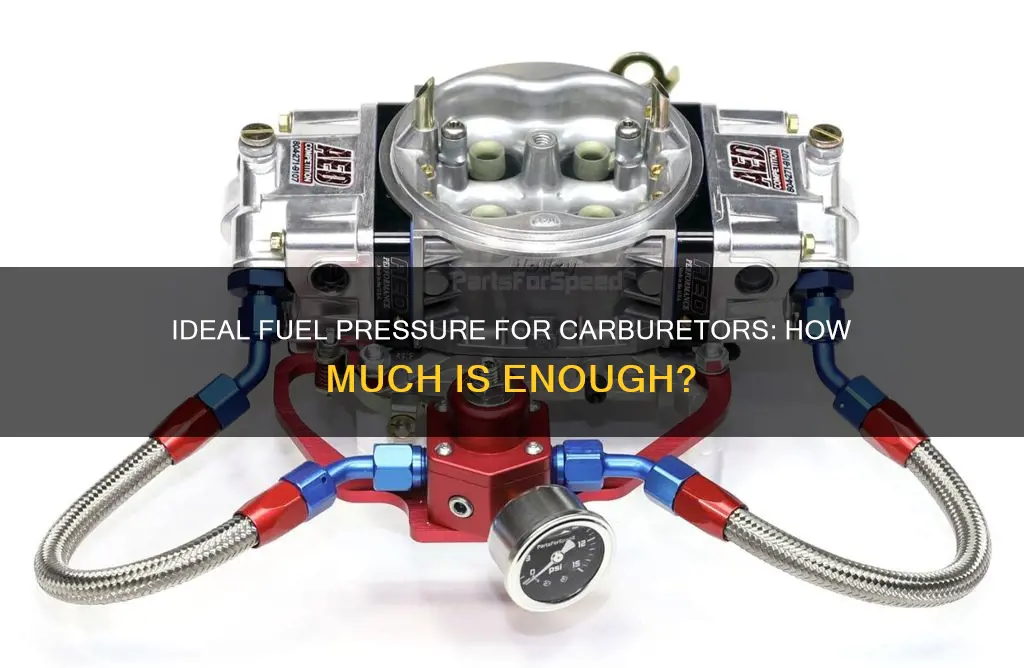

Fuel pressure is an important consideration for carburetted engines. Each carburettor style has an optimal fuel pressure range, and the owner's manual will provide set-up and tuning instructions. However, generally, fuel pressure between 5-7 psi is sufficient for carburettors, with too much pressure risking blowing the needle off the seat and causing fuel leaks, and too little pressure starving the engine of fuel.

What You'll Learn

Fuel pressure regulators can help maintain consistent pressure

Fuel pressure regulators are essential in maintaining consistent pressure in a fuel system, which is critical for achieving maximum and consistent performance. They work by controlling the pressure of the fuel supplied to the fuel injectors, ensuring that the fuel pressure remains within the appropriate range. This, in turn, guarantees optimal engine performance, fuel efficiency, and longevity.

A fuel pressure regulator with bypass, also called a "return-style" regulator, is a common type that uses a spring and diaphragm mechanism to control fuel system pressure. It is typically installed between the fuel pump and carburetor or throttle body. The diaphragm has a plug that rests in the bypass port below the set fuel pressure. When the set pressure is exceeded, the fuel pressure lifts the plug out of the bypass port, allowing excess fuel to be returned to the gas tank. This prevents fuel system overpressure and ensures a continuous flow of fuel to the engine.

The vacuum or boost reference feature of a fuel pressure regulator is designed to compensate for changes in intake manifold vacuum or boost pressure, ensuring consistent fuel pressure under varying engine load and throttle conditions. This feature allows the regulator to adjust the fuel pressure based on the engine's needs, taking into account factors such as altitude, throttle position, and boost levels. By maintaining a steady fuel pressure, the vacuum or boost reference optimises engine performance and responsiveness throughout its operating range.

Fuel pressure regulators also play a crucial role in fuel atomization, which is the process of breaking down fuel into small, uniformly distributed droplets. Efficient fuel atomization allows for a thorough mixing of fuel with air, promoting complete combustion and maximising power output. Additionally, precise fuel pressure control ensures that the fuel-air mixture remains within the ideal stoichiometric ratio, minimising fuel wastage and reducing harmful emissions.

Isolating Fuel Pressure Gauges: A Step-by-Step Guide

You may want to see also

Too much pressure can blow the needle off its seat

Carburettors require a careful balance of fuel pressure and volume to operate correctly. If the pressure is too high, it can blow the needle off its seat, causing fuel to leak out of the air vents, into the carb, and washing the cylinder walls down. This can also cause fuel to get onto the exhaust manifold and catch fire.

The ideal fuel pressure for a carburettor is dependent on the carburettor's style. For example, Eddy/Carter carbs can handle up to 6 psi of fuel pressure before the needle is blown off its seat, whereas Holley-style carbs (Quick Fuel, Demon, Holley, Proform, etc.) can tolerate up to 8.5 psi before this happens. It's worth noting that most fuel pumps have an internal relief valve that limits maximum pressure.

To adjust and maintain consistent fuel pressure, use a Fuel Pressure Regulator. The owner's manual that came with your carburettor will give you set-up and tuning instructions, but you can also refer to basic guidelines available online.

It's important to monitor fuel pressure to ensure it doesn't exceed the maximum level that your carburettor can handle. This can be done with a fuel pressure gauge installed in the engine bay. However, it's crucial to choose the right type of gauge as liquid-filled gauges are not suitable for this purpose due to the fluid heating up and causing inaccurate pressure readings.

Fuel Pressure Check: 2001 Cougar Maintenance Guide

You may want to see also

Fuel pressure is important to prevent the engine from leaning out

To ensure that the engine receives the correct amount of fuel, it is crucial to maintain adequate fuel pressure. The fuel pressure should be high enough to keep the fuel bowls filled to the prescribed levels, but not so high that it overpowers the needle and seat. The ideal fuel pressure range for carbureted engines is typically between 5-7 psi. However, it's important to refer to the owner's manual for specific recommendations as each style of carburetor has a fuel pressure range where they perform the best.

Maintaining the correct fuel pressure is essential to prevent the engine from running lean. If the pressure drops below the demand, the engine will not receive enough fuel, resulting in a lean condition. This can lead to performance issues and even engine damage. Therefore, it is crucial to monitor fuel pressure and make adjustments as necessary to ensure optimal engine performance.

Additionally, other factors such as fuel volume, fuel pump capacity, and fuel line size can also impact the engine's performance. It is important to ensure that the fuel delivery system is adequately sized and functioning properly to meet the engine's fuel demands. Regular maintenance, including replacing the fuel filter at recommended intervals, can also help prevent issues related to fuel pressure and volume.

By paying close attention to fuel pressure and making necessary adjustments, you can help prevent the engine from leaning out and ensure optimal performance, efficiency, and longevity.

Troubleshooting Honda's Fuel Pressure Regulator: DIY Guide

You may want to see also

Fuel bowls should be kept half-full

Fuel bowls should be kept at least half-full to prevent engine issues. If the fuel pressure is too low, the fuel bowls can run dry, and if the pressure is too high, it can force too much fuel into the engine, causing fouled spark plugs and other issues.

Additionally, ensuring that the fuel bowls are half-full can help prevent issues with the needle and seat. If there is too much pressure, it can blow the needle off the seat, causing fuel to come out of the air vents, go into the carburettor, and wash down the cylinder walls or get onto the exhaust manifold and catch fire. On the other hand, if there is too little pressure, it can cause a lean condition, leading to engine issues.

Keeping the fuel bowls half-full also ensures that there is enough fuel in the bowls to meet the demand of the engine. This is especially important during high-RPM Wide Open Throttle (WOT) when the fuel demand is high. If the fuel bowls are not kept full, the engine may not get enough fuel, leading to performance issues and potential damage.

Finally, maintaining the correct fuel level in the bowls can help with the proper functioning of the floats. If the fuel pressure is too high, it can push the floats down, causing the needle and seat to not open fully and preventing the fuel bowls from filling up. By keeping the fuel bowls half-full, you can ensure that the floats are at the correct level and that the needle and seat can function properly.

Fuel Pump Pressure Essentials for the Classic 73Beetle

You may want to see also

Fuel pressure is dependent on pressure and volume

A pump that delivers more volume at a lower pressure is desirable because too much pressure will blow the needle off the seat, causing fuel to come out of the air vents, go into the carb and wash the cylinder walls down and/or get onto the exhaust manifold and catch fire. Too little pressure causes a lean condition and you will still lose an engine. Therefore, fuel pressure needs to be high enough to keep the bowls filled to the prescribed levels under all conditions, but low enough not to overpower the needle and seat. Usually, between 5-7 psi is sufficient.

However, it is important to note that each style of carburettor has a fuel pressure range where they perform the best, so it is always best to check the owner's manual that came with your carburettor. This will give you set-up and tuning instructions.

Understanding Diesel Engine Fuel Pressure Performance

You may want to see also

Frequently asked questions

Each style of carburetor has a fuel pressure range where they perform the best. The owner's manual that came with your carb will give you set-up and tuning instructions. However, you can use the following as a basic guideline: Quadrajet (street engines) and Quadrajet (performance engines).

If your fuel pressure is too low, you run the risk of running the fuel bowls dry. If the pressure is too high, it can force too much fuel into the engine, causing fouled spark plugs and other issues.

Edelbrock carburetors should be set at 6 psi.