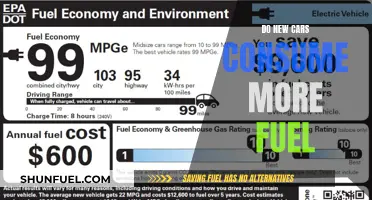

When filling a car's fuel tank, it's important to understand the process of how the tank breathes. This phenomenon occurs due to the pressure changes within the tank as it is filled. As the fuel is added, the air inside the tank expands, causing the pressure to increase. This pressure differential between the inside and outside of the tank creates a natural breathing effect, allowing air to flow in and out to maintain equilibrium. Understanding this process is crucial for ensuring proper fuel management and preventing issues such as fuel contamination or engine performance problems.

What You'll Learn

- Vacuum Effect: The fuel tank's pressure drops as it fills, creating a vacuum that pulls fuel in

- Fuel Pump: The fuel pump ensures a steady flow of fuel into the tank during filling

- Breathing Mechanism: The tank's breathing mechanism allows air to enter and fuel to expand

- Pressure Regulation: The fuel system regulates pressure to prevent overflow and ensure safe filling

- Venting System: A venting system releases excess pressure and allows air to enter the tank

Vacuum Effect: The fuel tank's pressure drops as it fills, creating a vacuum that pulls fuel in

The process of filling a car's fuel tank is an intriguing interplay of physics and engineering, and at the heart of this mechanism lies the concept of the vacuum effect. When you initiate the fueling process, the fuel pump, often located within the fuel tank, begins to operate. This pump is designed to create a controlled pressure within the fuel system, ensuring that the fuel flows efficiently and safely into the tank. As the pump activates, it generates a slight positive pressure in the fuel lines, which is essential for the proper functioning of the engine. However, the key to understanding the vacuum effect lies in what happens when the fuel tank is being filled.

As the fuel tank is filled, the pressure inside the tank gradually decreases, creating a pressure differential between the tank and the surrounding atmosphere. This pressure drop is a natural consequence of the fuel's volume increasing within the confined space of the tank. The atmospheric pressure, which is the pressure exerted by the weight of the air molecules in the air around us, is typically higher than the pressure inside the tank. As a result, a partial vacuum is formed within the fuel tank, drawing fuel into the tank. This vacuum effect is a critical component of the fueling process, ensuring that the fuel flows smoothly and efficiently.

The vacuum effect is a result of the fuel's incompressible nature. Unlike gases, liquids like gasoline cannot be compressed indefinitely. As the fuel is added to the tank, the pressure inside the tank cannot increase indefinitely due to the fuel's incompressibility. Instead, the pressure drops, creating a low-pressure region within the tank. This low pressure acts as a suction force, pulling the fuel into the tank. The fuel pump's role is to maintain a consistent flow rate, ensuring that the fuel enters the tank at a controlled pace, preventing excessive pressure buildup and potential damage to the fuel system.

This phenomenon is a well-designed safety feature in modern vehicles. The vacuum effect prevents the fuel from being pushed out of the tank when it is full, which could lead to fuel spilling or even damage to the fuel system. Additionally, it ensures that the fuel is drawn into the tank at a controlled rate, allowing for efficient fueling without the risk of overfilling. The design of the fuel tank and pump system takes into account the varying atmospheric pressures at different altitudes, ensuring that the vacuum effect remains effective regardless of the vehicle's location.

In summary, the vacuum effect is a fascinating aspect of how a car's fuel tank operates during the fueling process. It showcases the intricate balance of pressure and suction, ensuring a safe and efficient fuel supply to the engine. Understanding this principle provides valuable insights into the engineering marvels that power our vehicles.

Car Gasket Leaks: Impact on Fuel Efficiency and Savings

You may want to see also

Fuel Pump: The fuel pump ensures a steady flow of fuel into the tank during filling

The fuel pump plays a crucial role in the process of filling a car's fuel tank, ensuring a smooth and efficient operation. When you initiate the fueling process, the pump springs into action, creating a controlled and steady flow of fuel from the reservoir to the tank. This mechanism is designed to prevent any sudden surges or fluctuations in pressure, which could potentially damage the fuel system or cause spillage.

As the fuel tank begins to fill, the pump's primary function is to maintain a consistent and regulated flow rate. This is achieved through a precise mechanism that monitors the pressure and adjusts accordingly. The pump's operation is often controlled by an electronic system, which ensures that the fueling process adheres to the optimal parameters. This electronic control system is a key component in modern vehicles, allowing for accurate and safe fuel management.

During the filling process, the pump's performance is critical to the overall efficiency and safety. It must provide a steady flow rate that matches the vehicle's fueling requirements. This is especially important when considering the varying fuel levels and temperatures that the pump might encounter during operation. The pump's ability to adapt and maintain a consistent flow rate is essential to prevent any issues related to fuel pressure or engine performance.

In addition to ensuring a steady flow, the fuel pump also contributes to the overall longevity of the fuel system. By maintaining a controlled environment during fueling, the pump helps prevent air bubbles from forming in the fuel lines. These bubbles can lead to issues such as engine misfires or reduced performance. The pump's role in managing the fuel flow rate and pressure ensures that the fuel remains in optimal condition, promoting efficient combustion and engine operation.

Furthermore, the fuel pump's design and placement are strategically chosen to optimize performance. It is typically located close to the fuel tank, allowing for quick response times and efficient fuel transfer. This proximity ensures that the pump can quickly adapt to changes in fuel level, providing a continuous and steady flow. The pump's design also considers factors such as noise reduction and vibration dampening, ensuring a smooth and quiet fueling experience for the vehicle's occupants.

Starter Fluid: A Quick Fix for Fuel-Injected Cars?

You may want to see also

Breathing Mechanism: The tank's breathing mechanism allows air to enter and fuel to expand

The breathing mechanism in a car's fuel tank is a crucial component that ensures the safe and efficient filling of fuel. When a vehicle's fuel tank is being filled, the breathing mechanism plays a vital role in allowing air to enter the tank while preventing fuel from escaping. This process is essential to maintain the proper pressure and ensure the tank's integrity during the filling process.

At the core of this mechanism is a small, usually rubber or plastic, one-way valve. This valve is designed to open when air enters the tank and close when fuel is poured in. When the fuel tank is empty, the pressure inside the tank is lower than the atmospheric pressure outside. As the fuel is poured in, it creates a higher pressure environment within the tank. The one-way valve is strategically positioned to allow air to flow into the tank when the pressure is low, ensuring that the fuel can expand without causing any issues.

The breathing mechanism is often located near the top of the fuel tank, where there is typically a small opening or port. This design choice is intentional, as it allows for the easy flow of air into the tank while keeping the fuel contained. When the fuel level rises, the valve closes, creating a sealed environment that prevents fuel from spilling out when the vehicle is in motion. This simple yet effective mechanism ensures that the fuel tank can breathe, allowing for the smooth and safe operation of the vehicle during fuel refilling.

During the filling process, the fuel pump in the vehicle creates a slight vacuum, drawing air into the tank through the breathing mechanism. This air intake is crucial to prevent the fuel from becoming too hot and expanding excessively, which could lead to potential issues. The mechanism acts as a safety net, allowing for the controlled expansion of fuel and ensuring that the tank remains full without any spillage.

In summary, the breathing mechanism in a car's fuel tank is a critical safety feature. It enables the tank to 'breathe' by allowing air to enter and fuel to expand safely. This mechanism ensures that the fuel tank is filled efficiently and securely, providing a reliable source of power for the vehicle's engine. Understanding this process highlights the ingenuity in automotive design, where every component plays a role in ensuring optimal performance and safety.

Fuel Efficiency vs. Safety: Debunking the Myth

You may want to see also

Pressure Regulation: The fuel system regulates pressure to prevent overflow and ensure safe filling

The process of filling a car's fuel tank involves a delicate balance of pressure regulation to ensure a safe and efficient filling process. When you open the fuel filler door and start the fueling process, the fuel system employs several mechanisms to manage the pressure within the tank and prevent any potential hazards.

One critical component in pressure regulation is the fuel pump. As the fuel tank is filled, the pump operates to maintain a consistent flow rate of fuel into the tank. This pump is designed to handle the pressure and ensure that the fuel is delivered at a controlled rate, preventing any sudden surges that could lead to overflow. The pump's operation is crucial in managing the pressure, especially during the initial stages of filling when the tank is nearly empty.

Additionally, the fuel system incorporates a pressure relief valve as a safety measure. This valve is strategically positioned to monitor and control the pressure within the fuel tank. When the pressure exceeds a predetermined threshold, typically due to rapid fueling or a malfunction, the valve opens to release excess fuel vapor and pressure. This prevents the tank from becoming overfilled, which could lead to potential safety risks such as fuel spillage or even fire hazards. The pressure relief valve acts as a safeguard, ensuring that the fuel system operates within safe parameters during the filling process.

Furthermore, the fuel tank itself is designed with a breathing mechanism that allows for the release of built-up pressure. This breathing system is often a small vent or a series of vents located near the top of the fuel tank. As the tank fills, the fuel expands, creating pressure. The vents allow this excess pressure to escape, preventing a buildup that could lead to potential issues. This simple yet effective design ensures that the fuel tank can breathe, allowing for a smooth and controlled filling process.

In summary, the fuel system's pressure regulation mechanisms are vital for a safe and efficient fueling process. Through the use of pumps, pressure relief valves, and breathing vents, the system manages the flow of fuel, prevents overflow, and ensures that the fuel tank is filled without compromising safety. Understanding these pressure regulation processes is essential for both car owners and mechanics to maintain the integrity and safety of the vehicle's fuel system.

Unleash Your Car's Potential: When Fuel Additives Matter

You may want to see also

Venting System: A venting system releases excess pressure and allows air to enter the tank

The process of filling a car's fuel tank is a delicate balance of pressure and volume, and it's all thanks to the venting system that ensures a smooth and safe filling experience. When you open the fuel door and start the fueling process, the venting system plays a crucial role in managing the internal pressure of the tank. As the fuel pump draws fuel from the reservoir, it creates a partial vacuum inside the tank, which is where the venting system comes into play.

This system is designed to release any excess pressure that might build up during the filling process. When the fuel tank is being filled, the pressure inside the tank increases as the fuel level rises. If this pressure weren't managed, it could lead to several issues. Firstly, excessive pressure could cause the fuel to overflow, potentially causing a mess and even posing a safety hazard. Secondly, the pressure might lead to a situation where the fuel doesn't flow smoothly into the tank, causing the pump to work harder and potentially leading to engine issues.

The venting system's primary function is to allow air to enter the tank, which helps to equalize the pressure. As the fuel is pumped into the tank, the vent valve opens, allowing air to be drawn into the tank. This air enters through the vent port, which is typically located near the top of the fuel tank. The air acts as a cushion, preventing the fuel from being pushed out of the tank as it fills up. This simple yet effective mechanism ensures that the fuel flows smoothly and that the tank is filled efficiently.

Additionally, the venting system also helps to prevent the formation of vapor locks, especially in warmer climates. As the fuel is heated by the sun, it can turn into vapor, and if this vapor is not properly managed, it could lead to engine problems. The venting system allows the air to enter and mix with the fuel, preventing the vapor from building up and causing issues. This is particularly important during the summer months when fuel tanks are more susceptible to overheating.

In summary, the venting system is a critical component of a car's fuel tank design, ensuring that the filling process is safe, efficient, and free from potential issues. It manages the pressure and allows for the necessary air exchange, making it an essential feature for any vehicle's fuel system. Understanding how this system works can help drivers appreciate the intricate mechanisms that keep their cars running smoothly.

Uncover the Secrets: Why Your Car's Fuel Efficiency Plummets

You may want to see also

Frequently asked questions

When you fill your car's fuel tank, the process is designed to allow the fuel to enter while also enabling the tank to "breathe," which means releasing any built-up pressure. This is crucial to prevent fuel vapor from building up inside the tank, which could lead to issues like fuel pump damage or even fuel tank explosions. The breathing mechanism is typically a small valve or a breather port that allows air to enter the tank as fuel is added, maintaining a balanced pressure.

The breathing function is essential to ensure the proper operation of the fuel system. If the tank doesn't breathe, the fuel vapor can condense, leading to sludge formation and potential blockages. Over time, this can restrict fuel flow, causing engine performance issues and even starting problems. Additionally, a non-breathing tank might result in a fuel pump that works harder, potentially reducing its lifespan.

It is generally recommended to fill the fuel tank when the engine is turned off. Filling the tank while the engine is running can lead to increased pressure and potential safety hazards. The engine's vacuum system, which helps draw fuel into the tank, might also be affected, leading to improper fuel level readings. Always ensure the car is in a safe and stable state before refueling.

A clogged breather valve can cause a range of problems. The primary issue is that it hinders the tank's ability to breathe, leading to a buildup of fuel vapor. This can result in a fuel gauge that reads incorrectly, often showing a lower fuel level than is actually present. In some cases, a clogged breather can cause the engine to run poorly, with symptoms like reduced power, rough idling, or even stalling. Regular maintenance and fuel system cleaning can help prevent such issues.