The weight of a car's fuel tank is a crucial factor in vehicle performance and efficiency. Understanding the weight of a fuel tank is essential for drivers and mechanics alike, as it can impact fuel economy, vehicle handling, and overall safety. This paragraph will explore the factors that determine the weight of a car's fuel tank and provide insights into how different vehicles handle fuel storage.

What You'll Learn

- Fuel Type: Different fuels have varying densities, affecting tank weight

- Tank Material: Steel, aluminum, and composites impact weight and durability

- Size and Capacity: Larger tanks weigh more, but capacity is crucial

- Design and Efficiency: Advanced designs can reduce weight without compromising fuel capacity

- Environmental Factors: Temperature and altitude can influence fuel density and tank weight

Fuel Type: Different fuels have varying densities, affecting tank weight

The weight of a car's fuel tank is influenced by the type of fuel it holds, as different fuels have distinct densities. This density directly impacts the overall weight of the tank, which is a crucial factor in vehicle design and performance. For instance, gasoline has a lower density compared to diesel, which means that a gasoline tank will generally weigh less than a diesel tank of the same capacity. This difference in density is primarily due to the molecular structure and composition of the fuel. Gasoline molecules are less dense and more spread out, resulting in a lighter fuel. On the other hand, diesel fuel has a higher density and more compact molecular structure, leading to a heavier fuel and, consequently, a heavier tank.

The varying densities of fuels have practical implications for vehicle manufacturers. When designing a vehicle, engineers must consider the weight distribution and overall balance. A lighter fuel tank can contribute to better handling and improved fuel efficiency, especially in high-performance vehicles where weight reduction is essential. However, it's important to note that the weight of the fuel tank is not the sole determinant of a vehicle's performance. Other factors, such as engine power, aerodynamics, and tire pressure, also play significant roles in a vehicle's overall efficiency and driving experience.

In the context of fuel efficiency, the density of the fuel becomes even more critical. Vehicles with smaller fuel tanks may be more fuel-efficient, but they also require more frequent refueling. The trade-off between tank size and fuel efficiency is a delicate balance that engineers strive to optimize. For instance, hybrid vehicles often utilize smaller fuel tanks to accommodate their additional battery systems, further emphasizing the importance of understanding fuel density and its impact on vehicle design.

Furthermore, the weight of the fuel tank can affect the vehicle's center of gravity. A heavier fuel tank, especially when filled with denser fuels like diesel, can lower the vehicle's center of gravity, potentially improving stability and handling. This is particularly relevant for off-road vehicles or those designed for heavy-duty applications, where maintaining a low center of gravity is essential for safety and performance.

In summary, the type of fuel a car's tank holds significantly influences its weight. Gasoline tanks are generally lighter due to the lower density of gasoline, while diesel tanks are heavier. This knowledge is vital for vehicle manufacturers to optimize design, performance, and fuel efficiency. Understanding the relationship between fuel type and density is a key consideration in the complex process of creating efficient and well-balanced vehicles.

The Fuel-Wasting Truth: Does Idling Drain Your Car's Gas?

You may want to see also

Tank Material: Steel, aluminum, and composites impact weight and durability

The weight of a car fuel tank is a critical factor in vehicle design and performance, especially when considering fuel efficiency and overall vehicle weight. The choice of material for the fuel tank significantly influences its weight and, consequently, the vehicle's overall weight. Three primary materials are commonly used for fuel tanks: steel, aluminum, and composites. Each material offers unique advantages and disadvantages in terms of weight and durability.

Steel Tanks:

Steel fuel tanks are known for their durability and strength. They provide excellent protection against punctures and impacts, ensuring the safe containment of fuel. However, steel tanks are significantly heavier than their aluminum and composite counterparts. The density of steel means that a steel fuel tank will weigh more, which can impact the vehicle's fuel efficiency. Despite the increased weight, steel tanks are often preferred in high-performance vehicles or those operating in harsh environments where durability is a priority.

Aluminum Tanks:

Aluminum is a popular choice for fuel tanks due to its lightweight properties. It offers a good balance between weight and durability. Aluminum tanks are less dense than steel, resulting in a lighter fuel tank. This reduction in weight can contribute to improved fuel efficiency, which is a significant advantage for vehicle manufacturers and drivers alike. Additionally, aluminum is known for its corrosion resistance, ensuring the tank's longevity, especially in vehicles exposed to varying weather conditions.

Composite Tanks:

Composite materials, often a blend of polymers and fibers, offer a unique solution for fuel tanks. These tanks can be designed to be lightweight and durable, providing excellent impact resistance. Composites excel in weight reduction compared to steel and aluminum, making them ideal for vehicles aiming to maximize fuel efficiency. The composite material's ability to be tailored to specific strengths and weaknesses allows for the creation of fuel tanks that are both lightweight and robust. However, the manufacturing process for composite tanks can be more complex and costly, which may limit their use in certain applications.

In summary, the choice of material for a car fuel tank is a critical decision that impacts both the vehicle's performance and its overall weight. Steel tanks offer durability but at the cost of increased weight, while aluminum and composite tanks provide lightweight solutions with varying levels of durability. The material selection ultimately depends on the specific requirements of the vehicle, considering factors such as performance, fuel efficiency, and environmental conditions.

Misfire Mystery: Uncover the Fuel Filter's Role

You may want to see also

Size and Capacity: Larger tanks weigh more, but capacity is crucial

The weight of a car's fuel tank is an important consideration for vehicle owners and enthusiasts, especially when it comes to performance and fuel efficiency. One of the primary factors influencing the weight of a fuel tank is its size and capacity. Larger fuel tanks, while offering the advantage of increased range, inherently weigh more due to the additional material required to construct them. This is a fundamental trade-off that vehicle manufacturers must consider when designing cars.

In the context of automotive engineering, the size of the fuel tank directly correlates with its weight. A larger tank, typically measured in liters or gallons, will contain more fuel, which means it will also be heavier. For instance, a 60-liter tank will weigh more than a 40-liter tank, all else being equal. This relationship is crucial for vehicle dynamics, as a heavier fuel tank can impact the overall weight distribution and, consequently, the car's handling and performance characteristics.

Capacity, in this case, refers to the volume of fuel the tank can hold. While larger tanks provide a longer driving range, they also contribute to a higher vehicle weight. This is particularly significant in high-performance or sports cars, where every kilogram matters in terms of acceleration, braking, and overall driving experience. Engineers often face the challenge of balancing the need for sufficient fuel capacity with the desire for lightweight construction.

The design of fuel tanks also plays a role in their weight. Modern tanks are often made from lightweight materials such as aluminum or advanced composites, which help reduce overall vehicle weight. These materials are chosen for their strength-to-weight ratio, allowing engineers to create larger tanks without significantly increasing the car's overall mass. As a result, drivers can enjoy extended travel distances without compromising on performance.

In summary, the size and capacity of a car's fuel tank are critical factors in determining its weight. Larger tanks offer increased range but come at the cost of additional weight. Vehicle manufacturers must carefully consider these trade-offs to ensure optimal performance, fuel efficiency, and a positive driving experience. Understanding these relationships is essential for anyone interested in the intricate details of automotive engineering and vehicle design.

Exploring the Feasibility of Using Aviation Fuel in Cars

You may want to see also

Design and Efficiency: Advanced designs can reduce weight without compromising fuel capacity

The weight of a car's fuel tank is a critical consideration in vehicle design, as it directly impacts performance, fuel efficiency, and overall driving experience. While the primary function of a fuel tank is to store gasoline or diesel, its design plays a significant role in determining the vehicle's weight and, consequently, its fuel efficiency. Advanced engineering techniques have led to the development of lightweight fuel tanks that offer improved performance without sacrificing fuel capacity.

One of the key strategies to reduce the weight of fuel tanks is through innovative design and material selection. Engineers are increasingly utilizing advanced materials such as lightweight composites, including carbon fiber-reinforced polymers (CFRP). These materials offer an exceptional strength-to-weight ratio, allowing for the creation of robust yet lightweight fuel tanks. By replacing traditional steel or aluminum structures with these advanced composites, manufacturers can significantly reduce the overall weight of the vehicle while maintaining the necessary fuel capacity. This approach not only enhances fuel efficiency but also contributes to improved handling and acceleration, making the vehicle more responsive and enjoyable to drive.

In addition to material advancements, engineers are employing sophisticated design techniques to optimize the shape and structure of fuel tanks. The design process involves meticulous calculations and simulations to ensure that the tank's dimensions are tailored to the specific requirements of the vehicle. By minimizing dead weight and optimizing the distribution of fuel, these designs can reduce the overall weight of the tank without compromising its ability to store the required fuel volume. This level of precision in design is crucial for achieving the desired weight reduction while maintaining the vehicle's performance and safety standards.

Another aspect of advanced fuel tank design is the implementation of lightweight mounting systems. The fuel tank's mounting points are often a significant contributor to overall weight, especially in traditional designs. By employing lightweight mounting brackets and suspension systems, engineers can further reduce the weight of the fuel tank assembly. This optimization ensures that the fuel tank's weight is efficiently distributed throughout the vehicle, contributing to a more balanced and responsive driving experience.

Furthermore, the integration of advanced fuel tank technologies can lead to improved fuel efficiency. Modern fuel tanks are equipped with sophisticated monitoring systems that optimize fuel delivery and reduce wastage. These systems ensure that the engine receives the precise amount of fuel required, minimizing fuel consumption and, consequently, reducing the overall weight of the fuel tank. With these advancements, manufacturers can achieve a delicate balance between weight reduction and fuel capacity, resulting in vehicles that are both efficient and high-performing.

Car Starting Without Fuel Pump: What You Need to Know

You may want to see also

Environmental Factors: Temperature and altitude can influence fuel density and tank weight

The weight of a car's fuel tank is influenced by various factors, and understanding these environmental impacts is crucial for vehicle owners and mechanics alike. One significant factor is temperature, which plays a pivotal role in determining the density of the fuel. As temperature decreases, the density of the fuel increases, leading to a heavier fuel tank. This phenomenon is particularly noticeable in colder climates or at higher altitudes, where the air is thinner and the temperature drops significantly. For instance, a fuel tank that might weigh 15 pounds at sea level could weigh up to 20 pounds in colder conditions, a difference that can affect the overall weight distribution of the vehicle.

Altitude also has a substantial impact on fuel tank weight. At higher elevations, the air pressure and temperature are lower, causing the fuel to expand and occupy more space. This expansion results in a decrease in fuel density, which, in turn, reduces the weight of the fuel tank. Conversely, at lower altitudes, the fuel density is higher, and the tank weighs more. The relationship between altitude and fuel weight is particularly important for vehicles operating in mountainous regions or at varying elevations, as it can affect performance and fuel efficiency.

The environmental conditions can also impact the overall weight of the fuel tank. In colder climates, the fuel may require a fuel heater to maintain optimal performance, adding a small amount of weight to the tank. Additionally, the type of fuel used can influence weight; for example, ethanol-blended fuels may have different density characteristics compared to conventional gasoline or diesel. These factors, combined with temperature and altitude, contribute to the complex relationship between environmental conditions and fuel tank weight.

Understanding these environmental influences is essential for vehicle maintenance and performance optimization. Mechanics and car owners should consider the impact of temperature and altitude when assessing fuel tank weight, especially in regions with varying climates. By recognizing these factors, one can make informed decisions regarding fuel management, vehicle performance, and potential adjustments to accommodate different environmental conditions.

In summary, temperature and altitude are critical environmental factors that directly affect fuel density and, consequently, the weight of a car's fuel tank. The interplay between these elements and other variables, such as fuel type and additional equipment, highlights the complexity of determining fuel tank weight. Being aware of these influences is vital for ensuring optimal vehicle performance and fuel efficiency across diverse geographical locations.

Gumout Fuel Cleaner: Safe for E85 Engines?

You may want to see also

Frequently asked questions

The weight of a car fuel tank can vary significantly depending on several factors. On average, a standard fuel tank for a passenger car can weigh around 15 to 30 kilograms (33 to 66 pounds). However, this can range from as little as 10 kg (22 lbs) for smaller vehicles to over 50 kg (110 lbs) for larger SUVs or trucks.

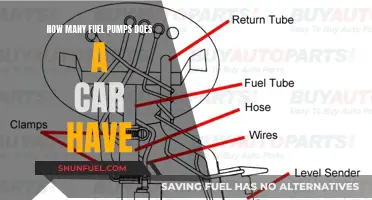

The weight is primarily influenced by the tank's capacity, material, and design. Larger tanks will naturally weigh more due to increased volume. The material used, such as steel or aluminum, also affects the weight. For instance, aluminum tanks are often lighter than steel ones. Additionally, the shape and design of the tank can impact its overall weight distribution.

While the weight of the fuel tank itself might not have a significant impact on a vehicle's overall performance, it can play a role in fuel efficiency and handling. A heavier fuel tank may contribute to a slight increase in the vehicle's overall weight, which could lead to a marginal reduction in fuel efficiency. However, this effect is usually minimal and often not noticeable in everyday driving.