Gas-powered cars have long been associated with traditional fuel injection systems, but the question of whether they can utilize direct fuel injection is an intriguing one. Direct fuel injection, often found in diesel engines, offers improved performance and efficiency by delivering fuel directly to the combustion chamber. This method allows for more precise control over the fuel-air mixture, resulting in enhanced power output and reduced emissions. While gas engines typically rely on port fuel injection, advancements in technology have led to the development of direct fuel injection systems for gasoline vehicles. This innovation promises to revolutionize the gas-powered car industry, offering a more efficient and environmentally friendly driving experience.

| Characteristics | Values |

|---|---|

| Technology | Yes, gas-powered cars can utilize direct fuel injection (DFI). |

| Advantages | Improved fuel efficiency, better performance, reduced emissions, and enhanced engine response. |

| Common in Gasoline Engines | DFI is widely used in modern gasoline engines, especially in high-performance and luxury vehicles. |

| Fuel Delivery | DFI systems inject fuel directly into the engine's cylinders, allowing for precise control over the fuel-air mixture. |

| Performance | Gas engines with DFI can deliver more power and torque, resulting in faster acceleration and improved overall performance. |

| Efficiency | Direct injection can lead to better fuel economy, as it ensures that fuel is delivered directly to the combustion chamber, minimizing waste. |

| Emissions | This technology contributes to lower emissions by optimizing the fuel-air mixture, reducing unburned hydrocarbons and carbon monoxide. |

| Engine Management | Advanced engine control units (ECUs) are often used with DFI to precisely manage fuel injection, timing, and other parameters. |

| Reliability | Gas engines with DFI are generally considered reliable, providing consistent performance and longevity. |

| Cost | While DFI systems can be more expensive to implement, they offer long-term benefits in terms of performance and fuel efficiency. |

What You'll Learn

- Engine Design: Gasoline engines with direct fuel injection often feature unique engine designs to optimize fuel-air mixing

- Fuel Delivery: The system delivers fuel directly to the combustion chamber, improving power and efficiency

- Performance Benefits: Direct injection enhances power, torque, and fuel economy in gas-powered cars

- Emission Control: This technology can help reduce emissions by precise fuel control, meeting stricter environmental standards

- Engine Management: Advanced engine management systems optimize fuel injection for optimal performance and fuel efficiency

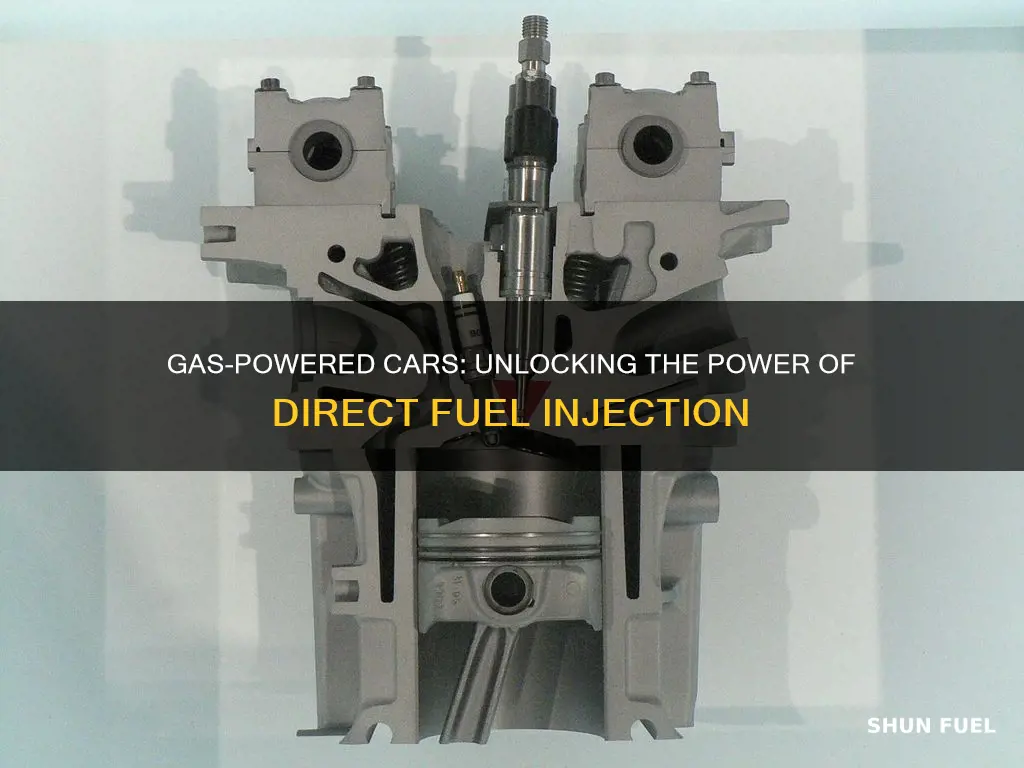

Engine Design: Gasoline engines with direct fuel injection often feature unique engine designs to optimize fuel-air mixing

Gasoline engines with direct fuel injection have revolutionized the automotive industry, offering improved performance and efficiency. One of the key aspects that set these engines apart is their unique design, which is specifically tailored to optimize the fuel-air mixing process. This design is crucial as it directly impacts the combustion process, leading to better power output and fuel economy.

In traditional gasoline engines, the fuel-air mixture is created by a carburetor or a port fuel injection system, where fuel is injected into the intake manifold or directly into the intake ports. However, direct fuel injection takes a different approach. The fuel is injected directly into the combustion chamber, often in multiple locations, such as near the spark plug or directly into the cylinder. This design change is significant because it allows for a more precise control of the fuel-air ratio, which is essential for efficient combustion.

Engineers have designed these engines with specific considerations to optimize this process. One notable feature is the use of multiple injectors. Instead of a single injector, some engines employ several injectors per cylinder, strategically positioned to ensure optimal fuel distribution. This design enables a more uniform fuel-air mixture, reducing the risk of incomplete combustion and improving overall engine performance. Additionally, the injectors are often designed to spray fuel at high pressure, ensuring that the fuel is atomized and mixed thoroughly with the air.

Another critical aspect of engine design in direct fuel injection systems is the combustion chamber geometry. The shape and size of the chamber are carefully engineered to promote efficient combustion. This includes optimizing the placement of the spark plug, which is crucial for igniting the fuel-air mixture. By carefully designing the combustion chamber, engineers can enhance the mixing process, ensuring that the fuel and air are thoroughly combined before ignition, resulting in a more complete and efficient combustion event.

Furthermore, the engine's intake and exhaust systems play a vital role in this design. The intake valves and ports are often designed to allow for a more precise control of air flow, ensuring that the correct amount of air is available for the injected fuel. The exhaust system is also optimized to efficiently remove combustion byproducts, allowing for a more complete burn and improved engine performance. This comprehensive engine design approach is what sets direct fuel injection gasoline engines apart, making them a popular choice for modern vehicles.

Carburetor and Fuel Injection: A Dual-Fuel Engine's Tale

You may want to see also

Fuel Delivery: The system delivers fuel directly to the combustion chamber, improving power and efficiency

Direct fuel injection (DFI) is a technology that has been adopted in both gasoline and diesel engines, and it offers significant advantages in terms of fuel delivery and combustion efficiency. In a gas-powered car, the fuel delivery system plays a crucial role in ensuring optimal performance and fuel economy.

The traditional fuel injection system in gasoline engines involves a multi-point injection, where fuel is injected into the intake manifold, and then distributed to multiple cylinders. However, with DFI, the process is more precise and efficient. The system delivers fuel directly to the combustion chamber, which is the space where the air-fuel mixture is ignited to power the engine. This direct approach has several benefits. Firstly, it allows for a more accurate fuel-air mixture, ensuring that the right amount of fuel is injected at the right time. This precision results in improved combustion, leading to increased power output and better overall engine performance.

In a DFI system, the fuel is injected under high pressure, which atomizes it into a fine mist. This fine fuel spray mixes thoroughly with the air in the combustion chamber, creating an optimal air-fuel mixture. The high-pressure injection ensures that the fuel is distributed evenly, reducing the chances of fuel accumulation in specific areas, which could lead to inefficient combustion. As a result, the engine can operate with a leaner air-fuel mixture, allowing for better fuel economy and reduced emissions.

The direct injection of fuel also contributes to improved engine efficiency. By delivering fuel directly to the combustion chamber, the system minimizes the time it takes for the fuel to travel through the engine's passages. This reduces the fuel's exposure to heat and pressure, preventing the formation of harmful byproducts. Additionally, the precise control over the fuel-air mixture enables the engine to operate at its most efficient combustion temperature, further enhancing overall efficiency.

Furthermore, DFI systems often feature advanced electronic controls that optimize fuel injection timing and quantity. These controls can adapt to various driving conditions, ensuring that the engine receives the right amount of fuel for optimal performance. This level of control contributes to a more responsive and powerful driving experience while maintaining excellent fuel efficiency.

In summary, direct fuel injection in gas-powered cars revolutionizes fuel delivery by injecting fuel directly into the combustion chamber. This technology enhances power, efficiency, and overall engine performance by providing precise control over the fuel-air mixture, improving combustion, and allowing for leaner operation. The result is a more responsive and efficient driving experience, making DFI a valuable advancement in modern automotive engineering.

Troubleshooting: Getting Your Car Started with a Faulty Fuel Pump

You may want to see also

Performance Benefits: Direct injection enhances power, torque, and fuel economy in gas-powered cars

Direct fuel injection (DFI) is a technology that has revolutionized the performance of gas-powered engines, offering a range of benefits that enhance the overall driving experience. One of the most significant advantages of DFI is its ability to improve power and torque output, making it a favorite among car enthusiasts and performance-oriented drivers.

When a gas-powered car utilizes direct injection, the fuel is injected directly into the combustion chamber, in contrast to the traditional port injection method. This direct approach allows for a more precise and efficient fuel-air mixture, resulting in improved power delivery. By injecting fuel directly, the engine can ignite the mixture more effectively, leading to a more powerful and responsive power output. This is particularly noticeable during acceleration, where the car can quickly respond to the driver's input, providing a more dynamic and engaging driving experience.

The torque benefits of DFI are equally impressive. Torque is the rotational force that an engine generates, and it directly impacts the car's performance and drivability. With direct injection, the engine can produce higher torque levels at lower engine speeds, which translates to better low-end performance. This is especially advantageous for everyday driving, as it provides better acceleration from a standstill and improved responsiveness when driving in stop-and-go traffic or on steep inclines. The increased torque also contributes to a smoother and more linear power delivery, making the car feel more refined and less likely to lag under load.

In addition to power and torque gains, DFI also contributes to improved fuel economy. The precise control of the fuel-air mixture allows for more efficient combustion, resulting in better fuel efficiency. This means that gas-powered cars with direct injection can travel further on a single tank of fuel, reducing the frequency of refuels and saving money in the long run. The technology also enables the engine to run at more optimal combustion conditions, reducing fuel consumption and emissions, which is an environmentally friendly benefit.

Furthermore, the performance enhancements provided by DFI can be felt across various engine speeds. The technology ensures that the engine operates at its most efficient levels, whether it's idling, cruising, or revving at high speeds. This versatility allows for a more balanced and responsive driving experience, catering to both everyday driving needs and performance-focused enthusiasts. The improved power and torque delivery, coupled with enhanced fuel economy, make direct injection a valuable addition to gas-powered cars, offering a compelling alternative to traditional port-injected engines.

The Future of Hydraulic Power: Can Cars Run on Water?

You may want to see also

Emission Control: This technology can help reduce emissions by precise fuel control, meeting stricter environmental standards

Direct fuel injection (DFI) is a technology that has been making waves in the automotive industry, particularly for gas-powered engines. This innovative system allows for a more precise and efficient way of delivering fuel to the engine's combustion chamber, which has significant implications for emission control. By optimizing the fuel injection process, DFI can play a crucial role in reducing harmful emissions and meeting the ever-tightening environmental standards set by regulatory bodies.

The primary benefit of DFI in emission control is its ability to provide precise fuel control. Traditional fuel injection systems often deliver fuel in a less controlled manner, leading to potential over-fuelling and increased emissions. With DFI, the fuel is injected directly into the combustion chamber at the exact moment it is needed, ensuring a more accurate ratio of fuel to air. This precision results in more complete combustion, where the fuel is burned more efficiently, leaving fewer unburned hydrocarbons and other pollutants in the exhaust.

In the context of emission standards, these stricter regulations demand a reduction in various pollutants, including nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. DFI technology can effectively combat these issues. For instance, by optimizing the fuel-air mixture, DFI can reduce NOx emissions, which are a byproduct of high-temperature combustion. This is achieved by ensuring that the fuel is injected at the correct timing and in the right amount, preventing the engine from reaching the high temperatures that typically produce NOx.

Furthermore, DFI's impact on emission control extends to the reduction of CO and particulate matter. CO is a harmful gas produced when the fuel-air mixture is not burned completely. DFI's precise control over the fuel injection process ensures that the engine operates at optimal conditions, minimizing CO emissions. Additionally, by improving combustion efficiency, DFI can also reduce the amount of particulate matter, which consists of tiny particles that can be harmful to human health and the environment.

In summary, direct fuel injection technology is a powerful tool for emission control in gas-powered engines. Its ability to provide precise fuel control allows for more efficient combustion, resulting in reduced emissions of harmful pollutants. As environmental standards continue to evolve, DFI can play a vital role in helping automotive manufacturers meet these challenges while also contributing to a cleaner and more sustainable future. This technology's impact on engine performance and environmental compliance is a significant step forward in the evolution of gas-powered vehicles.

Green Energy, Clean Drive: Are Fuel Cell Cars the Future?

You may want to see also

Engine Management: Advanced engine management systems optimize fuel injection for optimal performance and fuel efficiency

The evolution of engine management systems has played a pivotal role in enhancing the performance and efficiency of gas-powered vehicles, particularly in the context of fuel injection technology. Advanced engine management systems are sophisticated computer-controlled units that regulate and optimize various aspects of the engine's operation, including fuel injection. These systems have revolutionized the way fuel is delivered to the engine, ensuring precise control over the combustion process.

Direct fuel injection (DFI) is a technology that has gained prominence in modern gas-powered engines. Unlike traditional port fuel injection, where fuel is injected into the intake manifold, DFI involves injecting fuel directly into the combustion chamber. This method offers several advantages. Firstly, it allows for more precise fuel control, as the fuel can be injected at specific points in the engine's cycle, ensuring optimal air-fuel mixture formation. This precision results in improved combustion efficiency, leading to better performance and higher power output. Secondly, DFI enables better fuel atomization, which enhances the engine's ability to burn fuel more completely, reducing emissions and improving overall efficiency.

Advanced engine management systems are designed to optimize the performance of DFI engines. These systems use sophisticated algorithms and sensors to monitor and adjust various parameters in real-time. They can calculate the ideal fuel-air mixture ratio, taking into account factors such as engine speed, load, and temperature. By precisely controlling the fuel injection timing and amount, these systems ensure that the engine operates at its most efficient level, delivering the required power while minimizing fuel consumption. This level of control is particularly beneficial during different driving conditions, allowing the engine to adapt and optimize performance accordingly.

The benefits of advanced engine management systems in conjunction with DFI are significant. Firstly, they contribute to improved fuel efficiency, which is a critical aspect of modern vehicle ownership. By optimizing fuel injection, these systems reduce fuel wastage and lower operating costs. This is especially important in today's market, where fuel prices are volatile and efficient fuel usage is a priority for both drivers and manufacturers. Secondly, these systems enhance engine performance by providing the necessary power output while maintaining stability and responsiveness. The precise control over fuel injection ensures that the engine delivers its maximum potential, resulting in quicker acceleration and improved overall driving experience.

In summary, advanced engine management systems play a crucial role in maximizing the potential of direct fuel injection technology in gas-powered vehicles. By optimizing fuel injection, these systems enable engines to achieve superior performance, fuel efficiency, and emissions reduction. The real-time monitoring and adjustment capabilities of these systems ensure that the engine operates at its peak, providing drivers with a responsive and efficient driving experience. As engine technology continues to advance, the integration of such sophisticated management systems will become increasingly vital in meeting the demands of modern transportation while maintaining environmental sustainability.

Electric Car Lobbyists: Fuel Cell Future in Doubt?

You may want to see also

Frequently asked questions

Direct fuel injection (DFI) is a technology where the fuel is injected directly into the combustion chamber of an engine, as opposed to the intake manifold or carburetor. This method allows for more precise control over the fuel-air mixture, resulting in improved performance, better fuel efficiency, and reduced emissions. DFI systems can be used in both gasoline and diesel engines, but they are commonly associated with gasoline engines due to their ability to enhance power and responsiveness.

Absolutely! Gas-powered cars can indeed utilize direct fuel injection, and many modern vehicles are equipped with this technology. DFI in gasoline engines offers several advantages, including increased power output, improved throttle response, and better fuel economy. It also contributes to cleaner combustion, reducing harmful emissions and improving overall engine performance.

Direct fuel injection can significantly enhance the driving experience. With DFI, gas-powered cars tend to have faster acceleration, delivering more responsive power delivery. The engine's performance is improved, providing a smoother and more linear power output. Additionally, DFI can contribute to better fuel efficiency, allowing drivers to save on fuel costs without compromising on performance. This technology is particularly beneficial for sports cars and high-performance vehicles, offering a blend of power and efficiency.