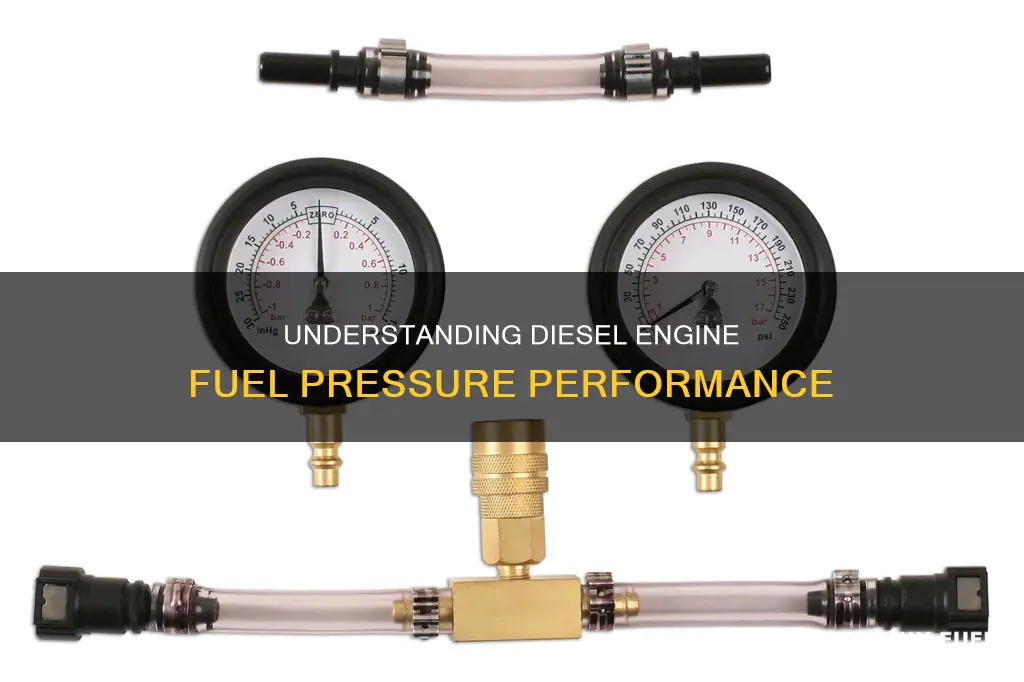

Diesel engines are known for their high fuel pressure, which is a key factor in their performance and efficiency. The fuel pressure in diesel engines can vary, but typically ranges from 10,000 to 30,000 psi, which is significantly higher than the 10-60 psi found in fuel-injected gasoline engines. This high-pressure fuel injection is a defining characteristic of diesel engines and plays a crucial role in their combustion process.

What You'll Learn

Injector nozzle design is critical in direct-injection engines

The fuel injector nozzle is critical to the performance and emissions of diesel engines. Injector nozzle design is critical in direct-injection engines as it plays a vital role in determining combustion characteristics, emissions, and You may want to see also Another factor contributing to the fuel efficiency of diesel engines is their use of direct fuel injection. This process involves injecting fuel directly into the cylinder, resulting in minimal fuel waste. In contrast, gasoline engines introduce a mixture of fuel and air during the intake stroke, which can lead to greater fuel consumption. The fuel system in a diesel engine typically consists of three main parts: the injector, the injection pump, and sometimes, the engine control unit (ECU). Diesel fuel injection systems operate in the 10,000-30,000 psi range, with some modern engines even exceeding this range. This high-pressure injection ensures a more efficient burn and reduces waste heat. The efficiency of diesel engines is further enhanced by the use of turbochargers, which increase the volume of air entering the engine. This, in turn, lays the groundwork for the combustion of more fuel, leading to improved thermal efficiency. While diesel engines are generally more fuel-efficient, it's important to consider driving habits and usage patterns. Diesel engines are particularly advantageous for those who drive a lot of highway miles or tow heavy loads. The improved fuel economy on highways and the increased torque for towing can lead to significant fuel savings over time. However, for those who primarily engage in city driving or drive fewer miles per year, the higher purchase price of a diesel vehicle may not be offset by the fuel savings. Additionally, the availability and cost of diesel fuel can vary, with prices sometimes rising above or dropping below those of gasoline. Therefore, when considering a diesel engine, it's essential to weigh the upfront costs, fuel prices, and expected usage to determine if the improved fuel efficiency aligns with one's specific needs and preferences. You may want to see also The heavy-duty construction of diesel engines is a direct result of the higher cylinder pressures they operate under. Cylinder pressures in modern turbocharged applications have reached 3,600 psi, and they can exceed 8,000 psi in performance applications. On a 4-inch bore, this translates to 45,000 pounds of pressure pushing down on the piston. To withstand these extreme forces, the engine block, crankshaft, connecting rods, pistons, cylinder heads, and valves are all designed to be significantly more robust than those found in gasoline engines. The use of turbochargers in diesel engines is another factor that contributes to their heavy-duty nature. Turbochargers take advantage of the exhaust gases produced by the engine to boost its performance. By increasing the volume of air entering the engine, turbochargers allow for the injection of more fuel, which results in higher cylinder pressure and increased torque. This combination of high cylinder pressure and boosted air volume is what gives diesel engines their impressive torque-to-horsepower ratios, which are typically around 2:1 but can reach 3:1 or even 4:1 in industrial applications. The fuel injection systems in diesel engines also contribute to their heavy-duty nature. Unlike gasoline engines, which inject fuel at 10-60 psi, diesel fuel injection systems operate in the range of 10,000-30,000 psi. This high-pressure fuel injection is a key factor in the superior fuel efficiency of diesel engines, as it allows for a leaner air-fuel ratio and a more complete burn. The precise control of fuel injection is critical to the performance of a diesel engine, as it determines the timing and amount of fuel injected into the cylinder, directly impacting the power and efficiency of the engine. In summary, diesel engines are built with heavy-duty components to handle the extreme cylinder pressures, high boost levels, and precise fuel injection that characterize their operation. The use of robust materials and construction ensures that diesel engines can withstand the tremendous stresses imposed on them, resulting in exceptional durability and longevity. You may want to see also The fuel system on most diesel engines is composed of three main parts: the injector, the injection pump, and sometimes the engine control unit (ECU). In most diesel engines, fuel injectors are mounted in the engine's cylinder head(s), and the tip or nozzle of the injector sprays directly into the combustion chamber. Diesel fuel-injection systems run in the 10,000-30,000-psi range. Turbocharging of diesel engines began in the 1920s with large marine and stationary engines. Trucks became available with turbo-diesel engines in the mid-1950s, followed by passenger cars in the late 1970s. Since the 1990s, the compression ratio of turbo-diesel engines has been dropping due to better specific power and better exhaust-emission behaviour. Diesel engines are well-suited to turbocharging due to two factors. Firstly, a "lean" air-fuel ratio caused by the turbocharger supplying excess air into the engine is not a problem for diesel engines because torque control is dependent on the mass of fuel injected into the combustion chamber, rather than the quantity of the air-fuel mixture. Secondly, the additional quantity of air in the cylinder due to turbocharging effectively increases the compression ratio, which can cause pre-ignition and high exhaust gas temperatures in a petrol engine. However, in a diesel engine, fuel is not present in the combustion chamber during the compression stroke, as it is only added shortly before the piston reaches top dead centre, so pre-ignition cannot occur. Turbochargers make diesels what they are: great. They improve the thermal efficiency of the diesel engine by increasing the volume of air entering it, which lays the groundwork for the combustion of more fuel. The boost created by the turbocharger, along with the stroke and cylinder pressure, contribute to the high torque-to-horsepower ratio in diesel engines. You may want to see also Rudolf Diesel, the German engineer who invented the diesel engine, originally designed it to run on coal dust as fuel. However, he also experimented with vegetable oil before the petroleum industry began making petroleum diesel fuel. Today, diesel engines are used in a wide range of industries. They are valued for their high efficiency, high torque, and ability to handle demanding tasks. Here are some of the industries that rely on diesel engines: Transportation Diesel engines are commonly used in freight trucks, trains, barges, and even some automobiles. They are favoured for their fuel efficiency, safety, and ability to handle heavy loads. Diesel fuel has a higher energy density than other liquid fuels, providing more useful energy per unit of volume. This makes it ideal for transporting goods over long distances. Agriculture Diesel engines power most of the farm equipment in the United States. They are valued for their ability to handle demanding tasks such as lifting steel beams, digging trenches, and drilling wells. Diesel engines are also less likely to stall than gasoline engines, making them a reliable choice for agricultural work. Military The US military uses diesel fuel in tanks and trucks due to its safety and performance advantages. Diesel fuel is less flammable and less explosive than other fuels, making it a safer option for military operations. Diesel engines are also more reliable and less likely to stall, which is crucial in military contexts. Construction Diesel engines are the powerhouse behind most construction equipment in the US. They can handle demanding construction tasks such as paving roads, moving soil and rocks, and drilling foundations and trenches. The high torque and efficiency of diesel engines make them well-suited for construction applications. Electricity Generation Diesel engines are often used in generators for backup and emergency power supply. Many industrial facilities, large buildings, hospitals, and even remote villages in Alaska rely on diesel generators for their electricity needs. The reliability and performance of diesel engines make them a dependable choice for electricity generation. You may want to see also The fuel pressure of a diesel engine varies depending on the type of engine and its specific design. Common rail diesel engines typically operate at around 2000 atmospheres, while some engines can reach up to 3000 atmospheres or 30,000 psi. The fuel injection pressure in a gasoline engine typically ranges from 10-60 psi, while diesel engines operate in the range of 10,000-30,000 psi. The fuel pressure in a diesel engine is influenced by factors such as the engine speed (RPM), the number of combustion events per second, and the precision of the injector delivery schedules and volumes. Diesel engines throttle the amount of fuel injected, while gasoline engines throttle airflow. The higher fuel pressure in diesel engines allows for more precise control of the fuel injection process, which is critical for optimizing engine performance and efficiency. Higher fuel pressure in a diesel engine can increase the power output and improve fuel efficiency. It also enables more precise control over the timing and volume of fuel injected, resulting in improved engine performance and reduced emissions.Fuel Pressure: Maintaining Normal Range While Idling

Diesel engines are more fuel-efficient than gasoline engines

Fuel Pressure Maintenance for the 93 240SX: Getting it Right

Diesel engines are built with heavy-duty components

Troubleshooting a Rig: Testing Fuel Pressure

Diesel engines are typically turbocharged

Understanding Fuel Pressure Gauges: A Beginner's Guide

Diesel engines are used in a wide range of industries

Adjusting Beckett Burner Fuel Pressure: A Step-by-Step Guide

Frequently asked questions