Modern cars are equipped with sophisticated fuel measurement systems that play a crucial role in optimizing performance and efficiency. These systems employ various sensors and technologies to accurately gauge the amount of fuel consumed during a journey. The process begins with the fuel injection system, which precisely measures the fuel flow rate into the engine. This data is then analyzed by the engine control unit (ECU), which calculates the total fuel consumption based on factors like engine speed, load, and driving conditions. Additionally, some vehicles utilize onboard diagnostic tools that provide real-time fuel efficiency data, allowing drivers to monitor their vehicle's fuel usage and make informed decisions to improve mileage. Understanding these mechanisms is essential for drivers seeking to maximize their vehicle's fuel efficiency and minimize environmental impact.

What You'll Learn

- Engine Efficiency: Measures fuel consumption based on engine power output

- Fuel Injection: System regulates fuel-air mixture for optimal combustion

- Sensor Technology: Sensors monitor fuel levels and engine performance in real-time

- Fuel Economy Ratings: Standardized tests provide fuel efficiency estimates for vehicles

- On-Board Diagnostics: OBD systems analyze fuel usage and engine performance data

Engine Efficiency: Measures fuel consumption based on engine power output

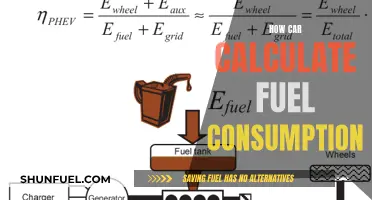

The concept of engine efficiency is a critical aspect of understanding how a car measures fuel consumption. It involves evaluating the power output of the engine and its ability to convert fuel into useful work. This efficiency is measured by the ratio of power output to the amount of fuel consumed, providing a clear indicator of how effectively the engine utilizes the energy from the fuel.

Engine power output is a fundamental parameter in this process. It represents the rate at which the engine can produce mechanical work, typically measured in horsepower (hp) or kilowatts (kW). Higher power output generally indicates a more powerful engine, but it doesn't necessarily mean better fuel efficiency. The relationship between power and fuel consumption is not linear; a more powerful engine may consume more fuel at higher speeds or during acceleration, but it can also be designed to be more efficient at lower loads.

To measure engine efficiency, engineers use various methods, including dynamometer testing and on-board diagnostic systems. Dynamometer tests involve running the engine on a specialized machine that simulates real-world driving conditions, allowing for precise measurements of power output and fuel consumption. These tests provide valuable data for engine calibration and optimization. On-board diagnostic systems, on the other hand, continuously monitor the engine's performance and fuel usage, providing real-time feedback to the driver and enabling the detection of any inefficiencies or issues.

The efficiency calculation is based on the principle that a more efficient engine will produce more power for a given amount of fuel. This is achieved through various design considerations, such as optimizing the combustion process, improving the engine's thermodynamics, and reducing friction. For instance, advanced engine management systems can adjust fuel injection and ignition timing to ensure optimal combustion, maximizing power output while minimizing fuel consumption.

In summary, engine efficiency is a key factor in understanding fuel consumption. By measuring and optimizing power output, engineers can develop vehicles that offer better fuel economy without compromising performance. This balance between power and efficiency is essential for creating sustainable and cost-effective transportation solutions.

Filling Up: Does Your Car Burn More Fuel When Empty?

You may want to see also

Fuel Injection: System regulates fuel-air mixture for optimal combustion

Fuel injection is a sophisticated system in modern vehicles that plays a crucial role in optimizing engine performance and fuel efficiency. This technology has evolved significantly over the years, replacing the traditional carburetor in many cars. The primary function of fuel injection is to precisely regulate the fuel-air mixture, ensuring that the engine receives the perfect amount of fuel for efficient combustion. This process is vital for maximizing power output while minimizing fuel consumption and emissions.

At its core, the fuel injection system consists of several key components. These include the fuel pump, injectors, a control unit, and sensors. The fuel pump draws fuel from the tank and sends it to the injectors, which are strategically positioned near the engine's intake valves. Each injector delivers a precise amount of fuel directly into the engine's cylinders, bypassing the carburetor. This direct injection method allows for better control over the fuel-air mixture, as the system can precisely measure and adjust the fuel flow based on various engine parameters.

The control unit, often referred to as the Engine Control Unit (ECU), is the brain of the fuel injection system. It receives input from various sensors, such as the engine temperature, speed, and load sensors. These sensors provide real-time data about the engine's operating conditions. The ECU then uses this information to calculate the ideal fuel-air mixture ratio and instructs the injectors accordingly. By continuously monitoring and adjusting the fuel delivery, the system ensures that the engine operates at its most efficient level, regardless of the driving conditions.

One of the significant advantages of fuel injection is its ability to adapt to different driving scenarios. For instance, during high-speed cruising, the system can deliver a leaner fuel-air mixture, promoting better fuel economy. Conversely, when the driver demands more power, such as during acceleration, the fuel injection system compensates by providing a richer mixture, resulting in a powerful response. This dynamic adjustment ensures that the engine performs optimally in various situations, from everyday driving to high-performance applications.

In summary, fuel injection technology is a critical advancement in automotive engineering, offering precise control over the fuel-air mixture. By regulating the fuel delivery process, this system optimizes engine performance, improves fuel efficiency, and reduces emissions. The intricate interplay between the fuel pump, injectors, control unit, and sensors ensures that modern vehicles can deliver power and efficiency in harmony, catering to the diverse needs of drivers in different circumstances.

Mazda's Fuel Efficiency: A Comprehensive Guide to Eco-Friendly Driving

You may want to see also

Sensor Technology: Sensors monitor fuel levels and engine performance in real-time

Modern cars rely on sophisticated sensor technology to accurately measure fuel levels and monitor engine performance, ensuring optimal efficiency and safety. These sensors play a crucial role in providing real-time data, allowing for precise fuel management and improved overall vehicle operation.

One key component in this system is the fuel level sensor, typically located in the fuel tank. This sensor employs various technologies, such as capacitive or ultrasonic, to measure the volume of fuel present. Capacitive sensors use an electrical field to detect changes in fuel level, while ultrasonic sensors emit high-frequency sound waves and measure the time it takes for the signal to bounce back, providing an accurate measurement. These sensors provide drivers with an indication of the remaining fuel, ensuring they are aware of when to refuel.

In addition to fuel level monitoring, sensors also contribute to engine performance tracking. Engine sensors are strategically placed throughout the engine bay and cylinder head, measuring critical parameters like temperature, pressure, and airflow. These sensors provide real-time data to the engine control unit (ECU), which processes this information to optimize fuel injection, ignition timing, and overall engine operation. By continuously monitoring engine performance, these sensors help maintain efficient combustion, reduce emissions, and improve the overall driving experience.

The integration of sensor technology offers numerous benefits. Firstly, it enables precise fuel management, ensuring that the engine receives the correct amount of fuel at any given time. This precision results in improved fuel efficiency, reduced fuel consumption, and lower emissions. Secondly, real-time monitoring of engine performance allows for prompt detection of any anomalies or issues. If a sensor detects an abnormal temperature or pressure, for instance, the ECU can take immediate action, such as adjusting fuel injection or alerting the driver to potential problems.

Furthermore, sensor technology contributes to the overall safety and reliability of the vehicle. By continuously monitoring engine performance, these sensors help prevent engine damage caused by excessive heat or pressure. They also assist in identifying potential issues before they become major problems, reducing the risk of unexpected breakdowns. Additionally, the data provided by these sensors can be used for diagnostic purposes, allowing mechanics to quickly identify and resolve any fuel-related or engine-performance-related concerns.

Understanding the Cost of Fuel Pumps: A Comprehensive Guide

You may want to see also

Fuel Economy Ratings: Standardized tests provide fuel efficiency estimates for vehicles

The concept of fuel economy ratings is a crucial aspect of the automotive industry, offering consumers a standardized way to compare the fuel efficiency of different vehicles. These ratings are derived through controlled tests that simulate real-world driving conditions, ensuring a fair and accurate representation of a car's fuel performance. The primary purpose of these standardized tests is to provide consumers with a clear understanding of how much fuel a vehicle will consume over a specific distance or time period.

In the United States, the Environmental Protection Agency (EPA) plays a pivotal role in establishing and regulating these fuel economy ratings. The EPA's Corporate Average Fuel Economy (CAFE) standards mandate that all new vehicles sold in the country must meet certain fuel efficiency requirements. To achieve these standards, manufacturers conduct rigorous testing, often using specialized equipment like dynamometers, which simulate various driving conditions. These tests include city driving cycles, highway driving cycles, and combined cycles, each designed to mimic specific real-world scenarios.

During these tests, vehicles are driven on a rolling road or a dynamometer, which measures the power output and fuel consumption. The data collected is then used to calculate the vehicle's fuel economy in miles per gallon (mpg) or liters per 100 kilometers (l/100 km). This standardized testing ensures that the fuel economy ratings provided to consumers are consistent and comparable across different vehicle models and manufacturers.

The standardized test procedures are meticulously designed to account for various factors that can influence fuel consumption, such as vehicle weight, tire pressure, and aerodynamic drag. By controlling these variables, the tests provide a more accurate representation of a vehicle's fuel efficiency. Additionally, the test cycles are updated periodically to reflect changes in driving patterns and vehicle technology, ensuring that the ratings remain relevant and reliable over time.

Consumers can use these fuel economy ratings as a valuable tool when making purchasing decisions. A higher fuel economy rating indicates better fuel efficiency, which translates to cost savings for the vehicle owner. Standardized testing also encourages manufacturers to innovate and develop more efficient engines and vehicles, ultimately benefiting the environment and consumers alike. This approach to fuel measurement and rating has become an essential part of the automotive industry's commitment to sustainability and consumer transparency.

Mixed Fuel in Your Car: What You Need to Know

You may want to see also

On-Board Diagnostics: OBD systems analyze fuel usage and engine performance data

On-Board Diagnostics, commonly known as OBD, is a system designed to monitor and diagnose the health of a vehicle's engine and various subsystems. It plays a crucial role in modern automobiles, providing real-time data and insights into fuel usage and engine performance. OBD systems have evolved significantly since their introduction, offering a comprehensive approach to vehicle maintenance and efficiency.

The primary function of OBD is to collect and analyze data related to fuel consumption and engine operation. It does this through a network of sensors and actuators strategically placed throughout the vehicle. These sensors measure various parameters such as engine speed, load, temperature, and fuel pressure. By gathering this data, the OBD system can calculate and provide information on fuel efficiency, power output, and overall engine performance. This includes monitoring fuel injection timing, spark plug conditions, and the accuracy of the air-fuel mixture.

One of the key advantages of OBD is its ability to provide immediate feedback on fuel usage. It can detect and alert drivers to any deviations from optimal performance, such as excessive fuel consumption or inefficient combustion. For instance, if the engine is burning more fuel than expected, the OBD system can identify the issue, whether it's a faulty sensor, a problem with the fuel injectors, or an issue with the engine control unit (ECU). This real-time analysis allows for prompt maintenance, ensuring the vehicle operates at its best and helps optimize fuel economy.

OBD systems also store diagnostic trouble codes (DTCs) when a problem is detected. These codes are like a language that mechanics and technicians can understand, providing specific information about the nature of the issue. When a vehicle is taken to a service center, these DTCs can be retrieved and analyzed, allowing technicians to quickly identify and rectify the problem. This not only saves time but also ensures that potential fuel-related issues are addressed promptly, preventing further complications.

In summary, OBD systems are an essential component of modern vehicles, offering a sophisticated way to measure and analyze fuel usage and engine performance. By continuously monitoring various parameters, these systems provide valuable insights, ensuring optimal fuel efficiency and engine health. The ability to detect issues in real-time and provide detailed diagnostic information has revolutionized vehicle maintenance, making it more accessible and efficient for both drivers and automotive professionals.

EPA's Lead-Free Fuel Revolution: A Green Shift for Cars

You may want to see also

Frequently asked questions

Fuel efficiency is typically measured using a metric called miles per gallon (mpg) or liters per 100 kilometers (l/100 km). Modern vehicles often have on-board computers that monitor and display fuel efficiency in real-time. These systems calculate the distance traveled per unit of fuel consumed, providing an accurate measurement of how far a car can go on a full tank.

There are two primary methods to measure fuel in a car: the mechanical method and the electronic method. The mechanical method involves a device called a fuel gauge, which uses a float and a needle to indicate the fuel level in the tank. This traditional gauge is often found in older vehicles. In contrast, modern cars use electronic fuel injection systems, which measure fuel flow and level through sensors and send this data to the engine control unit (ECU) for precise fuel management.

The accuracy of fuel measurement systems can vary depending on the vehicle's make and model, as well as the age of the technology. Modern cars with electronic fuel injection systems tend to provide more accurate fuel readings due to advanced sensors and real-time data processing. However, factors like fuel type, driving conditions, and vehicle maintenance can also influence accuracy. It's always a good idea to regularly check fuel levels and monitor fuel efficiency to ensure optimal performance and avoid unexpected fuel-related issues.