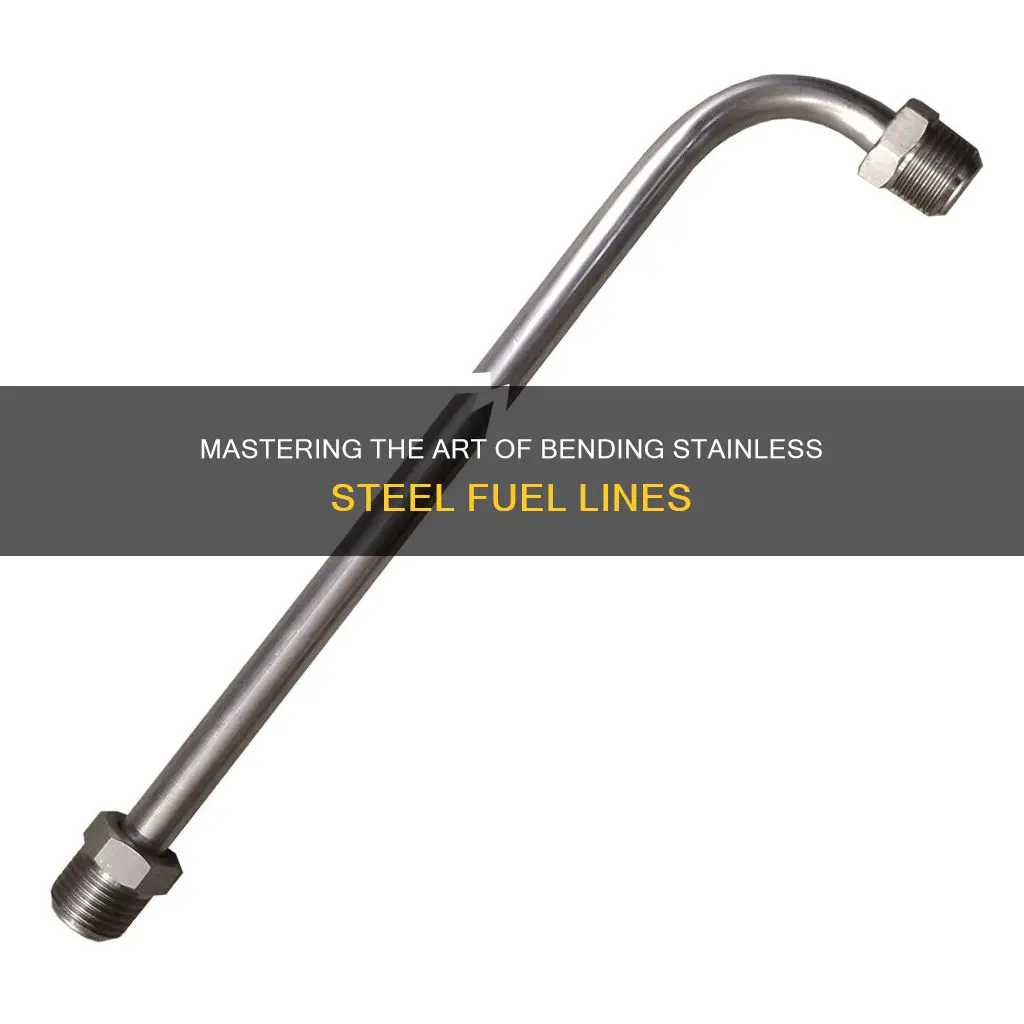

Bending stainless steel fuel lines requires precision and care to ensure a secure and leak-free connection. This process involves using specific tools and techniques to manipulate the metal without compromising its structural integrity. By following a step-by-step approach, you can effectively bend these lines to fit your project's needs, ensuring a reliable fuel supply for your vehicle or equipment. Understanding the proper methods and safety precautions is essential to achieving a successful and long-lasting installation.

What You'll Learn

- Preparation: Clean and inspect lines, ensuring no debris or corrosion

- Bending Tools: Use a tube bender or vice grips for precise bends

- Angle and Radius: Plan bends at 90 degrees or less, with a smooth radius

- Safety: Wear protective gear and work in a well-ventilated area

- Testing: Check for leaks and ensure bends are secure

Preparation: Clean and inspect lines, ensuring no debris or corrosion

Before attempting to bend stainless steel fuel lines, it's crucial to ensure a clean and thorough preparation process. This step is often overlooked but is essential for the success and longevity of the project. Here's a detailed guide on how to prepare the fuel lines for bending:

Cleaning the Fuel Lines: Start by disconnecting the fuel lines from the vehicle's fuel system to access them for cleaning. Use a suitable solvent or a mild detergent solution to remove any dirt, grease, or grime that may have accumulated over time. Pay close attention to the threads and connections, as these areas can often trap contaminants. Rinse the lines thoroughly with clean water to eliminate any residue. For a more thorough clean, consider using a wire brush or a small drill bit to remove stubborn deposits, especially in tight spaces. Ensure that all traces of contaminants are removed to prevent any interference during the bending process.

Inspection and Debris Removal: Once the lines are clean, a thorough inspection is necessary. Check for any signs of corrosion, pitting, or damage that could affect the bending process. Look for any debris or foreign objects that might have entered the lines during the disconnection process. Use a small magnet or a probe to retrieve any metal particles or small tools that may have fallen into the lines. Ensure that the interior of the fuel lines is clear and free from any obstacles that could cause issues when bending.

Corrosion Prevention: If you notice any corrosion, it's important to address it promptly. Use a mild acid bath or a specialized corrosion remover to treat the affected areas. Follow the manufacturer's instructions carefully, as some products may require specific application methods. After treatment, rinse the lines thoroughly to remove any acid residue. This step is crucial to ensure that the stainless steel remains in optimal condition and doesn't weaken during the bending process.

Documentation and Note-Taking: As you clean and inspect, take detailed notes on the condition of the fuel lines, any issues found, and the steps taken to resolve them. This documentation will be invaluable for future reference, especially if you need to troubleshoot or modify the fuel system again. It also ensures that you maintain a consistent and organized approach to your work.

By following these preparation steps, you'll ensure that the stainless steel fuel lines are clean, free from debris, and in good condition, setting the stage for a successful bending process. This attention to detail is a hallmark of professional work and will contribute to the overall quality of your fuel system modifications.

Unveiling the Secrets: Corvette Fuel Line Sizing, 1969 Edition

You may want to see also

Bending Tools: Use a tube bender or vice grips for precise bends

When it comes to bending stainless steel fuel lines, using the right tools is crucial for achieving precise and clean bends. One of the most effective methods is employing a tube bender, which is specifically designed for this purpose. These benders provide the necessary force and control to create accurate bends without causing damage to the material. The process involves positioning the fuel line securely on the bender's work surface, ensuring it is taut and free of any kinks. Then, carefully apply the bender's pressure to the desired angle, taking into account the material's thickness and the desired bend radius. This technique allows for tight and consistent bends, ensuring the fuel lines fit perfectly into the intended shape.

Another option for bending stainless steel fuel lines is using vice grips, a versatile tool that can provide the required grip and force. Vice grips offer a mechanical advantage, allowing you to bend the material by applying pressure to the handles. To use this method, secure the fuel line firmly between the vice grips, ensuring it is centered and stable. Then, slowly and steadily, apply pressure to the grips while rotating the line to create the desired bend. This approach requires a steady hand and a good understanding of the material's flexibility to avoid any cracks or damage.

Both tube benders and vice grips provide a level of control and precision that is essential for working with stainless steel fuel lines. The key is to use the right tool for the job and to apply the necessary force gradually to avoid any sudden stress that could lead to material failure. It is also important to consider the environment and ensure proper ventilation when working with fuel lines, as they may contain volatile substances.

Practice and patience are essential when learning to bend stainless steel fuel lines. Take your time to understand the material's behavior and the tools' capabilities. With experience, you'll develop a feel for the necessary force and angle required for each bend, ensuring a professional-looking result. Remember, the goal is to create clean, precise bends that will ensure the fuel lines function optimally and last for the long term.

In summary, bending stainless steel fuel lines requires the use of specialized tools like tube benders or vice grips to achieve accurate and clean bends. These tools provide the necessary force and control to manipulate the material without causing damage. By following the proper techniques and taking the time to understand the process, you can ensure a successful outcome, resulting in well-fitted fuel lines that will perform reliably.

Can Fuel Line Tubing Be Used for Oil Lines?

You may want to see also

Angle and Radius: Plan bends at 90 degrees or less, with a smooth radius

When working with stainless steel fuel lines, it's crucial to plan your bends carefully to ensure a professional and functional result. The angle and radius of the bend are critical factors to consider, as they directly impact the line's performance and longevity. Here's a detailed guide on achieving the desired bend:

Angle and Radius: The key to successful bending is to aim for a gentle curve with a smooth radius, especially when bending at 90 degrees or less. This approach minimizes stress points and potential weaknesses in the material. A sharp bend, even at a 90-degree angle, can lead to excessive pressure and potential cracking or damage to the stainless steel. Instead, strive for a gradual curve, ensuring the bend is as close to a perfect circle as possible. This technique allows the fuel line to maintain its structural integrity while accommodating the necessary turns.

Planning the Bend: Start by visualizing the bend and its intended purpose. Consider the space available and the overall layout of the fuel system. For tight bends, a smaller radius is required, but it should still be smooth to avoid sharp kinks. Use a straightedge or a ruler to outline the bend on the fuel line. This initial step helps you determine the exact angle and radius needed, ensuring a precise and consistent bend.

Bending Techniques: When bending, use a combination of tools to achieve the desired shape. A mandrel bending machine is ideal for creating smooth, consistent bends, especially for tight radii. Alternatively, you can use a hydraulic press brake, adjusting the die sets to match your planned angle and radius. For smaller projects or tight spaces, a simple hand-held bender can be used, but it requires more skill and precision. Always follow the manufacturer's guidelines for the chosen bending tool to ensure the best results.

Safety and Practice: Bending stainless steel fuel lines requires patience and practice. Take your time to get the hang of it, as rushing can lead to mistakes. Safety is also essential; always wear protective gear, including gloves and eye protection, when working with metal and tools. With practice and attention to detail, you'll be able to master the art of bending stainless steel fuel lines, ensuring a professional finish every time.

The Truth About Rubber Hoses in Car Fuel Lines: What You Need to Know

You may want to see also

Safety: Wear protective gear and work in a well-ventilated area

When working with stainless steel fuel lines, prioritizing safety is essential to prevent accidents and ensure a successful outcome. Here's a detailed guide on the safety measures to consider:

Protective Gear: Before beginning any bending or manipulation of stainless steel fuel lines, it is crucial to put on the appropriate protective gear. Safety goggles are a must to shield your eyes from any potential debris or sparks that may occur during the bending process. Additionally, consider wearing heat-resistant gloves to protect your hands from any heat generated by the bending tools or the fuel lines themselves. These simple precautions can prevent injuries and ensure a safer working environment.

Well-Ventilated Area: Working in a well-ventilated area is of utmost importance when dealing with fuel lines, especially those made of stainless steel. These lines can release volatile substances, and proper ventilation ensures that any potential fumes or gases are dispersed, reducing the risk of inhalation. Ensure that the work area has a strong exhaust system or open windows to allow fresh air circulation. This simple step can significantly minimize the hazards associated with working with fuel-related components.

In addition to the above, it is recommended to wear a respirator mask to filter out any airborne particles or fumes. This extra layer of protection is especially important when cutting or welding stainless steel, as it can release fine metal dust. A well-ventilated space and appropriate respiratory protection will create a safer environment, reducing the risk of health issues associated with fuel line work.

Remember, taking these safety precautions is non-negotiable to ensure your well-being and the success of your project. Always prioritize safety, and if you're unsure about any aspect of the process, consult with professionals or experienced individuals in the field.

Ethanol Fuel Line: Can It Support Gasoline?

You may want to see also

Testing: Check for leaks and ensure bends are secure

When you've finished bending the stainless steel fuel lines, it's crucial to thoroughly test them to ensure they are secure and leak-free. This step is essential to guarantee the safety and efficiency of your fuel system. Here's a detailed guide on how to perform these tests:

Leak Testing:

Start by preparing the necessary materials. You'll need a soapy water solution, a spray bottle, and a clean cloth. Soak the bent fuel lines in the soapy water, ensuring they are fully submerged. Then, spray the soapy water onto the connections and bends of the lines. The soap acts as a visual indicator, forming bubbles where there are leaks. If you notice any bubbles forming around the bends or connections, it indicates a potential leak. In such cases, you'll need to re-bend the lines or tighten the connections to eliminate the source of the leak.

Pressure Testing:

Another critical aspect of testing is pressure testing. This method helps identify any weaknesses or potential failure points in the bent fuel lines. You can use a fuel line pressure tester or a simple pump to apply pressure to the lines. Start with a low pressure and gradually increase it while monitoring for any signs of leakage. If you detect any leaks, it's important to identify the exact location and address it promptly. Reinforcing the bend or tightening the connections might be necessary to prevent further issues.

Visual Inspection:

While testing for leaks, also perform a thorough visual inspection of the bent fuel lines. Look for any visible signs of damage, such as cracks, sharp bends, or kinks. These issues can compromise the integrity of the lines and lead to potential leaks or fuel system failures. If you notice any damage, it's best to replace the affected sections to ensure the overall safety of the fuel system.

Secure Fastening:

Ensure that all bends and connections are securely fastened. Use the appropriate tools and fasteners recommended for stainless steel fuel lines. Tighten the connections firmly, but be careful not to overtighten, as this can cause damage. Double-check that all bends are smooth and free from sharp edges that could lead to fuel leaks or system malfunctions.

By following these testing procedures, you can ensure that your bent stainless steel fuel lines are secure, leak-free, and ready for installation, providing a reliable fuel supply for your vehicle or equipment. Remember, proper testing is crucial to maintaining the performance and safety of any fuel system.

Mastering Ford Fuel Line Disconnect: A Comprehensive Guide

You may want to see also

Frequently asked questions

Bending stainless steel fuel lines requires a careful approach to avoid cracking or weakening the material. Start by cleaning the line and ensuring it's free of any debris or contaminants. Use a mandrel or a bending tool specifically designed for stainless steel to create a smooth bend. Apply gentle force and take small, controlled bends to maintain the line's integrity. Practice on a scrap piece first to get a feel for the process.

Bending fuel lines at a 90-degree angle can be achieved by using a combination of techniques. First, measure and mark the line at the desired bend point. Then, use a mandrel or a bending tool to create a series of small, controlled bends, gradually building up to the 90-degree angle. Ensure the bends are consistent and smooth to prevent any sharp edges that could cause leaks.

It is not recommended to use regular pliers for bending stainless steel fuel lines. Regular pliers may not provide the necessary precision and can potentially damage the line. Instead, invest in a good-quality mandrel or bending tool designed for stainless steel. These tools are specifically engineered to create clean, precise bends without distorting the material's properties.