The efficiency of fuel usage in vehicles is a critical aspect of modern transportation, and understanding the factors contributing to fuel waste is essential for both environmental sustainability and economic savings. In this discussion, we will explore the various elements that lead to fuel wastage in cars, including inefficient driving habits, vehicle maintenance, and the impact of external factors such as weather and road conditions. By examining these factors, we can gain insights into practical strategies to reduce fuel consumption and promote a more sustainable approach to vehicle usage.

What You'll Learn

- Engine Idling: Excess fuel consumption during prolonged idling, a common waste

- Stop-Start Technology: Reduces waste by turning off the engine at stops

- Fuel Injection: Precise fuel delivery minimizes waste and improves efficiency

- Engine Maintenance: Regular tune-ups ensure optimal fuel usage

- Aerodynamics: Design improvements reduce drag, thus saving fuel

Engine Idling: Excess fuel consumption during prolonged idling, a common waste

Engine idling, the practice of leaving a vehicle's engine running while stationary, is a significant contributor to fuel waste and environmental pollution. It is a common habit among drivers, often driven by convenience or a lack of awareness about the associated costs and environmental impact. When a car's engine is idling, it consumes fuel at a higher rate than when it is in motion, leading to unnecessary fuel expenditure and increased emissions.

The primary reason for this excess fuel consumption is the continuous operation of the engine's various systems, including the fuel pump, injectors, and ignition system. During idling, the engine operates at a lower efficiency compared to driving, as it is not utilizing its full potential. This inefficiency results in more fuel being burned per minute, leading to higher fuel costs and a larger carbon footprint. On average, a car can burn around 0.2 to 0.5 gallons of fuel per hour during idling, depending on the vehicle's age, engine size, and driving conditions. Over time, this can add up to a substantial amount of wasted fuel.

Prolonged idling is especially wasteful in modern vehicles with advanced fuel injection systems. These systems are designed to optimize fuel delivery based on engine load, but they require a certain level of engine speed to function correctly. When idling, the engine speed is often too low, causing the fuel injectors to deliver more fuel than necessary, leading to wastage. Additionally, the engine's computer may not accurately calculate the required fuel-air mixture, further exacerbating the problem.

To combat this issue, drivers can adopt several practices. Firstly, turning off the engine when parked or waiting is the most effective way to reduce fuel waste. Modern vehicles with electronic controls can safely shut off the engine without causing any damage. Secondly, utilizing the 'stop-start' technology available in many newer cars can significantly reduce idling. This technology automatically shuts off the engine when the vehicle comes to a stop and restarts it when the driver releases the brake pedal, eliminating the need for prolonged idling.

In conclusion, engine idling is a common yet easily avoidable source of fuel waste. By understanding the impact of prolonged idling on fuel consumption and emissions, drivers can take simple actions to reduce their environmental footprint and save on fuel costs. Encouraging the practice of turning off engines when stationary and promoting the use of stop-start technology can contribute to a more sustainable and efficient driving culture.

Unveiling the Truth: Do Cars Still Burn Fossil Fuels?

You may want to see also

Stop-Start Technology: Reduces waste by turning off the engine at stops

Stop-start technology is an innovative feature designed to minimize fuel waste and improve fuel efficiency in modern vehicles. This technology is particularly beneficial for urban drivers who frequently encounter stop-and-go traffic conditions. The primary concept behind stop-start systems is to eliminate the unnecessary idling of the engine when the car is stationary, which is a significant source of fuel waste.

When a vehicle equipped with stop-start technology comes to a stop, the engine automatically shuts off. This process is almost instantaneous, ensuring a smooth and seamless transition. The system then restarts the engine when the driver applies pressure to the accelerator pedal, providing power to the wheels and propelling the vehicle forward. By eliminating the need for continuous engine operation during brief stops, this technology significantly reduces fuel consumption.

The benefits of stop-start technology are twofold. Firstly, it reduces fuel waste by preventing the engine from idling when it's not needed. Idling engines consume fuel without contributing to forward motion, resulting in unnecessary emissions and wasted resources. Secondly, this technology contributes to a more responsive driving experience. With the engine restarting promptly, drivers can accelerate quickly without the lag associated with manual restarts, enhancing overall driving performance.

This technology is especially advantageous for city drivers who spend a considerable amount of time in stop-and-go traffic. In urban areas, vehicles often idle for extended periods at traffic lights or in congested areas. Stop-start systems can save a significant amount of fuel and reduce the environmental impact of frequent starts and stops. Over time, the fuel savings can be substantial, making this technology an attractive option for those seeking to optimize their vehicle's efficiency.

In summary, stop-start technology is a clever solution to the problem of fuel waste in cars, particularly in urban driving conditions. By turning off the engine at stops and restarting it promptly when needed, this system reduces fuel consumption, improves efficiency, and provides a more responsive driving experience. It is a valuable feature for drivers who want to minimize their environmental impact and maximize their vehicle's performance in stop-and-go traffic.

Unleashing Speed: Nascar Fuel Capacity Explored

You may want to see also

Fuel Injection: Precise fuel delivery minimizes waste and improves efficiency

The concept of fuel efficiency has become increasingly important in the automotive industry, as engineers strive to reduce environmental impact and improve vehicle performance. One of the key innovations that has revolutionized fuel delivery systems is fuel injection technology. This system ensures that the engine receives the precise amount of fuel required for optimal combustion, thereby minimizing fuel waste and maximizing efficiency.

Traditional carburetors, which were once the standard in internal combustion engines, had limitations in delivering fuel to the engine. They often resulted in an uneven mixture of air and fuel, leading to inefficient combustion and increased fuel consumption. In contrast, fuel injection systems offer a more controlled and accurate approach. These systems directly inject fuel into the engine's cylinders, ensuring a precise ratio of fuel to air, which is crucial for efficient combustion. By eliminating the need for a carburetor, fuel injection technology streamlines the fuel delivery process, reducing waste and improving overall engine performance.

The precision of fuel injection is achieved through a series of intricate processes. When the engine's throttle is opened, the fuel injection system calculates the required fuel amount based on various factors such as engine speed, load, and temperature. This calculation is performed by an electronic control unit (ECU), which acts as the brain of the system. The ECU then sends a signal to the fuel injectors, instructing them to release the precise amount of fuel into the engine's intake manifold or directly into the cylinders. This real-time adjustment ensures that the engine always receives the optimal fuel-air mixture, minimizing fuel waste and reducing emissions.

One of the significant advantages of fuel injection is its ability to adapt to changing conditions. Modern fuel injection systems are equipped with advanced sensors that monitor engine parameters, such as oxygen levels, engine temperature, and exhaust gas composition. These sensors provide real-time feedback to the ECU, allowing it to make instantaneous adjustments to the fuel injection process. For example, if the engine is running lean (with too much air and not enough fuel), the system can inject more fuel to achieve the correct ratio, preventing engine knock and improving efficiency. Conversely, if the engine is running rich (with too much fuel), the system can reduce the fuel injection to maintain optimal combustion.

By minimizing fuel waste, fuel injection technology contributes to significant improvements in fuel efficiency. This not only benefits the environment by reducing greenhouse gas emissions but also provides economic advantages for vehicle owners. With more efficient fuel usage, drivers can travel longer distances on a single tank of fuel, resulting in cost savings at the pump. Additionally, the reduced fuel consumption leads to lower maintenance costs associated with fuel system components, as they experience less wear and tear.

In summary, fuel injection technology plays a pivotal role in minimizing fuel waste and maximizing efficiency in modern vehicles. Its precise fuel delivery system ensures that the engine receives the exact amount of fuel required for optimal combustion, leading to improved performance and reduced emissions. With the ability to adapt to changing conditions and provide real-time adjustments, fuel injection systems contribute to a more sustainable and cost-effective driving experience. As the automotive industry continues to evolve, fuel injection technology will undoubtedly remain a key component in the pursuit of efficient and environmentally friendly transportation.

Frozen Fuel: Can Your Car Suffer from Fuel Flood?

You may want to see also

Engine Maintenance: Regular tune-ups ensure optimal fuel usage

Regular engine maintenance is an essential practice that often goes overlooked by car owners, but it plays a pivotal role in optimizing fuel efficiency and reducing fuel waste. Over time, engines can develop issues that lead to decreased performance and increased fuel consumption, ultimately resulting in wasted fuel and higher running costs. This is where the importance of regular tune-ups comes into play.

A well-maintained engine operates more efficiently, ensuring that fuel is burned at the right rate and in the correct ratio with air. This precision in fuel-air mixture is crucial for optimal combustion, which directly translates to better fuel economy. When an engine is not properly tuned, it may struggle to maintain the ideal air-fuel ratio, leading to inefficient combustion and increased fuel usage. This inefficiency can be attributed to various factors, such as worn-out spark plugs, faulty fuel injectors, or a malfunctioning engine control unit (ECU).

During a regular tune-up, mechanics perform a series of checks and adjustments to ensure the engine is running at its best. This includes inspecting and replacing worn-out components like spark plugs, fuel filters, and air filters. These components are vital for maintaining the engine's performance and fuel efficiency. For instance, a clogged fuel filter can restrict fuel flow, causing the engine to run leaner, which results in poor fuel economy and increased emissions. Similarly, dirty or faulty spark plugs can lead to misfires, causing the engine to burn more fuel than necessary.

Additionally, a tune-up involves calibrating the engine's ECU, which is the brain of the engine. The ECU controls the fuel injection and timing, ensuring the engine operates within the optimal parameters. Over time, the ECU's programming may become outdated or corrupted, leading to incorrect fuel-air mixture calculations. By recalibrating the ECU, mechanics can optimize the engine's performance, ensuring it runs efficiently and burns fuel effectively. This process is particularly important for engines with advanced electronic systems, where software updates and calibration can significantly improve fuel efficiency.

In summary, regular engine maintenance, including tune-ups, is a proactive approach to ensure your vehicle's engine operates at its peak. By addressing potential issues and keeping the engine well-maintained, you can optimize fuel usage, reduce fuel waste, and ultimately save money on fuel costs. It is a simple yet effective way to keep your car running efficiently and minimize the environmental impact of your vehicle.

Flooding a Fuel-Injected Car: Risks and Solutions for 928 Owners

You may want to see also

Aerodynamics: Design improvements reduce drag, thus saving fuel

The concept of aerodynamics is crucial in understanding and reducing fuel waste in vehicles. When a car moves through the air, it experiences drag, which is the force that opposes its motion. This drag force increases with the square of the vehicle's speed and is directly related to the car's frontal area and the shape of its body. As a result, vehicles with poor aerodynamic design can waste a significant amount of fuel due to the extra effort required to overcome this drag.

Designing cars with improved aerodynamics is an effective way to combat this issue. One of the primary goals is to minimize the frontal area of the vehicle, which is the part that presents the most significant obstacle to airflow. By reducing the size of the front end and streamlining the overall shape, engineers can decrease the car's frontal area, thereby reducing drag. This can be achieved through various design techniques, such as incorporating slanted windshields, optimizing the placement of headlights and grille, and designing a sleek, curved roofline.

Another critical aspect of aerodynamic design is managing the flow of air around the car. This involves creating a smooth, continuous airflow over the vehicle's surface, reducing turbulence and separation of air. One way to achieve this is by using a technique called 'underbody treatment,' where the undercarriage and wheels are designed to allow air to flow smoothly underneath the car. This reduces the pressure difference between the top and bottom of the vehicle, minimizing drag. Additionally, adding small spoilers or air dams at the front and rear can help direct airflow, further reducing drag and improving overall efficiency.

In addition to these design changes, the use of advanced materials can also contribute to better aerodynamics. Modern vehicles often employ lightweight, high-strength materials that not only reduce the overall weight of the car but also allow for more precise shaping. This precision in design enables engineers to create vehicles with a more streamlined silhouette, reducing the car's effective frontal area and, consequently, its drag coefficient.

By implementing these aerodynamic improvements, car manufacturers can significantly reduce the fuel consumption of their vehicles. Studies have shown that even small reductions in drag can lead to substantial fuel savings over the lifetime of a car. For example, a 5% reduction in drag can result in a 2-3% improvement in fuel efficiency, translating to hundreds of miles more range or reduced emissions for the same amount of fuel. Therefore, investing in aerodynamic design is a crucial step towards creating more efficient and environmentally friendly vehicles.

Fuel Included: Unlocking the Mystery of Car Rental Rates

You may want to see also

Frequently asked questions

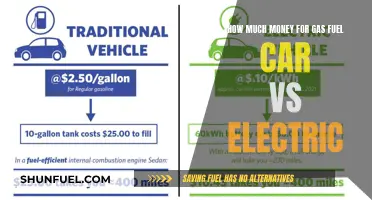

The amount of fuel wasted in a car can vary significantly depending on various factors such as driving habits, vehicle efficiency, and environmental conditions. On average, a typical car can waste around 5-10% of its fuel due to inefficiencies in the engine, air conditioning, and other accessories. However, this percentage can be reduced with proper maintenance and adopting fuel-efficient driving practices.

Fuel wastage in cars is primarily caused by several factors. One major reason is engine inefficiency, where the engine struggles to maintain optimal performance, leading to increased fuel consumption. Additionally, factors like excessive idling, poor tire pressure, and the use of air conditioning or heating systems can contribute to fuel wastage. Regular vehicle maintenance and adopting a more fuel-conscious driving style can help minimize these losses.

Absolutely! Regular maintenance plays a crucial role in reducing fuel waste. By ensuring your car receives routine check-ups, including engine tune-ups, replacing worn-out parts, and keeping the air filter clean, you can improve engine efficiency. Proper maintenance also involves checking and adjusting tire pressure, which directly impacts fuel efficiency. Additionally, regular oil changes and engine diagnostics can identify and rectify issues that may lead to unnecessary fuel consumption.