once the hose is disconnected, you can proceed with the next steps of lowering the fuel tank and replacing the fuel pump. Remember to always exercise caution when working with fuel systems and refer to a qualified mechanic if you are unsure about any steps.

Stay focused and take your time, as working with fuel systems can be challenging and requires attention to detail.

Adjusting Air-Fuel Ratios: The Honda Way

You may want to see also

Disconnect the fuel pump module electrical connector

Disconnecting the fuel pump module electrical connector is a crucial step in replacing the fuel pump in your 2005 Ford Explorer Sport Trac. Here is a detailed, step-by-step guide on how to do this safely and effectively:

Step 1: Place the vehicle in neutral and position it on a hoist. This will give you access to the underside of the vehicle, where the fuel pump is located.

Step 2: Release the fuel system pressure. This is an important safety precaution to prevent any accidental discharge of fuel when you start working on the pump.

Step 3: Disconnect the battery ground cable. This will prevent any electrical power from reaching the fuel pump, reducing the risk of sparks or short circuits during the disconnection process.

Step 4: Release the fuel tank filler cap and position it aside. You may need to open the fuel filler door and unscrew the cap to access the fuel tank filler pipe.

Step 5: Insert a suitable fuel drain tube into the fuel tank filler pipe until it reaches the fuel tank inlet spout. This will allow you to drain any remaining fuel from the tank before proceeding.

Step 6: Attach a fuel storage tanker to the fuel drain tube and remove any residual fuel from the tank. This step is crucial for safety, as you do not want to work with a full fuel tank.

Step 7: Release the fuel tank filler pipe hose clamp and disconnect the hose from the fuel tank. This will give you access to the fuel pump module.

Step 8: Clean the surrounding area of the fuel pump module mounting flange and the quick connect couplings with compressed air. This will help prevent any dirt or debris from entering the fuel system during the disconnection process.

Step 9: Place absorbent pads in the general work area to catch any spilled fuel.

Step 10: Now, carefully disconnect the fuel pump module electrical connector. This is the critical step you have been building up to. Take your time and be gentle to avoid any damage to the connector or the surrounding components.

Step 11: Once the electrical connector is disconnected, you can proceed to disconnect the rear fuel supply tube and the fuel vapor control tube assembly valve from the fuel pump module.

Step 12: Install the special tool and remove the fuel pump module lock ring. This will free the fuel pump module from the fuel tank, allowing you to lift it out carefully.

By following these steps, you will be able to safely and effectively disconnect the fuel pump module electrical connector and proceed with the rest of the fuel pump replacement process. Remember always to work with a helper and take all necessary safety precautions when working with fuel and electrical systems.

Changing Fuel Filters in a Mini: Step-by-Step Guide

You may want to see also

Frequently asked questions

Check the fuel inertia switch on the passenger side under the dash. Push down on the switch, if it clicks it was tripped. If its not, check for 12v reaching it. There is a fuel pump relay that feeds it in the under-hood fuse box.

You will need to drain the tank. You can do this by inserting a hose into the filler neck or by removing the tank.

Disconnect the battery and release the fuel pressure. Remove the left rear wheel and fender liner. Loosen the hose clamps on the filler and breather tube at the tank end. Remove the tank shield and loosen the tank bolts at the front of the tank. Support the tank with a jack and plywood. Remove the strap bolt and lower the rear of the tank.

It is recommended to use a Motorcraft or Ford fuel pump to ensure compatibility.