Car fuel is a complex system that powers the internal combustion engine, which is the heart of most vehicles. The process begins with the fuel being injected into the engine's cylinders, where it is ignited by a spark plug, creating a controlled explosion that drives the pistons and ultimately powers the vehicle. This intricate dance of fuel and air, ignited by a spark, is the essence of how cars move. Understanding the mechanics of fuel injection, combustion, and the role of various components like the fuel pump and injectors is key to appreciating the engineering marvel that is modern transportation.

What You'll Learn

- Engine Combustion: Fuel ignites in cylinders, creating power

- Fuel Injection: Precise fuel delivery for optimal engine performance

- Engine Cycles: Four-stroke process converts fuel into mechanical energy

- Fuel Efficiency: Miles per gallon measures car's fuel economy

- Emissions Control: Systems reduce harmful gases from fuel combustion

Engine Combustion: Fuel ignites in cylinders, creating power

The process of engine combustion is a fascinating and intricate dance of physics and chemistry, where the transformation of fuel into energy is a key player in a car's performance. When you step into a vehicle and turn the key, a complex sequence of events unfolds, culminating in the ignition of fuel within the engine's cylinders. This ignition process is the heart of an internal combustion engine's power generation.

In the engine's cylinders, a precise mixture of fuel and air is carefully prepared. This mixture is carefully crafted to ensure optimal combustion, a delicate balance that engineers have fine-tuned over decades of automotive development. The air-fuel mixture is carefully timed and metered, ensuring that the right amount of fuel is available for each cylinder's combustion event. This precision is crucial, as too much or too little fuel can lead to inefficient combustion, reduced performance, and even engine damage.

As the piston reaches the top of its compression stroke, a spark plug introduces a high-voltage spark. This spark ignites the air-fuel mixture, causing it to rapidly combust. The combustion process is a rapid and controlled explosion, generating a significant amount of energy in a very short time. This energy is transferred to the piston, causing it to move downward with great force, which in turn rotates the crankshaft and ultimately powers the vehicle's wheels.

The timing of this spark is critical. It must occur at the precise moment when the piston is at the top of its compression stroke, ensuring maximum power output and efficient combustion. Modern engines use sophisticated timing systems, often controlled by an engine control unit (ECU), to ensure that the spark plugs fire at the optimal moment for each cylinder. This timing is so precise that it can vary slightly between cylinders, optimizing performance and fuel efficiency.

The combustion process is a complex interplay of various factors, including fuel type, compression ratio, and engine design. Different fuels, such as gasoline or diesel, have unique properties that influence combustion characteristics. For instance, gasoline engines typically use a higher compression ratio and a more volatile fuel-air mixture, while diesel engines operate with a lower compression ratio and a denser fuel-air mixture, leading to a different ignition process. Understanding these nuances is essential for engineers to design engines that are efficient, powerful, and environmentally friendly.

When the Gas Runs Out: Does the Car Stop?

You may want to see also

Fuel Injection: Precise fuel delivery for optimal engine performance

Fuel injection is a critical component of modern engine technology, revolutionizing the way engines operate and delivering precise fuel delivery for optimal performance. This system has evolved from the traditional carburetor setup, offering improved efficiency, power, and control over the combustion process. At its core, fuel injection involves the precise metering and injection of fuel into the engine's cylinders, ensuring a balanced and efficient burn.

The process begins with the fuel injection system receiving signals from various engine sensors, such as the engine control unit (ECU). These sensors provide real-time data on engine speed, load, temperature, and other parameters. Based on this information, the ECU calculates the exact amount of fuel required for optimal combustion. This calculation takes into account the engine's current state and the driver's demands, ensuring a dynamic and responsive fuel delivery system.

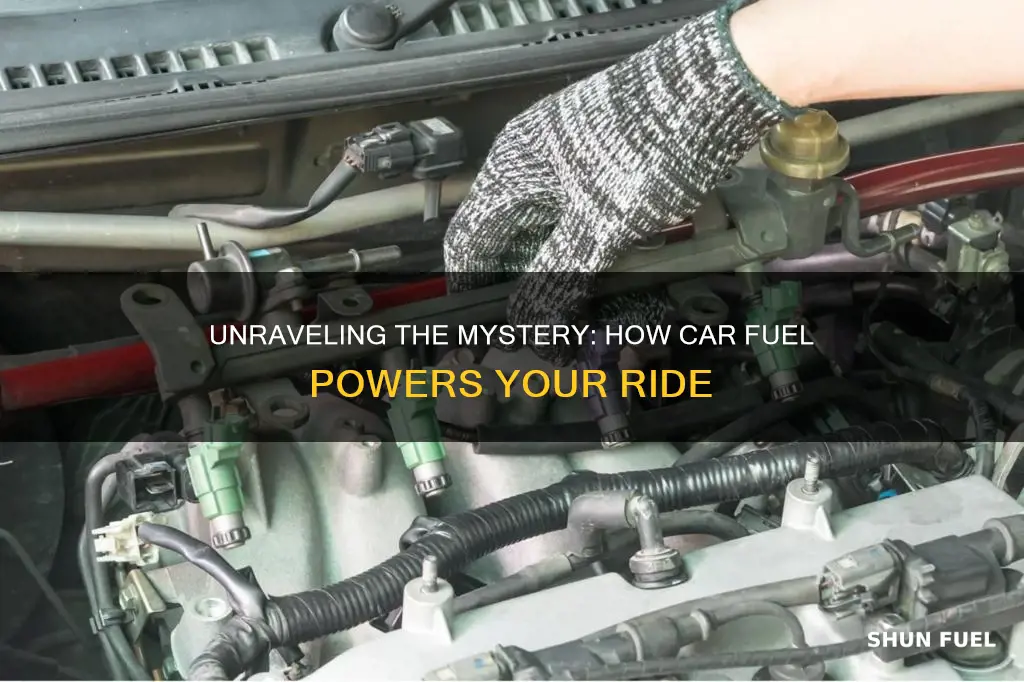

Fuel injectors, typically located near the intake valves, are responsible for spraying the precise amount of fuel into the engine's cylinders. These injectors are highly accurate, capable of delivering fuel in tiny, controlled droplets. The fuel is injected under high pressure, ensuring it mixes thoroughly with the air-fuel mixture in the combustion chamber. This high-pressure injection guarantees efficient atomization, allowing for better combustion and increased power output.

One of the key advantages of fuel injection is its ability to adapt to varying engine conditions. Unlike a carburetor, which relies on a fixed air-fuel mixture, fuel injection can adjust the fuel-air ratio in real-time. This adaptability is crucial for maintaining optimal performance across different driving conditions and loads. For instance, during high-speed cruising, the system can deliver a leaner mixture to improve fuel efficiency, while under heavy acceleration, it provides a richer mixture for maximum power.

Furthermore, fuel injection offers improved emissions control. By precisely controlling the fuel-air ratio, the system can ensure complete combustion, reducing the release of harmful pollutants. This level of control contributes to meeting stricter environmental regulations and promoting a cleaner, more sustainable driving experience. In summary, fuel injection technology provides a sophisticated and efficient approach to fuel delivery, enabling engines to operate at their peak performance while maintaining a balance between power, efficiency, and environmental considerations.

Understanding Fuel Service Charges on Rental Cars: A Comprehensive Guide

You may want to see also

Engine Cycles: Four-stroke process converts fuel into mechanical energy

The four-stroke engine cycle is a fundamental process that powers modern internal combustion engines, which are the heart of most cars and vehicles. This cycle is a four-step process that efficiently converts chemical energy from fuel into mechanical energy, enabling the engine to perform work. Here's a detailed breakdown of this fascinating mechanism:

Step 1: Intake Stroke: The process begins with the intake stroke, where the piston moves downward in the cylinder, creating a vacuum. This vacuum draws a mixture of air and fuel into the cylinder through the open intake valve. The air-fuel mixture is carefully measured and timed to ensure optimal combustion. This step is crucial as it sets the stage for the upcoming power generation.

Step 2: Compression Stroke: As the piston reaches the bottom of its travel, it begins to move upward, compressing the air-fuel mixture. This compression increases the pressure and temperature within the cylinder, creating a highly efficient environment for combustion. The compression ratio, which is the ratio of the cylinder's volume at the bottom of the stroke to its volume at the top, plays a critical role in engine performance. Higher compression ratios generally result in more power but also require higher-octane fuel.

Step 3: Power Stroke (Combustion): At the top of the compression stroke, the spark plug ignites the compressed air-fuel mixture, causing a rapid combustion process. This combustion releases a significant amount of energy, which is transferred to the piston, causing it to move downward with great force. This downward movement of the piston is the power stroke, where the mechanical energy is generated. The force exerted by the piston is what ultimately turns the crankshaft, driving the vehicle's wheels.

Step 4: Exhaust Stroke: After the power stroke, the piston continues its upward movement, pushing the exhaust gases out of the cylinder through the open exhaust valve. This exhaust stroke ensures that the cylinder is ready for the next intake stroke, completing the four-stroke cycle. The exhaust gases are expelled from the vehicle through the exhaust system, and the process repeats, providing a continuous flow of mechanical energy.

This four-stroke process is a highly efficient and reliable way to convert chemical energy from fuel into the mechanical energy that powers our vehicles. It has been a cornerstone of automotive engineering, allowing for the development of powerful and efficient engines that have shaped the modern transportation industry. Understanding these engine cycles is essential to appreciating the intricate workings of a car's fuel system.

Can Fuel-Efficient Cars Access California HOV Lanes?

You may want to see also

Fuel Efficiency: Miles per gallon measures car's fuel economy

Fuel efficiency is a critical aspect of modern automobiles, and it's an essential factor for car owners to understand. Miles per gallon (mpg) is the standard unit used to measure a vehicle's fuel economy, indicating how far a car can travel on a single gallon of fuel. This metric provides valuable insights into a vehicle's efficiency and performance, allowing drivers to make informed decisions about their car's fuel consumption.

The concept of mpg is straightforward: it represents the distance a vehicle can cover in miles using one gallon of gasoline. For instance, a car with a fuel efficiency of 30 mpg can travel 30 miles for every gallon of fuel consumed. This measurement is a powerful tool for car buyers and owners alike, as it directly impacts their daily driving experience and long-term costs. Higher mpg means better fuel efficiency, resulting in reduced fuel expenses and a smaller environmental footprint.

To calculate mpg, you can use a simple formula: mpg = total miles driven / total gallons of fuel used. This calculation is a practical way to assess a vehicle's performance over time. For example, if a driver fills up their tank with 10 gallons of fuel and drives 300 miles, the mpg would be 300/10 = 30 mpg. This real-world data helps drivers understand how their vehicles perform in everyday driving conditions.

Understanding fuel efficiency is crucial for several reasons. Firstly, it empowers drivers to make cost-effective choices. Vehicles with higher mpg can significantly reduce fuel costs, especially for those who drive long distances or frequently. Secondly, fuel efficiency contributes to environmental sustainability. Cars with better mpg ratings produce fewer emissions, making them more environmentally friendly. This aspect is increasingly important as consumers become more conscious of their carbon footprint.

In summary, miles per gallon is a vital metric for assessing a car's fuel efficiency and overall performance. It provides a clear indication of how far a vehicle can travel on a given amount of fuel, enabling drivers to make informed decisions. By considering fuel efficiency, car owners can optimize their driving experience, reduce fuel expenses, and contribute to a greener environment. This knowledge is essential for anyone looking to purchase a new vehicle or manage their existing car's fuel consumption.

Lowering Your Car: Efficiency Boost or Just a Stylish Mod?

You may want to see also

Emissions Control: Systems reduce harmful gases from fuel combustion

The combustion of fuel in a car's engine is a complex process that, while essential for transportation, also produces various harmful emissions. To mitigate these environmental impacts, modern vehicles are equipped with sophisticated emissions control systems. These systems play a crucial role in reducing the release of pollutants into the atmosphere, ensuring cleaner and more sustainable vehicle operation.

One of the primary components of emissions control is the catalytic converter, a device positioned in the exhaust system. It acts as a chemical reactor, facilitating the conversion of harmful gases into less toxic substances. As exhaust gases pass through the converter, it uses a catalyst, often made of precious metals like platinum and rhodium, to initiate chemical reactions. These reactions transform toxic gases such as carbon monoxide (CO), nitrogen oxides (NOx), and unburned hydrocarbons into harmless byproducts like carbon dioxide (CO2), nitrogen gas (N2), and water vapor (H2O). The catalytic converter is designed to maximize the efficiency of these conversions, ensuring that the exhaust released into the environment is significantly less harmful.

In addition to catalytic converters, emissions control systems employ various other mechanisms. One such system is the three-way catalyst, which is particularly effective in controlling emissions in gasoline engines. This catalyst operates optimally at specific engine speeds and temperatures, allowing it to simultaneously reduce CO, NOx, and hydrocarbons. Another crucial component is the oxygen sensor, which monitors the oxygen content in the exhaust stream. This sensor provides real-time data to the engine's electronic control unit (ECU), enabling precise fuel-air mixture adjustments to optimize combustion and minimize emissions.

Furthermore, emissions control extends beyond the engine and exhaust system. Modern vehicles are equipped with electronic control units that continuously monitor and adjust engine performance. These ECUs ensure that the engine operates within specific parameters to meet emissions standards. For instance, they can adjust fuel injection timing, spark plug timing, and air-fuel mixture to optimize combustion, thereby reducing the release of harmful gases. Additionally, some vehicles employ exhaust gas recirculation (EGR) systems, which redirect a controlled amount of exhaust gas back into the engine's intake manifold, reducing NOx emissions.

The development of emissions control systems has been a significant focus in the automotive industry, driven by environmental regulations and public awareness. These systems not only contribute to cleaner air but also enhance engine performance and fuel efficiency. As technology advances, emissions control mechanisms continue to evolve, incorporating new materials, designs, and control strategies to further minimize the environmental impact of vehicles.

Unleash Fuel Additives' Power: Do They Boost Gas Mileage?

You may want to see also

Frequently asked questions

Car fuel, typically gasoline or diesel, is a mixture of hydrocarbons and other compounds. When ignited in the engine's combustion chamber, it undergoes a rapid expansion and contraction process, creating energy that powers the vehicle. This process is known as the combustion cycle.

The fuel injection system is responsible for delivering the precise amount of fuel required for each cylinder in the engine. It meters and injects fuel into the engine's intake manifold or directly into the cylinders, ensuring efficient combustion and optimal performance.

Fuel efficiency is measured by the distance a vehicle can travel per unit of fuel consumed. It is influenced by various factors, including engine design, aerodynamics, vehicle weight, and driving habits. Modern cars often employ technologies like direct fuel injection and turbocharging to improve fuel efficiency.

Gasoline engines use spark plugs to ignite the air-fuel mixture, while diesel engines rely on compression ignition. Gasoline engines typically have higher power-to-weight ratios, making them suitable for sports cars. Diesel engines are known for their torque and fuel efficiency, often used in trucks and larger vehicles.

The fuel gauge provides an estimate of the remaining fuel in the tank. It operates by measuring the electrical current flow through a small resistor in the fuel tank. As fuel is consumed, the resistance changes, allowing the gauge to display the fuel level accurately.