Changing a fuel pump pushrod is a relatively straightforward task, but there are a few precautions to take to avoid further issues. Before removing the old pushrod, it's important to check for any easy-to-fix problems that might be causing fuel delivery issues, such as a loose or cracked inlet line, a blocked fuel filter, or a frozen fuel line in cold weather. If the fuel pump is indeed at fault, it can be quickly checked by disconnecting the fuel line at the carburettor and testing fuel delivery. If the pump fails this test, it must be replaced. When removing the old pushrod, it's important to use the correct tools to avoid damaging any fittings. Some engines use a fuel pump pushrod that can be removed by taking out the access plug. To install a new pushrod, coat it with grease to hold it in place, then carefully position and bolt the fuel pump into place, taking care to verify that the actuating arm is properly positioned. Finally, reconnect all lines to the fuel pump, being careful not to overtighten or crossthread any of the fuel line fittings.

| Characteristics | Values |

|---|---|

| Difficulty | Medium |

| Tools required | Wrenches, tubing wrenches, grease |

| Time required | A few hours |

| Cost | Varies depending on the car model and parts required |

| Precautions | Use two wrenches when loosening or tightening brass fittings to avoid damage; verify the pump needs replacement before starting the job; be careful not to overtighten or crossthread fuel line fittings |

| Symptoms of fuel pump failure | Vehicle stops running as if it ran out of gas; engine runs short of gas during high load; pump leaks gasoline or oil |

| Other possible causes of fuel delivery issues | Loose or cracked inlet line to the pump from the gas tank; blocked tank vent; blocked fuel filter; frozen condensation in the fuel line in cold weather |

| Fuel pump pushrod removal | Remove the access plug and then the pushrod |

| Fuel pump pushrod installation aid | Coat the pushrod with wheel bearing grease to hold it in place while installing the new fuel pump |

What You'll Learn

Removing the pushrod

- Locate the Access Plug: The first step is to identify the access plug, which is usually located near the fuel pump. This plug provides access to the pushrod and can be removed using the appropriate tools.

- Remove the Access Plug: Using a suitable tool, carefully remove the access plug. This will expose the fuel pump pushrod and allow you to access it for removal.

- Loosen or Remove Any Retaining Components: In some cases, there may be additional components holding the pushrod in place, such as a bolt or a clip. Loosen or remove these components to free the pushrod.

- Gently Pull Out the Pushrod: Once the access plug and any retaining components have been removed, you should be able to gently pull out the pushrod. It may be helpful to wiggle it slightly to loosen it before removing it entirely.

- Clean and Inspect the Pushrod: After removing the pushrod, take the opportunity to clean it and inspect it for any damage or wear. This will help you determine if it needs to be replaced or can be reused.

- Store or Replace the Pushrod: If you plan to reuse the pushrod, store it in a safe place. If you're replacing it, have the new pushrod ready for installation.

- Reinstall the Access Plug: Before proceeding, make sure to reinstall the access plug securely. This will ensure that the area remains sealed and protected.

Remember to work carefully and methodically when removing the pushrod to avoid any accidental damage to surrounding components. It is also important to refer to your vehicle's specific repair manual or seek guidance from a qualified mechanic if you are unsure about any steps or procedures.

Fuel Injector Maintenance: Post-Installation Care and Performance Tips

You may want to see also

Installing a new pushrod

Before beginning the installation, it is important to gather the necessary tools and materials. These include a new pushrod, grease (preferably wheel bearing grease or engine assembly lube), and any tools required to remove and reinstall the access plug and fuel pump.

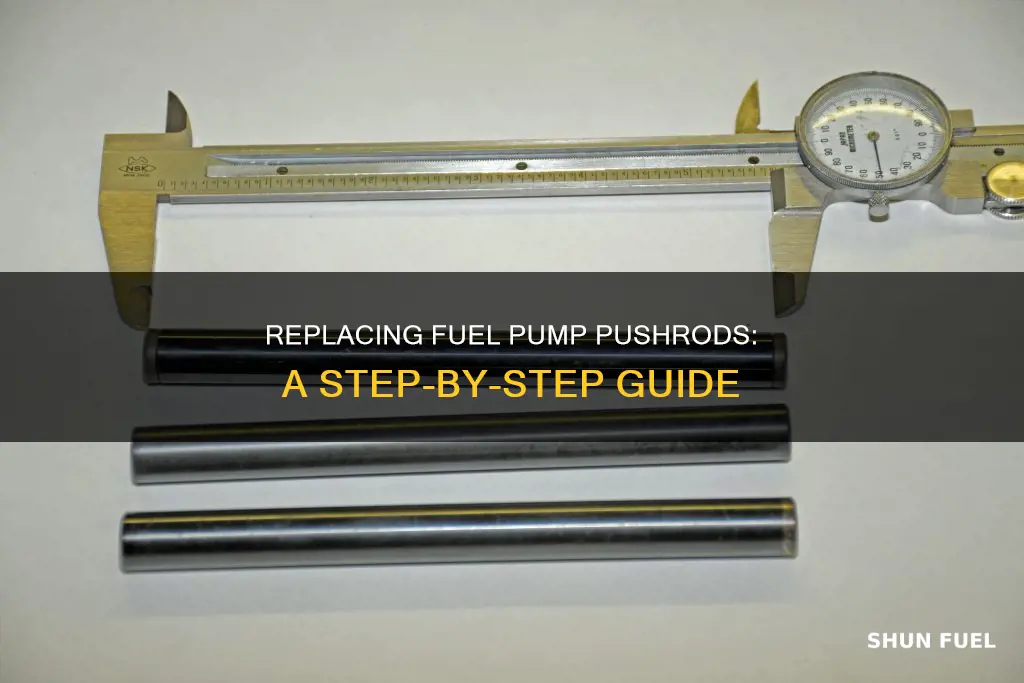

First, remove the access plug from the engine. This will expose the pushrod and allow for its removal. Take note of the position of the pushrod and any attached components, such as a spring, to ensure proper installation of the new pushrod. Once the old pushrod is removed, inspect the new pushrod for any defects and ensure it is the correct size and type for your engine.

Next, apply a coating of grease to the new pushrod. This will help keep the pushrod in place during the installation of the fuel pump. Insert the greased pushrod back into the engine through the access hole, ensuring it is in the correct position. Reinstall the access plug to secure the pushrod in place.

With the pushrod in place, you can now install the new fuel pump. Carefully transfer any fuel line fittings from the old pump to the new one, ensuring they are installed in the same direction as before. Position the new fuel pump on the engine, using a new gasket, and verify that the actuating arm is properly aligned before tightening the fuel pump bolts.

Finally, reconnect all the lines to the fuel pump, being careful to not overtighten or cross-thread any fuel line fittings. Start the engine and check for any leaks. Ensure that the pushrod is functioning correctly and engaging with the fuel pump lever.

It is important to note that different engines may have specific variations in the installation process, so it is always recommended to refer to the manufacturer's instructions or a trusted mechanic for specific guidance on your particular engine.

Climate Change: War Instigator or Peacekeeper?

You may want to see also

Coating the pushrod with grease

To do this, simply apply a generous amount of grease to the pushrod before inserting it into the engine. You can use a variety of greases for this purpose, such as engine assembly lube, wheel bearing grease, or even silicone grease. However, it is important to avoid using gun grease or any type of grease that contains lithium soap, as these can cause issues with seal compatibility and wash away with water.

While coating the pushrod with grease is an effective method, there are also other tricks you can use to keep the pushrod in place. One method is to use a longer bolt to hold the pushrod up against the bolt hole. This prevents the pushrod from falling out while you install the fuel pump. Just remember to replace the longer bolt with the original shorter bolt once you're done. Another creative solution is to use a bent coat hanger or a thin saw blade to hold the pushrod in place while you work.

Additionally, it's important to ensure that the pushrod is straight before attempting to install it. A bent pushrod may bind and cause issues during installation. If necessary, use some sandpaper to smooth out any imperfections on the pushrod before proceeding.

Fuel-Efficient Cars: Driving Towards a Greener Future

You may want to see also

Selecting the right pushrod

When selecting a fuel pump pushrod, it is important to consider the compatibility with your engine and the type of camshaft you are using.

First, you need to narrow down your options to pushrods that match the year, make, and size of your engine. For example, if you are looking for a pushrod for a Chevy 454 engine, you would want to choose a pushrod specifically designed for that engine.

Once you have identified the compatible pushrods, you can then select the one that best suits your application and budget. Here are some factors to consider:

- Weight of the pushrod: A lighter pushrod can help reduce pump float and improve fuel delivery at high engine speeds.

- Compatibility with camshaft material: If you are using a steel camshaft, choose a pushrod that is compatible with it, such as those made from composite materials or with bronze tips. This will prevent premature wear and tear on the camshaft and pushrod.

- Durability and performance: Choose a pushrod made from high-quality materials that offer long service life and reliable performance.

- Budget: Consider your budget and choose a pushrod that offers the best value for your money.

Some reputable manufacturers of fuel pump pushrods include Chevrolet Performance, COMP Cams, ARP, Moroso, JEGS, and Howards Cams. They offer a range of options in terms of materials, weight, and compatibility with different engines and camshafts.

Make sure to refer to the specific installation instructions for your chosen pushrod, as some may have particular requirements, such as the orientation of the bronze tip towards the camshaft.

Fuel Mileage and B20: Any Difference?

You may want to see also

Troubleshooting

Step 1: Check for Proper Installation

Before assuming a faulty pushrod, ensure that the fuel pump pushrod is correctly installed. Check if the pushrod is aligned correctly and fully seated in its designated slot.

Step 2: Verify Pushrod Length

If the pushrod appears correctly installed, verify that the pushrod length is appropriate for your specific engine and fuel pump configuration. An incorrect pushrod length may prevent proper engagement with the pump.

Step 3: Inspect for Binding or Obstruction

If the pushrod length is correct, inspect the pushrod for any binding or obstruction that may prevent it from moving freely. This can include checking for any debris or crud in the guide hole that the pushrod sits in.

Step 4: Check for Disconnected Components

In some cases, the issue may lie in a disconnected component rather than the pushrod itself. Inspect the lever on the fuel pump to ensure it is properly connected to the diaphragm rod. A loose connection here can prevent the pump from functioning correctly.

Step 5: Test for Suction

If the lever and diaphragm rod are securely connected, perform a test to check for suction in the pump. Turn over the engine and inspect the feed line for any signs of suction. A lack of suction could indicate an issue with the pump itself or an improper installation.

Step 6: Assess Pump Compatibility

If you're still encountering issues, assess the compatibility of the fuel pump with your specific engine. Ensure that the pump arm is suitable for your engine type (e.g., small-block vs. big-block engines) and that the pump is correctly oriented.

Step 7: Consider Pump Quality

Finally, consider the quality of the fuel pump. As highlighted in the sources, some stock replacement pumps may have manufacturing defects or inconsistent quality, leading to engagement issues with the pushrod.

By following these systematic troubleshooting steps, you can identify and resolve issues related to replacing a fuel pump pushrod, ensuring a smooth and successful installation process.

Natural Gas Cars: Resale Value Impact?

You may want to see also

Frequently asked questions

A fuel pump pushrod is a device that joins a lobe on the camshaft (or an eccentric) to a lever on the fuel pump. It moves the fuel pump lever up and down, drawing fuel from the tank to the carburettor(s). Over time, the pushrod can wear down and may need to be replaced.

The fuel pump pushrod can be accessed by removing the access plug from the engine.

When dealing with fuel lines and brass tubing nuts and fittings, always use two wrenches to support both halves of the fitting to prevent damage to the relatively fragile fittings. Tubing wrenches are preferable as they provide a greater contact area and reduce potentially damaging stresses.

An easy way to prevent the pushrod from falling out is to coat it with wheel bearing grease or engine assembly grease. This will help the pushrod stay in place while you position and bolt the new fuel pump into place.

Before changing the pushrod, verify that the fuel pump actually needs to be replaced. Other problems in the fuel system could be causing a shortage or stoppage of fuel delivery to the engine, such as a loose or cracked inlet line, a blocked fuel filter, or a frozen fuel line in cold weather.