Bleed fuel lines on a 1997 Cummins engine is a process that ensures the fuel system is free of air bubbles, which can cause performance issues. This procedure involves removing the fuel lines, allowing air to escape, and then reinstalling them. It's important to follow a step-by-step guide to ensure the process is done safely and effectively. The process typically requires a fuel pump primer bulb and a fuel line bleeding kit, which can be purchased from automotive supply stores.

| Characteristics | Values |

|---|---|

| Fuel Type | Diesel |

| Engine Model | Cummins 5.9L |

| Year | 1997 |

| Bleed Process | Start the engine and allow it to idle. Turn the ignition to 'On' without starting. Open the fuel line bleeder valves and release any built-up pressure. Close the bleeder valves and start the engine. Rev the engine to a high speed and open the bleeder valves again to release any air bubbles. Repeat this process until no more bubbles are released. |

| Tools Required | Wrench, Socket set, Fuel line bleeder kit, Air pump (optional) |

| Safety Precautions | Ensure the engine is cool before bleeding. Use protective gear, such as gloves and safety goggles. Work in a well-ventilated area. |

| Common Issues | Clogged fuel lines, Air locks, Low fuel pressure |

| Maintenance Tips | Regularly check and replace fuel filters. Keep the fuel tank full to prevent condensation. |

What You'll Learn

- Preparation: Gather tools, safety gear, and a clean workspace

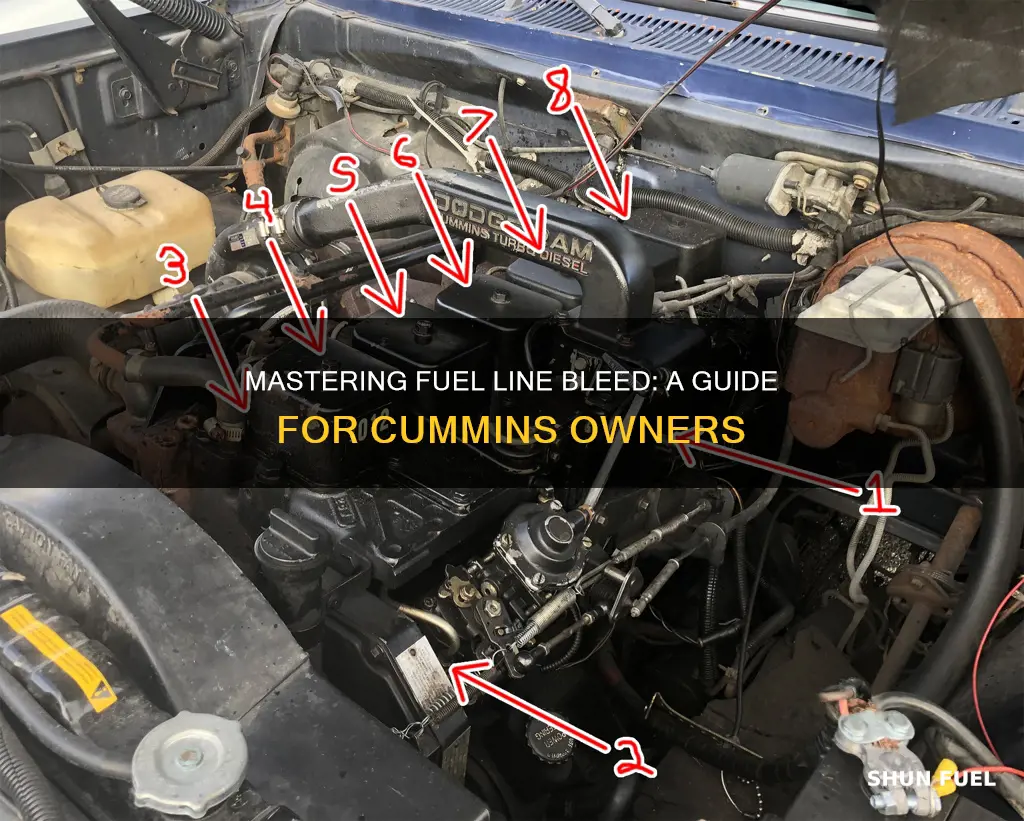

- Fuel Line Location: Identify fuel lines under the hood and engine bay

- Bleeding Process: Attach a bleeder valve and open the fuel tank

- Bleeding Technique: Use a pump or gravity to remove air bubbles

- Testing: Check for leaks and ensure fuel flow is clear

Preparation: Gather tools, safety gear, and a clean workspace

Before you begin the process of bleeding fuel lines on a 97 Cummins engine, it's crucial to prepare your workspace and gather the necessary tools and safety equipment. This step ensures a safe and efficient procedure, minimizing the risk of fuel spills and engine damage.

Tools and Equipment:

- Fuel Line Bleeding Kit: This kit typically includes a specialized tool or adapter that connects to the fuel line, allowing you to control the flow of fuel. It may also include a pressure gauge and a container to collect any drained fuel.

- Wrenches and Pliers: You'll need various sizes of wrenches and pliers to loosen and tighten fuel line connections and fittings.

- Funnel and Container: A funnel is essential for directing fuel into a container during the bleeding process. Ensure you have a suitable container to collect the drained fuel, preferably one with a tight-fitting lid to prevent spills.

- Cleaning Supplies: Keep a supply of clean rags or paper towels for wiping down fuel lines and connections. This helps to keep the workspace tidy and prevents contamination.

Safety Gear:

- Safety Goggles: Protect your eyes from any potential fuel splashes or debris.

- Gloves: Wear gloves to protect your hands from fuel contact and sharp objects.

- Respiratory Mask: If working in a confined space or with a large engine, a respiratory mask can help prevent inhaling fuel vapors.

- Fire Extinguisher: Keep a fire extinguisher nearby as a precaution, especially when working with fuel.

Workspace Preparation:

- Clean and Clear Area: Choose a well-ventilated workspace, preferably outdoors or in a well-ventilated garage. Ensure the area is clear of any obstacles or trip hazards.

- Drain Pan: Place a drain pan or large container under the engine to catch any fuel that may drain during the process. This prevents fuel from spreading and makes cleanup easier.

- Lighting: Ensure the workspace is well-lit to facilitate the procedure and identify any potential issues.

- Reference Materials: Have the engine's manual or a fuel system diagram readily available for reference during the bleeding process.

By thoroughly preparing your workspace and gathering the required tools and safety gear, you set the foundation for a successful and safe fuel line bleeding procedure on your 97 Cummins engine. This preparation step is often overlooked but is essential to ensure a smooth and efficient repair or maintenance task.

Fuel Line Tool Size Guide: Scion TC

You may want to see also

Fuel Line Location: Identify fuel lines under the hood and engine bay

When working on a 97 Cummins engine, identifying the fuel lines is a crucial step before attempting to bleed them. The fuel lines are responsible for transporting fuel from the tank to the engine, and ensuring they are in good condition is essential for optimal performance. Here's a detailed guide on how to locate the fuel lines under the hood and engine bay:

Start by opening the hood of your Cummins engine. Locate the fuel tank, which is typically mounted on the driver's side of the engine bay. The fuel lines will originate from this tank and run towards the engine. There will be two primary fuel lines: the primary line, which is usually larger in diameter, and the secondary line, which branches off to supply fuel to different parts of the engine. These lines are often protected by rubber or plastic covers to prevent damage.

Look for the primary fuel line, which is the larger of the two and typically has a larger diameter. It will run from the fuel tank towards the engine, often at a slight angle to accommodate the engine's position. The primary line is usually the main supply line and is crucial for delivering fuel to the engine's injectors. You might find a small filter attached to this line, which helps in removing contaminants from the fuel.

In addition to the primary line, there will be a secondary fuel line that splits off from the primary line. This secondary line is responsible for supplying fuel to various components of the engine, such as the fuel pump, injectors, and possibly a return line to the tank. The secondary line might have smaller diameters and could be located closer to the engine block or in the engine bay, depending on the specific Cummins engine design.

As you inspect the fuel lines, take note of any signs of damage, such as cracks, leaks, or corrosion. Also, check for any clogs or blockages, especially around the fuel filter and any valves or fittings. Proper identification of these components will ensure that you can effectively bleed the fuel lines and maintain the engine's performance. Remember to refer to your Cummins engine's manual for specific details regarding the fuel line layout and any unique features of your vehicle.

Unleash the Power: Breaking Fuel Lines: A Quarry Decision

You may want to see also

Bleeding Process: Attach a bleeder valve and open the fuel tank

The process of bleeding fuel lines in a 97 Cummins engine involves ensuring that the fuel system is free from air bubbles, which can cause performance issues. One crucial step in this process is attaching a bleeder valve and opening the fuel tank. Here's a detailed guide on how to perform this task:

Start by locating the fuel tank, which is typically mounted in the rear of the engine compartment. Identify the bleeder valve, which is usually a small, screw-on valve attached to the fuel line near the tank. This valve is designed to allow air to escape from the system. If you don't have a bleeder valve, you can use a small, straight-edged screwdriver or a similar tool to create an opening in the fuel line.

Once you've located the bleeder valve, carefully remove the fuel tank's cap to access the interior. Insert the bleeder valve into the fuel line, ensuring it is securely attached. The valve should have a small opening that allows air to escape. If you're using a tool instead of a dedicated bleeder valve, make sure it fits snugly into the fuel line.

Now, open the fuel tank by removing the cap. This step is crucial as it allows the air to be released from the tank and the fuel lines. As you open the tank, you might hear a hissing sound, which is the air being expelled. If you notice any fuel leaking, it's important to address this issue promptly as it could indicate a problem with the fuel system.

After opening the fuel tank, you can start the engine and allow it to run for a few minutes. This will help ensure that the fuel system is properly bled and that there are no further air bubbles present. During this process, keep an eye on the engine's performance and listen for any unusual noises. If everything is functioning correctly, you should notice a smooth and consistent engine operation.

Car Fuel Hose Length: A Comprehensive Guide

You may want to see also

Bleeding Technique: Use a pump or gravity to remove air bubbles

To effectively bleed the fuel lines of a 97 Cummins engine, you can employ a simple yet effective technique: using a pump or gravity to remove air bubbles. This method is particularly useful when dealing with older engines or systems that may have accumulated air pockets over time. Here's a step-by-step guide to ensure a successful bleeding process:

Start by locating the fuel lines and the fuel filter. Identify the points where the fuel lines connect to the filter and the engine. It's crucial to have a clear understanding of the system's layout to ensure you target the right areas. Typically, the fuel lines will have bleeder screws or valves, which are small openings that allow for the release of air and contaminants.

Next, you'll need to attach a pump or a simple gravity-fed setup. If using a pump, ensure it is compatible with the fuel line size and material. Connect the pump to the bleeder screw or valve on the fuel line. For gravity-fed systems, you can use a clear container or a bucket to collect the fuel as it drains. Place the container or bucket below the bleeder screw or valve to allow for the natural flow of fuel.

Once the setup is in place, slowly turn the bleeder screw or valve counterclockwise to open it. This action will release any air bubbles or trapped fuel that has accumulated in the system. As you turn, observe the fuel flowing out. For the pump method, you'll see the fuel being drawn into the pump and then released back into the line. With gravity, the fuel will slowly drain into your container. The goal is to ensure a steady flow of fuel, indicating that the air bubbles are being expelled.

Continue this process until you notice a steady, consistent flow of fuel. You may need to adjust the bleeder screw or valve slightly to find the optimal position for bleeding. Once you achieve a continuous flow, tighten the bleeder screw or valve securely. This final step ensures that the system is sealed, and any remaining air bubbles are trapped, preventing their re-entry into the fuel lines.

Remember, patience is key during this process. Take your time to ensure you've removed all air bubbles, as incomplete bleeding can lead to engine performance issues. By using a pump or gravity, you can effectively address the common problem of air bubbles in the fuel lines of a 97 Cummins engine.

Universal Yamaha Fuel Line Fittings: A Comprehensive Guide

You may want to see also

Testing: Check for leaks and ensure fuel flow is clear

When working on the fuel system of a 97 Cummins engine, it's crucial to thoroughly test for leaks and ensure optimal fuel flow. This process involves a series of steps to guarantee the system's integrity and performance. Here's a detailed guide on how to approach this testing phase:

Leak Detection: Begin by inspecting all fuel lines for any signs of damage, cracks, or deterioration. Pay close attention to connections, fittings, and areas where lines are routed through the engine compartment. Use a soapy water solution to test for leaks. Apply the solution to the fuel lines and watch for bubbles or foam, indicating a potential leak. If any leaks are detected, repair or replace the affected lines immediately. Ensure all connections are tightened securely to prevent future issues.

Fuel Flow Assessment: After addressing any initial leaks, it's time to check the fuel flow. Start the engine and monitor the fuel pressure using a gauge. The pressure should be within the specified range for your Cummins engine. If the pressure is too low, it may indicate a restriction or blockage in the fuel lines. Check for any clogs or obstructions in the lines and clear them if necessary. Additionally, verify that the fuel pump is functioning correctly by listening for its operation and checking the voltage output.

Visual Inspection: A visual inspection is essential to identify any hidden issues. Look for any signs of fuel contamination, such as water accumulation or debris in the fuel tank. Ensure that the fuel filter is clean and free of blockages. Inspect the fuel injectors for any signs of damage or malfunction, as they play a critical role in fuel distribution.

Pressure Testing: Perform a pressure test to further ensure the fuel system's integrity. Use a fuel pressure tester and connect it to the fuel rail. Gradually increase the pressure and monitor the gauge. The pressure should hold steady without any rapid drops or fluctuations. If the pressure drops significantly, it may indicate a problem with the fuel pump, lines, or injectors.

Flow Rate Measurement: To ensure optimal fuel flow, measure the flow rate. This can be done using a flow meter connected to the fuel line. Adjust the engine speed and load to test the flow at different operating conditions. The flow rate should meet the engine's requirements for efficient performance.

By following these testing procedures, you can effectively identify and address any issues related to fuel line bleeding and ensure the 97 Cummins engine's fuel system operates flawlessly.

Marine Fuel Line: Choosing the Right Option for Your Boat

You may want to see also