Universal fuel line kits are a handy tool for any DIY enthusiast or mechanic, offering a convenient and cost-effective solution for replacing or repairing fuel lines in various vehicles. These kits typically include all the necessary components, such as fuel lines, fittings, and connectors, designed to fit a wide range of car models. By using a universal fuel line kit, you can streamline the process of replacing damaged or worn-out fuel lines, ensuring a reliable and safe fuel supply to your engine. This guide will provide a step-by-step overview of how to effectively utilize a universal fuel line kit, covering installation techniques, troubleshooting common issues, and ensuring a proper fit for your specific vehicle.

What You'll Learn

- Assembly: Carefully assemble the kit, ensuring all components are correctly aligned and secured

- Fitting: Use the appropriate fittings for your specific fuel line application

- Routing: Route the lines away from moving parts to prevent damage

- Clamping: Secure with the provided clamps, tightening them evenly

- Testing: Check for leaks and ensure proper flow before use

Assembly: Carefully assemble the kit, ensuring all components are correctly aligned and secured

When working with a universal fuel line kit, the assembly process is crucial to ensure optimal performance and safety. Here's a step-by-step guide to help you through the assembly:

Preparation: Begin by laying out all the components of the kit on a clean, well-lit work area. This includes the fuel lines, fittings, clamps, and any additional parts provided. Inspect each item for any visible damage or defects. Ensure you have the necessary tools, such as wrenches, pliers, and a tape measure, readily available. It is essential to double-check the compatibility of the kit with your specific application to avoid any issues during installation.

Assembly Process: Start by identifying the primary fuel source and the target component it needs to supply. Carefully align the fuel line with the appropriate fitting, ensuring the correct orientation. Use the provided clamps or securing mechanisms to fasten the fuel line to the fitting securely. Make sure there is no excessive force applied, as this might damage the line or fitting. Repeat this process for each connection, maintaining consistency in the assembly. Pay close attention to the flow direction indicators on the fuel lines and ensure they are correctly oriented to prevent fuel flow issues.

Securing Connections: After establishing the primary connections, focus on securing the entire assembly. Use the provided clamps or ties to fasten the fuel lines together at regular intervals, creating a neat and organized layout. Ensure that all connections are tight and secure, as loose fittings can lead to fuel leaks and potential hazards. Consider using a fuel-resistant tape or sealant on the connections to provide an extra layer of protection against leaks.

Testing and Inspection: Once the assembly is complete, it is vital to test the system. Start the engine and monitor for any unusual noises or vibrations. Check for any signs of fuel leakage around the connections. If everything appears to be functioning correctly, give the system a thorough visual inspection to ensure there are no kinks or damage to the fuel lines. Properly dispose of any waste fuel or components during the testing phase to maintain a clean work environment.

Remember, during the assembly process, take your time and be meticulous. Each component has a specific role, and proper alignment and securing will ensure the kit's functionality and longevity. Always refer to the manufacturer's instructions or seek professional guidance if you encounter any unique or complex assembly requirements.

T100 Fuel Line Guide: Choosing the Right Option

You may want to see also

Fitting: Use the appropriate fittings for your specific fuel line application

When using a universal fuel line kit, it's crucial to select the right fittings to ensure a secure and efficient fuel delivery system. The key to a successful installation lies in understanding the compatibility of the fittings with your specific fuel line application. Here's a step-by-step guide to help you with this process:

Identify Your Fuel Line Type: Different fuel lines have varying diameters and requirements. Common types include small-bore, medium-bore, and large-bore fuel lines. Determine the diameter of your fuel line to choose the appropriate fittings. Universal kits often provide a range of sizes to accommodate various applications.

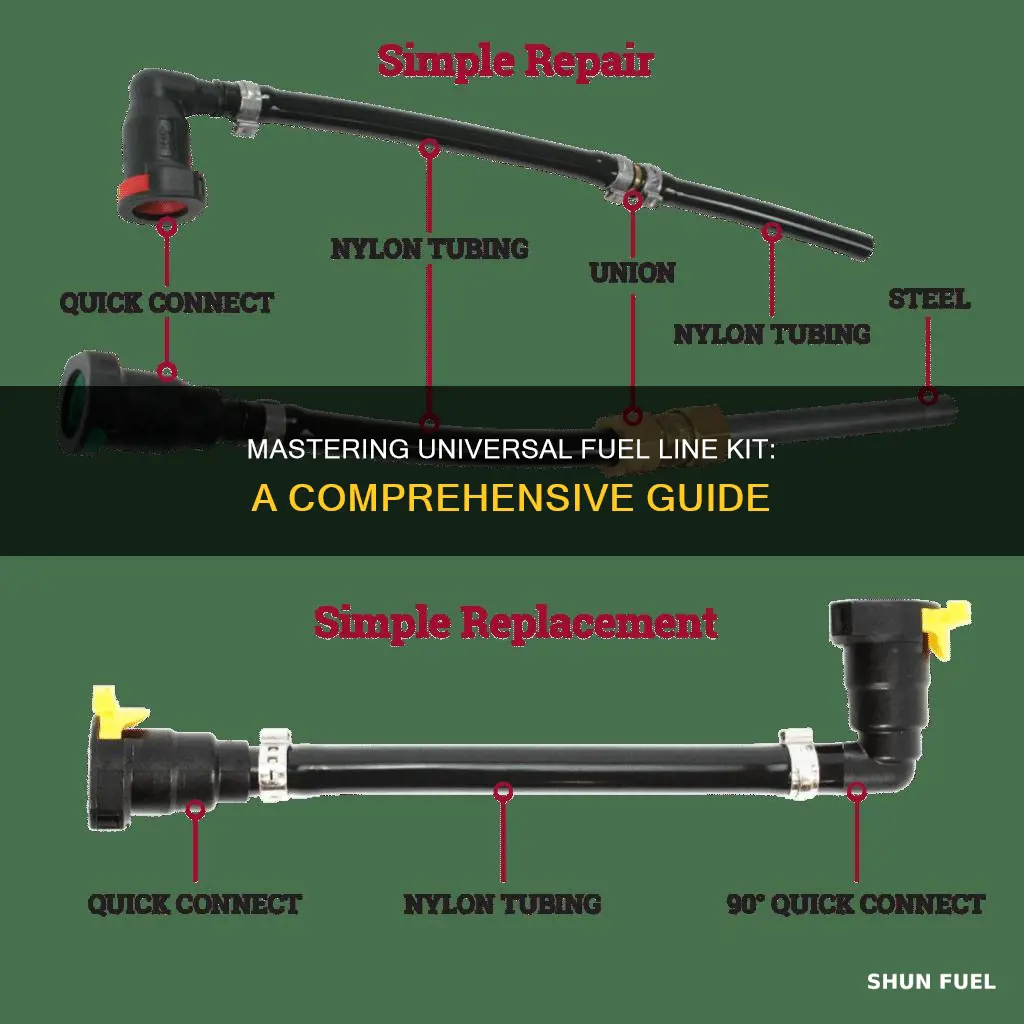

Consider the Fitting Material: Universal fuel line kits offer fittings made from different materials such as steel, aluminum, or plastic. The choice of material depends on factors like temperature resistance, flexibility, and compatibility with the fuel type. For instance, stainless steel fittings are durable and suitable for high-temperature environments, while plastic fittings are lightweight and resistant to corrosion.

Select the Right Fitting Style: Fittings come in various styles, including quick-connect, compression, and barbed. Quick-connect fittings are convenient for temporary installations or when frequent disconnections are required. Compression fittings provide a tight seal and are ideal for permanent installations. Barbed fittings are versatile and easy to install, making them suitable for various fuel line configurations. Choose the style that best suits your project's needs.

Match the Fitting Size: Ensure that the fittings' inner diameter matches the fuel line's outer diameter. A precise fit is essential for a leak-free connection. Universal kits often provide a range of sizes, allowing you to select the most appropriate one for your fuel line. Measure the fuel line carefully to determine the required fitting size.

Follow Installation Instructions: Each universal fuel line kit will come with specific instructions for fitting installation. These guidelines will help you understand the proper techniques for connecting the fittings to the fuel line. Adhere to these instructions to ensure a secure and reliable connection. Proper installation techniques include using the correct tools, applying the appropriate amount of sealant, and ensuring tight connections.

Simplifying Engine Maintenance: A Guide to Removing Tight Fuel Lines on Mowers

You may want to see also

Routing: Route the lines away from moving parts to prevent damage

When working with a universal fuel line kit, proper routing is crucial to ensure the longevity of your fuel system and to prevent any potential issues. The primary goal is to keep the fuel lines away from any moving parts that could cause damage or lead to leaks. Here's a step-by-step guide on how to achieve this:

Start by identifying the various components of your vehicle's fuel system, including the fuel tank, fuel pump, and any existing fuel lines. Visualize the path these lines take and the areas where they might be susceptible to damage. Moving parts such as engines, transmissions, or suspension components can pose a significant risk. The objective is to create a clear and safe path for the fuel lines, ensuring they are not in contact with these potential hazards.

Begin routing the fuel lines by carefully following the manufacturer's guidelines or the diagram provided with the universal kit. Typically, you'll want to run the lines along the frame rails or the inner fender wells, where there is typically less movement and impact. Avoid areas where the lines might come into contact with exhaust pipes, suspension components, or any other moving parts that could cause wear and tear. Use appropriate fuel line clips or ties to secure the lines in place, ensuring they are taut and not rubbing against any surfaces.

As you route the lines, maintain a consistent and neat layout. Avoid sharp bends or kinks, as these can lead to fuel restriction or damage over time. Instead, opt for gentle curves and allow the lines to follow the natural contours of the vehicle's body. This not only looks more professional but also reduces the risk of fuel line damage. Remember to leave enough slack in the lines to accommodate for any minor movements, ensuring they don't become taut or stressed.

Finally, double-check your routing to ensure all lines are secure and away from potential sources of damage. Inspect the lines for any sharp bends or areas where they might rub against other components. Make any necessary adjustments to ensure a smooth and safe path for the fuel. By taking the time to properly route the fuel lines, you'll contribute to the overall reliability and performance of your vehicle's fuel system.

Thawing Frozen Fuel Lines: A Step-by-Step Guide to Unfreezing

You may want to see also

Clamping: Secure with the provided clamps, tightening them evenly

When working with a universal fuel line kit, clamping is a crucial step to ensure a secure and reliable connection. The provided clamps are specifically designed to fit various fuel line sizes and shapes, offering a customizable and effective solution for your plumbing needs. Here's a step-by-step guide on how to properly secure the fuel lines using these clamps:

Start by laying out all the necessary components, including the fuel lines, clamps, and any additional tools you might require. Ensure that you have the correct size and type of clamp for your specific application. Universal fuel line kits often come with a variety of clamps to accommodate different scenarios. Inspect the fuel lines for any bends or kinks that might need to be straightened before clamping. Smooth out any sharp bends to prevent damage to the lines during the clamping process.

Position the clamp over the fuel line, ensuring that it covers the entire length of the line you intend to secure. The clamp should be centered and aligned properly, with no twists or misalignments. Use the provided screws or fasteners to tighten the clamp securely. It's important to apply even pressure to the clamp to ensure a tight seal without causing any damage to the fuel line. Avoid over-tightening, as this can lead to line distortion or potential leaks.

To achieve an even and secure hold, follow these techniques: Tighten the clamp in a cross-pattern, moving the screws or fasteners in a crisscross motion. This ensures that the clamp applies equal pressure on all sides, providing a uniform hold. For larger or thicker fuel lines, consider using multiple clamps in a staggered or overlapping manner to distribute the load and create a more robust connection. Always refer to the manufacturer's guidelines for specific recommendations based on your fuel line kit.

Remember, the goal is to create a tight, leak-free connection while being mindful of the fuel line's integrity. Proper clamping ensures that the fuel lines remain secure during transportation and operation, preventing potential hazards associated with fuel leaks. By following these instructions, you can effectively utilize the universal fuel line kit's clamping mechanism to achieve a professional and reliable fuel system setup.

FASS Fuel Line: Unlocking the Power of Your Engine

You may want to see also

Testing: Check for leaks and ensure proper flow before use

Before you begin using your universal fuel line kit, it is crucial to conduct a thorough testing procedure to ensure safety and optimal performance. This step is often overlooked, but it is essential to identify and rectify any potential issues before connecting the kit to your fuel source. Here's a detailed guide on how to test for leaks and ensure proper flow:

Leak Testing:

- Gather the necessary tools: You will need a soapy water solution, a spray bottle, and a clean cloth. Ensure you have the universal fuel line kit components ready, including the lines, fittings, and any additional parts.

- Prepare the Test: Start by cleaning the areas where the fuel lines will be connected. Remove any dirt or debris to ensure a proper seal. Then, mix the soapy water solution and fill the spray bottle.

- Spray and Inspect: Connect one end of the fuel line to a temporary fitting or a test port (if available). Spray the soapy water onto the connection and along the length of the line. Look for any bubbles or soap suds forming, indicating a potential leak. If you notice any, carefully inspect the connections and tighten or replace the fittings as needed.

- Repeat for All Connections: Test each connection point, including where the fuel line joins the fuel tank, pump, or any other component. Ensure that all fittings are secure and tight to prevent fuel leaks.

Flow Testing:

- Set Up the System: Once you've confirmed there are no leaks, it's time to test the flow. Connect the fuel line kit to your fuel source and ensure all connections are secure.

- Start the Engine (if applicable): If you have access to the engine, start it and let it run for a few minutes. This will allow the fuel system to prime and ensure proper flow. Alternatively, you can use a fuel pump tester to simulate the engine's operation.

- Monitor the Flow: Keep an eye on the fuel gauge or use a fuel flow meter to measure the rate of fuel passing through the lines. Ensure that the flow is consistent and meets the required specifications for your vehicle or equipment.

- Check for Blockages: While testing, be vigilant for any signs of fuel not reaching the desired destination. This could indicate a blockage in the line or a faulty pump. If you notice any issues, investigate further and address the problem before proceeding.

Remember, proper testing is critical to prevent fuel-related issues and ensure the longevity of your equipment. By following these steps, you can identify and rectify any problems, guaranteeing a safe and efficient fuel supply. Always refer to the manufacturer's guidelines for specific instructions tailored to your universal fuel line kit.

Thawing Diesel Fuel Lines: Quick Tips for Cold Weather

You may want to see also

Frequently asked questions

A universal fuel line kit is a set of components designed to connect a fuel source to an engine or any device that requires fuel. It typically includes various sizes of fuel lines, fittings, and adapters to accommodate different fuel types and engine configurations. The kit is versatile and can be used for a wide range of applications, from small engines to larger industrial machinery.

Installation process may vary depending on the specific kit and your application. Here's a general step-by-step guide: First, ensure you have the necessary tools like a fuel line cutter, crimping tool, and solvent cleaner. Prepare the fuel lines by cutting them to the desired length and cleaning the ends. Then, connect the lines to the fittings provided in the kit, ensuring a secure and tight fit. Use fuel line tape or adhesive to reinforce the connections if needed. Finally, route the lines to the engine or device, ensuring they are protected and free from any obstructions.

While universal fuel line kits are designed to be versatile, it's important to consider the pressure requirements of your specific application. Some kits are rated for high-pressure systems and can handle fuel pressures typically found in engines. However, always check the manufacturer's specifications and guidelines for the particular kit you are using. For high-pressure applications, it's recommended to choose a kit with materials and fittings that can withstand the required pressure levels to ensure safety and optimal performance.