HP Tuners is a leading provider of automotive tuning solutions, offering advanced hardware and software that enable users to enhance their vehicle's performance, improve fuel efficiency, and customize their driving experience. One of the key aspects of engine performance is the air-to-fuel ratio, which determines how efficiently the engine burns fuel. HP Tuners allows users to adjust this ratio, ensuring optimal combustion and maximizing power while reducing waste. By utilizing the VCM Suite software, which includes the VCM Scanner and VCM Editor, users can access and adjust parameters such as fuel injection, ignition timing, and air consumption, resulting in improved fuel efficiency and enhanced vehicle performance.

| Characteristics | Values |

|---|---|

| HP Tuners' role | HP Tuners provides advanced automotive tuning hardware and software to enhance vehicle performance, improve fuel efficiency, and customize driving dynamics |

| Fuel economy improvement | Achievable through dedicated fuel economy tune using HP Tuners interface, resulting in better and more consistent MPG |

| Fuel economy tuning parameters | Spark Table optimization, Deceleration Fuel Cutoff (DFCO) optimization, Cylinder Deactivation, Optimize Closed-Loop Fuel Control, Transmission recalibration, Torque Converter adjustments, Limit throttle response, Drop Idle Speed |

| Tuning process | Check vehicle compatibility, determine credits needed, use MPVI3 device with VCM Suite software, perform diagnostic scans and logging, adjust parameters, test drive |

| Benefits | Improved performance, better fuel efficiency, customized driving experience, enhanced horsepower and torque, optimized combustion, tailored driving experience, optimized performance beyond factory settings |

What You'll Learn

Adjusting the air-to-fuel ratio

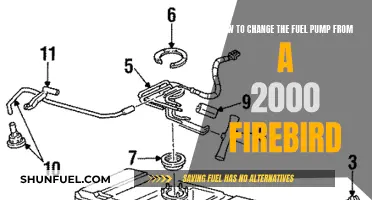

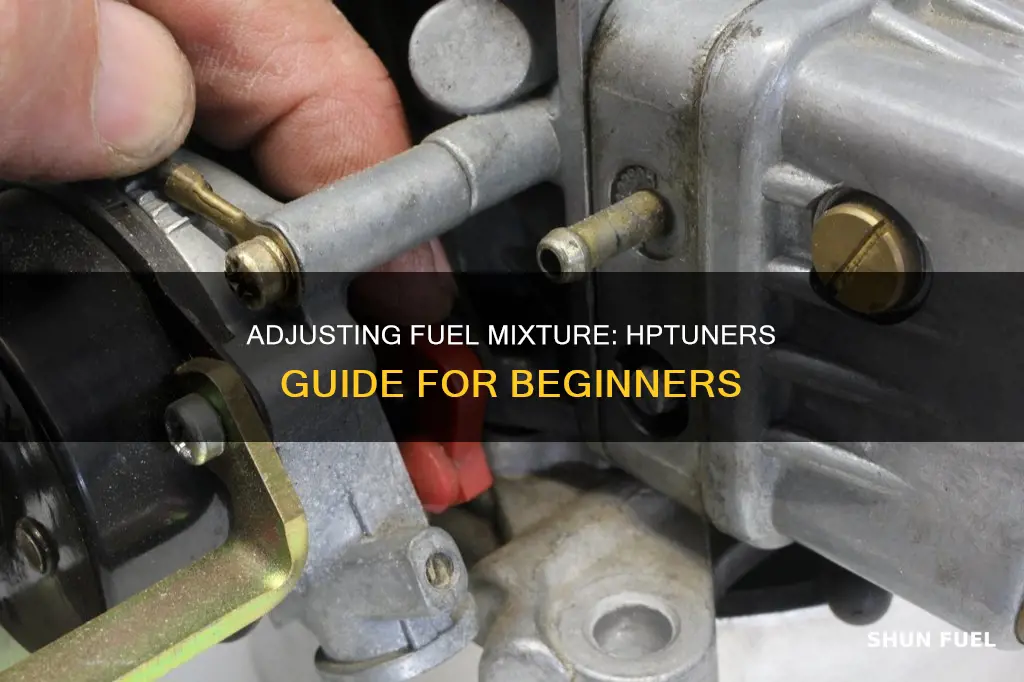

To adjust the air-to-fuel ratio using HP Tuners, you will need their MPVI3 interface tool and the VCM Suite software. First, check your vehicle's compatibility with HP Tuners and determine the number of credits needed to license your vehicle's control modules. Once you've sorted the prerequisites, follow these steps:

- Connect the MPVI3 device to your vehicle's OBDII port and your laptop.

- Launch the VCM Scanner software to perform a diagnostic scan and log initial performance data.

- Review the data to understand your vehicle's performance and identify any issues.

- Use the VCM Editor to adjust parameters related to fuel injection, ignition timing, and air consumption.

- Save your changes and write the new calibration to your vehicle.

- Test drive your vehicle to evaluate the effects of your adjustments.

When adjusting the air-to-fuel ratio, it's crucial to aim for the stoichiometric ratio, which is the ratio of air to fuel that results in perfect combustion. For normal pump fuel, this ratio is approximately 14.7:1, meaning 14.7 kilograms of air are consumed for every kilogram of fuel burned.

While a leaner air-to-fuel ratio can improve fuel economy, there is a limit. With conventional engines, an extremely lean ratio can cause the engine to misfire as the combustion charge becomes too lean for the spark plug to ignite. Direct injection engines, however, can employ a strategy called stratified charge, allowing for extremely lean overall air-to-fuel ratios while maintaining stable combustion.

Remember that adjustments to the air-to-fuel ratio can impact emissions. The stoichiometric ratio of 14.7:1 is the point at which the minimum amount of pollutants is emitted, and it is crucial for the catalytic converter to function optimally. Therefore, while adjusting the ratio for improved fuel economy, be mindful of staying within emissions compliance.

Changing Fuel Filter: Onan 4KW Generator 2007 Edition

You may want to see also

Spark plug ignition timing

Understanding Spark Plug Ignition Timing

The spark plug ignition timing refers to the precise moment when the spark plug fires to ignite the air-fuel mixture in the engine's cylinders. This timing is crucial for achieving optimal combustion and engine performance. Advanced timing can lead to increased power, but it must be carefully managed to avoid pre-ignition or engine knocking, which can cause damage. On the other hand, retarded ignition timing can result in a sluggish engine response and reduced power output.

HP Tuners and Ignition Timing

HP Tuners provides tools and software, such as the VCM Scanner and VCM Editor, that allow you to adjust the ignition timing of your vehicle's engine. By reflashing the Engine Control Unit (ECU), you can make precise adjustments to the ignition timing, among other parameters, to improve performance, fuel efficiency, and responsiveness.

Steps to Adjust Spark Plug Ignition Timing:

- Diagnostics: Before making any adjustments, it is crucial to perform a thorough diagnostics exam using the HP Tuners interface and VCM Scanner. Address any check engine lights, mechanical issues, or sensor problems. Ensure that all major sensors and systems are fully functional.

- Log Total Advance: It is important to log the total advance to understand the current ignition timing and how it is being adjusted by the various correction tables. This information will help you make informed decisions about your adjustments.

- Knock-Retard Logging: Log the knock-retard to identify areas of the ignition tables where there is too much advance. This information will help you avoid potential engine knocking or pre-ignition issues.

- Use of Premium Fuel: Consider using premium fuel with a higher octane rating. Higher-octane fuel is less prone to pre-ignition and engine knock, allowing for more advanced ignition timing and improved torque and fuel efficiency.

- Adjust Spark Tables: Using the HP Tuners software, you can modify the spark tables to adjust the ignition timing. Make gradual adjustments, starting with small increments of 2 degrees at a time. Monitor the engine's performance and knock sensor activity to ensure you do not exceed the Maximum Brake Torque (MBT).

- Smoothen Spark Tables: Once you have identified the optimal timing for each cell in the spark tables, go back and smoothen the transitions between cells. This will result in smoother acceleration and improved engine performance.

- Real-World Testing: After making your adjustments, it is important to test the vehicle in real-world driving conditions. This can be done on a dyno or at the track, allowing you to fine-tune the ignition timing based on actual performance and feedback.

- Read Spark Plugs: Examining the spark plugs can provide valuable information about the engine's performance. The colour of the insulator and the presence of any timing marks can indicate whether the ignition timing is optimal or needs further adjustment.

- Maintain Emission Standards: Throughout the process, ensure that your vehicle remains compliant with emission standards. Adjustments to ignition timing can impact emissions, so it is crucial to consider this aspect during the tuning process.

By following these steps and considerations, you can effectively adjust the spark plug ignition timing using HP Tuners to optimise your vehicle's performance, fuel efficiency, and overall driving experience. Remember to approach any engine modifications with caution and consider seeking assistance from a professional tuner if you are unsure.

Kawasaki Prairie Fuel Filter: DIY Replacement Guide

You may want to see also

Exhaust system optimisation

The exhaust system is a crucial component of engine performance, as it allows the exhaust gases to exit the engine efficiently. Optimising the exhaust system can enhance performance and improve fuel efficiency. Here are some tips for exhaust system optimisation:

Reduce Back Pressure

Back pressure is the resistance created by the exhaust system that hinders the free flow of exhaust gases. By reducing back pressure, you can improve the engine's breathing and revving capabilities. This can be achieved by using larger diameter exhaust pipes or installing performance exhaust systems that minimise resistance for outgoing gases.

Improve Volumetric Efficiency

Volumetric efficiency refers to how effectively the engine can move air in and out of the cylinders. A better exhaust design can improve this by allowing the engine to breathe more easily. This, in turn, enhances combustion and fuel efficiency.

Minimise Pumping Losses

Pumping losses occur when the throttle body is closed during cruising, causing the engine to work harder to pull air past the throttle. While removing the throttle body is not feasible for petrol engines, manufacturers employ techniques such as variable cam control systems to optimise cam overlap, thus minimising pumping losses.

Consider Direct Injection Technology

Direct injection engines inject fuel directly into the combustion chamber, allowing precise control over the timing and mixture of fuel injection. This technology enables the use of a strategy called stratified charge, where the fuel is directed primarily towards the spark plug. This results in an extremely lean overall air-fuel ratio while maintaining stable combustion, improving fuel economy.

Modify Control Parameters

By changing the control parameters, you can allow the engine to enter a lean cruise mode faster and more frequently. This mode improves fuel economy by running the engine with a leaner air-fuel ratio, reducing fuel consumption. However, it is important to note that there is a limit to how lean the air-fuel ratio can be before the engine begins to misfire.

Upgrade to High-Performance Exhaust Systems

Upgrading to high-performance exhaust systems can significantly enhance the efficiency of the exhaust system. These systems are designed to reduce resistance, improve airflow, and optimise the exhaust gas exit. Ensure that you consult a professional or a qualified tuner before making any modifications to your vehicle's exhaust system.

How to Replace a Fuel Sensor Without Tools?

You may want to see also

Reflashing the ECU

Step 1: Understanding the ECU

The ECU plays a crucial role in your vehicle's performance and efficiency. It communicates with various components, such as fuel injectors, ignition coils, throttle, and emission controls. The ECU receives data from sensors throughout the vehicle, processes it, and executes decisions to ensure optimal performance.

Step 2: Backing Up Existing Data

Before making any changes to the ECU, it is essential to back up the existing data. Connect a laptop or PC to the OBD2 port and download the raw data from the ECU. This data will include maps and software parameters specifically tailored to your vehicle's engine.

Step 3: Manipulating Data

Once you have downloaded the raw data, use specialised software to manipulate and modify the required data/maps. This process involves changing various parameters, such as fuel injection volume and throttle-fuel volume mapping, to achieve the desired fuel mixture and performance enhancements. Ensure that you have the correct definition file, which acts as a roadmap for locating and modifying the necessary maps within the raw data.

Step 4: Uploading Altered Data

After making the desired changes, it's time to upload the altered data back into the ECU. Connect to the OBD2 port again and flash, or upload, the modified data. This process will replace the existing software in the ECU with the new software, allowing for customised settings and improved performance.

Step 5: Post-Reflashing Checks

Once the reflashing process is complete, it is crucial to verify that the new software is functioning correctly. Conduct thorough diagnostics to ensure that all sensors and systems are fully operational. Check for error codes, starting issues, rough idling, stalling, or emissions failures. Ensure that the vehicle meets emissions compliance standards.

Important Considerations

When reflashing the ECU, it is essential to maintain an uninterrupted power supply. A sudden loss of power during the reflashing process can cause the reflash to fail and potentially damage the ECU. Ensure that the battery voltage remains stable throughout the procedure, which can last more than 45 minutes. Use appropriate tools, such as the E-XTEQ 512EVO and 1012EVO, to maintain a constant power source.

Replacing Fuel Injectors: Ford Edge 2008 Step-by-Step Guide

You may want to see also

Diagnostics and data logging

Data Collection:

VCM Scanner allows you to collect a wealth of data from your vehicle's engine, transmission, air and fuel systems, and exhaust. This includes information from oxygen sensors, catalytic converters, spark plugs, and emission systems. By analysing this data, you can identify potential issues and inefficiencies that may impact your vehicle's performance and fuel economy.

Diagnostic Trouble Codes (DTC):

The diagnostic data can help you interpret Diagnostic Trouble Codes (DTC) and address the root causes of problems. This goes beyond simply addressing check engine lights; it enables you to optimise your vehicle's performance and efficiency.

Calibration:

Diagnostics are not just about fixing issues but also about uncovering hidden performance and efficiency improvements. The data helps you formulate the best calibration for your vehicle based on its current state and operating behaviours. For example, you may find that your vehicle's stock calibration is running lean or rich at specific points in the RPM range, and adjustments can be made accordingly.

Data Logging:

HP Tuners offers high-speed data logging capabilities. After making mechanical improvements and efficiency adjustments, you can use the HP Tuners interface and VCM Scanner to analyse the results and validate your changes. This data logging feature is available with the Pro Feature Set or the new MPVI3 interface.

Visualisation:

The VCM Scanner also allows you to customise your data with charts and graphs, helping you better understand and visualise the information collected. This visualisation feature aids in interpreting the data and making informed decisions.

Emission Control:

Another important aspect of diagnostics and data logging is maintaining emission control. HP Tuners' hardware and software are designed to bring vehicles into emissions compliance and maintain compliance over their lifetime. You can utilise emission drive cycles tests in the VCM Scanner to ensure your vehicle meets the required standards.

Vehicle-Specific Applications:

HP Tuners provides support for various vehicle makes and models, including Toyota, Chevrolet, and more. For example, with the MPVI3 interface and VCM Suite software, you can data log, scan, read, and write to any supported Toyota model, offering custom tune flashing and data logging capabilities.

Professional Support:

While HP Tuners provides powerful tools for diagnostics and data logging, professional tuning services can ensure that adjustments are made correctly and maintain the vehicle's reliability and compliance with emissions standards. Their technical support team can assist you in finding a certified dealer near you.

Changing Fuel Filters in Poulan Chainsaws: Step-by-Step Guide

You may want to see also

Frequently asked questions

The ideal ratio is 14.7:1, meaning for every kilogram of fuel the engine burns, 14.7 kilograms of air is consumed. This is called the stoichiometric ratio.

First, get the car to its running temperature. Open HP Tuners scanner and hit the space bar. Let the car idle for about 2 minutes with the scanner running, watching the cylinder air mass and the fuel trims (short and long term). Add the short and long-term fuel trims together to find out what to multiply the correct section of the MAF chart by.

You can use the MPVI3 or another HP Tuners interface, the Pro Feature Set + Pro Link+, and the VCM Suite software. You will also need a professional, qualified tuner.