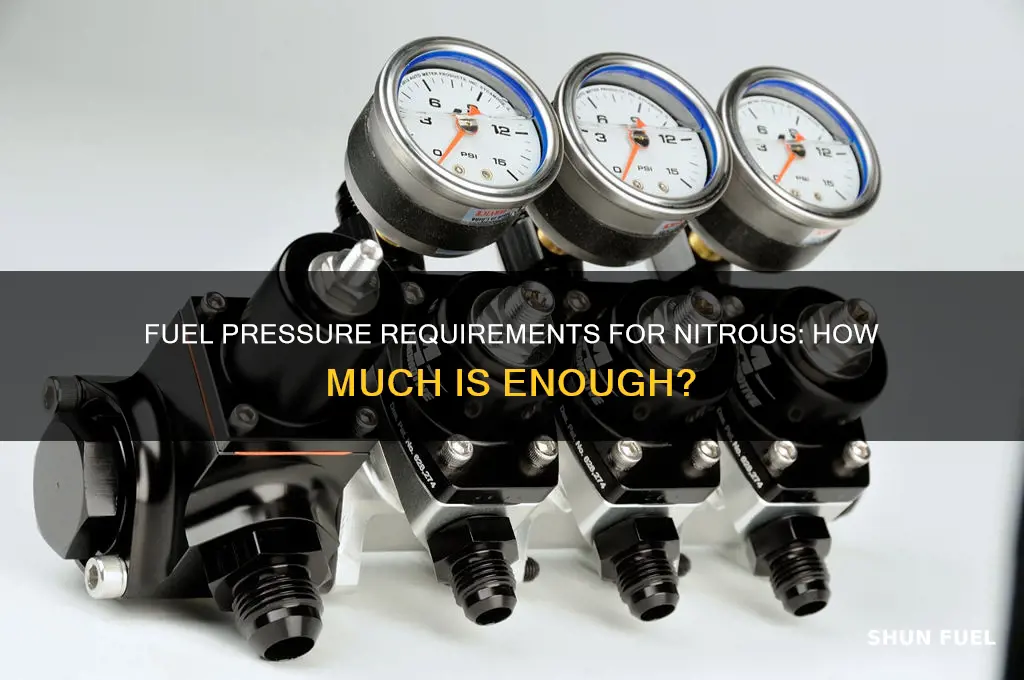

Nitrous oxide systems are designed to use a combination of fuel and nitrous jets, which are based on specific nitrous and fuel pressures. The amount of nitrous and fuel pressure can significantly impact the power an engine makes. If the pressure is not monitored and controlled, performance at the track will be different on each pass, tuning will be difficult, and parts may be damaged. The higher the starting pressure, the faster and further it will fall during a run. Flowing fuel pressure is another key to a proper tune-up. To get the best results, you must have pressure that remains consistent.

What You'll Learn

- Nitrous oxide requires consistent pressure to tune properly as it enters the engine

- Reducing fuel pressure lowers the total flow, while increasing it allows the same jet size to flow more fuel

- A closed-end nitrous fuel system increases line pressure, causing fuel pressure creep

- A dedicated fuel system can be used to fine-tune fuel pressure

- Nitrous and fuel pressure need to be monitored and controlled to avoid damage and performance issues

Nitrous oxide requires consistent pressure to tune properly as it enters the engine

Nitrous systems are designed to use a combination of fuel and nitrous jets based on specific nitrous and fuel pressures. Reducing either fuel or nitrous pressure lowers the total flow. Therefore, fuel pressure is critical. With a closed-end or dead-head nitrous fuel system, the fuel pump pushes fuel against a closed valve when the fuel solenoid is inactive, increasing line pressure and causing fuel pressure creep. Most fuel pumps have an internal bypass set to a given pressure, usually higher than the nitrous fuel system flowing pressure. When the nitrous system is activated and the fuel solenoid opens, the pressure drops significantly.

To properly tune a nitrous system, it is essential to have the right tools in place, such as a fuel flow tool and an accurate nitrous pressure gauge. The fuel flow tool is used to flow fuel through the regulator to set and adjust the fuel pressure accurately. A nitrous pressure gauge in the car ensures that the nitrous bottle is always set to the same gauge, regardless of the bottle used.

Understanding and controlling both nitrous pressure and fuel flow pressure are crucial for using and tuning a nitrous system effectively. By keeping these variables in check, a racer can consistently make more significant horsepower without any major issues.

Flooded Engines: Impact on Oil Pressure and Performance

You may want to see also

Reducing fuel pressure lowers the total flow, while increasing it allows the same jet size to flow more fuel

The relationship between fuel pressure and nitrous flow is an important aspect of maximising engine performance and keeping it healthy. Reducing fuel pressure lowers the total flow, while increasing it allows the same jet size to flow more fuel. This is a critical relationship to understand for effective nitrous tuning.

Nitrous systems are designed to use a combination of fuel and nitrous jets, which are calibrated to specific nitrous and fuel pressures. When fuel or nitrous pressure is decreased, the total flow is also reduced. Conversely, increasing the pressure will result in a higher flow rate for the same jet size. Therefore, fuel pressure plays a crucial role in ensuring the optimal performance of a nitrous system.

To elaborate on this relationship, let's consider the concept of fuel pressure creep in a closed-end or dead-head nitrous fuel system. In such a system, when the fuel solenoid is inactive, the fuel pump pushes fuel against a closed valve, leading to an increase in line pressure. Most fuel pumps have an internal bypass that is set at a higher pressure than the nitrous fuel system's flowing pressure. Consequently, when the nitrous system is activated and the fuel solenoid opens, the pressure drops significantly. This underscores the importance of setting the correct fuel pressure to ensure the desired flow rate.

It is worth noting that maintaining consistent nitrous pressure is also essential for optimal engine performance. Any changes in nitrous pressure can significantly impact the power output of the engine. Therefore, accurate monitoring and control of nitrous pressure are crucial to achieving consistent performance and preventing potential damage to engine components.

In summary, the interplay between fuel pressure and nitrous flow is a fundamental aspect of nitrous tuning. By understanding and manipulating fuel pressure, one can fine-tune the performance of a nitrous system to achieve the desired power output while also maintaining the health of the engine.

Fuel Rail Pressure Drop: Causes and Solutions

You may want to see also

A closed-end nitrous fuel system increases line pressure, causing fuel pressure creep

Tuning Nitrous Fuel Pressure

Nitrous oxide systems are a great way to boost power output in internal combustion engines. The combination of nitrous and gasoline can lead to excellent power gains. However, to keep your nitrous engine healthy and powerful, it's important to understand how nitrous and fuel pressure interact.

Nitrous and Fuel Pressure Relationship

All nitrous systems rely on a combination of fuel and nitrous jets, which are calibrated based on specific nitrous and fuel pressures. Adjusting either the fuel or nitrous pressure will impact the total flow. Therefore, fuel pressure plays a critical role in the performance of a nitrous system.

Closed-End Nitrous Fuel System and Fuel Pressure Creep

Now, let's focus on the closed-end or dead-head nitrous fuel system. In this system, when the fuel solenoid is inactive, the fuel pump pushes fuel against a closed valve, leading to an increase in line pressure. This phenomenon is known as fuel pressure creep.

Most fuel pumps have an internal bypass set at a specific pressure, typically higher than the nitrous fuel system's flowing pressure. Consequently, when the nitrous system is activated and the fuel solenoid opens, the pressure drops significantly. This significant pressure drop highlights the importance of setting the nitrous fuel pressure by creating system fuel flow.

To effectively tune the nitrous fuel pressure, specialized tools and gauges are required. For instance, the Zex kit offers a high-quality Winters liquid-filled 0-15-psi gauge with exceptional accuracy (+/- 0.04 psi). Additionally, the kit includes four fuel jets of varying sizes (0.043, 0.064, 0.083, and 0.125 inches).

By plumbing the Zex gauge inline with the nitrous system's gas jet, you can simulate fuel flow and fine-tune the fuel pressure accordingly. It's important to remember that nitrous pressure and fuel flow pressure must be carefully monitored and controlled to ensure optimal performance and prevent potential damage to engine components.

Fuel Rail Pressure Sensor: Safe to Drive?

You may want to see also

A dedicated fuel system can be used to fine-tune fuel pressure

The relationship between nitrous pressure and fuel pressure is critical. Reducing fuel pressure also lowers the total flow, while increasing pressure results in higher flow rates. This is why fine-tuning fuel pressure is essential to maintain the desired power output.

A dedicated fuel system allows for precise adjustments to fuel pressure, ensuring the correct amount of fuel is delivered to the engine. This is particularly important when using nitrous oxide, as the combination of fuel and nitrous jets is based on specific pressures. By having a separate system, users can make changes to fuel pressure independently, without affecting other components.

For example, with a closed-end or dead-head nitrous fuel system, the fuel pump pushes against a closed valve, increasing line pressure. This is known as fuel pressure creep. When the nitrous system is activated, the pressure drops. A dedicated fuel system can mitigate this issue by allowing for more precise control over fuel pressure, ensuring it remains consistent with nitrous pressure.

Additionally, a dedicated fuel system can help prevent issues such as fuel pressure creep and ensure the fuel injectors are receiving the correct amount of fuel. This, in turn, can help prevent engine damage caused by running too lean. By fine-tuning fuel pressure, users can also make small adjustments to the injector flow rate, optimizing performance without needing to upgrade to larger injectors.

In conclusion, a dedicated fuel system provides the ability to fine-tune fuel pressure, ensuring optimal performance and engine health in nitrous oxide-powered vehicles. The ability to make precise adjustments to fuel pressure independently allows for a more efficient and reliable system.

Testing Fuel Pressure: 1997 Acura Guide

You may want to see also

Nitrous and fuel pressure need to be monitored and controlled to avoid damage and performance issues

Nitrous oxide systems are designed to use a combination of fuel and nitrous jets based on specific nitrous and fuel pressures. As a result, nitrous and fuel pressure need to be monitored and controlled to avoid damage and performance issues.

Nitrous oxide depends on pressure for it to be tuned properly as it enters the engine. You must have pressure that remains consistent to get the best results, and any changes in the pressure can significantly impact the engine's power output. If nitrous pressure is not monitored and controlled accurately, performance can vary, tuning becomes difficult, and parts may be damaged. The higher the starting pressure, the faster and further it will fall during a run. Additionally, higher nitrous pressure can challenge the progressive controller and the nitrous solenoid plunger, and reduce nitrous density in the bottle.

Flowing fuel pressure is another critical factor. Without correct flowing fuel pressure, obtaining a good tune-up becomes impossible, leading to frustration with track performance. It is important to remember that a dead-headed regulator cannot be properly set when working with flowing fuel pressure. Fuel pressure changes are a method to lean or enrich the tune as needed, based on plug reading and time slip incrementals.

To effectively use and tune a nitrous system, a fuel flow tool and an accurate nitrous pressure gauge installed in the car are essential. The flow tool enables the accurate setting and adjustment of fuel pressure. A four-inch nitrous pressure gauge in the car ensures that regardless of the nitrous bottle used, the pressure remains consistent.

By keeping nitrous and fuel pressure variables in check, a racer can learn to make more significant horsepower consistently and without any significant issues.

Kia Spectra5 SX: Replacing Fuel Pressure Regulator

You may want to see also

Frequently asked questions

There is no definitive answer to this question as different setups will require different fuel pressures. It is recommended to have a dedicated fuel system and to tune the pressure for your specific setup. The pressure should remain consistent to get the best results, and any changes in pressure can significantly affect engine performance.

All nitrous systems are designed to use a combination of fuel and nitrous jets based on specific nitrous and fuel pressures. Reducing either fuel or nitrous pressure lowers the total flow, while increasing pressure will cause more fuel or nitrous to flow at a higher pressure. Therefore, fuel pressure is critical to the performance of a nitrous system.

To properly tune a nitrous system, you will need a fuel flow tool and an accurate nitrous pressure gauge installed in the car. The flow tool is used to flow fuel through the regulator to accurately set and change the fuel pressure. A four-inch nitrous pressure gauge is recommended to ensure consistent readings regardless of the nitrous bottle used.

A fuel pressure of 3-5 PSI should be sufficient for a 100-150 HP nitrous system. However, it is important to follow the instructions provided with your specific kit as different systems may have different requirements. It is also recommended to have a dedicated fuel regulator for the nitrous supply and to set the pressure while flowing it into a bucket to ensure stable pressure.