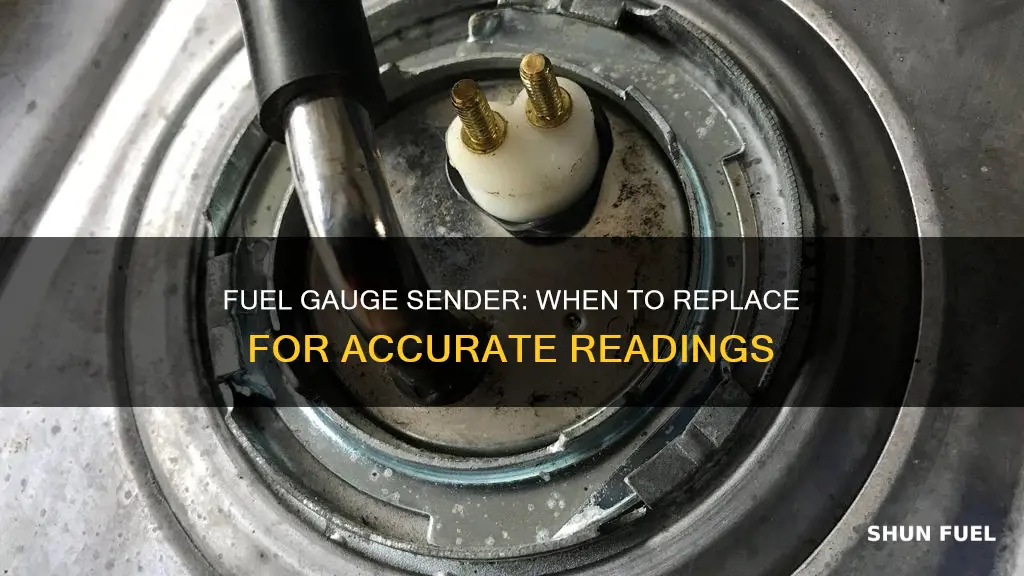

The fuel gauge sender, a crucial component in vehicle fuel management systems, plays a vital role in accurately measuring the fuel level in your tank. Over time, however, this sender can wear out, leading to inaccurate readings and potential issues with your fuel gauge. Understanding how often to replace the fuel gauge sender is essential for maintaining the reliability and safety of your vehicle. Regular maintenance and timely replacements can prevent costly repairs and ensure your vehicle's fuel system operates efficiently. This guide will explore the factors influencing the sender's lifespan and provide insights into when and how to replace it.

| Characteristics | Values |

|---|---|

| Average Lifespan | 5-10 years |

| Reliability | High, but can vary based on usage and maintenance |

| Symptoms of Failure | Inaccurate fuel level readings, gauge not working, engine stalling |

| Causes of Failure | Corrosion, wear and tear, electrical issues, sensor malfunction |

| Maintenance Tips | Regularly check for leaks, keep the fuel tank clean, inspect wiring |

| Replacement Cost | $50 - $200 (parts) + labor |

| DIY vs Professional | DIY possible with technical knowledge, professional recommended for complex issues |

| Common Issues | Malfunctioning sensors, damaged wiring, faulty gauge display |

| Prevention | Regular maintenance, avoiding overfilling fuel tank, using high-quality fuel |

What You'll Learn

- Fuel Gauge Sender Location: Determine the sender's position in the fuel tank

- Sender Wear and Tear: Inspect for signs of damage or corrosion

- Calibration and Accuracy: Calibrate the gauge for precise fuel level readings

- Fuel System Maintenance: Regularly clean and maintain the fuel system

- Replacement Timing: Replace when accuracy drops or gauge fails

Fuel Gauge Sender Location: Determine the sender's position in the fuel tank

The fuel gauge sender, also known as the fuel level sensor, is a crucial component in your vehicle's fuel management system. Its primary function is to provide accurate information about the fuel level in the tank to the fuel gauge, ensuring that drivers are aware of their vehicle's fuel status. Understanding the location of this sender is essential for proper maintenance and troubleshooting.

In most vehicles, the fuel gauge sender is strategically positioned at the bottom of the fuel tank. This placement allows it to be in direct contact with the fuel, ensuring an accurate reading of the fuel level. The sender is typically a small, cylindrical device with electrical connections that transmit the fuel level data to the dashboard. It is designed to float on the fuel surface, rising and falling as the fuel level changes, which then triggers the corresponding gauge reading.

The sender's location at the bottom of the tank is crucial for its functionality. If the sender were placed higher up, it might not accurately represent the fuel level, especially when the tank is nearly empty or full. For instance, if the sender were positioned near the top of the tank, it could read a higher fuel level than actually exists, leading to incorrect gauge readings.

When inspecting or replacing the fuel gauge sender, it is essential to consider the vehicle's specific design. Some cars may have the sender located in a slightly different position, such as near the rear of the tank or in a specific compartment. Consulting the vehicle's service manual or seeking professional advice can provide detailed information about the sender's exact location in your particular make and model.

Knowing the sender's position is vital for maintenance and troubleshooting. If you suspect issues with the fuel gauge, such as erratic readings or a complete malfunction, locating the sender can help in diagnosing the problem. Regular maintenance, including checking the sender's condition and ensuring proper electrical connections, can contribute to the overall reliability of your vehicle's fuel management system.

Wind Power: The Future of Energy, Replacing Fossil Fuels

You may want to see also

Sender Wear and Tear: Inspect for signs of damage or corrosion

When it comes to the fuel gauge sender, regular inspection is crucial to ensure its longevity and accurate performance. Wear and tear can occur over time, leading to potential issues with the fuel gauge's functionality. One of the primary concerns is the development of corrosion, which can significantly impact the sender's performance.

Start by removing the fuel gauge sender from the vehicle. This process may vary depending on the vehicle model, so it's essential to consult the vehicle's manual for specific instructions. Once removed, thoroughly inspect the sender for any visible signs of corrosion. Corrosion often appears as a white or green powdery substance on the sender's surface, especially in areas where it comes into contact with the fuel or has been exposed to moisture. Pay close attention to the electrical connections and wiring, as corrosion here can lead to erratic behavior or complete failure of the fuel gauge.

Additionally, check for any physical damage to the sender. Inspect the sender's housing for cracks, chips, or any other form of damage that could compromise its integrity. Even a small crack can allow fuel or moisture to seep into the sender, causing internal corrosion or short circuits. If any damage is detected, it is crucial to replace the sender immediately to prevent further deterioration.

Another aspect to consider is the sender's float mechanism, if applicable. In some vehicles, the sender uses a float to measure the fuel level. Inspect this mechanism for any signs of wear or damage. Over time, the float can become stuck or malfunction, leading to inaccurate fuel level readings. If the float shows signs of wear, such as sticking or improper movement, it may need to be adjusted or replaced.

Regularly inspecting the fuel gauge sender for wear and tear is essential for maintaining the overall health of the fuel gauge system. By promptly addressing any corrosion or damage, you can ensure the sender continues to provide accurate fuel level information, contributing to the safe and efficient operation of your vehicle. Remember, proper maintenance and timely replacements can help avoid more extensive and costly repairs in the future.

Replacing Fuel Pump in Oldsmobile Alero: Step-by-Step Guide

You may want to see also

Calibration and Accuracy: Calibrate the gauge for precise fuel level readings

The fuel gauge sender, a critical component in your vehicle's fuel management system, is responsible for transmitting fuel level data to the gauge, ensuring you always know how much fuel is left in your tank. Over time, this sender can become less accurate due to various factors, including sediment buildup, corrosion, or mechanical wear. Calibration is a process that can help restore the gauge's accuracy, ensuring you have reliable fuel level readings.

Calibration involves adjusting the gauge's settings to match the actual fuel levels in the tank. This process is particularly important if you've recently replaced the fuel gauge sender or if you've noticed discrepancies between the gauge reading and the actual fuel level. Here's a step-by-step guide to calibrating your fuel gauge:

- Locate the Calibration Points: Most fuel gauges have specific points where they can be calibrated. These points are usually marked on the gauge itself or can be found in the vehicle's service manual. Common calibration points include 'Empty,' 'Half Full,' and 'Full.'

- Drain the Tank: To calibrate accurately, you'll need to drain the fuel tank to the specified calibration points. This may involve using a fuel pump or a specialized tool to remove fuel from the tank. Ensure you follow safety precautions and work in a well-ventilated area.

- Adjust the Gauge: Once the tank is drained to the desired levels, adjust the gauge settings accordingly. Turn the gauge to the 'Empty' position and then slowly fill the tank, checking the gauge's reading at each calibration point. Adjust the gauge's sensitivity or offset to match the actual fuel levels. This process may require a professional tool or a software calibration kit, depending on your vehicle's make and model.

- Test and Verify: After calibration, test the gauge by adding fuel to the tank and observing the reading. It should now accurately reflect the fuel level. Repeat this process at different fuel levels to ensure the gauge is calibrated correctly across the entire range.

Regular calibration is essential to maintain the accuracy of your fuel gauge. Over time, factors like temperature changes and fuel type can affect the sender's performance, leading to inaccurate readings. By calibrating your fuel gauge, you ensure that you have a reliable indicator of your vehicle's fuel status, helping you make informed decisions about refueling and maintenance. Remember, if you're unsure about the calibration process, consulting a professional mechanic is always a good idea to ensure the job is done correctly.

Replacing Scion tC Fuel Filler Door: Step-by-Step Guide

You may want to see also

Fuel System Maintenance: Regularly clean and maintain the fuel system

The fuel system in your vehicle is a complex network of components that work together to deliver fuel from the tank to the engine. Over time, this system can accumulate deposits, contaminants, and debris, which can lead to reduced performance and potential issues. Regular maintenance and cleaning of the fuel system are essential to ensure optimal operation and longevity. Here's a guide on how to maintain your fuel system effectively:

Routine Cleaning: One of the most critical aspects of fuel system maintenance is regular cleaning. Over time, the fuel system can become contaminated with water, dirt, and other impurities. These contaminants can cause issues such as engine misfires, reduced fuel efficiency, and even engine damage. To combat this, it is recommended to flush and clean the fuel system periodically. You can use fuel system cleaner products available at auto parts stores. These cleaners dissolve deposits and remove contaminants from the fuel lines, injectors, and carburetor (if applicable). Follow the manufacturer's instructions for the correct usage and application method.

Fuel Filter Replacement: The fuel filter is a crucial component that traps contaminants and ensures clean fuel reaches the engine. Over time, the filter can become clogged, leading to reduced fuel flow and potential engine performance issues. It is generally advised to replace the fuel filter at regular intervals, typically every 30,000 to 50,000 miles, or as recommended by the vehicle manufacturer. Regular filter replacement helps maintain fuel quality and system efficiency.

Inspect and Maintain Fuel Tank: The fuel tank is another area that requires attention. Inspect the tank for any signs of corrosion, leaks, or damage. Ensure that the fuel tank cap is secure and in good condition to prevent fuel evaporation and potential health hazards. Keep the fuel tank relatively full to minimize the risk of water accumulation, as water can contaminate the fuel and cause issues. Regularly checking the fuel level and topping up the tank when necessary is a simple yet effective maintenance practice.

Use Quality Fuel: While regular cleaning and maintenance are essential, using high-quality fuel is equally important. Lower-grade fuels may contain more contaminants and can contribute to system degradation over time. Opt for premium-grade gasoline or diesel, depending on your vehicle's requirements, to ensure optimal performance and minimize the need for frequent cleaning.

By implementing these fuel system maintenance practices, you can keep your vehicle's fuel system in excellent condition, ensuring reliable performance and potentially extending the life of your engine. Remember, regular care and attention to the fuel system can save you from costly repairs and keep your vehicle running smoothly.

Replacing Fuel Pump in Chevy Sonic: Step-by-Step Guide

You may want to see also

Replacement Timing: Replace when accuracy drops or gauge fails

The fuel gauge sender, a crucial component in your vehicle's fuel management system, is responsible for transmitting fuel level data to the dashboard gauge. Over time, this sender can wear out or malfunction, leading to inaccurate fuel readings. It is essential to recognize the signs of a failing or inaccurate fuel gauge sender to ensure you don't run out of fuel unexpectedly or face potential safety hazards.

One of the primary indicators that your fuel gauge sender needs replacement is a noticeable drop in accuracy. If you consistently find that your fuel gauge reads lower than the actual fuel level, or if it shows an empty tank when you still have fuel, this is a clear sign of a faulty sender. For instance, if you fill up your tank and the gauge only shows half full, it's time to consider replacing the sender. This issue can be caused by sediment buildup, corrosion, or a damaged sensor, all of which can disrupt the accurate transmission of fuel level data.

Another reason to replace the fuel gauge sender is when the gauge itself fails. If the gauge becomes unresponsive, displays erratic readings, or stops working entirely, it's a strong indication that the sender is no longer functioning correctly. A failed gauge can be a result of internal circuit issues, sensor damage, or even a loose connection. In such cases, replacing the sender is necessary to restore the proper functionality of the fuel gauge.

The timing of replacement is critical to avoid unexpected fuel-related issues. When you notice a decline in accuracy or a complete failure of the fuel gauge, it's imperative to address the problem promptly. Driving with an inaccurate or non-functional fuel gauge can lead to overfilling, which may cause fuel overflow and potential engine damage. Moreover, it can create a false sense of security, leading to dangerous situations where you might run out of fuel while on the road.

In summary, the fuel gauge sender should be replaced when its accuracy diminishes or when the gauge itself malfunctions. Regular maintenance and timely attention to these signs can help ensure your vehicle's fuel management system operates efficiently and safely. Remember, addressing these issues promptly can prevent more significant problems and costly repairs in the long run.

The Future of Energy: Can Renewables Replace Fossil Fuels?

You may want to see also

Frequently asked questions

The frequency of replacement depends on various factors, including the age of your vehicle, the quality of the fuel gauge sender, and your driving habits. Generally, a fuel gauge sender can last for many years without issues if it's well-maintained and of good quality. However, over time, the sender's performance may degrade, leading to inaccurate fuel level readings. It's recommended to inspect the sender regularly and consider replacement if you notice any of the following signs: erratic gauge behavior, frequent fuel gauge warnings, or a sudden drop in fuel level indication.

Replacing a fuel gauge sender is a task that requires some mechanical knowledge and skill. It involves disassembling the dashboard and fuel system components, which can be complex and time-consuming. If you're comfortable with DIY projects and have experience with car repairs, you can certainly attempt the replacement. However, if you're unsure or lack the necessary skills, it's best to consult a professional mechanic who can ensure the job is done correctly and safely.

Yes, proper maintenance can help extend the lifespan of your fuel gauge sender. Here are a few tips: keep the fuel tank clean and free of debris, as contaminants can affect the sender's performance; regularly check for and address any fuel leaks to prevent corrosion; and ensure that the fuel gauge sender wiring is intact and securely connected. Additionally, using a fuel stabilizer in your tank can help maintain the health of the fuel system and potentially extend the sender's life.