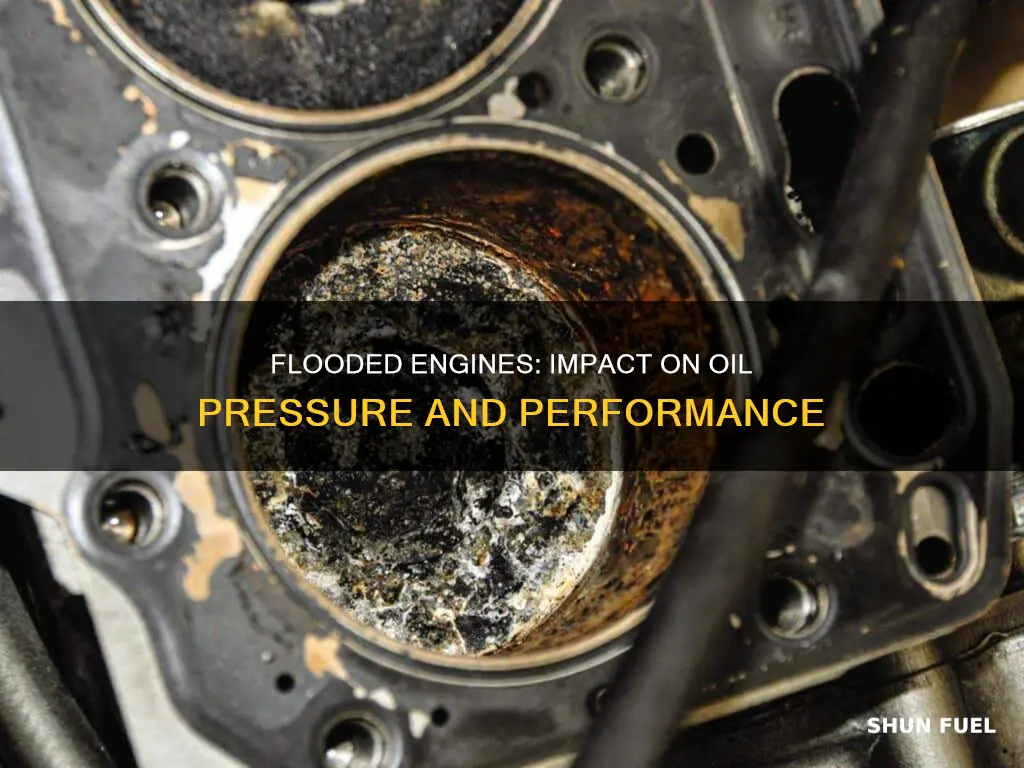

A flooded engine is an internal combustion engine that has been fed an excessively rich air-fuel mixture that cannot be ignited. This can lead to fuel dilution, where the excess fuel dilutes the engine oil, affecting its viscosity and reducing its ability to lubricate effectively. This can result in increased wear and tear on engine components, which may lead to increased oil consumption. While a flooded engine typically affects the engine's performance and can cause hard starting, it is unclear if it directly affects oil pressure. However, it is recommended to check the oil level and viscosity after a flooding incident to ensure there is no significant fuel contamination, as this can cause damage to the engine if left unchecked.

Fuel dilution

The effects of fuel dilution are detrimental to the engine's performance and longevity. Firstly, it reduces the viscosity of the oil, which is crucial for maintaining a film of lubricant between moving parts. With reduced viscosity, the oil film may not be strong enough to withstand the loads and speeds in the engine, leading to metal-on-metal contact and increased wear.

Secondly, fuel dilution dilutes the additive content of the oil. Engine oils contain special anti-wear additives that form a sacrificial layer, protecting the metal surfaces. When diluted, the concentration of these additives decreases, reducing their ability to prevent wear.

Thirdly, the introduction of fuel into the oil can lead to increased oxidation, causing the oil to darken, thicken, and form corrosive compounds that attack the engine's internal components. This can result in the formation of sludge and varnish deposits, further exacerbating the issue.

To address fuel dilution, it is essential to use high-quality engine oils that are specifically formulated to withstand dilution. Additionally, regular oil changes and maintenance are crucial to removing diluted oil and preventing excessive wear.

In summary, fuel dilution in engine oil is a serious issue that can lead to accelerated engine wear and even catastrophic failure if not addressed. By using appropriate oils and adhering to maintenance schedules, the risks associated with fuel dilution can be mitigated.

Fuel Pressure Regulator: Signs of Imminent Failure

You may want to see also

Bore wash

The symptoms of bore wash include a strong smell of petrol, abnormal whirring sounds when trying to start the engine, and the engine starting briefly and then cutting out. If bore wash is suspected, it is recommended to check the dipstick for a strong smell of petrol or an increased oil level.

To fix bore wash, the underlying cause of overfuelling must be addressed, such as a bad driveability sensor or a leaking injector. Additionally, the combustion chambers need to be re-oiled by squirting a small amount of transmission or engine oil into each chamber, followed by slow and fast cranks to expel excess oil. Finally, the spark plugs, coils, and fuel pump fuse should be replaced before attempting to start the engine.

Checking Fuel Rail Pressure: A Step-by-Step Guide

You may want to see also

Compression loss

When there is too much fuel in the cylinder, the excess fuel washes away the oil from the cylinder walls, piston skirt, and piston rings. This leads to a loss of compression as gasoline does not enable piston rings to seal like motor oil does. The piston rings are coated with gasoline instead of oil, and since gasoline is too thin to perform the same function as motor oil, it cannot seal the piston to the bore effectively. This results in a reduction in cylinder sealing and, consequently, compression loss.

To address compression loss due to a flooded engine, it is recommended to crank the engine with the accelerator pedal fully depressed. This allows a maximum flow of air through the engine, flushing out the excess fuel. Once the engine starts, it is crucial to allow it to rev up and then maintain a higher-than-normal idle speed momentarily. If the engine does not start within 10 seconds, there may be other underlying issues, and professional assistance should be sought.

Fuel Pressure Control: Understanding the Key Factors

You may want to see also

Spark plug damage

A flooded engine is an internal combustion engine that has been fed an excessively rich air-fuel mixture that cannot be ignited. This can occur when a vehicle is started in cold weather and switched off before it has warmed up. The unburned fuel remains in the engine, wetting the spark plugs and preventing ignition.

Spark plugs are essential for starting a vehicle as they create the spark that ignites the fuel. When the spark plugs are wet, they cannot create this spark, and the vehicle will not start. In some cases, the spark plugs may need to be cleaned or replaced before the engine will start. This is most likely to occur in carbureted engines in cold weather, after a running engine has been shut off briefly and then restarted.

If the spark plugs are damaged by excess fuel, they will need to be replaced. This will result in a misfire as the spark plugs ground out instead of firing. It is recommended that you take your car to a garage so that professional mechanics can handle the problem.

There are several ways to identify if your engine is flooded. You may hear abnormal whirring sounds when trying to start the engine, or the engine may start briefly and then cut out. You may also notice a strong smell of petrol, especially around the exhaust.

To fix a flooded engine, crank the engine with the accelerator pedal pushed to the floor. Continue cranking the engine for up to 10 seconds until you hear the engine trying to start. Once the engine has started, allow it to rev up for a few seconds, then hold it at a higher-than-normal idle speed for a few more seconds. If the engine doesn't start within 10 seconds, switch off and call for assistance.

It is important to note that a flooded engine will not fix itself. Steps need to be taken to clear the excess fuel from the engine or repair any damage that may have been caused.

Setting Fuel Pressure: 94 Z28 Camaro Guide

You may want to see also

Oil contamination

When fuel mixes with the engine oil, it reduces its viscosity and lubricating properties, leading to decreased oil pressure. This can cause increased friction and wear on engine components, resulting in poor engine performance, abnormal noises, and even engine failure. In addition, fuel in the oil can form deposits and sludge, further exacerbating the problem.

To prevent and address oil contamination due to fuel dilution, it is important to:

- Avoid flooding the engine by allowing it to warm up sufficiently before driving and avoiding excessive idling or aggressive driving.

- Maintain the fuel injection system and address any fuel system issues promptly.

- Regularly check the engine oil level and quality, including monitoring for fuel odour in the oil.

- Change the engine oil and filter at recommended intervals or more frequently if contamination is suspected.

- Consult a professional mechanic if the issue persists or if you are unsure about the condition of your engine oil.

In addition to fuel dilution, oil contamination can also be caused by other factors such as water intrusion, coolant leaks, dirt and debris, and failing engine components. Therefore, it is crucial to maintain the engine and address any leaks or issues promptly to prevent contamination and maintain optimal oil pressure.

Ideal Fuel Pressure for Lexus IS350: 2006 Edition

You may want to see also

Frequently asked questions

A flooded engine is an internal combustion engine that has been fed an excessively rich air-fuel mixture that cannot be ignited. This is caused by the mixture exceeding the upper explosive limit for the particular fuel.

A flooded engine can dilute the engine oil, leading to increased friction and wear on the piston, piston rings, and cylinder walls. This will result in increased oil consumption.

Signs of a flooded engine include a loud, high-pitched whirring sound when trying to start the engine, a strong smell of petrol, and the engine starting briefly and then cutting out.

To fix a flooded engine, crank the engine with the accelerator pedal pushed to the floor and continue cranking for up to 10 seconds. Once the engine starts, allow it to rev up and then hold it at a higher-than-normal idle speed for a few seconds. If the engine doesn't start, there may be other issues and you should call for assistance.