Derby cars, a thrilling sport that combines speed and precision, are known for their impressive performance on the track. However, the question of how much fuel these high-speed vehicles consume is an important one, as it directly impacts their efficiency and sustainability. Understanding the fuel usage of derby cars is crucial for optimizing their performance, ensuring fair competition, and promoting environmentally conscious racing practices. This paragraph aims to delve into the factors that influence fuel consumption in derby cars and explore the strategies teams employ to manage their fuel usage effectively.

What You'll Learn

Fuel Efficiency: How much fuel is used per mile or kilometer

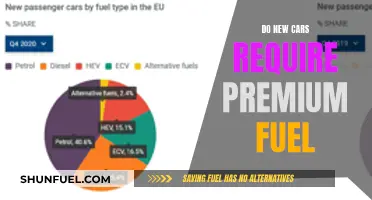

The fuel efficiency of a derby car is a critical aspect of its performance and design. When discussing fuel efficiency, we are primarily concerned with how much fuel the car consumes per mile or kilometer traveled. This metric is essential for understanding the car's efficiency and its impact on the environment.

In the context of derby cars, which are typically high-performance vehicles designed for speed and agility, fuel efficiency is a challenging aspect to optimize. These cars often have powerful engines, which require a significant amount of fuel to operate. The efficiency of a derby car is influenced by various factors, including engine design, aerodynamics, and the car's overall weight.

To calculate fuel efficiency, you would need to measure the amount of fuel consumed during a specific test drive or race and then divide it by the distance traveled. For example, if a derby car uses 10 gallons of fuel to complete a 100-mile race, its fuel efficiency would be 10 gallons per 100 miles, or 0.1 gallons per mile. This calculation provides a clear indication of how much fuel the car uses per mile, which is a key performance indicator.

Several factors contribute to the fuel consumption of derby cars. Firstly, the engine's power output plays a significant role. High-performance engines with larger displacements tend to consume more fuel. Secondly, the car's aerodynamics are crucial. A well-designed body with minimal drag can reduce fuel consumption by optimizing air flow around the vehicle. Additionally, the car's weight directly affects fuel efficiency; lighter cars generally require less fuel to accelerate and maintain speed.

Improving fuel efficiency in derby cars often involves a trade-off between power and economy. Engineers might focus on optimizing the engine's performance while also reducing its fuel consumption. This could include using advanced materials for lighter construction, improving engine management systems, or implementing hybrid or electric powertrains, which can significantly enhance fuel efficiency without compromising performance. Understanding and optimizing fuel efficiency is essential for both racing teams and manufacturers, as it directly impacts the car's performance, cost, and environmental impact.

AC in Cars: Fuel Efficiency and Comfort Trade-Offs

You may want to see also

Engine Power: Impact of engine power on fuel consumption

The power output of an engine is a critical factor in determining fuel consumption, especially in high-performance vehicles like derby cars. Engine power, measured in horsepower (hp) or kilowatts (kW), represents the rate at which an engine can produce energy. When an engine generates more power, it requires more fuel to operate, as the engine needs to work harder to accelerate, maintain speed, and overcome resistance. This relationship between engine power and fuel consumption is a fundamental principle in automotive engineering.

In the context of derby cars, which are designed for speed and performance, engine power plays a pivotal role in determining their fuel efficiency. These vehicles are built to reach and maintain high speeds, requiring substantial power to overcome aerodynamic drag, tire traction, and other forces acting against their motion. As engine power increases, the engine's ability to convert fuel into useful work also increases, resulting in higher fuel consumption. This is because more powerful engines demand more fuel to operate at their peak performance levels.

The impact of engine power on fuel consumption can be understood through the concept of specific fuel consumption (SFC), which is the amount of fuel consumed per unit of power output. Higher engine power generally leads to a higher SFC, meaning that more fuel is required to generate a given amount of power. This is why derby cars with powerful engines tend to consume more fuel, especially during high-speed runs or when pushing the vehicle to its limits.

Engineers and designers must carefully consider the power-to-weight ratio of a derby car to optimize fuel efficiency. A higher power-to-weight ratio indicates a more powerful engine relative to the vehicle's weight, which can lead to increased fuel consumption. Balancing engine power with weight reduction techniques, such as lightweight materials and efficient aerodynamics, is essential to minimize fuel usage without compromising performance.

In summary, engine power has a direct and significant impact on fuel consumption in derby cars. Higher power outputs require more fuel to operate, making fuel efficiency a critical consideration in the design and engineering of these high-performance vehicles. Understanding this relationship allows engineers to optimize power delivery while minimizing fuel usage, ensuring that derby cars can achieve their speed and performance goals while maintaining efficiency.

The Role of Cars in Sustaining Racial Inequality

You may want to see also

Aerodynamics: Design influences fuel efficiency in high-speed racing

Aerodynamics plays a pivotal role in the fuel efficiency of high-speed racing cars, particularly in events like the Derby. The design of these vehicles is meticulously crafted to optimize performance while minimizing fuel consumption. One of the primary considerations is the reduction of drag, which is the force that opposes the motion of the car as it moves through the air. By streamlining the body and reducing the frontal area, engineers can significantly decrease drag, allowing the car to cut through the air more efficiently. This is achieved through careful shaping and the use of smooth, curved surfaces, often incorporating intricate details to manage airflow.

The front end of the car is a critical area for aerodynamic design. Designers aim to create a smooth, streamlined nose that redirects airflow, reducing the pressure and drag experienced at the front. This involves intricate work on the front bumper, grille, and air intakes to ensure minimal disruption to airflow. Additionally, side mirrors and rearview cameras are strategically positioned to avoid creating turbulent eddies that could increase drag.

Another crucial aspect is the design of the car's underbody. By carefully shaping the underbody panels and incorporating diffusers, engineers can manage airflow beneath the vehicle, reducing drag and improving stability at high speeds. This technique, known as ground effect, helps to maintain contact between the car and the track, enhancing cornering capabilities and overall performance. The underbody design also includes air vents and ducts to manage engine cooling, ensuring optimal performance without compromising fuel efficiency.

Aerodynamic testing and simulation are essential tools in the development process. Wind tunnel tests allow engineers to study airflow around the car at various speeds and angles, identifying areas of high drag and inefficiency. Computer simulations further enhance this process, providing detailed data on airflow patterns and pressure distribution. These simulations enable designers to make informed decisions, making iterative improvements to the car's aerodynamics.

In high-speed racing, where fuel efficiency is a critical factor, the right aerodynamic design can make a significant difference. By optimizing the car's shape and managing airflow, engineers can reduce drag, improve stability, and enhance overall performance. This not only contributes to better lap times but also ensures that the car can maintain its speed and efficiency over extended periods, making the most of the fuel it carries. The intricate balance between aerodynamics and other performance aspects is what makes high-speed racing cars so fascinating and challenging to design.

Fuel Cleaner: Does It Boost Performance in Modern Engines?

You may want to see also

Weight Distribution: Lighter cars generally use less fuel

Weight distribution plays a crucial role in determining fuel efficiency, especially in high-performance vehicles like derby cars. The principle is simple: the lighter the car, the less fuel it will consume. This is primarily due to the relationship between weight and power output. Heavier vehicles require more power to accelerate and maintain speed, which directly translates to increased fuel consumption. In contrast, lighter cars can achieve the same performance with less power, resulting in improved fuel efficiency.

The design and construction of a derby car must consider weight distribution carefully. Every component, from the chassis to the body and even the driver's weight, contributes to the overall weight of the vehicle. Engineers aim to minimize this weight while maintaining the structural integrity and safety of the car. This involves using lightweight materials such as carbon fiber composites, advanced alloys, and even lightweight batteries for electric derby cars. By reducing the overall weight, the car can achieve better acceleration, higher top speeds, and, most importantly, improved fuel efficiency.

One effective strategy to reduce weight is to optimize the vehicle's design. This includes streamlining the body to reduce aerodynamic drag, which is a significant factor in fuel consumption. A well-designed body can minimize the air resistance encountered by the car, allowing it to glide more efficiently through the air. Additionally, the placement of heavy components, such as the engine and batteries, should be optimized to ensure a balanced weight distribution. This balance ensures that the car's center of gravity remains low, which is essential for stability and handling during high-speed maneuvers.

Furthermore, the use of advanced materials can significantly impact weight reduction. Carbon fiber composites, for instance, offer an excellent strength-to-weight ratio, making them ideal for structural components. These materials can replace heavier metals without compromising the car's structural integrity. Lightweight alloys, such as those used in aircraft manufacturing, can also be employed for various parts, further reducing the overall weight.

In summary, weight distribution is a critical factor in fuel efficiency, especially in high-performance derby cars. By employing lightweight materials, optimizing vehicle design, and strategically placing components, engineers can create cars that are both powerful and fuel-efficient. This approach not only benefits the environment by reducing fuel consumption but also enhances the overall performance and competitiveness of the derby car.

Infiniti Fuel Pumps: Powering the Luxury Brand's Performance

You may want to see also

Tire Pressure: Optimal tire pressure reduces fuel usage

Tire pressure plays a significant role in a derby car's fuel efficiency, and maintaining optimal tire pressure is crucial for reducing fuel consumption. When tires are underinflated, they create more rolling resistance, which directly impacts the car's fuel economy. This is because underinflated tires have a larger contact patch with the road, leading to increased friction and energy loss. As a result, the engine has to work harder to overcome this resistance, burning more fuel in the process.

The relationship between tire pressure and fuel usage is quite straightforward. For every 1 psi (pound per square inch) drop in tire pressure, the fuel consumption can increase by approximately 3%. This might not seem like a significant amount, but over the course of a race or a long-distance event, these small increases can add up to substantial fuel savings. For instance, if a derby car's tires are 2 psi under the recommended pressure, it could lead to an extra 6% in fuel usage, which is a considerable amount of fuel over the duration of a race.

Optimal tire pressure is not just about fuel efficiency; it also contributes to better handling and tire longevity. When tires are properly inflated, they provide a smoother ride, reducing wear and tear. This is especially important in derby car racing, where tires can experience significant stress and heat. Proper tire pressure ensures that the tires maintain their shape and structure, preventing uneven wear and potential blowouts, which can be dangerous and costly.

To achieve optimal tire pressure, it's essential to regularly check and adjust the tires. Modern cars often have tire pressure monitoring systems (TPMS) that alert drivers when the pressure is low. However, for derby cars, which may have unique specifications, it's recommended to consult the vehicle's manual or seek professional advice. The ideal pressure can vary depending on factors such as tire type, load, and temperature.

In summary, maintaining the correct tire pressure is a simple yet effective way to reduce fuel consumption in derby cars. It not only improves fuel efficiency but also enhances overall performance and tire health. By ensuring that tires are properly inflated, derby car enthusiasts can make their vehicles more efficient and potentially gain a competitive edge in their racing endeavors.

Green Energy: The Future of Car Fuel in Plants

You may want to see also

Frequently asked questions

The fuel consumption of a derby car can vary significantly depending on several factors, including the car's design, engine power, driver's style, and track conditions. On average, a well-maintained derby car might use around 1-2 gallons of fuel per lap, but this can range from as little as 0.5 gallons to over 3 gallons per lap, especially during high-speed sections or intense competition.

Yes, many teams employ various strategies to optimize fuel efficiency. These include aerodynamic improvements to reduce drag, lightweight materials to decrease the car's overall weight, and efficient engine management systems. Some cars also utilize regenerative braking systems, which recover energy that would otherwise be lost as heat during braking, thus improving overall fuel efficiency.

Derby car racing often has strict rules and regulations to ensure fair competition and safety. These rules may include specifications for fuel type, octane rating, and the maximum amount of fuel a car can carry. For instance, some racing series might limit the total fuel capacity to a certain number of gallons, while others may restrict the use of high-octane fuels. These regulations are designed to manage the cost of racing and ensure that all cars have a similar power-to-weight ratio, creating a more competitive environment.