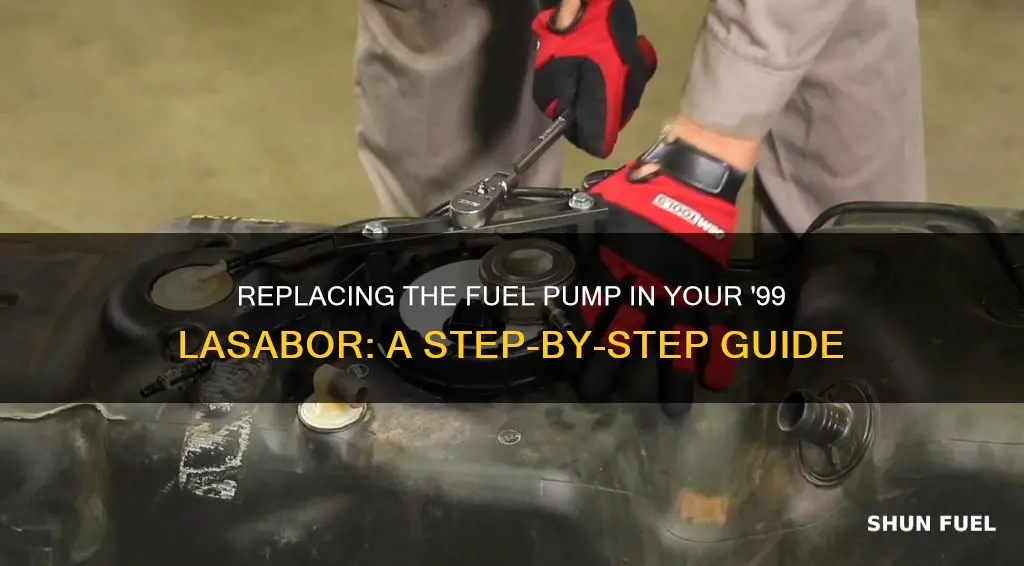

Changing a fuel pump can be a challenging task, but with the right tools and safety precautions, it can be done safely and efficiently. In this guide, we will walk you through the process of replacing the fuel pump in a 99 Lasabor, covering everything from the tools you'll need to the step-by-step procedure. So, whether you're an experienced mechanic or a novice DIYer, read on to learn how to tackle this repair project confidently and successfully.

| Characteristics | Values |

|---|---|

| Vehicle | 99 Firebird/Camaro |

| Tools Required/Recommended | Sockets/Wrenches, Fuel pressure gauge, Air compressor, Needle nose pliers, Flush side cutters, Jack stands, Gas can, etc. |

| Preparation Steps | Disconnect negative battery cable, Remove rear wheels, Remove fuel filler cap, Remove fuel fill pipe shield, Remove fuel tank pipe bracket support bolt, Remove track/Panhard bar, Disconnect electrical plugs, Remove exhaust, Remove heat shielding, Disconnect fuel return pipe and EVAP purge pipe, Disconnect fuel feed pipe, Remove rear pipe clip |

| Fuel Pump Replacement Steps | Find a friend to help, Remove fuel tank, Disconnect pipes and electrical connectors, Remove old fuel pump, Clean fuel tank, Install new fuel pump, Reassemble fuel system, Test new fuel pump |

| Tips | Work in a well-ventilated area, Use proper safety gear, Drain the fuel tank, Clean around the fuel pump, Replace fuel pump components |

What You'll Learn

Prepare your workspace and safety gear

Changing a fuel pump can be a dangerous task, so it is important to be well-prepared and take the necessary safety precautions. Here are some steps to help you prepare your workspace and safety gear:

Firstly, ensure you have a safe and accessible workspace. If possible, work outdoors or in a well-ventilated area to minimise the risk of fire and inhaling harmful fumes. Make sure you have enough space to move around the vehicle and access the fuel pump.

Next, gather all the necessary tools and safety gear. This includes safety glasses and gloves to protect your eyes and hands from fuel spills and splashes. Wear appropriate clothing that covers your body and arms. You will also need a pan and a rag to catch any fuel spills or leaks.

Before starting the repair, it is important to reduce the amount of fuel in the tank. Most fuel pumps are located inside the fuel tank, so lowering the fuel level will reduce the risk of spillage and make the tank lighter and easier to handle. You can do this by loosening a fuel line and draining the fuel into a gas can.

It is also recommended to disconnect the battery and pull the fuel pump relay to prevent any accidental activation of the pump during the repair.

Finally, consult your vehicle's service manual or online tutorials for specific instructions on replacing the fuel pump in your 99 Lasabor. These resources can provide valuable guidance and help you feel more confident in tackling the task.

Replacing Fuel Filler Neck Gasket: Step-by-Step Guide for DIYers

You may want to see also

Disconnect the battery

Disconnecting the battery is an important safety precaution when changing the fuel pump in your 1999 Lasabor. Fuel is highly flammable, and working on the fuel system with the battery connected could risk a spark. This could lead to a dangerous situation, so it is always better to be safe than sorry.

To disconnect the battery, you will need to locate the negative battery cable. This is usually a black cable with a negative (-) symbol or marking. Once you have located the cable, you will need to unplug it from the battery. In some cases, you may need to remove the battery entirely. It is recommended to use a fuel pressure gauge to relieve pressure on the system before disconnecting the battery. This can be done by wrapping a towel around the fitting and screwing the gauge onto the Schrader valve on the fuel rail.

After disconnecting the battery, be sure to move it away from the work area to avoid any accidental contact. It is also important to note that you should never smoke or use any open flames while working on the fuel system, as this could lead to a fire or explosion.

Additionally, it is a good idea to wear safety gear, such as safety glasses and gloves, to protect yourself from fuel spills and splashes. Working in a well-ventilated area or outdoors is also recommended to minimize the risk of inhaling harmful fumes.

By taking these precautions and following the instructions specific to your vehicle, you can safely replace the fuel pump in your 1999 Lasabor.

Changing Diesel Fuel Filter: Toyota Hilux Guide

You may want to see also

Relieve the fuel system pressure

To relieve the fuel system pressure, you can run the engine and then pull the fuel pump relay while the engine is on. This will cause the engine to stall. Alternatively, you can press the Schrader valve on the pressure line momentarily, capturing the small amount of fuel that sprays out. It is also recommended that you wrap a towel around the fitting in case of a leak.

Fossil Fuels: Powering Change and Progress

You may want to see also

Remove the fuel tank

To remove the fuel tank from a 99 Lasabor, you will first need to ensure you have a safe and accessible workspace. It is important to work in a well-ventilated area, preferably outdoors, to reduce the risk of fire or inhaling harmful fumes. You should also wear safety gear, including safety glasses, gloves, and appropriate clothing to protect yourself from fuel spills and splashes.

Before you begin, it is recommended to reduce the amount of fuel in the tank. This will make the tank lighter and easier to handle, and reduce the risk of spillage. You can do this by loosening a fuel line and either jumping power to the pump or bumping the key every few seconds to barely turn the engine and run the pump. Alternatively, put a hose on the line and drop the line into a gas can.

Next, you will need to locate the fuel tank and remove it from the vehicle. This process can vary depending on the vehicle. In some cases, you may need to use a jack to support the tank and lower it. On other models, there may be an access port under the rear seat or in the trunk area, which can save time and effort.

Once you have located the fuel tank and determined the removal process, you can begin disconnecting the necessary components. Make sure to take note of the fuel line connections and wiring before removing the old pump. Then, carefully remove all connections and turn the large lock nut to free the old pump. Finally, pull out the old pump and set it aside.

Now that the old fuel pump has been removed, you can proceed with installing the new pump and reassembling the fuel system. It is recommended to clean the area around the fuel pump before installing the new one to prevent dirt and debris from falling into the fuel tank. Additionally, consider replacing related components such as the fuel filter, fuel pump strainer, and fuel tank O-ring or gasket.

Replacing Fuel Injectors: Step-by-Step Guide for 2007 Ford Explorers

You may want to see also

Reassemble the fuel system

Once you have installed the new fuel pump, you can begin reassembling the fuel system.

Firstly, grab a partner to help you raise the tank back into place. Remember to start on the passenger side and raise the tank towards the driver's side to allow the filler hose to slot into place. Your partner can guide the hose as you raise the tank. Ensure all wires and fuel pipes are facing towards the front of the vehicle, including the new wiring kit.

Next, tighten the bolts for the fuel tank straps to 24 lb-ft. You can then mount the relay and ground in the general vicinity of the existing plugs. You will need to drill a hole and use a self-tapping screw to mount the relay if there is no suitable bolt. After drilling, clean the paint from the area using a sanding sponge to ensure a good connection for the ground. Mount the relay with the wires facing down to prevent corrosion, and ensure there is some slack in the wire.

Now, plug the fuel harness wires back in. You will find the fuel pipes marked with 'F' and 'R' for feed and return. Install the pipes back into the pipe clip with a 10mm bolt, tightening to 49 lb-in or 5.5 Nm. Install the fuel tank filler pipe support bracket bolt (10mm) and tighten to 89 lb-in or 10 Nm. Install the fuel tank filler pipe shield (7mm bolt and Phillips head trim piece).

Finally, install the heat shields (7mm bolts) and the exhaust. The factory clamps should be tightened to 35 lb-ft, and the hangers (1/2" socket) to 89 lb-in. Raise the rear end and place the springs and isolators back in. Install the torque arm bolts and nuts (13/16" bolt and washer at the top). Tighten to 96 lb-ft at the bolt and 97 lb-ft at the nut. Connect the shocks to the axle (66 lb-ft). Connect the sway/stabilizer bar end links (17 lb-ft). Install the track bar and the two 7mm screws into the factory track bar.

Replace the rear wheels. The factory calls for 89 lb-ft for the lug nuts. Once everything is reassembled, reconnect the battery and follow the manufacturer's instructions for priming the new pump.

Changing Diesel Fuel Filters: Step-by-Step Guide for Engine Health

You may want to see also