Ethanol, a common component in many fuels, has sparked debates regarding its potential to damage fuel lines in vehicles. While it is a renewable and cleaner-burning fuel source, its use raises concerns about its impact on the internal components of engines, including fuel lines. This paragraph aims to explore the relationship between ethanol and fuel lines, examining the potential risks and benefits associated with its use.

| Characteristics | Values |

|---|---|

| Ethanol's Solubility | Ethanol is highly soluble in water, which can lead to the dissolution of water in fuel lines, causing corrosion and damage over time. |

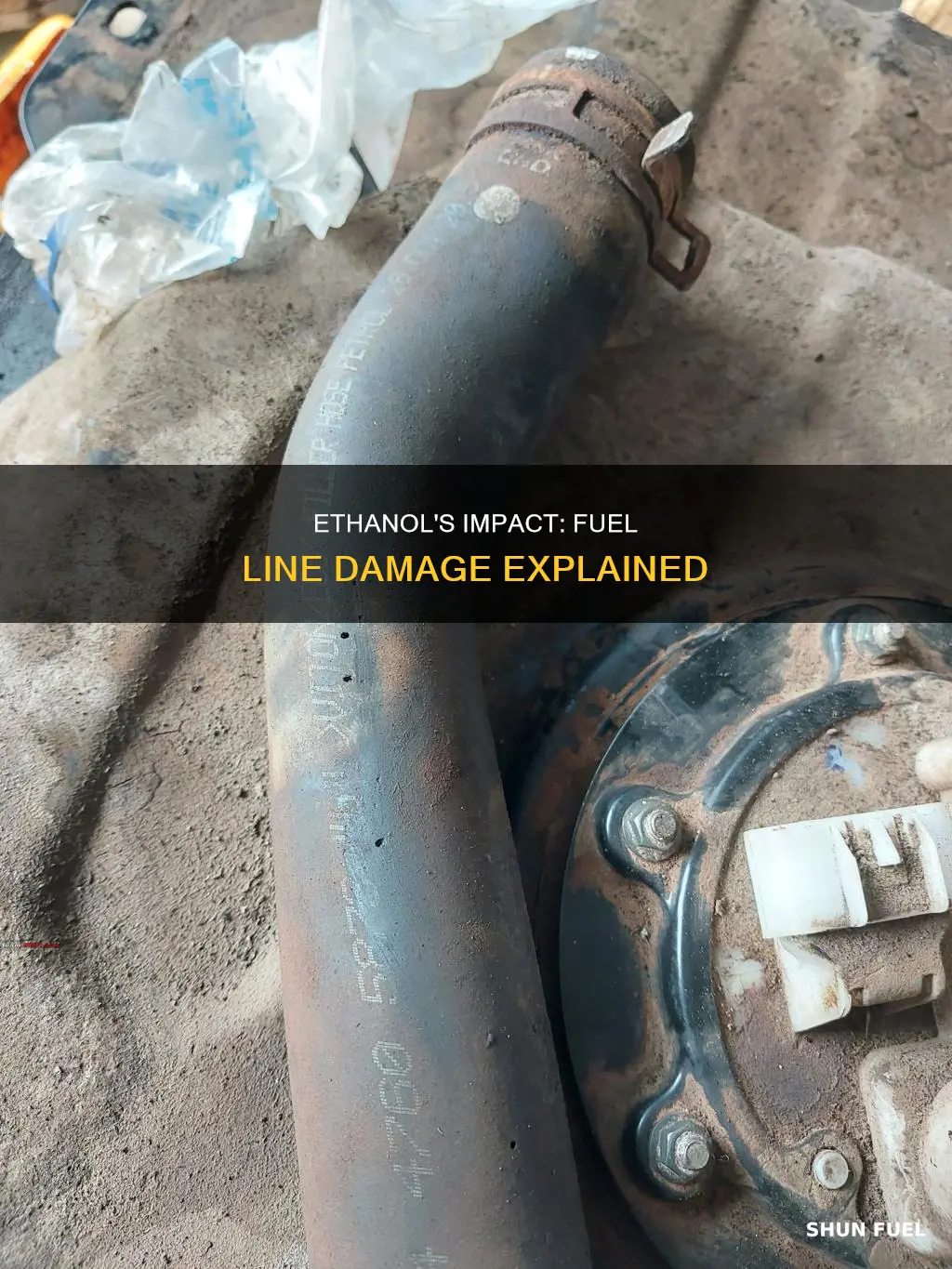

| Fuel Line Material Compatibility | Some fuel lines are not compatible with ethanol, especially those made from rubber or certain plastics. These materials can degrade when exposed to ethanol, leading to cracks, leaks, and fuel line failure. |

| Corrosion and Rusting | Ethanol can accelerate the corrosion of metal fuel lines, particularly those with exposed metal surfaces. This corrosion can result in reduced fuel flow, engine performance issues, and potential safety hazards. |

| Fuel Line Flexibility | Ethanol-blended fuels can affect the flexibility of fuel lines. Some lines may become brittle, while others might lose their flexibility, making them more prone to cracking or breaking. |

| Engine Performance | Using ethanol-blended fuel in engines not designed for it can lead to performance issues. These may include reduced power, increased fuel consumption, and potential engine misfires. |

| Long-Term Effects | Prolonged use of ethanol in fuel lines can cause permanent damage, including the degradation of fuel line materials, reduced fuel efficiency, and potential engine damage. |

| Maintenance and Replacement | Regular maintenance and inspection of fuel lines are crucial when using ethanol-blended fuels. This may involve replacing fuel lines more frequently to prevent damage and ensure optimal engine performance. |

What You'll Learn

- Ethanol's Corrosive Nature: Ethanol can erode fuel lines over time, leading to potential leaks and engine issues

- Fuel Line Flexibility: Ethanol's higher water content can cause fuel lines to become brittle and less flexible

- Engine Performance Impact: Using ethanol-blended fuel may result in reduced engine performance and increased maintenance needs

- Long-Term Storage Concerns: Storing ethanol-contaminated fuel for extended periods can cause fuel line degradation and engine problems

- Compatibility with Fuel Systems: Ethanol's properties can be incompatible with certain fuel systems, leading to potential damage

Ethanol's Corrosive Nature: Ethanol can erode fuel lines over time, leading to potential leaks and engine issues

Ethanol, a common component in many modern fuels, has a significant impact on vehicle fuel systems, particularly when it comes to fuel lines. These lines, often made of rubber or plastic, are designed to withstand the pressures and temperatures of gasoline or diesel. However, when ethanol is introduced into the fuel mix, it can have detrimental effects on these components.

The primary concern with ethanol is its corrosive nature. Ethanol can erode the inner walls of fuel lines over time, leading to a variety of issues. This corrosion is accelerated by the presence of moisture, as ethanol is highly hygroscopic, meaning it readily absorbs water. When ethanol absorbs water, it forms a corrosive acid, which then attacks the material of the fuel lines. This process can lead to the deterioration of the fuel lines' integrity, causing cracks, leaks, and even complete failure.

The consequences of ethanol-induced corrosion are significant. Leaks in the fuel lines can result in fuel spilling onto hot engine components, leading to potential fires or explosions. Moreover, the loss of fuel pressure can cause engine performance issues, such as reduced power, poor acceleration, and even engine stalls. In extreme cases, the engine may suffer permanent damage due to the lack of proper lubrication and cooling caused by fuel leaks.

To mitigate these problems, it is essential to use ethanol-free or low-ethanol fuels in vehicles designed for gasoline or diesel. Some modern vehicles are equipped with ethanol-resistant fuel lines, but it is still crucial to monitor the fuel system for any signs of corrosion or damage. Regular maintenance, including fuel system inspections and replacements, can help prevent and address ethanol-related issues in fuel lines.

In summary, the corrosive nature of ethanol poses a significant threat to fuel lines, potentially causing leaks and engine problems. Understanding this relationship is vital for vehicle owners and mechanics to ensure the longevity and safe operation of their engines, especially in regions where ethanol-blended fuels are common.

Fuel Pump Primer: Do You Need to Prime an Inline Fuel Pump?

You may want to see also

Fuel Line Flexibility: Ethanol's higher water content can cause fuel lines to become brittle and less flexible

Ethanol, a common alternative fuel source, has gained popularity due to its renewable nature and lower carbon emissions compared to traditional gasoline. However, its widespread use has raised concerns about its potential impact on vehicle fuel systems, particularly the fuel lines. One of the critical issues associated with ethanol is its higher water content, which can have detrimental effects on the flexibility and integrity of fuel lines.

The primary reason for this problem lies in the composition of ethanol. Unlike gasoline, ethanol contains a higher percentage of water, which can lead to several complications. When ethanol is blended with gasoline, the water content in the fuel mixture can reach up to 10%, significantly higher than the water levels in conventional fuel. This elevated water content is a major concern for fuel lines, as it can cause the rubber components to swell and deteriorate over time.

Fuel lines, often made of rubber or similar flexible materials, are designed to withstand the pressure and temperature changes within the fuel system. However, the increased water content in ethanol can cause these materials to absorb moisture, leading to several adverse effects. Firstly, the swelling of the fuel line material can result in a loss of flexibility. Rubber, when exposed to water, becomes softer and more pliable, but this change in consistency can make the fuel lines more susceptible to damage during engine operation.

Over time, the repeated flexing and expansion of the fuel lines due to engine operation can cause the rubber to break down, leading to cracks and brittleness. This degradation of the fuel line material can result in fuel leaks, engine misfires, and even complete fuel system failure. As the ethanol-water mixture circulates through the fuel lines, it can also lead to the formation of deposits and corrosion, further compromising the fuel system's performance and longevity.

To address this issue, it is essential for vehicle owners and mechanics to be aware of the potential risks associated with ethanol-blended fuels. Proper maintenance, including regular fuel line inspections and the use of ethanol-compatible fuel treatments, can help mitigate these problems. Additionally, ensuring that fuel systems are designed to handle the higher water content in ethanol can significantly reduce the likelihood of fuel line damage, ensuring the reliability and longevity of vehicles powered by alternative fuels.

Unraveling the Mystery: 1971 Jeep Fuel Line Fitting Secrets

You may want to see also

Engine Performance Impact: Using ethanol-blended fuel may result in reduced engine performance and increased maintenance needs

Using ethanol-blended fuel in your vehicle can have a significant impact on engine performance, often leading to reduced power and efficiency. Ethanol, a common additive in many fuels, can cause several issues that directly affect the engine's ability to function optimally. One of the primary concerns is its effect on the fuel system, particularly the fuel lines and injectors.

When ethanol is introduced into the fuel system, it can lead to a process known as 'fuel line corrosion'. Ethanol is highly corrosive to certain materials commonly used in fuel lines, such as rubber and plastic. Over time, this corrosion can cause the fuel lines to deteriorate, leading to cracks, leaks, and even complete failure. As a result, the engine may experience reduced fuel flow, which can lead to misfires, poor acceleration, and a decrease in overall performance.

The impact of ethanol on engine performance is not limited to the fuel system alone. Ethanol-blended fuels can also affect the engine's combustion process. Ethanol has a higher octane rating than gasoline, which can lead to increased engine knock or pinging, especially in high-performance engines. This knock can cause premature engine wear and reduce power output. Additionally, the higher moisture content in ethanol-blended fuels can lead to increased engine deposits, further compromising performance and fuel efficiency.

Regular maintenance becomes even more crucial when using ethanol-blended fuel. Engine owners should pay close attention to their vehicle's performance and be prepared for more frequent engine maintenance. This may include regular fuel system inspections, replacing fuel filters more often, and using ethanol-safe engine oils and lubricants. Proper maintenance can help mitigate some of the performance issues but may not completely prevent them.

In summary, the use of ethanol-blended fuel can result in reduced engine performance and increased maintenance requirements. The corrosive nature of ethanol on fuel system components, combined with its impact on combustion and engine knock, can lead to a decline in power and efficiency. Vehicle owners should be aware of these potential issues and take appropriate measures to ensure their engines remain in optimal condition.

Marine Fuel Line: Top Sources for Your Boat

You may want to see also

Long-Term Storage Concerns: Storing ethanol-contaminated fuel for extended periods can cause fuel line degradation and engine problems

Ethanol, a common additive in gasoline, can have detrimental effects on fuel systems when present in high concentrations, especially during long-term storage. One of the primary concerns is its impact on fuel lines, which can lead to significant engine problems over time. When ethanol-contaminated fuel is stored for extended periods, it can cause several issues that may not be immediately apparent but can result in costly repairs and performance issues.

The primary reason for this lies in the chemical properties of ethanol. Ethanol is a polar solvent, which means it attracts and dissolves water. Over time, ethanol-contaminated fuel can absorb moisture from the air, leading to the formation of water droplets within the fuel system. This is particularly problematic in fuel lines, as the small diameter of these lines makes it challenging for water to drain, leading to the potential for corrosion and rust formation. Corrosion inside the fuel lines can result in a loss of fuel pressure, reduced engine performance, and even engine damage.

Additionally, ethanol can also cause fuel line degradation directly. Ethanol has a higher oxygen content compared to gasoline, which can lead to the oxidation of certain materials in the fuel system, including rubber and plastic components. Over time, this can result in the deterioration of fuel lines, gaskets, and seals, leading to leaks and potential engine misfires. The presence of ethanol can also accelerate the breakdown of these materials, making them more susceptible to cracking and fragmentation.

To mitigate these long-term storage concerns, it is essential to ensure that fuel systems are properly maintained and that ethanol-contaminated fuel is used promptly. Regular fuel system maintenance, including fuel line inspections and replacements, can help prevent the onset of these issues. Additionally, using fuel stabilizers designed to reduce the negative effects of ethanol can be beneficial, especially when storing fuel for extended periods. These stabilizers can help minimize the absorption of moisture and the oxidation of fuel system components, thus preserving the integrity of the fuel and the fuel lines.

In summary, storing ethanol-contaminated fuel for extended periods without proper precautions can lead to fuel line degradation and engine problems. The absorption of moisture and the potential for corrosion, along with the direct degradation of fuel system components, highlight the importance of timely fuel usage and regular maintenance to ensure optimal engine performance and longevity.

Fuel Line Hose: A Viable Power Steering Solution?

You may want to see also

Compatibility with Fuel Systems: Ethanol's properties can be incompatible with certain fuel systems, leading to potential damage

Ethanol, a common additive in gasoline, has been a subject of interest and concern when it comes to its impact on fuel systems, particularly fuel lines. While ethanol can offer benefits such as increased octane and reduced carbon emissions, its properties can also lead to compatibility issues with certain fuel systems, resulting in potential damage. This is an important consideration for vehicle owners and mechanics alike, as it can affect the performance and longevity of their vehicles.

One of the primary concerns is the potential for ethanol to dissolve or weaken certain materials used in fuel lines. Over time, the ethanol can permeate the walls of rubber or plastic fuel lines, leading to a process known as "plasticizer migration." This migration can cause the fuel lines to become brittle, crack, or even rupture. As a result, fuel leaks can occur, posing a safety hazard and potentially causing engine misfires or performance issues.

Additionally, ethanol's higher water content compared to gasoline can lead to another set of problems. When ethanol-blended fuels come into contact with certain fuel system components, such as aluminum or certain types of metal, it can cause corrosion. This corrosion can lead to the degradation of metal parts, including fuel injectors, pumps, and even the engine block. Over time, this can result in reduced engine performance, increased fuel consumption, and potential engine damage.

To mitigate these issues, it is crucial to use ethanol-compatible fuel system components. This includes choosing fuel lines made from materials that can withstand ethanol's properties, such as certain types of rubber or synthetic materials. Upgrading to ethanol-resistant fuel filters, fuel pumps, and injectors can also help prevent damage. Regular maintenance and inspections are essential to identify any signs of ethanol-related damage early on.

In summary, while ethanol can provide advantages in terms of engine performance and emissions, its properties can also lead to compatibility issues with fuel systems. Vehicle owners should be aware of the potential risks and take proactive measures to ensure their fuel systems are compatible with ethanol-blended fuels. Proper maintenance, regular inspections, and the use of ethanol-resistant components can help minimize the chances of damage and ensure the long-term reliability of their vehicles.

Chevy Cobalt Fuel Line Unplug: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Ethanol, when used as a fuel additive, can have some negative effects on fuel lines and other fuel system components. Ethanol is a solvent and can dissolve certain materials, including rubber and plastic, which are commonly used in fuel lines and tanks. Over time, this can lead to fuel line degradation, cracking, and potential leaks. However, it's important to note that modern fuel systems are designed to handle ethanol blends up to E10 (10% ethanol), and most vehicles can operate without issues with this level of ethanol.

The signs of ethanol-related fuel line damage may include fuel leaks, reduced engine performance, hard starting, stalling, or erratic behavior. If ethanol has contaminated the fuel system, you might notice a change in engine operation, such as rough idling, reduced power, or difficulty starting the engine. In some cases, you may also see signs of corrosion or degradation in the fuel lines, such as cracks, brittleness, or the presence of a white or blueish residue.

To protect your fuel lines and fuel system from ethanol-related damage, consider the following:

- Use ethanol-free or low-ethanol fuel when possible, especially for older vehicles or those with known fuel system issues.

- Regularly inspect your fuel lines for any signs of damage or wear, and replace them if necessary.

- Maintain a clean fuel system by using fuel system cleaner treatments to prevent the buildup of contaminants.

- Keep your fuel tank full to minimize the exposure of the fuel lines to air, which can promote corrosion.

- Use fuel stabilizers, especially for long-term storage, to prevent ethanol-related issues.