Learning how to chainsaw fuel lines is an essential skill for anyone who owns or operates a chainsaw. Properly fueling a chainsaw is crucial for optimal performance and longevity. This guide will provide a step-by-step process to ensure your chainsaw runs smoothly and efficiently, covering everything from choosing the right fuel to maintaining the fuel line for long-term use.

What You'll Learn

- Fuel Line Material: Choose the right material for your chainsaw's fuel line

- Fuel Line Length: Determine the appropriate length for your chainsaw model

- Fuel Line Routing: Route the line away from moving parts to prevent damage

- Fuel Line Attachment: Secure the line to the fuel tank and engine

- Fuel Line Maintenance: Regularly inspect and replace the line to ensure optimal performance

Fuel Line Material: Choose the right material for your chainsaw's fuel line

When it comes to choosing the right fuel line material for your chainsaw, it's important to consider the specific requirements of your equipment and the environment in which you'll be using it. The fuel line is a critical component that connects the fuel tank to the carburetor, ensuring a steady supply of gasoline to the engine. Here's a guide to help you select the appropriate material:

Rubber or Vinyl: Traditional fuel lines are often made of rubber or vinyl, which have been used for decades in chainsaws. These materials are flexible and can withstand the high pressure and temperature fluctuations in the engine. Rubber is known for its durability and resistance to aging, ensuring a long-lasting connection. However, over time, rubber can become brittle, especially in colder climates, which may lead to cracks and leaks. Regular inspection and replacement are recommended to maintain optimal performance.

Braided Fuel Line: For modern chainsaws, especially those with higher performance and fuel injection systems, braided fuel lines are a popular choice. These lines are constructed with multiple layers of braided fibers, typically made of synthetic materials like polyester or Kevlar. Braided fuel lines offer superior flexibility, durability, and resistance to abrasion. They are less prone to cracking and can handle higher pressure, making them ideal for applications where the fuel line may be subjected to more stress. The braided design also provides better kink resistance, ensuring a consistent fuel supply.

Considerations: When selecting the material, consider factors such as temperature range, fuel type, and the overall environment. If you operate your chainsaw in extreme temperatures or use different types of fuel, opt for materials that can withstand these conditions. Additionally, check the manufacturer's recommendations for your specific chainsaw model, as they often provide guidelines for the most suitable fuel line material.

In summary, the choice of fuel line material depends on the specific needs of your chainsaw and the operating conditions. Rubber or vinyl lines are reliable for standard applications, while braided lines offer enhanced performance and durability for more demanding tasks. Always refer to the manufacturer's instructions and consider the environmental factors to ensure you select the right material for a safe and efficient chainsaw operation.

The Ultimate Guide to Choosing the Best 1-2 Fuel Line

You may want to see also

Fuel Line Length: Determine the appropriate length for your chainsaw model

When it comes to maintaining a chainsaw, one crucial aspect often overlooked is the fuel line. The fuel line is responsible for delivering gasoline from the tank to the carburetor, ensuring your chainsaw runs smoothly and efficiently. One common question among chainsaw owners is: "How long should the fuel line be?" The answer depends on various factors, including the specific model of your chainsaw and its design.

The length of the fuel line is a critical consideration to ensure optimal performance. It is essential to determine the appropriate length for your chainsaw model to avoid any issues related to fuel delivery. Different chainsaw manufacturers design their machines with varying fuel line lengths to accommodate different engine sizes and configurations. For instance, a fuel line that is too short may restrict fuel flow, leading to poor performance or even engine starvation. Conversely, an overly long fuel line can cause fuel to vaporize, resulting in reduced power and potential starting difficulties.

To find the correct fuel line length, start by consulting your chainsaw's user manual. The manual will provide specific guidelines and recommendations tailored to your model. It will often specify the ideal fuel line length for your particular chainsaw, ensuring it aligns with the engine's design. If you don't have access to the manual, consider contacting the manufacturer's customer support for assistance. They can provide valuable insights and recommendations based on your chainsaw's specifications.

In some cases, you might need to adjust the fuel line length to accommodate different fuel tank positions or engine configurations. For example, if your chainsaw has a side-mounted fuel tank, the fuel line might need to be longer to reach the carburetor. Similarly, for chainsaws with vertical fuel tanks, the line may be shorter. Understanding these variations is crucial to ensure proper fuel delivery and engine operation.

Additionally, when working with fuel lines, it's essential to use the right materials. High-quality rubber or synthetic fuel lines are commonly used due to their durability and resistance to fuel degradation. These materials ensure the fuel line can withstand the pressure and temperature changes associated with engine operation. Proper installation and regular maintenance of the fuel line are also vital to prevent leaks and ensure the longevity of your chainsaw's performance.

Saturn Ion Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Fuel Line Routing: Route the line away from moving parts to prevent damage

When it comes to maintaining a chainsaw, proper fuel line management is crucial to ensure optimal performance and longevity. One essential aspect of this maintenance is routing the fuel line correctly to prevent damage and potential issues. Here's a detailed guide on how to approach fuel line routing:

Identify the Fuel Line Path: Begin by familiarizing yourself with the chainsaw's fuel line layout. Locate the fuel tank, typically located near the handle, and trace the path of the fuel line from the tank to the carburetor or fuel injection system. Understanding this path is key to making informed routing decisions.

Route Away from Moving Components: The primary rule for fuel line routing is to keep it away from any moving parts of the chainsaw. Moving components, such as the chain, bar, and drive system, can cause damage to the fuel line if it comes into contact with them. Route the line in a way that ensures it is parallel to these moving parts, providing a safe distance. This practice helps prevent kinks, bends, and potential fuel leaks caused by friction or impact.

Use Protective Sleeving: Consider using protective sleeving or tubing to shield the fuel line from potential hazards. This is especially important if the chainsaw will be used in rugged terrain or areas with debris. Sleeving can be made of durable materials like rubber or plastic and should be routed along with the fuel line, ensuring it covers any potential impact points. This simple step adds an extra layer of protection and increases the fuel line's durability.

Secure the Line: Properly secure the fuel line to prevent it from coming loose during operation. Use fuel line clips or ties to fasten the line at regular intervals. Avoid tight bends or kinks, as these can restrict fuel flow and cause engine issues. Keep the line taut and ensure it doesn't interfere with the chainsaw's controls or the user's grip.

Regular Inspection: Implement a regular inspection routine to check the fuel line's condition. Look for any signs of damage, cracks, or leaks. Over time, fuel lines can deteriorate due to fuel exposure and environmental factors. Regular inspections allow for early detection of potential issues, ensuring you can address them promptly.

Fuel Line Adventure: Lines to Go's Real-World Test

You may want to see also

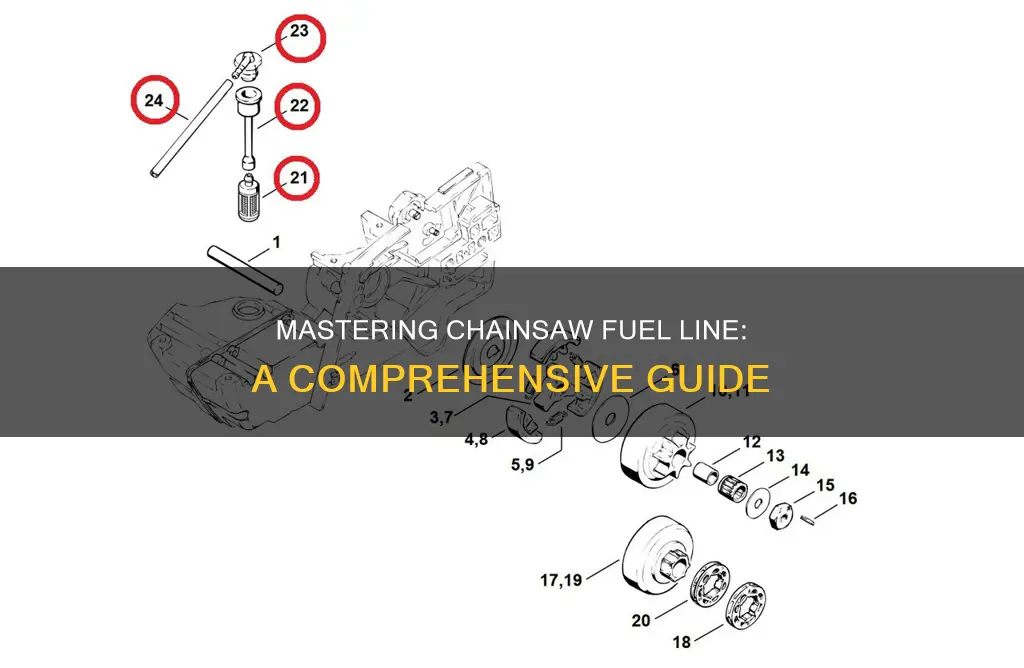

Fuel Line Attachment: Secure the line to the fuel tank and engine

When it comes to attaching the fuel line to your chainsaw, ensuring a secure and proper connection is crucial for optimal performance and safety. Here's a step-by-step guide on how to securely attach the fuel line to both the fuel tank and the engine:

Step 1: Locate the Fuel Tank and Engine Connections

Start by familiarizing yourself with your chainsaw's fuel system. Locate the fuel tank, which is typically a small container attached to the side or bottom of the chainsaw. Identify the fuel line, which is a flexible tube that connects the tank to the engine. Look for the fuel inlet or the point where the line connects to the engine's carburetor.

Step 2: Prepare the Fuel Line

Before attaching, ensure the fuel line is clean and free of any debris or contaminants. If necessary, use a fuel line cleaner or a mild detergent to wash the line. This step is important to prevent any blockages or contamination of the fuel system.

Step 3: Secure the Fuel Line to the Fuel Tank

Using a suitable fuel line clamp or tie-down strap, secure the fuel line to the fuel tank. Wrap the clamp or strap around the line, ensuring it is tight and secure. The goal is to prevent the line from moving or becoming loose during operation. Make sure the attachment point is close to the fuel tank to minimize the risk of fuel spillage.

Step 4: Connect the Fuel Line to the Engine

Now, carefully connect the fuel line to the engine's carburetor. Align the fuel line inlet with the corresponding port on the carburetor. Use a fuel line clamp or fitting to secure the connection. Ensure that the connection is tight and there are no leaks. You may need to adjust the carburetor settings or prime the carburetor according to the manufacturer's instructions.

Step 5: Test and Adjust

After attaching the fuel line, start the chainsaw and let it run for a few minutes. Check for any leaks or unusual noises. If everything is functioning correctly, you may need to adjust the fuel mixture or carburetor settings to optimize performance. Refer to your chainsaw's manual for specific instructions on tuning the engine.

Remember, proper fuel line attachment is essential for efficient fuel delivery and the overall longevity of your chainsaw's engine. Always exercise caution when working with fuel and ensure you follow the manufacturer's guidelines for your specific model.

2007 Hyundai Accent Fuel Lines: Location Guide

You may want to see also

Fuel Line Maintenance: Regularly inspect and replace the line to ensure optimal performance

Maintaining the fuel line of your chainsaw is a crucial aspect of regular care to ensure its longevity and optimal performance. Over time, fuel lines can deteriorate due to various factors, including exposure to fuel, heat, and physical wear. Regular inspection and replacement of the fuel line are essential to prevent potential issues and maintain the efficiency of your chainsaw. Here's a step-by-step guide to mastering fuel line maintenance:

Regular Inspections: Make it a habit to inspect your chainsaw's fuel line during routine maintenance checks. Start by visually examining the line for any signs of damage, cracks, or leaks. Look for areas where the line might have rubbed against the chainsaw's body or other components, as these points are prone to wear and tear. Check for any visible corrosion or discoloration, especially if your chainsaw is used in outdoor environments with varying weather conditions. Pay attention to the connections and fittings, ensuring they are secure and free from any leaks.

Identifying Issues: If you notice any issues during your inspection, such as cracks, kinks, or leaks, it's essential to address them promptly. Small cracks or holes in the fuel line can lead to fuel leakage, which may cause engine misfires or even stall the engine. Kinks or blockages in the line can restrict fuel flow, resulting in reduced power and performance. Always replace the fuel line if you identify any significant damage to prevent further complications.

Replacement Process: When it's time to replace the fuel line, follow these steps. First, ensure the chainsaw is turned off and cooled down to avoid any accidents. Locate the fuel line and carefully disconnect it from the fuel tank and the engine's carburetor. Take note of the connection points and their orientations for easier reattachment. Purchase a new fuel line that is compatible with your chainsaw model, ensuring it has the correct diameter and length. Clean the old line and the connections to remove any debris or old fuel residue. Install the new fuel line, securing it with the appropriate clamps or fittings. Reattach it to the fuel tank and carburetor, ensuring a tight and leak-free connection.

Post-Replacement Checks: After replacing the fuel line, it's crucial to test the chainsaw to ensure optimal performance. Start the engine and let it run for a few minutes, checking for any unusual noises or vibrations. Inspect the fuel gauge and ensure the fuel level is accurate. Test the chainsaw's power and performance, ensuring it operates smoothly and efficiently. Regularly perform these replacement and inspection tasks to keep your chainsaw in top condition.

By following these maintenance practices, you can ensure that your chainsaw's fuel line remains in excellent condition, contributing to the overall reliability and performance of your equipment. Remember, regular care and attention to the fuel line can save you from potential breakdowns and costly repairs in the long run.

Poulan Prolink P335 Fuel Line Size: Essential Guide for Optimal Performance

You may want to see also

Frequently asked questions

Priming the fuel line is essential to ensure your chainsaw starts smoothly. First, remove the fuel line from the fuel tank and prime the carburetor by pulling the starter cord a few times while holding the primer bulb. Then, reattach the fuel line and prime the line by pressing the primer bulb until fuel flows freely.

There could be several reasons for this issue. Check for any blockages in the fuel line, ensuring it is not kinked or damaged. Verify that the fuel filter is clean and free of debris. If the fuel line is old or damaged, it may need to be replaced. Also, ensure that the fuel tank has enough fuel and that the carburetor is properly adjusted.

No, gasoline should not be used directly in the fuel line. It is essential to use a fuel mixture specifically designed for chainsaws, typically a two-stroke oil mixture. Using pure gasoline can cause engine damage due to its higher volatility and lack of lubricating properties. Always refer to your chainsaw's manual for the recommended fuel type and mixture ratio.

The frequency of fuel line replacement depends on usage and maintenance. It is generally recommended to inspect the fuel line regularly for any signs of wear, damage, or blockages. If the fuel line is old, shows signs of deterioration, or has been exposed to harsh conditions, it should be replaced. As a rule of thumb, consider replacing the fuel line every 2-3 years or whenever you notice a decrease in engine performance.