Filling up a fuel cell car is a process that involves using hydrogen gas to power the vehicle's electric motor. Unlike traditional gasoline or diesel cars, fuel cell cars use a chemical reaction between hydrogen and oxygen to generate electricity, which then drives the car's electric motor. The process begins with the driver inserting a special fueling nozzle into the car's hydrogen fueling port, where compressed hydrogen gas is dispensed into the vehicle's fuel tank. This hydrogen is then directed to the fuel cell stack, where it reacts with oxygen from the air to produce electricity, heat, and water as a byproduct. This clean and efficient energy conversion process makes fuel cell cars an attractive alternative to conventional vehicles, offering zero-emission driving and the convenience of refueling in a similar manner to conventional cars.

What You'll Learn

- Fuel Cell Basics: Hydrogen fuel cells convert hydrogen and oxygen into electricity, water, and heat

- Fuel Storage: High-pressure tanks store hydrogen, ensuring a steady supply for the fuel cell

- refueling Process: Refueling involves replacing the depleted hydrogen with a fresh supply

- Fuel Cell Efficiency: Efficiency is maximized through optimized design and materials

- Environmental Impact: Hydrogen fuel cells produce zero emissions, offering a cleaner alternative to gasoline

Fuel Cell Basics: Hydrogen fuel cells convert hydrogen and oxygen into electricity, water, and heat

The concept of hydrogen fuel cells is an innovative and sustainable approach to powering vehicles, offering an alternative to traditional internal combustion engines. At its core, a hydrogen fuel cell is a device that harnesses the power of chemical reactions to generate electricity, with water, heat, and a small amount of air as the only byproducts. This technology is the driving force behind fuel cell cars, which have gained attention as a potential solution to reduce greenhouse gas emissions and combat climate change.

When it comes to filling up a fuel cell car, the process is quite different from conventional gasoline or diesel vehicles. Instead of refueling with liquid fuel, these cars require hydrogen gas, which is stored and supplied in specialized tanks. The process begins with the driver locating a hydrogen fueling station, which is similar to a gas station but with hydrogen gas as the product. These stations typically have high-pressure tanks that store hydrogen in a gaseous state, ready for use.

Upon arrival at the fueling station, the driver connects the vehicle's fueling port to the hydrogen supply. The port is usually located near the front of the car, often integrated into the front bumper or fender. The fueling process involves compressing and pumping hydrogen gas into the vehicle's fuel cell stack, which is the heart of the power system. The stack consists of multiple layers of fuel cell membranes, catalysts, and electrodes, all working together to facilitate the electrochemical reaction.

During refueling, hydrogen gas is directed into the fuel cell stack, where it undergoes a series of chemical reactions. The most critical reaction is the electrolysis of hydrogen, where hydrogen molecules (H₂) split into protons (H⁺) and electrons (e⁻). The protons pass through the fuel cell membrane, while the electrons are directed through an external circuit, generating an electric current. This process is known as the anode reaction. Simultaneously, oxygen from the air combines with the protons and electrons at the cathode, forming water (H₂O) as a byproduct.

As the hydrogen fuel cells convert hydrogen and oxygen into electricity, water, and heat, the vehicle's battery stores the electrical energy, ensuring a steady power supply to the electric motor. This motor then drives the car's wheels, providing a smooth and efficient driving experience. The water produced during the reaction is expelled as steam, and the heat generated can be utilized for various purposes, such as warming the car's interior or even powering auxiliary systems.

In summary, filling up a fuel cell car involves refueling with hydrogen gas at specialized stations, where the hydrogen is directed into the fuel cell stack for electrochemical reactions. This process generates electricity, water, and heat, powering the vehicle and offering a clean and sustainable transportation option.

Fuel System Cleaners: Can They Handle Water?

You may want to see also

Fuel Storage: High-pressure tanks store hydrogen, ensuring a steady supply for the fuel cell

The storage of hydrogen in fuel cell vehicles is a critical aspect of their design, ensuring a reliable and efficient power source. High-pressure tanks are a common and effective method to store hydrogen, playing a vital role in the overall functionality of these vehicles. These tanks are designed to withstand the immense pressure required to compress hydrogen gas, which is then stored at a high-pressure state.

The process of filling up a fuel cell car involves a precise and controlled mechanism. When the vehicle is at a hydrogen fueling station, the high-pressure tank is connected to the fueling nozzle, which is typically a specialized connector designed for hydrogen. The nozzle is connected to the vehicle's fueling system, which then delivers the hydrogen gas into the tank. This process is similar to refueling a conventional vehicle with gasoline, but with the added step of managing the high-pressure gas.

High-pressure tanks are often made of advanced materials such as carbon fiber composites or aluminum alloys, chosen for their strength and ability to withstand the extreme conditions. These materials ensure the structural integrity of the tank, preventing any potential leaks or failures during the filling process. The tanks are designed with multiple layers and protective coatings to enhance safety and durability.

The pressure inside these tanks can range from 350 to 700 bar (5,000 to 10,000 psi), depending on the vehicle's design and regional regulations. This high-pressure storage allows for a compact and lightweight design, making it feasible to fit the necessary hydrogen storage capacity within the vehicle's structure. The compressed hydrogen gas is then supplied to the fuel cell, where it undergoes a chemical reaction with oxygen from the air, producing electricity, heat, and water as byproducts.

Ensuring a steady supply of hydrogen to the fuel cell is crucial for the vehicle's performance and efficiency. High-pressure tanks provide the necessary volume and pressure to maintain a consistent flow of hydrogen, enabling the fuel cell to operate continuously without the need for frequent refueling. This technology is a key enabler for the widespread adoption of hydrogen fuel cell vehicles, offering a sustainable and environmentally friendly transportation solution.

E10 Fuel: Can Your Car Handle It?

You may want to see also

refueling Process: Refueling involves replacing the depleted hydrogen with a fresh supply

The refueling process for fuel cell vehicles is a straightforward procedure that ensures the car's hydrogen fuel cell can continue to generate electricity for the vehicle's operation. When the fuel cell car's hydrogen storage tanks are nearly empty, it is time to refuel. This process is similar to refueling a conventional gasoline or diesel vehicle but uses hydrogen gas instead of liquid fuel.

Refueling a fuel cell car typically involves a specialized fueling station equipped with the necessary infrastructure to handle hydrogen gas. These stations are designed to provide a safe and efficient refueling experience. The process begins with the driver locating a hydrogen fueling station, often found in designated areas or along major highways, similar to electric vehicle charging stations. Upon arrival, the driver connects the vehicle's fueling port to the station's hydrogen supply using a flexible hose or a quick-connect coupling.

During refueling, high-pressure hydrogen gas is delivered to the vehicle's fuel cell system. The process is rapid and efficient, often taking just a few minutes to replenish the hydrogen supply. The hydrogen is carefully metered and controlled to ensure precise filling, maintaining the integrity of the fuel cell's performance. Modern fuel cell vehicles are designed with safety mechanisms to prevent overfilling, ensuring the system operates within optimal parameters.

One of the key advantages of refueling a fuel cell car is the speed and convenience compared to traditional refueling methods. While gasoline or diesel refueling can take several minutes, hydrogen refueling is significantly faster, allowing drivers to quickly top up their fuel supply during a brief stop. This rapid refueling capability makes fuel cell vehicles highly practical for everyday use, providing a seamless driving experience without the long refueling times associated with conventional vehicles.

In summary, refueling a fuel cell car is a simple and efficient process that involves replacing the depleted hydrogen with a fresh supply. With the right infrastructure and specialized fueling stations, drivers can quickly and safely replenish their vehicle's hydrogen fuel, ensuring a continuous and sustainable source of energy for their electric vehicle. As hydrogen refueling technology advances, the accessibility and convenience of refueling fuel cell cars will continue to improve, further enhancing their appeal as an eco-friendly transportation option.

Can You Fuel Your Car While It's Running?

You may want to see also

Fuel Cell Efficiency: Efficiency is maximized through optimized design and materials

The efficiency of fuel cell vehicles is a critical aspect of their performance and environmental impact. Maximizing efficiency is achieved through a combination of innovative design and the selection of advanced materials. This approach ensures that the energy conversion process is highly effective, resulting in a more sustainable and powerful mode of transportation.

One key factor in optimizing fuel cell efficiency is the design of the fuel cell stack. Engineers focus on creating a compact and lightweight structure, allowing for better energy density. This involves precise arrangement of fuel cell components, including the electrolyte membrane, catalyst layers, and gas diffusion layers. By minimizing the distance between these layers, the reaction pathway is shortened, reducing energy losses and improving overall efficiency.

Advanced materials play a pivotal role in enhancing fuel cell performance. Researchers and engineers are constantly exploring new compounds and alloys to improve conductivity, catalyst activity, and durability. For instance, the use of precious metals like platinum as catalysts has been a significant challenge due to its high cost. However, ongoing efforts have led to the development of alternative catalysts, such as metal-free or metal-reduced catalysts, which can provide similar or even better performance while reducing costs.

Additionally, the design of the fuel cell's flow fields is crucial. These fields manage the flow of reactant gases (typically hydrogen and oxygen) through the cell. Optimized flow field designs minimize mass transfer limitations, ensuring that reactants reach the catalyst surface efficiently. This results in improved reaction rates and overall fuel cell efficiency.

Furthermore, the integration of fuel cell systems with other vehicle components is essential. Efficient thermal management systems help maintain optimal operating temperatures, reducing energy losses. Advanced control algorithms optimize the power output and efficiency by adjusting the fuel cell's operating conditions based on real-time data. This includes managing the flow rates, pressure, and temperature of the reactant gases.

In summary, maximizing fuel cell efficiency involves a meticulous approach to design and material selection. By optimizing the fuel cell stack's architecture, utilizing advanced materials, and refining system integration, engineers can significantly enhance the performance and sustainability of fuel cell vehicles. These efforts contribute to the overall goal of making fuel cell technology a viable and efficient alternative to traditional internal combustion engines.

Car Fuel Pump's Final Warning: The Noise Before It Fails

You may want to see also

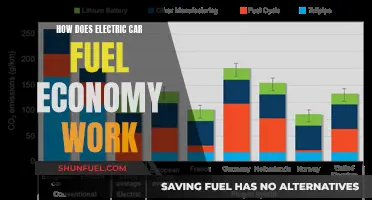

Environmental Impact: Hydrogen fuel cells produce zero emissions, offering a cleaner alternative to gasoline

The environmental benefits of hydrogen fuel cell technology are significant, particularly in the context of reducing greenhouse gas emissions and improving air quality. One of the most notable advantages is that hydrogen fuel cells produce zero emissions at the point of use. When hydrogen is combined with oxygen in the fuel cell, the only byproduct is water vapor, making it a clean and sustainable energy source. This is in stark contrast to conventional internal combustion engines, which release harmful pollutants such as carbon dioxide, nitrogen oxides, and particulate matter. By eliminating these emissions, hydrogen fuel cells contribute to a reduction in air pollution and a decrease in the carbon footprint of transportation.

The environmental impact becomes even more pronounced when considering the entire lifecycle of a hydrogen fuel cell vehicle. The production and transportation of hydrogen, as well as the manufacturing of the fuel cell stack, can have some environmental consequences. However, these impacts are generally lower compared to the emissions associated with traditional fossil fuel-based transportation. For instance, the extraction and processing of crude oil, a primary component in gasoline, involve energy-intensive processes that contribute to significant carbon emissions. In contrast, the production of hydrogen can be achieved through various methods, including electrolysis of water, which can be powered by renewable energy sources, further reducing the environmental impact.

The use of hydrogen fuel cells in vehicles also has the potential to improve air quality in urban areas. As mentioned earlier, the combustion of gasoline in traditional cars releases pollutants that can have adverse effects on human health, particularly in densely populated cities. By transitioning to hydrogen fuel cell vehicles, cities can experience a significant reduction in these harmful emissions, leading to improved air quality and public health. This is especially crucial in metropolitan areas where traffic congestion and pollution levels are often at their highest.

Furthermore, the adoption of hydrogen fuel cell technology can contribute to a more sustainable and resilient energy infrastructure. Hydrogen can be produced from a variety of sources, including renewable energy, making it a versatile and flexible energy carrier. This versatility allows for the integration of hydrogen into existing energy systems, providing a potential solution for the storage and distribution of renewable energy, which is often intermittent in nature. As the world moves towards a more sustainable energy future, hydrogen fuel cells can play a crucial role in supporting the transition by offering a clean and efficient alternative to conventional transportation fuels.

In summary, hydrogen fuel cells offer a promising environmental solution for the transportation sector. Their ability to produce zero emissions at the point of use, combined with the potential for a more sustainable and resilient energy infrastructure, makes them a cleaner and more environmentally friendly alternative to gasoline. As the world seeks to reduce its carbon footprint and combat climate change, the development and adoption of hydrogen fuel cell technology will be an essential part of the global effort to create a greener and more sustainable future.

The Truth About Oil: Powering Our Cars

You may want to see also

Frequently asked questions

Refueling a fuel cell car is similar to filling up a conventional gasoline or diesel vehicle, but instead of gasoline or diesel, you'll be filling up with hydrogen. You can typically do this at specialized hydrogen fueling stations, which are becoming more common in many countries. The process is straightforward: you park your car near the fueling nozzle, and the nozzle will connect to the vehicle's fueling port, usually located near the front or rear of the car. Then, you simply press a button to start the fueling process, and the hydrogen gas will be delivered to the fuel cell stack, where it reacts with oxygen in the air to produce electricity, which powers the vehicle.

The fueling process is quick and efficient. It typically takes only a few minutes to fill up the fuel tank, depending on the vehicle's capacity and the fueling station's capabilities. The hydrogen gas is compressed and delivered in a specific range of pressures to ensure safe and efficient storage in the fuel tank. Modern fuel cell vehicles often have advanced safety features to prevent any potential hazards during the fueling process.

Yes, there are different forms of hydrogen used for refueling fuel cell vehicles. The most common types are:

- Gaseous Hydrogen: This is the most common form used in refueling stations, stored at high pressure in tanks.

- Liquid Hydrogen: Used in some specialized applications, it requires extremely low temperatures to keep it in a liquid state.

- Hydrogen Gas from Renewable Sources: With the rise of green energy, hydrogen produced from renewable sources like wind or solar power is gaining popularity, offering a more sustainable fueling option.

The frequency of refueling depends on various factors, including the vehicle's range, the size of the fuel tank, and driving habits. Fuel cell cars can typically travel several hundred miles on a full tank of hydrogen. For example, some models can go over 300 miles on a single refueling, which is comparable to the range of electric vehicles on a full charge. Regular refueling intervals will vary, but it's generally a less frequent process than traditional refueling needs for internal combustion engine vehicles.

Fuel cell vehicles do not require the same frequent maintenance as traditional gasoline or diesel cars. However, it's essential to ensure the fuel tank is properly maintained. Regular inspections and maintenance checks are recommended to verify the integrity of the fuel system, including the fuel tank and lines. This helps ensure safe and efficient operation, as well as prolongs the lifespan of the vehicle's fuel cell system.