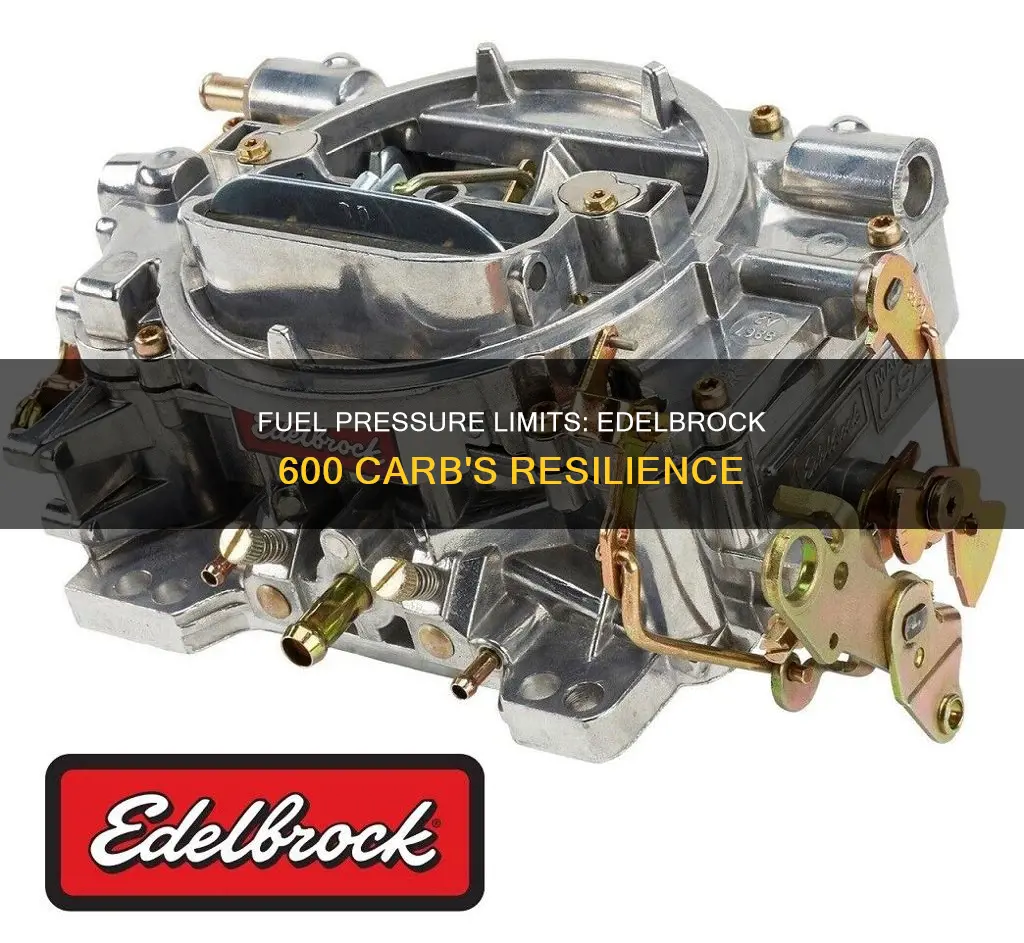

Edelbrock carburetors are designed to run on fuel pressures between 4.5 and 6.5 psi, with some users reporting that they can go up to 7 psi without any issues. However, it is generally recommended to not exceed 5 psi as going above this limit can cause the carburetor to bog down or become overly rich. Some users have also reported flooding issues when using fuel pumps that provide more than 6 psi. Therefore, it is advisable to use a fuel pressure regulator to ensure that the fuel pressure stays within the optimal range for Edelbrock carburetors.

What You'll Learn

Fuel pressure regulators can help prevent fuel flooding

Fuel pressure regulators are an essential component of a vehicle's fuel system, ensuring the engine receives the correct amount of fuel for optimal performance. They work by controlling the flow of fuel from the fuel pump to the engine, opening or closing a valve depending on the fuel demand. This is important for Edelbrock 600 carb users as the fuel pressure should be maintained between 5 to 5.5 psi; going above this range can cause the engine to bog or be over-rich.

A faulty fuel pressure regulator can lead to fuel flooding, which is when the engine receives too much fuel. This can be caused by a failing regulator, which may not be able to handle the pressure and allow excess fuel to pass through. Additionally, a stuck-open regulator can also cause flooding as it is unable to restrict the flow of fuel.

To prevent fuel flooding, it is important to maintain the fuel pressure regulator and ensure it is functioning properly. This includes regularly inspecting the regulator for any signs of damage or contamination and replacing it if necessary. It is also crucial to use high-quality fuel and maintain proper engine temperatures to prevent the regulator from failing due to excessive heat or contaminated fuel.

Furthermore, fuel pressure regulators can help optimize engine performance and fuel efficiency. They ensure the engine receives the right amount of fuel at the correct pressure, creating an optimal air-fuel mixture for efficient combustion. This results in improved fuel economy, reduced emissions, and enhanced engine performance.

In conclusion, fuel pressure regulators play a critical role in maintaining the correct fuel pressure, preventing fuel flooding, and optimizing engine performance. By regularly inspecting and maintaining the regulator, vehicle owners can ensure their engine runs smoothly and efficiently while also preventing potential damage caused by incorrect fuel pressure.

Understanding Fuel Injector Pressure Regulators: Performance and Control

You may want to see also

Fuel pressure should be set between 5 and 6 psi

Fuel pressure for an Edelbrock carb should be set between 5 and 6 psi. This is because anything over 6 psi will cause the carb to flood. The stock pumps from Carter are often too powerful, producing 6-9 psi, which can cause flooding issues.

Edelbrock techs insist that 4.5-5.5 psi is optimal, with no more than 6.5 psi. Going over this can cause needle and seat issues and flooding. This is backed up by many users who have experienced problems with fuel pressure and their Edelbrock carbs.

One user with an Edelbrock 600 CFM carb had issues with their car flooding. They were advised to use a fuel pressure regulator and to set fuel pressure to between 4.5 and 5.5 psi. Another user with the same carb had a similar issue and was advised to check their fuel pressure, which turned out to be almost 9 psi. They installed a regulator and set the pressure to 5 psi, solving the problem.

A user with an Edelbrock 1406 carb was experiencing bogs when turning corners and off-idle. They installed a fuel pressure regulator and set it to 5 psi, which solved the problem.

Therefore, it is recommended to set fuel pressure between 5 and 6 psi for an Edelbrock carb. This will prevent flooding issues and ensure optimal performance.

Finding the Fuel Pressure Regulator in Chevy 350 V8 Engines

You may want to see also

Fuel pressure above 6.5 psi can cause issues with the needle and seat

The needle and seat are critical components in a carburettor, working together to control the flow of fuel into the engine. The needle is a small brass or steel valve that sits inside the carburettor, while the seat is a matching tapered hole that the needle rests against. When the needle is seated correctly in the hole, it blocks the flow of fuel. However, when the needle lifts off the seat, fuel is allowed to flow through, mixing with air to create the combustible mixture that powers the engine.

If fuel pressure exceeds 6.5 psi, it can force the needle out of the seat, causing the carburettor to flood with fuel. This results in an overly rich fuel-air mixture, which can lead to difficult starting, excessive smoking, and poor performance. In some cases, excess fuel can even leak out of the carburettor, creating a fire hazard.

To prevent these issues, it's crucial to maintain fuel pressure within the recommended range for your particular Edelbrock carburettor. This usually means setting fuel pressure between 4.5 and 5.5 psi, though some Edelbrock carbs can tolerate up to 6 psi without issues. Installing a fuel pressure regulator is often the best way to ensure fuel pressure stays within this safe range.

Additionally, it's important to choose a compatible fuel pump. Many aftermarket performance fuel pumps deliver excessively high fuel pressure, which can overwhelm the carburettor and cause the needle and seat to malfunction. Instead, look for a fuel pump that delivers fuel pressure within the optimal range for your carburettor.

By keeping fuel pressure in check, you can prevent issues with the needle and seat, ensuring reliable performance from your Edelbrock carburettor.

Testing Diesel Fuel Rail Pressure: A Comprehensive Guide

You may want to see also

Fuel pressure can be measured with a fuel pressure gauge

Fuel pressure is an important aspect of an engine's performance, and too much or too little pressure can cause issues. For an Edelbrock 600 carb, fuel pressure should be set at around 5 to 5.5 psi. Going above this range can cause the engine to bog or be over-rich.

Now, fuel pressure can be measured with a fuel pressure gauge. This gauge is attached to a fuel hose with multiple fittings that can connect to almost any vehicle's fuel system. Here are the steps to measure fuel pressure:

First, ensure you are wearing the proper safety equipment, such as safety glasses and gloves, and work in a well-ventilated area. Releasing fuel under pressure can be dangerous, so it is important to take precautions.

Next, locate the fuel pressure test port on your vehicle. Place a rag under the test port to catch any fuel that may be released during the test. Then, install the pressure tester onto the port.

After the tester is installed, start the engine and record the pressure reading. You may need to run the engine at a specific RPM, as specified by the manufacturer.

Compare the pressure reading to the manufacturer's specifications. A typical port-injected vehicle requires fuel pressure between 30 and 80 PSI, but this can vary depending on the engine. For example, older throttle-body injected systems may need as little as 10 psi, while multi-port injection can see as high as 60 psi.

If the fuel pressure is lower than the recommended specification, there may be an issue with the fuel pump or a clog in the fuel filter. If the pressure is higher, there could be a problem with the fuel return line or the fuel pressure regulator.

Additionally, you can perform a fuel volume test to determine if the proper amount of fuel is being delivered to the fuel injectors. This can be done using a flowmeter or a glass measuring container to collect a fuel sample for a specified amount of time.

By following these steps and using a fuel pressure gauge, you can accurately measure and diagnose issues with your vehicle's fuel pressure.

Outlander Fuel Pressure Regulator: Performance and Efficiency

You may want to see also

Fuel line routing is important to prevent leaks and damage

Firstly, it is recommended to start with a fuel filter and ensure it is mounted in an accessible spot for servicing. The filter should be spaced in a way that allows access to both ends of the assembly. It is also important to determine the mounting locations of other components such as the fuel pump before laying out the fuel lines.

When routing the fuel lines, it is crucial to keep them away from rotating parts, such as driveshafts, CV axles, wheels, and steering components. Stay clear of suspension pinch points and lift points, and avoid running lines inside the vehicle cabin. Keep the lines away from the scrub line, which refers to areas that would rub or scrub on the car in the event of a flat tire or wheel departure.

Use insulated clamps to secure the fuel lines every few feet, ensuring they are tight to avoid abrasion and droop. When passing through a panel, use bulkhead fittings or grommets to protect the lines. If running hard lines, consider using flexible fuel hose connections at the engine and tank to isolate vibration and make future maintenance easier.

Heat is another important consideration. Keep the fuel lines away from heat sources, such as the engine, exhaust system, and headers. Exposure to excessive heat can cause vapor lock or even fire. If lines must be near a heat source, add a heat shield or sleeve, maintaining a minimum distance of 6 inches.

Additionally, regular maintenance and inspections are key to preventing leaks and damage. Check for cracks, wear, corrosion, or other signs of damage, especially at connections and junctions where leaks are more likely. Pressure testing and diagnostic tools can also help identify potential issues. By following these guidelines, you can help ensure the safe and efficient operation of your vehicle's fuel system.

Fuel Pressure and Throttle: What's the Relationship?

You may want to see also

Frequently asked questions

Edelbrock and Carter AFB carbs tend to like 5 to 5.5 psi. Going above 5.5 psi can cause the carb to bog or be over-rich.

If you go over 5.5 psi, you risk the needle and seat not being able to handle the pressure, which can cause flooding.

A Holley Red fuel pressure regulator is almost silent compared to the Carter street pump (4-6 psi).