Bypassing the fuel return line is a common troubleshooting step for various engine issues, such as fuel leaks or poor performance. This process involves redirecting the fuel that would normally flow back to the fuel tank to the engine's intake system, allowing for a more efficient fuel supply. It is important to understand the specific vehicle's mechanics and follow the manufacturer's guidelines to ensure the bypass is done safely and effectively. This method can help diagnose and resolve fuel-related problems, but it should only be attempted by those with the necessary knowledge and tools to avoid potential hazards.

What You'll Learn

Identify the fuel return line's location and its connection points

When attempting to bypass a fuel return line, it's crucial to first identify its location and connection points. This step is essential to ensure a successful and safe modification. Here's a detailed guide on how to locate and understand the fuel return line's setup:

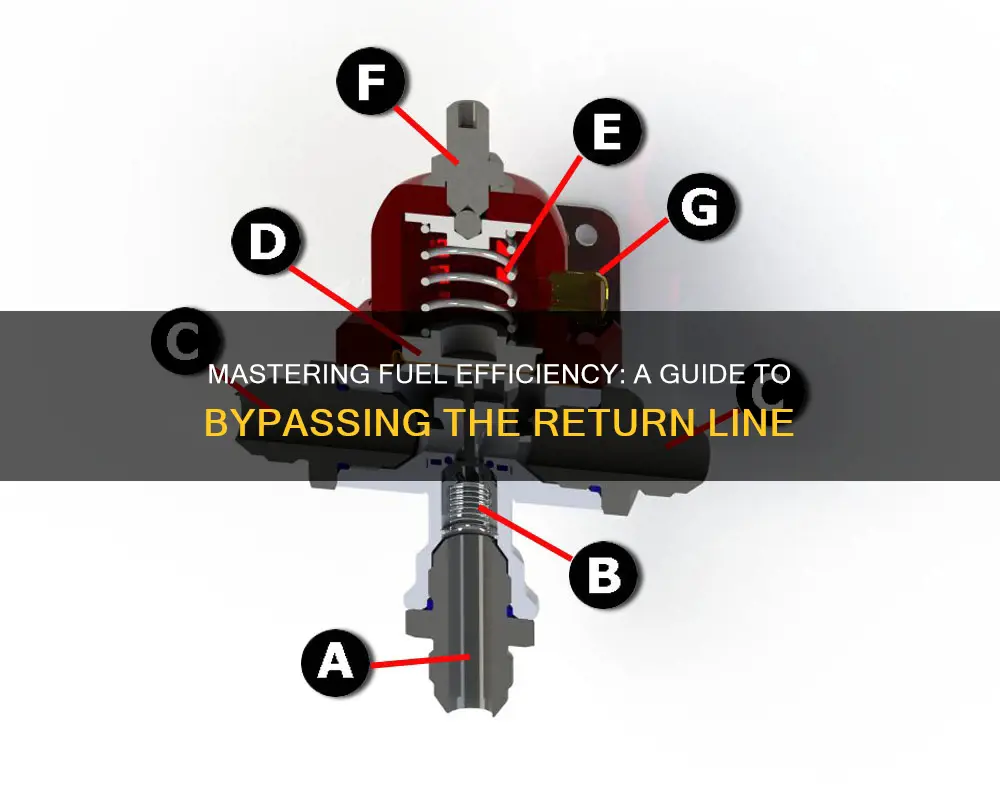

Locate the Fuel Return Line: The fuel return line is typically a smaller diameter hose or pipe that connects the fuel tank to the engine's fuel system. It is designed to return excess fuel from the engine back to the tank, ensuring efficient fuel management. Start by inspecting your vehicle's fuel system diagram, which can usually be found in the owner's manual. This diagram will provide a visual representation of the fuel lines and their connections. Look for the line that connects the engine to the fuel tank, as this is likely the fuel return line.

Identify Connection Points: The fuel return line will have several key connection points. Firstly, it connects to the fuel tank, usually via a fitting or a small hose clamp. Locate the fuel tank and inspect the area where the return line is attached. It might be a small port or a dedicated fitting. Secondly, it connects to the engine's fuel system. This connection point is often a smaller hose or a fitting that is part of the engine's fuel rail or injection system. Carefully examine the engine bay to find this connection, as it might be hidden under other components.

Understand the Routing: The fuel return line's routing can vary depending on the vehicle's design. It might run along the bottom of the engine bay, or it could be positioned vertically, following the contours of the engine. Pay attention to any bends, kinks, or potential interference points. Understanding the line's path will help you plan the bypass effectively.

Use Diagnostic Tools: In some cases, you might need to use diagnostic tools to locate the fuel return line. This is especially useful if the line is hidden or difficult to access. Scan tools or fuel pressure testers can help identify the line's path and its connection points. These tools can provide valuable insights into the fuel system's behavior, making the bypassing process more accurate.

By thoroughly inspecting the fuel system diagram, physically locating the fuel return line, identifying its connection points, and understanding its routing, you can proceed with the bypassing process with confidence. Remember, each vehicle is unique, so adapting these steps to your specific vehicle is essential for a successful outcome.

Step-by-Step Guide: Removing Fuel Lines from Ford Explorer Fuel Pump

You may want to see also

Use a fuel pump bypass tool to redirect fuel flow

When dealing with a fuel return line issue, a fuel pump bypass tool can be a handy solution to redirect fuel flow and ensure your vehicle's engine runs smoothly. This method is particularly useful when the return line is damaged or clogged, causing fuel to be wasted or not properly circulated. Here's a step-by-step guide on how to use a fuel pump bypass tool effectively:

Understanding the Tool: Begin by familiarizing yourself with the fuel pump bypass tool. This tool is designed to create an alternative path for fuel to flow around the problematic return line. It typically consists of a flexible hose or tube with connectors at each end, allowing it to be attached to the fuel pump and the fuel tank.

Locate the Fuel Pump and Return Line: Identify the fuel pump, which is usually located near the engine, and locate the fuel return line that connects the pump to the tank. This line is responsible for returning excess fuel from the pump to the tank.

Prepare the Tool: Take the fuel pump bypass tool and connect one end to the fuel pump's outlet port. Ensure a secure fit to prevent any fuel leaks. Then, attach the other end of the tool to the fuel tank's inlet port, which is typically located near the bottom of the tank. This setup creates a temporary loop for fuel flow.

Bypass the Return Line: With the tool in place, you can now bypass the damaged or clogged return line. When the engine is running, the fuel pump will push fuel through the bypass tool and into the fuel tank. This process ensures that the engine continues to receive the required fuel without the need for the problematic return line.

Testing and Adjustment: After setting up the bypass, start the engine and monitor its performance. You might need to adjust the position of the tool or make slight modifications to ensure optimal fuel flow. This step is crucial to fine-tune the system and prevent any potential issues.

Remember, using a fuel pump bypass tool is a temporary solution and should be considered a fix until a more permanent repair can be made. It's essential to address the underlying issue with the fuel return line to ensure long-term engine health. Always exercise caution when working with fuel systems and consider seeking professional assistance if you're unsure about any step.

Choosing the Right Fuel Line for Your Side-by-Side Adventure

You may want to see also

Disconnect the return line and redirect fuel to the tank

To bypass the fuel return line and redirect fuel back to the tank, you'll need to carefully disconnect the existing line and make the necessary modifications. Here's a step-by-step guide to help you through the process:

Start by locating the fuel return line, which is typically a small diameter hose or pipe that connects the fuel tank to the engine. It is usually positioned near the fuel pump and may be secured with a clamp or bracket. Carefully inspect the line to identify the points where it connects to the tank and the engine.

Using the appropriate tools, such as a fuel line cutter or a hose clamp, carefully disconnect the fuel return line from the engine. Take note of the orientation of the line to ensure proper reattachment later. Once disconnected, you might want to temporarily block the line to prevent fuel from spilling during the redirect process.

Now, you'll need to redirect the fuel flow to the tank. This can be achieved by creating a new path for the fuel to travel. One common method is to use a small diameter fuel line or a piece of tubing to connect the fuel pump outlet directly to the tank's fuel inlet. Ensure that the new line is securely attached and sealed to prevent any fuel leaks.

When reattaching the fuel pump, make sure it is functioning correctly and that the fuel pressure is adequate. Test the system by starting the engine and monitoring the fuel flow. You might need to adjust the fuel pressure regulator or make further modifications to ensure optimal performance.

Remember, this process requires a good understanding of automotive mechanics and fuel systems. If you're unsure, it's recommended to consult a professional mechanic or refer to a reliable online resource specific to your vehicle's make and model. Always prioritize safety and ensure that any modifications comply with local regulations.

Kinking a Nylon Fuel Line: A Guide to Avoiding Disaster

You may want to see also

Modify the fuel system to bypass the return line

Bypassing the fuel return line is a common modification made by enthusiasts and tuners to enhance engine performance and fuel efficiency. This process involves altering the fuel system to redirect the fuel flow, essentially bypassing the return line, which can lead to improved power and a more responsive engine. Here's a step-by-step guide on how to modify the fuel system to achieve this:

Understanding the Fuel System: Before making any modifications, it's crucial to understand the existing fuel system. The fuel return line is a critical component that recirculates excess fuel back to the fuel tank or the carburetor. By-passing this line, you are essentially removing a restriction in the fuel flow path. This process requires careful planning and an understanding of the engine's fuel requirements.

Step-by-Step Modification: 1. Identify the fuel pump and its connection to the fuel tank. You'll need to disconnect the fuel pump's electrical connection and remove any fuel lines connected to it. 2. Locate the fuel return line, which is typically a smaller diameter line returning fuel from the engine to the tank. Cut this line at a strategic point, ensuring you don't damage any other components. 3. Create a new path for the fuel by either extending the fuel line or using a suitable tubing system. Direct this new line to a point where the fuel can be injected or added directly to the engine's intake system. 4. Ensure the fuel bypass system has a sufficient capacity to handle the engine's fuel demands, especially during high-load conditions.

Important Considerations: When modifying the fuel system, it's essential to maintain proper fuel pressure and flow rates. You might need to install a fuel pressure regulator or gauge to monitor and adjust the pressure. Additionally, consider the engine's original design and ensure that the bypass system doesn't interfere with other components, such as the air intake system.

Safety and Testing: After the modification, it's crucial to test the fuel system thoroughly. Start the engine and monitor for any unusual noises or behavior. Check for proper fuel distribution and ensure that the engine runs smoothly. Safety should always be a priority, so it's recommended to have a professional mechanic inspect the work to ensure it meets safety standards.

Remember, modifying the fuel system can be complex and may require specialized tools and knowledge. It's always a good idea to consult with experienced enthusiasts or professionals who can provide guidance tailored to your specific engine and vehicle.

Nylon Fuel Line Lifespan: Unveiling the Ultimate Durability

You may want to see also

Test the fuel system to ensure proper fuel flow

To effectively test the fuel system and ensure proper fuel flow, you can follow these steps:

- Inspect the Fuel System Components: Begin by visually inspecting all the components of the fuel system, including the fuel tank, lines, pumps, and injectors. Look for any signs of damage, leaks, or blockages. Check for any loose connections or fittings that might need tightening. Ensure that all components are in good condition and properly assembled.

- Check Fuel Pressure: Proper fuel pressure is crucial for efficient fuel flow. Use a fuel pressure gauge to measure the pressure at the fuel rail or injectors. Compare the readings with the manufacturer's specifications to ensure they fall within the recommended range. If the pressure is too low, it may indicate a problem with the fuel pump or a restricted fuel line.

- Perform a Fuel Flow Test: Set up a fuel flow test to measure the actual fuel flow rate. You can use a fuel flow meter or a calibrated container to measure the volume of fuel passing through the system over a specific time period. Start the engine and allow it to idle. Measure the fuel flow rate at different engine speeds to ensure consistent fuel delivery. Compare the results with the expected flow rates for your vehicle's engine size and specifications.

- Inspect Fuel Lines and Filters: Carefully examine the fuel lines for any signs of damage, cracks, or kinks. Ensure that the lines are properly routed and not obstructed. Check the fuel filters for any clogs or debris. Clogged filters can restrict fuel flow, so consider replacing them if necessary.

- Listen for Fuel Pump Operation: With the engine off, listen to the fuel pump's operation. It should be audible and operational when the key is turned on. If you don't hear the pump, it could indicate a problem with the pump or the electrical connections.

- Use a Fuel Pressure Tester: Consider using a fuel pressure tester to simulate different driving conditions. This can help identify potential issues related to fuel pressure regulation and ensure that the system performs correctly under various loads.

By following these steps, you can thoroughly test the fuel system and identify any potential issues related to fuel flow, ensuring that your vehicle's engine receives the necessary fuel for optimal performance.

Perfect Fuel Line Size for Suzuki DT 140

You may want to see also

Frequently asked questions

The fuel return line is a crucial component in a vehicle's fuel system, designed to allow excess fuel to flow back from the injectors or carburetor to the fuel tank. By-passing this line is often necessary when performing maintenance or repairs that require the fuel system to be isolated from the main fuel supply.

Bypassing the fuel return line should be done with caution and proper preparation. Here's a general procedure: First, locate the fuel return line and identify its connections. Then, using a suitable hose or tubing, create a bypass path that connects the fuel injectors/carburetor outlet directly to the fuel tank, bypassing the original return line. Ensure all connections are secure and sealed to prevent fuel leaks.

Yes, there are a few important factors to keep in mind. Always ensure the engine is off and the vehicle is in a safe position before starting any work. Fuel can still be under pressure, so it's essential to release any residual fuel from the system before bypassing the line. Additionally, when reconnecting the fuel system after the bypass, ensure all components are properly sealed and secured to maintain the vehicle's performance and safety.