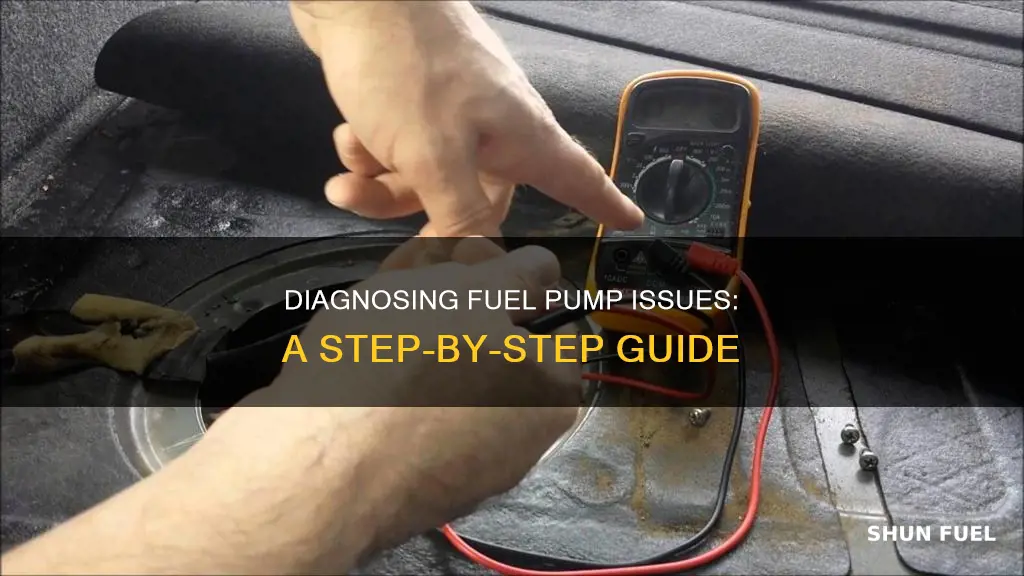

Fuel pump replacement is a common automotive repair, but diagnosing the need for this replacement can be tricky. The fuel pump is a critical component that delivers fuel from the tank to the engine, and issues with it can lead to poor performance or even engine failure. Diagnosing a faulty fuel pump often involves a systematic approach, starting with a visual inspection to check for any visible signs of damage or wear. Mechanics may also use diagnostic tools like scan tools or code readers to identify error codes related to the fuel system. Additionally, they might perform pressure tests to measure the pump's output and listen for any unusual noises that could indicate a failing pump. Understanding these diagnostic steps is essential for mechanics to accurately identify and address fuel pump issues.

| Characteristics | Values |

|---|---|

| Common Symptoms | Engine stalls or hesitates, reduced power, hard starting, frequent stalling during acceleration, fuel odor in the exhaust, and check engine light illumination. |

| Diagnostic Tools | Scan tool, fuel pressure gauge, engine diagnostic scanner, and visual inspection. |

| Steps | 1. Inspect the fuel lines for leaks. 2. Check the fuel filter for contamination or clogs. 3. Use a fuel pressure gauge to measure pressure at the fuel rail. 4. Test the fuel pump's electrical connections. 5. Listen for the pump's operation with the engine off. 6. If symptoms persist, replace the fuel pump. |

| Additional Tips | Ensure the vehicle is properly diagnosed for other potential issues before replacing the pump. Always refer to the vehicle's manual for specific instructions and safety precautions. |

What You'll Learn

- Visual Inspection: Check for visible damage, corrosion, or debris around the fuel pump

- Test Equipment: Utilize a fuel pressure gauge to measure pressure and identify leaks

- Engine Diagnostics: Use an OBD scanner to read error codes related to the fuel system

- Fuel Filter Check: Inspect and replace if clogged, affecting pump performance

- Professional Tools: Employ specialized tools like a fuel pump flow meter for accurate diagnosis

Visual Inspection: Check for visible damage, corrosion, or debris around the fuel pump

When performing a visual inspection to diagnose fuel pump replacement, it's crucial to carefully examine the area around the fuel pump for any signs of damage, corrosion, or debris. This initial assessment can provide valuable insights into the overall health and condition of the fuel system. Start by accessing the fuel pump, which is typically located near the engine or in the fuel tank, depending on the vehicle's design. Inspect the pump for any visible signs of impact damage, such as dents or scratches, which could indicate a previous collision or mishandling. Look for corrosion, especially in areas where the pump is exposed to moisture or harsh environmental conditions. Corrosion can lead to electrical issues and reduced pump performance. Check for any signs of debris or foreign matter around the pump, including dirt, rust, or even small stones. These particles can interfere with the pump's operation and potentially cause damage over time. Pay attention to the electrical connections and wiring harnesses connected to the fuel pump. Ensure they are secure and free from any signs of corrosion or damage. If any corrosion or debris is found, it may indicate a need for further investigation or potential replacement of the fuel pump or related components.

During the visual inspection, it's essential to document any issues or concerns. Take detailed notes or photographs to provide a comprehensive record of the fuel pump's condition. This documentation can be valuable when discussing the diagnosis with a mechanic or when making decisions about the next steps in the repair process. Additionally, consider the vehicle's maintenance history and any previous issues related to the fuel system. This information can help in understanding the potential causes of current problems and guide the decision-making process regarding fuel pump replacement.

The visual inspection is a critical step in diagnosing fuel pump replacement as it allows for an early detection of potential issues. By carefully examining the fuel pump and its surroundings, you can identify problems that may require immediate attention or further investigation. This proactive approach can help prevent more extensive damage to the fuel system and ensure the vehicle's optimal performance. Remember, a thorough visual inspection can save time and resources by identifying potential issues before they escalate, making it an essential skill for vehicle owners and mechanics alike.

Replacing Fuel Pump in '05 Mustang: Step-by-Step Guide

You may want to see also

Test Equipment: Utilize a fuel pressure gauge to measure pressure and identify leaks

When diagnosing fuel pump replacement, utilizing a fuel pressure gauge is an essential tool for identifying issues and ensuring proper functionality. This gauge measures the pressure of the fuel system, providing valuable insights into its performance. Here's a step-by-step guide on how to use a fuel pressure gauge effectively:

Preparation: Before beginning the test, ensure you have the correct fuel pressure gauge for your vehicle's fuel system. Different vehicles may require specific gauge types, so it's crucial to choose the right one. Additionally, locate the fuel pressure test port, which is typically a small opening on the fuel rail or a dedicated port on the engine. This port allows access to the fuel system for measurement.

Measurement: Start by disconnecting the negative battery cable to ensure the engine doesn't start accidentally during the test. Then, securely attach the fuel pressure gauge to the test port. The gauge will provide a reading, indicating the fuel pressure in the system. Note the pressure value, as it should fall within a specific range for your vehicle. If the pressure is significantly higher or lower than the expected range, it may indicate a potential issue with the fuel pump or related components.

Leak Detection: Fuel pressure gauges are also useful for identifying leaks in the fuel system. After taking the initial pressure reading, release the gauge and observe if the pressure drops rapidly. A significant drop in pressure suggests a leak, as fuel is escaping the system. Common leak points include damaged fuel lines, faulty fuel injectors, or a compromised fuel pump. It's important to address these leaks promptly to prevent fuel wastage and potential engine performance issues.

Comparison and Analysis: Compare the measured fuel pressure with the manufacturer's specifications for your vehicle. Most automotive manuals provide the ideal fuel pressure range for different engine types. If your measurement deviates significantly from the specified range, it may indicate a malfunctioning fuel pump or other related issues. Additionally, consider the engine's operating conditions; fuel pressure requirements may vary during idling, acceleration, or high-load conditions.

By utilizing a fuel pressure gauge, you can systematically diagnose fuel pump-related problems and ensure the overall health of your vehicle's fuel system. This test equipment is a valuable addition to any mechanic's toolkit, enabling efficient and accurate fuel pump replacement diagnostics.

Replacing Stihl MS291 Fuel Filter: Step-by-Step Guide

You may want to see also

Engine Diagnostics: Use an OBD scanner to read error codes related to the fuel system

When it comes to diagnosing fuel pump replacement issues, using an On-Board Diagnostics (OBD) scanner is a valuable tool for mechanics and car owners alike. This technology allows for the retrieval of error codes related to the fuel system, providing insights into potential problems that might otherwise be difficult to detect. Here's a step-by-step guide on how to utilize an OBD scanner for engine diagnostics related to the fuel system:

Step 1: Connect the OBD Scanner

Start by connecting the OBD scanner to your vehicle's diagnostic port, which is typically located under the dashboard on the driver's side. Ensure that the scanner is compatible with your car's OBD system (either OBD-I or OBD-II). Once connected, the scanner will communicate with the vehicle's computer, allowing you to access various diagnostic trouble codes.

Step 2: Retrieve Error Codes

Power on the OBD scanner and follow the manufacturer's instructions to initiate the error code retrieval process. The scanner will scan the vehicle's memory for any stored error codes related to the fuel system. These codes are usually specific to the make and model of your car. Common fuel-related error codes include issues with the fuel pump, injectors, sensors, or the fuel pressure regulator.

Step 3: Interpret the Error Codes

After retrieving the error codes, carefully review the scanner's display. Each code will provide information about the specific component or system that is malfunctioning. For instance, a code related to the fuel pump might indicate a problem with the pump's operation, such as inadequate pressure or failure to prime. Understanding these codes is crucial in diagnosing the root cause of the fuel-related issue.

Step 4: Prioritize Repairs

Based on the error codes, prioritize the necessary repairs or replacements. For example, if multiple fuel-related codes are present, it may indicate a more comprehensive issue with the fuel system. In such cases, addressing the underlying problem, such as a failing fuel pump, might be more effective than replacing individual components. The OBD scanner helps in identifying the most critical areas that require attention.

Step 5: Verify and Test

Once the repairs or replacements are made, it is essential to clear the error codes and retest the fuel system. Use the OBD scanner again to ensure that the issue has been resolved. If the error codes persist, further investigation may be required to identify any additional problems. This process ensures that the fuel pump replacement, or any other fuel-related repairs, are effective and long-lasting.

By utilizing an OBD scanner for engine diagnostics, car owners and mechanics can efficiently identify and address fuel system issues. This method provides a systematic approach to troubleshooting, ensuring that the root cause of the problem is accurately diagnosed and resolved.

Replacing Workhorse W22 Fuel Pump: Step-by-Step Guide

You may want to see also

Fuel Filter Check: Inspect and replace if clogged, affecting pump performance

Fuel filter checks are an essential part of maintaining a vehicle's fuel system and ensuring optimal performance. Over time, fuel filters can become clogged with contaminants, which can have a direct impact on the fuel pump's efficiency and overall engine operation. Here's a step-by-step guide on how to inspect and replace a fuel filter to address potential issues:

Step 1: Locate the Fuel Filter

Start by familiarizing yourself with your vehicle's fuel system layout. The fuel filter is typically located near the engine, often along the fuel line or in the fuel tank. Consult your vehicle's manual or online resources to identify the exact location. It is usually accessible without removing major components.

Step 2: Inspect for Clogging

Carefully inspect the fuel filter for any signs of clogging or contamination. Look for visible debris, dirt, or rust-colored particles in the filter housing. Clogged filters may also show signs of moisture or a foul odor due to the accumulation of contaminants. If you notice any of these issues, it's an indication that the filter needs to be replaced.

Step 3: Remove and Replace the Filter

- Drain the fuel system: Before replacing the filter, it's crucial to drain the fuel system to prevent any spills or mess. Locate the fuel drain valve, usually found near the fuel tank, and open it to release the fuel.

- Remove the filter: Carefully unscrew or unclip the old fuel filter, ensuring you have a clean workspace. Take note of the filter's orientation to facilitate the installation of the new one.

- Install the new filter: Clean the mounting surface and insert the new fuel filter, ensuring it is properly aligned and secured. Tighten any screws or clips to hold it in place.

Step 4: Check Pump Performance

After replacing the fuel filter, it's essential to verify that the fuel pump is functioning correctly. Start the engine and listen for any unusual noises, such as humming or whining, which could indicate a faulty pump. Check for proper fuel flow by monitoring the fuel gauge or using a fuel pressure gauge (if available) to ensure the pump is delivering the correct pressure.

Regularly inspecting and replacing the fuel filter can help prevent pump issues and maintain a healthy fuel supply to the engine. This simple maintenance task can save you from potential fuel-related problems and ensure your vehicle's engine operates efficiently. Remember, if you're unsure about any step, consulting a professional mechanic is always an option to ensure the job is done correctly.

Replacing Honda GX200 Fuel Tank: Step-by-Step Guide

You may want to see also

Professional Tools: Employ specialized tools like a fuel pump flow meter for accurate diagnosis

When it comes to diagnosing and replacing a fuel pump, professionals rely on specialized tools to ensure an accurate and efficient process. One crucial tool in their arsenal is the fuel pump flow meter. This device plays a vital role in assessing the performance of the fuel pump and identifying any potential issues.

A fuel pump flow meter is designed to measure the volume of fuel being delivered to the engine. It works by creating a precise measurement of the fuel flow rate, which is essential for proper engine operation. By connecting the flow meter to the fuel line, technicians can gather real-time data on the pump's performance. This data provides valuable insights into the pump's efficiency, pressure, and overall functionality.

The process begins with a thorough inspection of the fuel system. Technicians use the flow meter to measure the fuel pressure and flow rate at different operating conditions. By comparing these measurements with the manufacturer's specifications, they can pinpoint any deviations or abnormalities. For instance, if the flow rate is significantly lower than expected, it may indicate a clogged or malfunctioning fuel pump.

Furthermore, the fuel pump flow meter allows professionals to test the pump's response to various engine loads. By simulating different driving conditions, they can observe how the pump performs under stress. This testing helps identify any issues related to pump capacity, pressure regulation, or overall reliability. With this information, technicians can make informed decisions about the necessary repairs or replacements.

In summary, employing specialized tools like the fuel pump flow meter is essential for professionals when diagnosing fuel pump replacement. It enables accurate measurements, efficient troubleshooting, and informed decision-making. By utilizing these advanced tools, technicians can ensure that the fuel pump replacement process is carried out with precision and expertise.

Replacing Your 2002 VW Jetta Fuel Filter: Step-by-Step Guide

You may want to see also

Frequently asked questions

There are several signs that may indicate a failing or faulty fuel pump. These include difficulty starting the engine, especially during cold weather, weak or inconsistent engine performance, reduced fuel efficiency, and the presence of fuel odor in the cabin. If you notice any of these symptoms, it's advisable to have your vehicle inspected by a professional mechanic.

Fuel pump issues can arise from various factors. Common causes include age, excessive heat, contamination of the fuel, low-quality fuel, and mechanical wear and tear. Over time, fuel pumps can develop internal leaks, become corroded, or experience electrical problems, leading to their failure.

While some basic checks can be performed at home, diagnosing fuel pump issues accurately requires specialized knowledge and equipment. You can start by checking for fuel pressure using a gauge, listening for the fuel pump's operation when the engine is off, and inspecting the fuel lines for any signs of damage or leaks. However, for a precise diagnosis, it's best to consult a professional mechanic.

Replacing a fuel pump involves several steps and requires specific tools. Mechanics often use a fuel pressure gauge to measure and monitor pressure during the replacement process. They may also disconnect the fuel lines, drain the fuel tank, and carefully remove the old pump. The new pump is then installed, ensuring proper connections and seals.

Regular maintenance can help prevent fuel pump problems. It's essential to use high-quality fuel and keep the fuel tank full to prevent contamination. Regularly checking and replacing the fuel filter can also help maintain fuel system health. Additionally, ensuring that the fuel pump is properly lubricated and free from debris is crucial for its longevity.