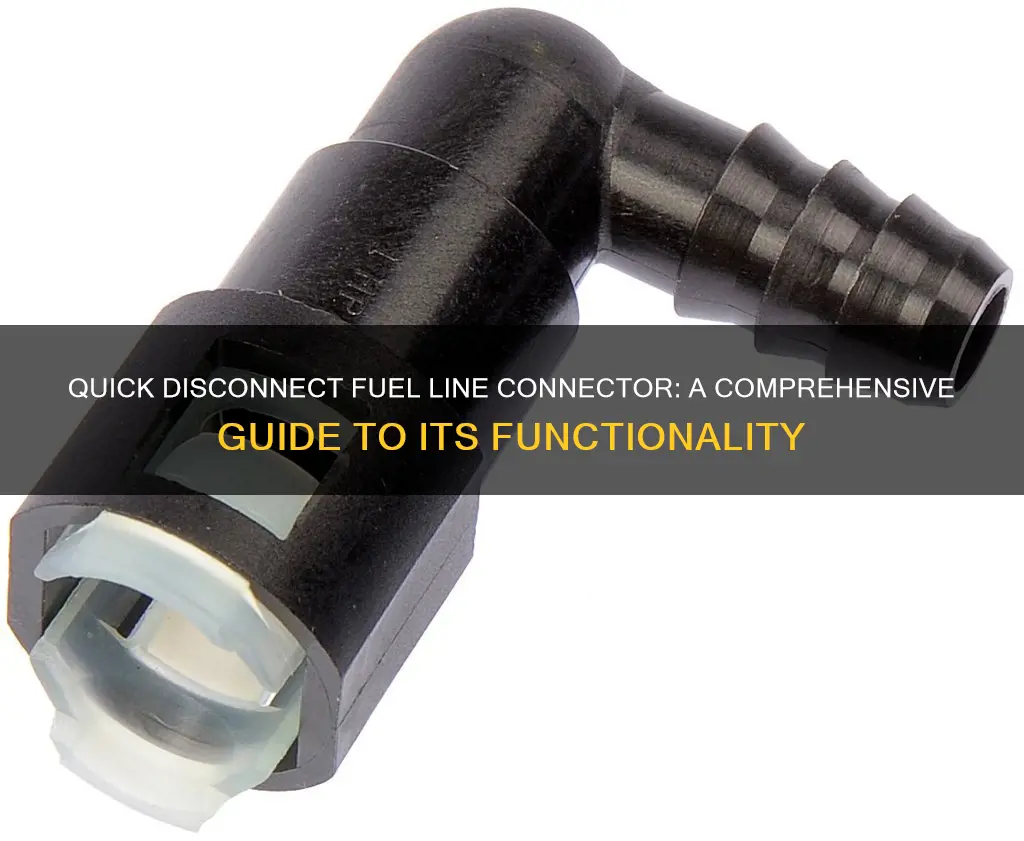

A quick disconnect fuel line connector is a handy device that allows for easy and efficient fuel transfer between a fuel tank and an engine. This connector is designed to provide a secure and reliable connection, ensuring that fuel is delivered to the engine without any leaks or disruptions. The mechanism involves a simple yet effective design, where a male connector is inserted into a female port, creating a tight seal through a combination of friction and sometimes a locking mechanism. This quick and easy connection process saves time and effort, making it a popular choice for mechanics and DIY enthusiasts alike.

| Characteristics | Values |

|---|---|

| Function | Allows for easy and quick connection and disconnection of fuel lines without the need for tools or permanent attachments. |

| Design | Typically consists of a male and female end, with a locking mechanism to ensure a secure connection. |

| Materials | Made from durable materials like brass, steel, or rubber compounds to withstand fuel pressure and temperature changes. |

| Pressure Rating | Designed to handle specific fuel pressures, ensuring safe and reliable operation. |

| Compatibility | Available in various sizes and thread types to fit different fuel lines and applications. |

| Ease of Use | Features a simple push-to-connect and pull-to-disconnect design, making it user-friendly. |

| Leakage Prevention | Sealed connections to prevent fuel leakage and ensure efficient transfer. |

| Durability | Built to last, withstanding vibrations and environmental factors in automotive applications. |

| Applications | Commonly used in automotive, marine, and industrial settings for fuel delivery systems. |

| Safety | Helps prevent fuel spills and potential hazards by allowing quick disconnection during maintenance or emergencies. |

What You'll Learn

- Design and Function: Quick disconnects feature a spring-loaded mechanism that seals the connection when engaged

- Material and Durability: Fuel lines are made of flexible materials like rubber or plastic for durability

- Pressure Release: The connector allows pressure to escape, preventing fuel line damage during disconnection

- Easy Installation: Users can quickly attach and detach the connector without specialized tools

- Safety Features: Some designs include safety clips or locks to prevent accidental disconnections

Design and Function: Quick disconnects feature a spring-loaded mechanism that seals the connection when engaged

Quick disconnect fuel line connectors are designed with a specific mechanism to ensure a secure and leak-free connection, especially in applications where frequent disconnections and reconnections are required, such as in automotive fuel systems. The key feature that sets these connectors apart is the spring-loaded design, which plays a crucial role in their functionality.

When a quick disconnect is engaged, the spring-loaded mechanism is activated. This mechanism typically consists of a spring-loaded pin or a spring-loaded ball, depending on the design. The pin or ball is positioned within the connector and is designed to move in a specific direction when force is applied. When the connector is connected, this spring-loaded component is compressed, creating a tight seal between the two mating surfaces. The spring's elasticity ensures that the connection is secure and maintains a constant pressure, preventing any fuel from leaking around the connection.

The design of this spring-loaded mechanism is critical to its performance. It must be strong enough to hold the connection firmly in place but also flexible enough to allow for easy disengagement. The spring's force should be calibrated to provide a snug fit without causing damage to the fuel line or the connector itself. This balance is essential to ensure the connector's reliability and longevity.

Upon disengagement, the spring-loaded mechanism releases its hold, allowing the connector to separate. This action is often accompanied by a distinct 'click' or 'snap' sound, indicating that the connection has been successfully broken. The spring's elasticity also helps to prevent any residual fuel from remaining in the connection, reducing the risk of contamination or fuel wastage.

In summary, the spring-loaded mechanism in quick disconnect fuel line connectors is a carefully engineered feature that ensures a secure and reliable connection. Its design allows for easy engagement and disengagement while maintaining a tight seal, making it an essential component in applications where quick and secure fuel connections are required.

Stock Fuel Lines for Honda Civic EK: Performance and Reliability

You may want to see also

Material and Durability: Fuel lines are made of flexible materials like rubber or plastic for durability

Fuel lines are a critical component in any vehicle's fuel system, responsible for transporting fuel from the tank to the engine. These lines are designed to be flexible and durable, ensuring they can withstand the rigors of the road and the demands of the engine. The choice of material is crucial to achieving this durability.

Rubber and plastic are the primary materials used in manufacturing fuel lines due to their inherent flexibility and resistance to wear and tear. Rubber, in particular, is an excellent choice for fuel lines as it can absorb vibrations and shocks, reducing the risk of damage to the fuel system. It is also resistant to fuel degradation, ensuring that the fuel remains fresh and clean. Plastic, on the other hand, offers a lightweight and cost-effective alternative, providing flexibility and durability without the same level of fuel resistance as rubber.

The flexibility of these materials is essential for the fuel lines' performance. It allows the lines to bend and move with the vehicle's body, accommodating various driving conditions and angles. This flexibility also reduces stress on the fuel lines, preventing cracks and leaks that could lead to fuel loss or contamination.

In addition to flexibility, the durability of fuel lines is vital for long-term reliability. High-quality fuel lines are designed to withstand extreme temperatures, both hot and cold, without compromising their structural integrity. This is especially important in regions with varying climates, where fuel lines must perform consistently across different weather conditions.

The choice of rubber or plastic for fuel lines ensures that they can handle the constant expansion and contraction caused by temperature changes without becoming brittle or cracking. This durability is further enhanced by the use of specialized additives and compounds that improve the material's resistance to fuel, oil, and other chemicals present in the vehicle's system. As a result, fuel lines made from these materials provide a reliable and long-lasting solution for fuel transportation in vehicles.

Camaro vs. Firebird: Unraveling Fuel Line Differences

You may want to see also

Pressure Release: The connector allows pressure to escape, preventing fuel line damage during disconnection

A quick disconnect fuel line connector is an essential component in the fuel system of vehicles, especially those with high-performance engines. Its primary function is to enable a secure and efficient connection for the fuel line, ensuring a reliable supply of fuel to the engine while also providing a means to safely disconnect the line when necessary. One of the key features that set this connector apart is its ability to release pressure, which is a critical aspect of its design and functionality.

When a fuel line is disconnected, there is often a significant amount of pressure built up within the system. This pressure can be caused by the fuel's inherent volatility and the engine's operation, which creates a vacuum effect. If this pressure is not managed properly, it can lead to several issues. Firstly, the sudden release of pressure can cause the fuel line to collapse or kink, potentially damaging the line itself and leading to fuel leaks. Secondly, the high pressure can cause the fuel to spray or even erupt from the line, creating a safety hazard and a mess.

The pressure release mechanism in a quick disconnect fuel line connector is designed to address these potential problems. It typically consists of a small, carefully designed orifice or a series of small openings within the connector. When the fuel line is disconnected, the pressure inside the line forces fuel through this orifice or openings, allowing the pressure to escape. This controlled release of pressure prevents the sudden and potentially damaging effects mentioned earlier.

The design of the pressure release feature is crucial to its effectiveness. It must be precise enough to control the flow of fuel and pressure but also robust enough to handle the forces involved. Manufacturers often use specialized materials and precision engineering to ensure that the pressure release mechanism functions flawlessly every time. This attention to detail is vital to maintaining the overall reliability of the fuel system.

In summary, the pressure release capability of a quick disconnect fuel line connector is a critical safety feature. It ensures that the fuel line remains intact and functional during disconnections, preventing potential damage and hazards. This simple yet effective design element is a testament to the ingenuity required in automotive engineering to balance performance and safety.

Mastering Small Engine Fuel Line Stretching: A Comprehensive Guide

You may want to see also

Easy Installation: Users can quickly attach and detach the connector without specialized tools

A quick disconnect fuel line connector is designed with ease of use and convenience in mind, allowing users to quickly attach and detach fuel lines without the need for specialized tools or complex procedures. This feature is particularly useful in various applications, from automotive repairs to industrial machinery, where time and efficiency are crucial. The installation process is straightforward and can be completed by individuals with basic mechanical knowledge or even those new to DIY projects.

The key to its easy installation lies in the design of the connector itself. Typically, it consists of two main components: a male connector and a female connector. The male connector features a barbed end, which is the part that connects to the fuel line, while the female connector has a smooth interior surface with a sealing mechanism. When assembled, these two parts form a secure and leak-tight connection. The process begins by inserting the male connector into the female connector, ensuring proper alignment. Once aligned, the connector is secured in place using a simple locking mechanism, often a twist or a push-button, which varies depending on the design.

One of the advantages of this design is the ability to quickly attach and detach the fuel lines. To disconnect, the user simply releases the locking mechanism, and the connector can be pulled apart. This process is reversible, allowing for easy reattachment when needed. The simplicity of this mechanism ensures that users can perform the task quickly, even in tight spaces or under challenging conditions, without the risk of damaging the fuel lines or the connector itself.

Furthermore, the materials used in these connectors are carefully chosen to ensure durability and reliability. High-quality materials, such as brass or stainless steel for the barbed ends, provide a strong and secure connection while also being resistant to corrosion and fuel degradation. The sealing mechanisms, often made of rubber or similar flexible materials, create a tight seal without compromising the ease of installation and removal.

In summary, the quick disconnect fuel line connector's design emphasizes simplicity and user-friendliness. Its straightforward assembly and disassembly process, coupled with durable materials, make it an ideal solution for various fuel line connection needs. Whether in a professional workshop or a home garage, this connector allows users to efficiently manage fuel lines, saving time and effort without compromising on performance or safety.

Can Fuel Line Tubing Be Used for Oil Lines?

You may want to see also

Safety Features: Some designs include safety clips or locks to prevent accidental disconnections

Quick disconnect fuel line connectors are designed with safety in mind, especially to prevent accidental disconnections that could lead to fuel leaks or system failures. One of the key safety features incorporated into these connectors is the use of safety clips or locks. These mechanisms are crucial in maintaining the integrity of the fuel system and ensuring the safety of the vehicle.

The safety clips or locks are typically integrated into the design of the quick disconnect connector. When the connector is properly connected, these clips engage with specific parts of the connector or the fuel line itself, creating a secure and stable connection. This engagement prevents the connector from being accidentally pulled off, even when subjected to vibrations or sudden movements.

In some designs, the safety clips are spring-loaded, providing a constant tension that holds the connector in place. This ensures that the connection remains secure as long as the fuel system is operating normally. The spring-loaded clips are designed to release only when a deliberate and forceful action is taken to disconnect the fuel line, such as pulling the release mechanism or lever.

Additionally, some quick disconnect fuel line connectors employ a locking mechanism that requires a specific action to unlock. For example, a lever or button might need to be pressed or pulled before the connector can be disconnected. This additional step adds an extra layer of security, making it even more difficult for the connector to be accidentally removed.

By incorporating these safety features, quick disconnect fuel line connectors provide a reliable and secure method for connecting and disconnecting fuel lines. The safety clips and locks ensure that the fuel system remains intact, reducing the risk of accidents and system failures caused by accidental disconnections. This is particularly important in high-performance vehicles or applications where fuel system reliability is critical.

Understanding Fuel Line Flush: A Comprehensive Guide

You may want to see also

Frequently asked questions

A quick disconnect fuel line connector is a specialized fitting designed to securely connect and disconnect fuel lines in automotive applications. It allows for easy and efficient fueling without the need for tools or complex procedures.

The connector typically features a unique locking mechanism, often a bayonet or a twist-lock design. When attached, the connector firmly grips the fuel line, creating a tight seal to prevent fuel leakage. This mechanism ensures a reliable connection, even during vibrations and movements experienced while driving.

Yes, quick disconnect fuel line connectors offer several advantages. They provide a convenient and time-saving method for fueling vehicles, eliminating the need for permanent connections and potential fuel contamination risks. These connectors are also designed to be durable, ensuring a long-lasting and reliable fueling solution for various vehicle types.