Hydrogen fuel cell cars are an innovative and sustainable mode of transportation, and understanding how to refuel them is essential for their widespread adoption. Refueling a hydrogen fuel cell car involves a process that is both efficient and environmentally friendly. Unlike traditional gasoline or diesel vehicles, hydrogen fuel cell cars require hydrogen gas to power their electric motors. The refueling process typically involves connecting a specialized nozzle to the car's hydrogen fueling port, which then injects compressed hydrogen gas into the vehicle's fuel tank. This gas is stored at high pressure and is quickly transferred to the fuel cell, where it undergoes a chemical reaction with oxygen from the air to produce electricity, heat, and water as the only byproducts. The refueling time is generally much shorter than that of electric vehicles, making hydrogen fuel cell cars a practical and convenient choice for drivers seeking a cleaner and more efficient driving experience.

What You'll Learn

- Hydrogen Refueling Stations: Infrastructure for supplying hydrogen to vehicles

- Hydrogen Storage: Methods to store hydrogen safely and efficiently in vehicles

- Fuel Cell Operation: How fuel cells convert hydrogen into electricity for the car

- Hydrogen Delivery: Processes for transporting hydrogen to refueling stations

- On-Board Systems: Components that manage hydrogen and power the fuel cell car

Hydrogen Refueling Stations: Infrastructure for supplying hydrogen to vehicles

The infrastructure for refueling hydrogen fuel cell vehicles is a critical component of the hydrogen economy, enabling the widespread adoption of this clean energy technology. Hydrogen refueling stations, also known as hydrogen fueling stations, are specialized facilities designed to supply hydrogen gas to fuel cell cars, buses, and other vehicles. These stations play a vital role in supporting the growing number of hydrogen-powered vehicles on the road.

The process of refueling a hydrogen fuel cell car involves the transfer of compressed or liquid hydrogen from the refueling station to the vehicle's fuel tank. Hydrogen refueling stations typically use high-pressure pumps to compress hydrogen gas to a pressure of around 5,000 to 10,000 pounds per square inch (psi), which is then stored in specialized tanks. Alternatively, some stations may offer refueling with liquid hydrogen, which is stored at extremely low temperatures and requires specialized equipment to handle. The refueling process is similar to that of a conventional gasoline or diesel pump, with the vehicle's fuel cell stack absorbing the hydrogen for power generation.

Building an efficient and widespread network of hydrogen refueling stations is essential to support the growing market for fuel cell vehicles. This infrastructure development requires careful planning and collaboration between governments, energy companies, and vehicle manufacturers. The location and design of these stations should consider factors such as vehicle density, transportation routes, and the availability of renewable energy sources for hydrogen production. Strategic placement of refueling stations along major highways and in urban areas can encourage the adoption of hydrogen fuel cell vehicles by providing convenient access to refueling options.

The construction of hydrogen refueling stations involves several key components. Firstly, high-pressure hydrogen storage tanks are required to store the compressed hydrogen gas. These tanks must adhere to strict safety standards and regulations to ensure the safe handling and transportation of hydrogen. Secondly, refueling equipment, including pumps and nozzles, is essential for the efficient transfer of hydrogen to vehicles. Specialized connectors and valves are designed to ensure a secure and controlled refueling process. Additionally, safety systems, such as leak detection and emergency shut-off mechanisms, are critical to prevent accidents and protect both the environment and public safety.

In summary, hydrogen refueling stations are the backbone of the infrastructure needed to support hydrogen fuel cell vehicles. These stations enable the practical and convenient refueling of hydrogen-powered cars, buses, and other transportation modes. The development of an extensive network of refueling stations, coupled with advancements in hydrogen production and storage technologies, will be crucial in accelerating the transition to a sustainable and low-carbon transportation system. As the demand for clean energy solutions grows, investing in the necessary infrastructure for hydrogen refueling will play a significant role in shaping a greener future.

Are Fuel-Efficient Cars Worth the Investment? Unlocking Long-Term Savings

You may want to see also

Hydrogen Storage: Methods to store hydrogen safely and efficiently in vehicles

The efficient and safe storage of hydrogen is a critical aspect of hydrogen fuel cell vehicle technology. Hydrogen storage systems in vehicles are designed to ensure the gas is securely contained and readily available for the fuel cell's energy conversion process. Here are some methods employed to store hydrogen in these vehicles:

Compressed Gas Storage: One of the most common methods is compressing hydrogen gas to a high pressure, typically around 350-700 bar (5,000-10,000 psi). This high-pressure storage allows for a relatively compact and lightweight design. The compressed hydrogen is stored in specialized tanks made from materials like carbon fiber composites or aluminum alloys, ensuring structural integrity under pressure. This method is widely used in the automotive industry due to its practicality and the ability to store sufficient hydrogen for vehicle range.

Metal Hydrides: Another approach involves using metal hydride compounds that can absorb and release hydrogen gas through chemical reactions. These compounds, such as sodium alanate (NaAlH4), can store hydrogen at relatively low pressures, around 1-5 bar (15-75 psi). Metal hydride storage systems offer advantages in terms of safety and energy density. They can be designed to release hydrogen gradually, providing a steady supply for the fuel cell. However, these systems may face challenges in terms of thermal management and the potential for hydrogen release during vehicle operation.

Liquid Hydrogen Storage: Storing hydrogen in its liquid state is another option, achieved by cooling the gas to extremely low temperatures, below -253°C (-423°F). Liquid hydrogen storage requires specialized insulated tanks and can provide high energy density. However, this method is less common in vehicles due to the challenges of maintaining extremely low temperatures and the potential for hydrogen boil-off, which can lead to pressure issues.

Hydrogen Tanks with Carbon-Based Materials: Researchers are also exploring the use of carbon-based materials, such as carbon nanotubes and graphene, to store hydrogen. These materials can adsorb hydrogen molecules onto their surfaces, providing a potential for higher energy density and faster hydrogen release. While this technology is still in development, it holds promise for future hydrogen storage solutions in vehicles.

The choice of storage method depends on various factors, including vehicle type, desired range, and performance requirements. Each storage method has its advantages and challenges, and ongoing research aims to optimize these systems for widespread adoption of hydrogen fuel cell vehicles.

Fuel Injection and Throttle Control: Exploring Individual Throttle Body Options

You may want to see also

Fuel Cell Operation: How fuel cells convert hydrogen into electricity for the car

The operation of a fuel cell is a fascinating process that powers hydrogen fuel cell cars, offering a clean and efficient alternative to traditional internal combustion engines. At its core, a fuel cell is an electrochemical device that directly converts the chemical energy of a fuel, in this case, hydrogen, into electrical energy through a reaction with oxygen. This process is fundamentally different from the combustion process in conventional vehicles, making hydrogen fuel cell cars a promising technology for a sustainable future.

When a hydrogen fuel cell car is in operation, the fuel cell stack is the heart of the system. This stack consists of multiple fuel cell units, each containing an anode and a cathode separated by an electrolyte membrane. The anode is where the magic happens; it is here that the hydrogen fuel is oxidized, releasing electrons and protons. The electrons are captured and directed through an external circuit, providing the electricity needed to power the car's electric motor. This is a crucial step as it initiates the entire energy conversion process.

Simultaneously, the protons (hydrogen ions) migrate through the electrolyte membrane to reach the cathode. At the cathode, oxygen from the air combines with the protons and electrons returning from the circuit to form water, completing the reaction. This water is then expelled as steam, along with a small amount of heat, making the process remarkably clean and environmentally friendly. The efficiency of this conversion process is impressive, typically ranging from 40% to 60%, which is significantly higher than the internal combustion engines found in traditional cars.

The beauty of this system lies in its simplicity and the fact that it produces electricity directly, eliminating the need for complex mechanical components like gears and turbines. This direct conversion of chemical energy to electrical energy is what makes fuel cells so efficient and environmentally friendly. The only byproduct of this reaction is water, making hydrogen fuel cell cars a zero-emission vehicle, especially when compared to gasoline or diesel-powered cars.

Refueling a hydrogen fuel cell car is a straightforward process. It involves connecting the vehicle to a hydrogen fueling station, which is similar to refueling a conventional car with gasoline. The hydrogen gas is compressed and stored in the fuel tank, and the refueling process is typically much faster than charging an electric vehicle battery. This rapid refueling capability is one of the key advantages of hydrogen fuel cell technology, making it a viable option for both personal and commercial transportation.

Ethanol-Free Fuel: Is It Safe for Your Car?

You may want to see also

Hydrogen Delivery: Processes for transporting hydrogen to refueling stations

The process of delivering hydrogen to refueling stations is a critical aspect of enabling the widespread adoption of hydrogen fuel cell vehicles. Hydrogen, being a highly flammable gas, requires careful transportation and handling to ensure safety and efficiency. Here's an overview of the key processes involved:

Pipeline Transportation: One of the most common methods is through dedicated hydrogen pipelines. These pipelines are designed to transport hydrogen over long distances, often from production facilities to regional distribution centers or directly to refueling stations. The pipelines are constructed with specialized materials to withstand the corrosive nature of hydrogen and are rigorously tested to ensure safety. This method is similar to the natural gas distribution system, where hydrogen is compressed and transported through a network of pipelines, making it a cost-effective and efficient way to move large volumes of hydrogen.

Truck and Trailer Transport: For shorter distances or when pipeline infrastructure is not available, hydrogen can be transported via specialized trucks and trailers. These vehicles are equipped with high-pressure tanks designed to store hydrogen safely. The process involves loading hydrogen from a production facility or storage tank onto the truck, which then delivers it to the refueling station. This method is flexible and can be used to supply hydrogen to remote areas or locations where pipeline construction is not feasible.

Cryogenic Transportation: Hydrogen is typically transported at extremely low temperatures, often close to absolute zero, to maintain its gaseous state. This cryogenic transportation method uses specialized refrigerated trucks or trains to keep the hydrogen in a liquid or slurry state during transit. The low temperature ensures that hydrogen remains in a stable form, making it safer to handle and transport. Upon arrival at the refueling station, the hydrogen is warmed and compressed before being dispensed to vehicles.

Safety and Regulatory Compliance: Throughout the transportation process, strict safety protocols are followed. This includes regular inspections of vehicles and infrastructure, monitoring of hydrogen levels and pressure, and adherence to international and local regulations. Hydrogen refueling stations are equipped with safety systems, such as leak detection and emergency shut-off mechanisms, to prevent accidents. Additionally, trained personnel are responsible for loading, unloading, and managing hydrogen deliveries to ensure compliance with safety standards.

The efficiency and safety of hydrogen delivery are crucial for the success of hydrogen fuel cell vehicles. As the infrastructure for hydrogen refueling stations expands, these transportation processes will play a vital role in making hydrogen-powered mobility accessible to the public.

Butane's Potential: Could It Power Your Next Car Ride?

You may want to see also

On-Board Systems: Components that manage hydrogen and power the fuel cell car

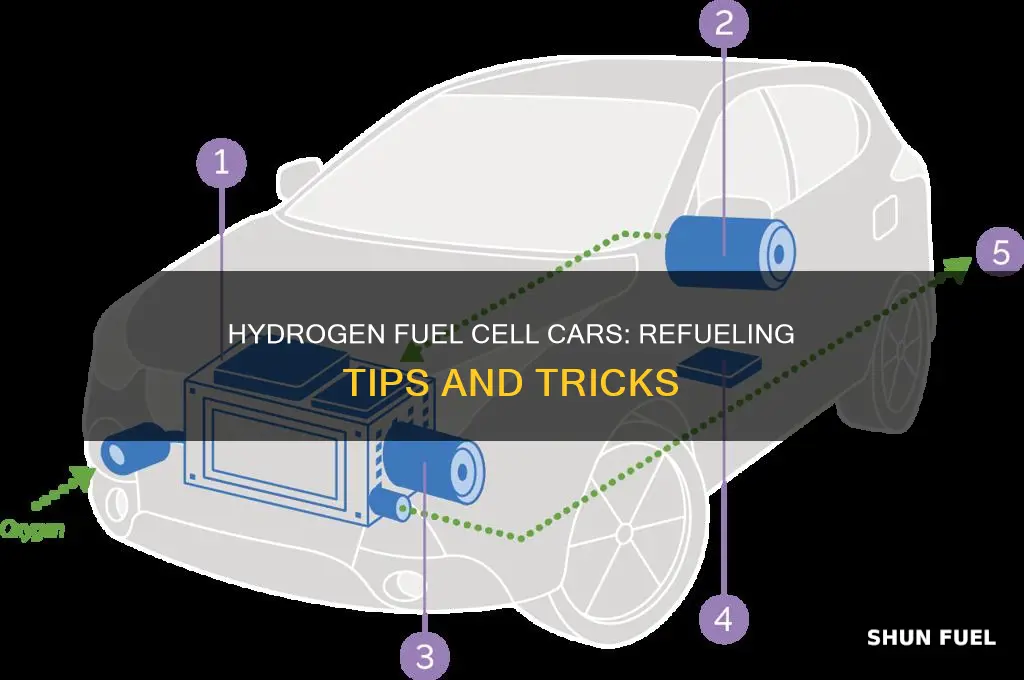

The on-board systems of a hydrogen fuel cell car are intricate and play a crucial role in managing the fuel and powering the vehicle. These systems are designed to handle the unique challenges of hydrogen storage, distribution, and utilization, ensuring efficient and safe operation. Here's an overview of the key components:

Hydrogen Storage: One of the primary on-board systems is the hydrogen storage system, which is designed to safely store the fuel in various forms. Hydrogen can be stored as a compressed gas or as a liquid, depending on the vehicle's design. High-pressure tanks are commonly used to store hydrogen gas, and these tanks are typically made of lightweight, durable materials to ensure structural integrity. Alternatively, some vehicles employ metal hydride storage, where hydrogen is absorbed into a metal alloy, offering a more compact and energy-dense solution. The storage system must adhere to strict safety regulations to prevent leaks and ensure the well-being of passengers and the environment.

Hydrogen Distribution and Delivery: After storage, hydrogen needs to be efficiently distributed to the fuel cell stack. This is achieved through a network of high-pressure pipelines or hoses that connect the storage tanks to the fuel cell. The distribution system must manage the flow rate and pressure to ensure a steady supply of hydrogen to the fuel cells. Advanced control valves and regulators are employed to maintain optimal conditions and prevent any potential issues during operation.

Fuel Cell Stack: At the heart of the fuel cell car is the fuel cell stack, which is responsible for converting hydrogen and oxygen into electricity through an electrochemical reaction. The stack consists of multiple fuel cell modules, each containing an anode, cathode, and electrolyte. When hydrogen is supplied to the anode, it undergoes oxidation, releasing electrons that generate an electric current. This process is highly efficient and produces only water and heat as byproducts, making fuel cell cars environmentally friendly.

Power Management and Control: The on-board systems also include sophisticated power management and control units. These units regulate the flow of electricity from the fuel cell stack to the vehicle's electrical systems and accessories. They ensure that the car's power demands are met while optimizing energy usage. Additionally, these systems monitor and control various parameters, such as temperature, pressure, and fuel cell efficiency, to maintain safe and efficient operation.

Refueling and Safety Mechanisms: Refueling a hydrogen fuel cell car is a straightforward process. Specialized refueling stations provide high-pressure hydrogen gas, which is then stored in the vehicle's tanks. The refueling system includes safety measures to prevent overfilling and ensure the process is conducted safely. These mechanisms are crucial for the widespread adoption of hydrogen fuel cell technology, addressing range anxiety and refueling infrastructure concerns.

Ethanol Fuel: Compatibility Across Car Models Explained

You may want to see also

Frequently asked questions

Refueling a hydrogen fuel cell car is similar to refueling a conventional gasoline or diesel vehicle, but instead of filling up with liquid fuel, you're supplying hydrogen gas. The process involves connecting a high-pressure hydrogen tank to a fueling station, which then injects hydrogen gas into the vehicle's fuel tank. This is typically done using a specialized fueling nozzle designed for hydrogen. The refueling time can vary, but it's generally much faster than refueling a battery electric vehicle, often taking just a few minutes.

The primary difference is the energy source and the environmental impact. Hydrogen refueling involves compressing or liquefying hydrogen gas and storing it in high-pressure tanks. When refueling, the hydrogen is typically sourced from an external supply, often produced through electrolysis of water or extracted from natural gas. In contrast, traditional fuels like gasoline or diesel are refined from crude oil. Hydrogen refueling stations are becoming more common, especially in regions with supportive infrastructure, and the process is clean and efficient, producing only water as a byproduct when used in fuel cells.

Yes, hydrogen storage is a critical aspect of fuel cell vehicles. The tanks are designed to withstand high pressure and are often made of lightweight, durable materials like carbon fiber composites. It's essential to ensure proper ventilation when refueling or storing hydrogen due to its low boiling point and the potential for hydrogen gas to disperse quickly. Additionally, fuel cell cars have safety mechanisms and sensors to monitor hydrogen levels and detect any leaks, ensuring the vehicle remains safe for operation and refueling.