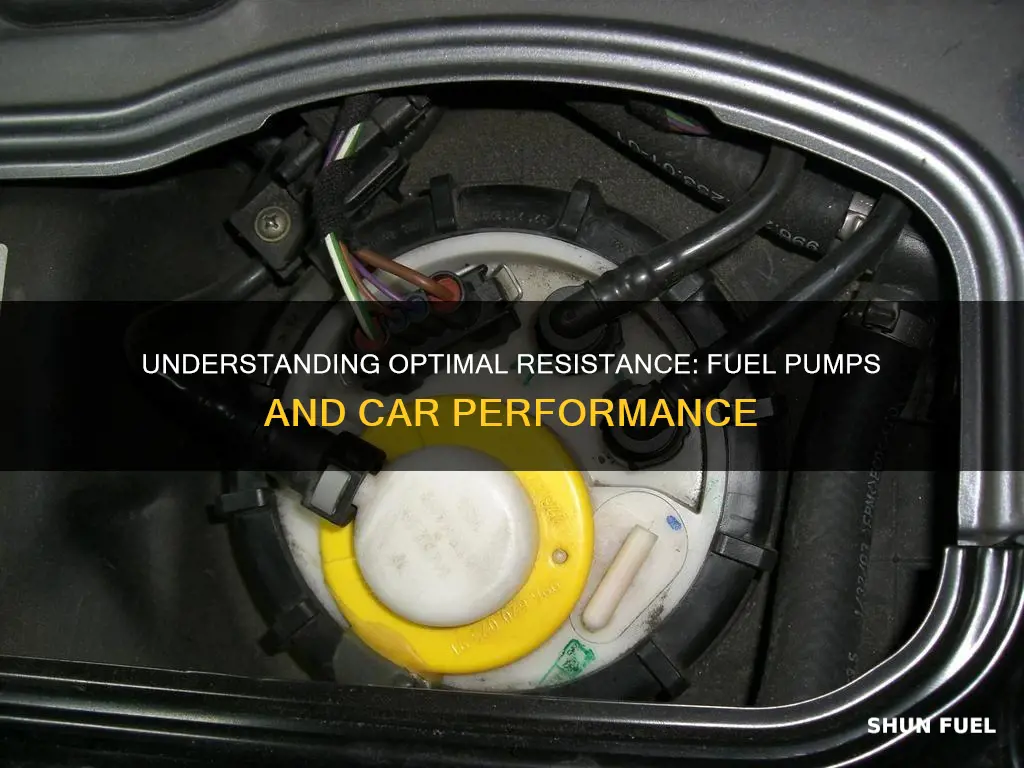

The car fuel pump is a critical component in the fuel system, responsible for delivering fuel from the tank to the engine. The amount of resistance in the fuel pump can significantly impact the performance and efficiency of the vehicle. Understanding the factors that influence resistance and how it affects the pump's operation is essential for maintaining optimal engine performance and fuel efficiency. This paragraph will explore the various aspects of resistance in car fuel pumps, including its causes, effects, and methods to measure and manage it.

What You'll Learn

- Pump Capacity: Determine the pump's flow rate and pressure to ensure it meets car requirements

- Resistance Measurement: Use a multimeter to measure resistance at different operating conditions

- Fuel Type Impact: Different fuels have varying effects on pump resistance; adjust accordingly

- Environmental Factors: Temperature and humidity can influence pump performance and resistance

- Maintenance and Cleaning: Regular maintenance reduces resistance and ensures optimal pump function

Pump Capacity: Determine the pump's flow rate and pressure to ensure it meets car requirements

When it comes to ensuring your car's fuel pump meets the necessary requirements, understanding the pump's capacity is crucial. The flow rate and pressure of the pump are key factors to consider, as they directly impact the engine's performance and overall driving experience. Here's a detailed guide to help you determine the pump's capacity and ensure it meets your car's needs.

Flow Rate: The flow rate of a fuel pump is measured in liters per minute (L/min) and represents the volume of fuel it can deliver to the engine in one minute. It is essential to check the manufacturer's specifications for your car model to determine the required flow rate. A higher flow rate is often desirable as it ensures a steady and efficient fuel supply, especially during high-performance driving or when the engine is under load. When selecting a replacement pump, aim for a flow rate that is at least equal to, if not slightly higher than, the original pump's capacity. This extra capacity can provide a performance boost and ensure that your engine receives the required fuel during demanding conditions.

Pressure: Fuel pump pressure is measured in bar (pascal) and indicates the force with which the pump delivers fuel to the engine. Adequate pressure is vital to ensure proper atomization of the fuel, allowing for efficient combustion. Low pressure can result in poor engine performance, while extremely high pressure may lead to fuel system issues. The ideal pressure range for your car can vary depending on the engine type and design. It is recommended to consult the vehicle's manual or seek professional advice to determine the specific pressure requirements. When replacing the pump, ensure that the chosen pump can maintain the necessary pressure within the specified range.

To determine the pump's capacity, you can start by measuring the flow rate and pressure of the existing pump in your car. This can be done using specialized tools or by consulting a mechanic who has access to such equipment. Alternatively, you can refer to the car's service manual, which often provides detailed information about the original pump's specifications. If you're replacing the pump, it's crucial to select a high-quality replacement that matches or exceeds the original pump's flow rate and pressure. Online forums and automotive communities can be excellent resources for finding compatible pump models and recommendations.

In summary, ensuring your car's fuel pump meets the required capacity involves carefully considering the flow rate and pressure. By matching or surpassing the original pump's specifications, you can guarantee a reliable fuel supply, optimize engine performance, and enhance your overall driving experience. Remember, when making any modifications or replacements, it is always advisable to consult the manufacturer's guidelines or seek professional assistance to ensure compatibility and avoid potential issues.

Lincoln Town Car's Throttle Body Fuel Injection: A Deep Dive

You may want to see also

Resistance Measurement: Use a multimeter to measure resistance at different operating conditions

To measure the resistance of a car fuel pump, you can use a multimeter, which is a versatile tool for electrical testing. This method allows you to assess the pump's performance under various operating conditions, ensuring it functions optimally. Here's a step-by-step guide on how to perform this measurement:

Preparation: Before you begin, ensure you have the necessary tools and safety equipment. You'll need a multimeter, preferably one with a range suitable for measuring low resistance values. Additionally, wear appropriate safety gear, such as gloves and eye protection, when handling electrical components. It's crucial to disconnect the battery or power source of the vehicle to avoid any accidental electrical shocks or damage.

Location of the Fuel Pump: Locate the fuel pump in your vehicle. The pump is typically found in the fuel tank or along the fuel line. Accessing the pump might require removing some panels or components, so have the necessary tools ready.

Measuring Resistance: Set your multimeter to the appropriate resistance setting (ohms). Ensure the multimeter is in good working condition and properly calibrated. Connect the multimeter's probes to the fuel pump's terminals. You might need to clean the terminals to ensure good contact. Measure the resistance at the operating voltage of the pump. This could be the battery voltage or the voltage supplied by the fuel pump controller, depending on your setup. Record the resistance value.

Testing at Different Conditions: To get a comprehensive understanding of the pump's performance, measure resistance under different operating conditions:

- Idling: Start the vehicle and let it idle. Measure the resistance again.

- Accelerating: During acceleration, the fuel pump may need to work harder. Measure the resistance while the engine is revving.

- High Load: If possible, simulate a high-load condition by connecting a load resistor or using a power supply to test the pump's behavior under increased demand.

Analysis: Compare the resistance values obtained at different operating conditions. A healthy fuel pump should exhibit relatively stable resistance across various loads. Significant variations in resistance may indicate issues such as internal resistance changes, pump wear, or electrical connections problems.

Remember, this process requires careful handling of electrical components and a systematic approach to data collection. It's essential to consult the vehicle's manual or seek professional guidance if you're unsure about any specific steps or components.

Uncover the Fuel Cost: Car AC Usage and Efficiency

You may want to see also

Fuel Type Impact: Different fuels have varying effects on pump resistance; adjust accordingly

The resistance in a car fuel pump is a critical factor that can significantly impact engine performance and efficiency. When considering the impact of different fuel types on pump resistance, it's essential to understand the unique characteristics of each fuel and how they interact with the pump.

Gasoline, a commonly used fuel, typically requires a lower resistance pump compared to other fuel types. This is because gasoline has a lower viscosity and density, allowing it to flow more easily through the pump. As a result, the pump's design can be optimized for efficient fuel delivery without excessive resistance. Modern gasoline engines often utilize pumps with a specific resistance range to ensure optimal performance.

On the other hand, diesel fuel presents a different challenge. Diesel has a higher viscosity and density, which can lead to increased resistance in the fuel pump. Engineers have designed diesel pumps with higher resistance capabilities to handle the more viscous fuel effectively. These pumps are engineered to maintain a consistent fuel flow rate, ensuring the engine receives the required amount of fuel under various operating conditions.

Additionally, alternative fuels like ethanol blends and biodiesel have their own considerations. Ethanol, for instance, has a lower energy content compared to gasoline, which may require adjustments to the pump's resistance to compensate for the reduced power. Biodiesel, being more viscous than gasoline, might necessitate a pump with higher resistance to ensure proper fuel delivery.

When selecting or modifying a fuel pump, it is crucial to consider the specific fuel type and its properties. Adjusting the pump's resistance accordingly can optimize engine performance, fuel efficiency, and overall vehicle reliability. Proper resistance calibration ensures that the pump can handle the unique demands of different fuels, providing a seamless and efficient fueling process.

Build Your Own Flame-Throwing Car Exhaust: DIY Fuel-Injected Inferno

You may want to see also

Environmental Factors: Temperature and humidity can influence pump performance and resistance

The performance and efficiency of a car's fuel pump can be significantly impacted by environmental factors, particularly temperature and humidity. These elements play a crucial role in determining the resistance encountered by the pump during its operation. When the temperature rises, the resistance in the fuel pump tends to decrease. This is primarily due to the expansion of the fuel and the pump's internal components, which allows for smoother flow. Warmer temperatures can lead to a more efficient pumping process, ensuring that the engine receives the required fuel volume. However, it's important to note that extremely high temperatures can also cause issues, such as excessive wear and tear on the pump's moving parts, potentially leading to premature failure.

Conversely, low temperatures can increase the resistance in the fuel pump. As the temperature drops, the fuel can become thicker and more viscous, making it harder for the pump to draw the liquid. This increased resistance may result in reduced fuel flow, which can negatively impact engine performance, especially during cold starts. In such conditions, the engine may struggle to start or may run poorly until the fuel system warms up.

Humidity, the amount of water vapor in the air, also has an effect on pump performance. High humidity can lead to condensation within the fuel system, including the pump. This condensation can cause corrosion and contamination of the fuel, as well as the pump's internal components. Over time, this may result in increased resistance and reduced pump efficiency. Additionally, moisture in the fuel can lead to engine misfires and reduced power, especially in high-performance vehicles.

To optimize the performance of a car's fuel pump, it is essential to consider these environmental factors. During colder seasons, ensuring that the fuel system is properly insulated and using fuel additives can help mitigate the effects of low temperatures. Regular maintenance, including fuel system cleaning and inspection, is crucial to prevent issues related to humidity. By understanding and addressing these environmental influences, vehicle owners can ensure their fuel pumps operate efficiently, providing reliable fuel delivery to the engine regardless of the external conditions.

98 Civic Fuel Pump: A Common Cause of Stalling?

You may want to see also

Maintenance and Cleaning: Regular maintenance reduces resistance and ensures optimal pump function

Regular maintenance of a car's fuel pump is crucial to ensure its longevity and optimal performance. Over time, fuel pumps can experience wear and tear, leading to increased resistance and potential issues with fuel delivery. By implementing a routine maintenance schedule, you can significantly reduce the chances of encountering problems and maintain a healthy fuel system.

One essential aspect of maintenance is checking and replacing the fuel filter regularly. The fuel filter plays a vital role in removing contaminants from the fuel before it reaches the pump. Accumulated dirt, debris, and contaminants can restrict the flow of fuel, causing increased resistance. By replacing the filter at recommended intervals, you can prevent these issues and ensure clean fuel delivery. It is recommended to consult the vehicle's manual for specific filter replacement schedules, as different car models may have varying requirements.

Additionally, inspecting and cleaning the fuel pump itself is essential. Over time, the pump's internal components can become coated with fuel residue, varnish, and carbon deposits. These deposits can restrict the pump's operation, leading to increased resistance and potential performance issues. Cleaning the pump involves using a suitable fuel system cleaner, which can be added to the fuel tank or sprayed directly into the engine. This process helps dissolve and remove any built-up contaminants, ensuring the pump operates freely and efficiently.

Furthermore, maintaining the fuel tank's cleanliness is often overlooked but is equally important. The fuel tank can accumulate moisture, sediment, and debris, especially if the vehicle is parked for extended periods. These contaminants can enter the fuel pump and cause damage or increased resistance. Regularly checking and cleaning the fuel tank, including draining and replacing old fuel if necessary, can prevent such issues.

In summary, regular maintenance and cleaning of the fuel pump and associated components are vital to minimize resistance and ensure the pump's optimal function. By following a routine maintenance schedule, including filter replacements, cleaning the pump, and maintaining a clean fuel tank, car owners can significantly extend the life of their fuel pump and maintain a reliable fuel supply to the engine.

The Science of F1 Fuel: Powering the Ultimate Race Cars

You may want to see also

Frequently asked questions

The resistance of a fuel pump can vary depending on the make and model of the car, as well as the specific pump design. However, a typical range for the resistance of a car fuel pump is between 0.5 and 3 ohms.

Resistance plays a crucial role in the operation of a fuel pump. Higher resistance can lead to reduced flow rate and pressure, causing the pump to struggle to deliver fuel to the engine. Lower resistance values generally result in better performance and efficiency.

Yes, having extremely low resistance can be a cause for concern. It may indicate a faulty pump or a short circuit, which can lead to excessive current draw and potential damage to the pump or the vehicle's electrical system.

High resistance in a fuel pump can be caused by several factors, including contamination or debris in the pump, worn-out pump components, or issues with the wiring harness. Regular maintenance and inspections can help identify and address these problems.

Resistance is typically measured using an ohmmeter, a device that applies a small current to the pump and measures the resulting voltage drop. This measurement helps diagnose any issues related to the pump's electrical performance.