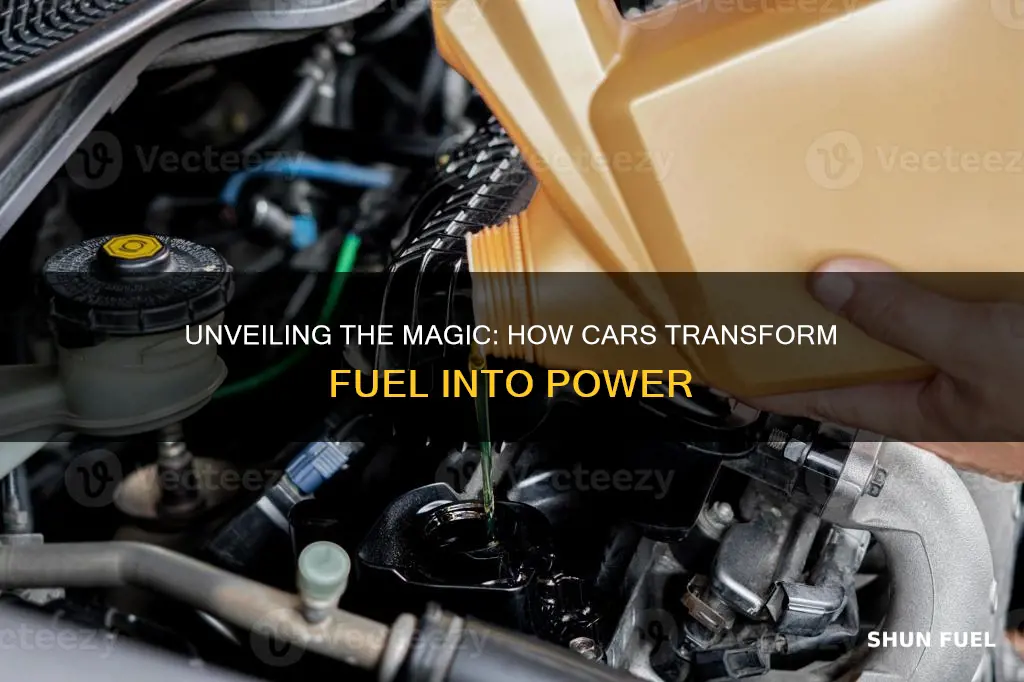

The process of converting fuel into energy in a car is a fascinating and complex mechanism that powers our vehicles. It begins with the combustion of gasoline or diesel in the engine's cylinders, where the fuel's chemical energy is released through a controlled burning process. This energy is then transformed into mechanical work, which ultimately turns the wheels and propels the car forward. The intricate dance of fuel, air, and engine components is a testament to the ingenuity of automotive engineering, allowing us to harness the power of fuel and transform it into the energy that keeps our vehicles running.

What You'll Learn

- Engine Combustion: Fuel ignites in cylinders, driving pistons and turning the crankshaft

- Power Generation: The crankshaft powers the alternator, which generates electricity for the car

- Transmission: Gear changes transfer power from the engine to the wheels

- Exhaust Systems: Catalytic converters reduce emissions and manage exhaust gases

- Efficiency: Engine design and materials optimize energy conversion and minimize waste

Engine Combustion: Fuel ignites in cylinders, driving pistons and turning the crankshaft

The process of converting fuel into energy in a car's engine is a fascinating and intricate dance of mechanics and chemistry. At the heart of this process lies the combustion chamber, specifically the engine cylinder, where the magic happens. When the engine is running, the piston moves up and down within the cylinder, creating a rhythmic cycle that is crucial to the engine's operation.

As the piston reaches the bottom of its stroke, it compresses the air-fuel mixture. This compression is a critical step, as it increases the temperature and pressure within the cylinder, creating the perfect environment for ignition. The air-fuel mixture is carefully composed, ensuring the right balance of fuel and air, which is essential for efficient combustion. This mixture is then injected into the cylinder, where it is carefully timed to be ignited by the spark plug.

The spark plug acts as a spark igniter, providing the necessary heat and energy to initiate the combustion process. When the spark plug fires, it creates a tiny explosion, igniting the air-fuel mixture. This controlled explosion is the essence of engine combustion. The rapid expansion of gases produced by this explosion exerts a tremendous force on the piston, causing it to move upward with great power. This upward movement of the piston is the driving force behind the engine's operation.

As the piston reaches the top of its stroke, it begins to push down, and the process repeats. The crankshaft, a vital component, is connected to the piston via a connecting rod. As the piston moves, it rotates the crankshaft, converting the linear motion into rotational energy. This rotational motion is then transferred to the engine's output shaft, which is connected to the transmission. The transmission, in turn, delivers the power to the wheels, propelling the vehicle forward.

In essence, engine combustion is a precise and powerful process. It involves the careful management of fuel and air, the precise timing of ignition, and the efficient conversion of energy. This intricate dance of mechanics and chemistry ensures that the car's engine can produce the necessary power to move the vehicle, all while maintaining a delicate balance between performance and efficiency. Understanding this process is key to appreciating the complexity and ingenuity of modern automobiles.

Unveiling the Secrets: How Car Makers Boost Engine Fuel Efficiency

You may want to see also

Power Generation: The crankshaft powers the alternator, which generates electricity for the car

The process of converting fuel into energy in a car is a complex system that involves multiple components working together. One crucial aspect of this process is power generation, which is primarily facilitated by the alternator. The alternator is an essential component that plays a vital role in keeping the car's electrical systems running smoothly.

When the engine is running, the crankshaft, a key component in the engine's mechanism, is in constant motion. This motion is a result of the engine's pistons compressing and expanding the air-fuel mixture, creating a power stroke. The crankshaft's job is to convert this linear motion into rotational energy. It does so by connecting to the camshaft and other engine components, ensuring the engine's valves open and close at the right times, and the pistons move in a coordinated manner.

As the crankshaft rotates, it drives the alternator, which is typically located near the front of the engine. The alternator is an electrical generator that converts mechanical energy into electrical energy. It consists of a rotating armature and a stationary stator. The armature is connected to the crankshaft via a belt or a pulley system, ensuring that it rotates at the same speed as the engine. Inside the alternator, the magnetic field of the stator induces an electric current in the armature, generating electricity.

This generated electricity is then used to power various electrical components in the car, such as the headlights, radio, air conditioning, and the car's various electronic systems. The alternator's efficiency is crucial as it ensures that the car's electrical needs are met while the engine is running. Modern cars often have sophisticated alternators that can handle higher electrical demands, especially with the increasing number of electronic features in modern vehicles.

In summary, the crankshaft's role in power generation is to drive the alternator, which then converts mechanical energy into electrical energy. This process is fundamental to the overall fuel conversion process, ensuring that the car's electrical systems receive the necessary power to function optimally. Understanding these mechanical and electrical interactions is essential to comprehending the intricate process of energy conversion in modern automobiles.

Mazda's Fuel Efficiency: A Comprehensive Guide to Eco-Friendly Driving

You may want to see also

Transmission: Gear changes transfer power from the engine to the wheels

The transmission in a car is a crucial component that ensures the engine's power is effectively transferred to the wheels, allowing the vehicle to move. It operates on the principle of gear changes, which is a fundamental aspect of mechanical power transmission. When you shift gears in a car, you are essentially altering the ratio between the engine's rotational speed and the wheels' speed, which directly impacts the vehicle's performance and efficiency.

In a manual transmission, the driver manually selects different gear ratios by moving a gear stick and pressing a clutch pedal. Each gear has a specific number of teeth on the gear wheel, which determines the speed and torque at the wheels. Lower gears provide more torque, making it easier to accelerate from a standstill or climb steep hills. As the car gains speed, the driver shifts to higher gears, which reduce the engine's speed and increase the vehicle's top speed while maintaining efficiency.

Automatic transmissions, on the other hand, use a complex system of sensors, actuators, and computers to change gears without driver intervention. These systems monitor engine speed, vehicle speed, and driver input to determine the optimal gear ratio for a given situation. When you press the accelerator pedal, the transmission adjusts the gear ratio to provide the necessary power to the wheels, ensuring smooth acceleration and optimal fuel efficiency.

The process of gear changes in a transmission is designed to optimize power transfer. When the engine's rotational speed is higher than the wheels' speed, the transmission engages a lower gear, allowing more torque to be transferred to the wheels. This enables the car to accelerate quickly and efficiently. Conversely, when the engine's speed needs to be reduced to maintain a constant speed or when descending a hill, the transmission shifts to a higher gear, reducing the power output and improving fuel economy.

Efficient power transfer is critical for a vehicle's performance and fuel consumption. A well-functioning transmission ensures that the engine's power is utilized effectively, minimizing energy loss and maximizing the car's speed and range. Modern transmissions are designed to provide seamless gear changes, ensuring a smooth driving experience and optimal power delivery to the wheels, ultimately contributing to the overall efficiency of the vehicle.

Car Tunes: Fuel Economy Trade-Offs and Performance Gains

You may want to see also

Exhaust Systems: Catalytic converters reduce emissions and manage exhaust gases

The exhaust system of a car plays a crucial role in managing the byproducts of the combustion process, ensuring that the vehicle operates efficiently and environmentally friendly. One of the key components in this system is the catalytic converter, a device that has revolutionized the automotive industry's approach to reducing harmful emissions.

Catalytic converters are designed to catalyze, or accelerate, chemical reactions in the exhaust gases, primarily aiming to minimize the release of pollutants into the atmosphere. When fuel is burned in the engine, it produces a range of byproducts, including carbon dioxide, nitrogen oxides, and various hydrocarbons. These emissions are not only harmful to the environment but also contribute to air pollution and potential health risks.

The converter's structure is intricate, often consisting of a ceramic or metal monolith with a honeycomb-like shape, providing a large surface area. This design is crucial as it exposes the exhaust gases to a greater surface area, allowing for more efficient reactions. Inside, a precious metal catalyst, typically platinum, palladium, or rhodium, is coated onto the monolith. These metals act as catalysts, facilitating the breakdown of harmful substances.

The process begins when the exhaust gases pass through the converter. As the gases come into contact with the catalyst, a series of chemical reactions occur. For instance, carbon monoxide (CO) and unburned hydrocarbons undergo oxidation, breaking down into less harmful carbon dioxide (CO2) and water (H2O). Nitrogen oxides (NOx) are reduced, forming nitrogen (N2) and oxygen (O2), which are harmless gases. These reactions are essential in reducing the overall toxicity of the exhaust.

The efficiency of a catalytic converter is a critical factor in a vehicle's environmental impact. Modern converters are designed to handle a wide range of temperatures and are optimized to work at the specific conditions present in a car's exhaust system. This ensures that the chemical reactions occur rapidly and efficiently, minimizing the release of pollutants. Regular maintenance, such as checking the converter for any signs of damage or contamination, is vital to maintaining its performance and the overall health of the vehicle's exhaust system.

Optimizing Fuel Efficiency: Understanding Ideal Car Consumption

You may want to see also

Efficiency: Engine design and materials optimize energy conversion and minimize waste

The efficiency of a car's engine is a critical factor in how effectively it converts fuel into energy. This is achieved through meticulous engine design and the use of advanced materials. One key aspect is the optimization of the combustion process. Modern engines employ advanced combustion chamber designs, such as the use of turbochargers or superchargers, which increase the pressure and temperature within the chamber, allowing for more complete combustion of the fuel-air mixture. This results in a higher energy output from the same amount of fuel.

Engine materials play a significant role in efficiency as well. The use of lightweight, high-strength materials like aluminum alloys and advanced steels reduces the overall weight of the engine, leading to improved performance and fuel efficiency. These materials also contribute to better heat dissipation, ensuring that the engine operates at optimal temperatures, which is crucial for efficient energy conversion.

Engine design also focuses on minimizing friction, which is a major source of energy loss. Engineers achieve this through the use of advanced bearings, low-friction seals, and optimized piston rings. These components reduce internal friction, allowing for smoother operation and more efficient energy transfer. Additionally, the implementation of variable valve timing and lift systems enables precise control over the intake and exhaust processes, optimizing the engine's performance across different operating conditions.

Another strategy to enhance efficiency is the integration of advanced sensors and control systems. These systems monitor various engine parameters in real-time, allowing for immediate adjustments to optimize performance. For instance, they can adjust fuel injection timing, optimize air-fuel mixture ratios, and manage engine speed and load, all of which contribute to improved energy conversion efficiency.

Furthermore, the use of advanced materials in engine components, such as the cylinder head and exhaust system, helps in reducing heat loss and improving overall efficiency. Materials like advanced ceramics and heat-resistant alloys are employed to withstand extreme temperatures, ensuring that the engine operates efficiently even under demanding conditions. This attention to detail in engine design and material selection is essential for maximizing the energy output from the fuel, thereby improving the overall fuel efficiency of the vehicle.

Flex Fuel Flexibility: Can Your Car Run on 87 Octane?

You may want to see also

Frequently asked questions

The process begins with the combustion of fuel, typically gasoline or diesel, inside the engine's cylinders. When fuel is injected into the engine and ignited by a spark plug (in gasoline engines) or injected directly into the combustion chamber (in diesel engines), it rapidly burns, creating a small explosion. This explosion generates a rapid expansion of gases, which pushes the pistons down, converting the chemical energy from the fuel into mechanical energy. This mechanical energy is then transferred to the wheels, allowing the car to move.

The engine's components work in harmony to ensure efficient energy conversion. The pistons, for instance, are connected to a crankshaft, which converts the linear motion of the pistons into rotational motion. This rotational motion is then transferred to the transmission, which adjusts the speed and torque according to the driver's needs. The exhaust system plays a crucial role in removing the combustion gases, and the cooling system maintains optimal engine temperature, ensuring efficient operation.

Modern vehicles have made significant strides in improving fuel efficiency. Engine designs, such as direct injection and turbocharging, enhance combustion efficiency by optimizing fuel-air mixture and combustion timing. Additionally, technologies like variable valve timing and direct fuel injection allow for more precise control over the fuel-air mixture, improving power output and fuel economy. Advanced engines can achieve higher thermal efficiencies, converting a larger portion of the fuel's chemical energy into useful work, thus reducing fuel consumption and emissions.