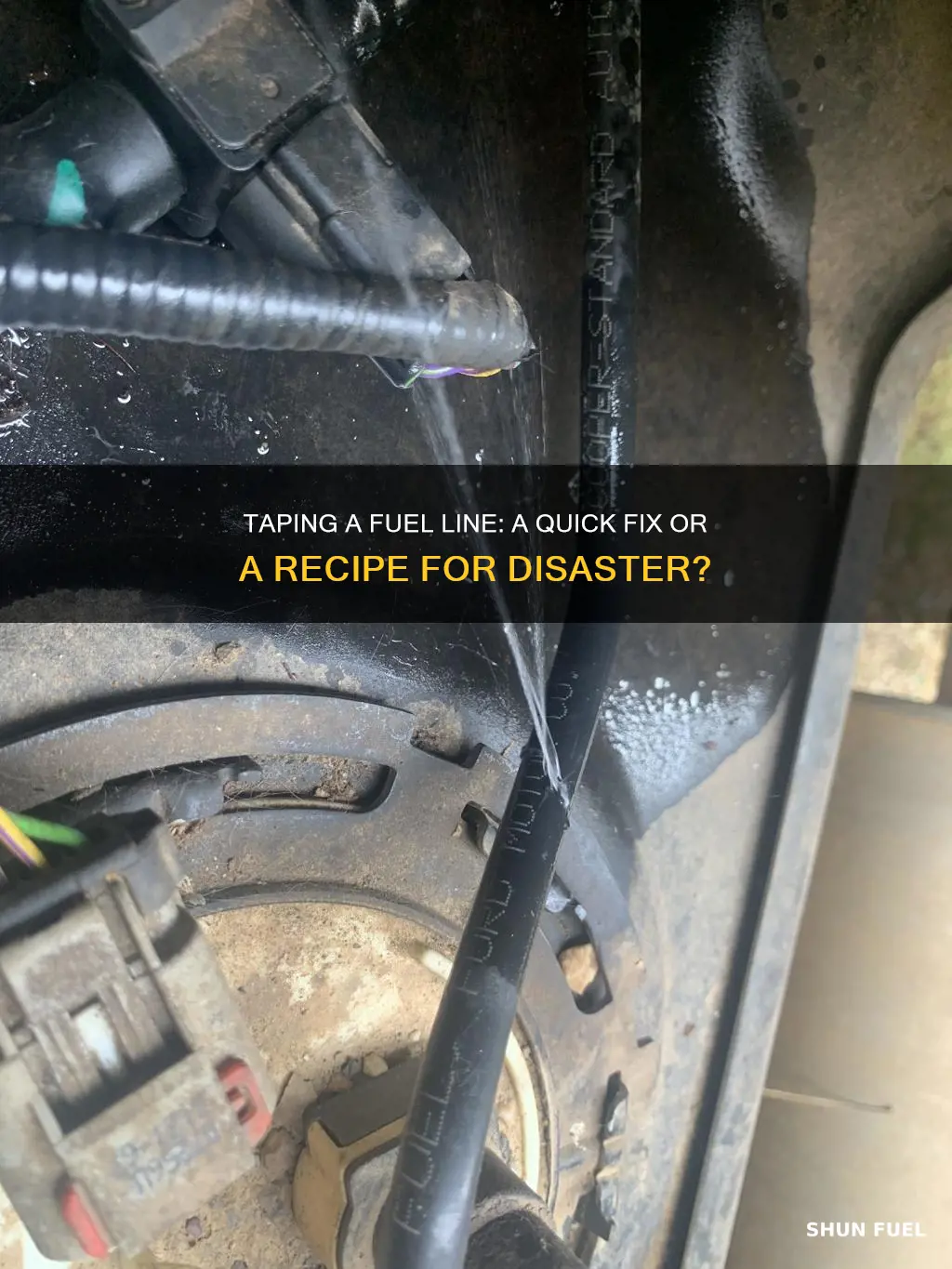

When it comes to vehicle maintenance, it's crucial to understand the importance of addressing fuel line issues promptly. While it might be tempting to attempt a quick fix, it's generally not recommended to tape a fuel line as a long-term solution. Taping a fuel line can lead to potential safety hazards, including fuel leaks and fire risks. Instead, it's best to consult a professional mechanic who can diagnose and repair the issue safely and effectively.

What You'll Learn

- Fuel Line Taping Techniques: Quick fixes for temporary repairs, using duct tape or electrical tape

- Fuel Line Material Compatibility: Choose the right tape material to avoid fuel leaks

- Fuel Line Inspection Before Taping: Check for damage, cracks, and leaks before applying any tape

- Fuel Line Taping for Emergency Use: Temporary solutions for sudden fuel line issues

- Fuel Line Taping Best Practices: Proper methods to ensure safety and effectiveness of the repair

Fuel Line Taping Techniques: Quick fixes for temporary repairs, using duct tape or electrical tape

Taping a fuel line is not a recommended permanent solution, but in emergency situations, it can provide a temporary fix to prevent fuel leaks. It's crucial to understand that this method should only be used as a last resort and for short-term repairs until professional help is available. The key to a successful temporary repair is using the right type of tape and applying it correctly.

For fuel line repairs, duct tape and electrical tape are commonly used due to their availability and ease of application. Duct tape, known for its strong adhesive and durability, is ideal for sealing small holes or tears in fuel lines. It can provide an effective barrier against fuel leakage. When using duct tape, ensure the surface is clean and dry, and wrap the tape tightly around the fuel line, overlapping the edges slightly to create a secure bond.

Electrical tape, on the other hand, is more flexible and can be useful for temporary repairs on fuel lines that are still functional but need extra protection. It is particularly useful for covering small cracks or fissures. Electrical tape is available in various colors, and its flexibility allows it to conform to the shape of the fuel line, providing a discreet repair. Apply the tape carefully, ensuring it adheres well to the fuel line surface.

In both cases, the tape should be applied firmly and smoothly, ensuring there are no creases or bubbles. It's important to note that these repairs are temporary and should not be relied upon for extended periods. Always seek professional assistance for a proper and safe fuel line repair.

Remember, while taping a fuel line can provide a quick fix, it is not a long-term solution. The primary goal is to prevent fuel leaks and ensure safety. If you find yourself in a situation where a fuel line is damaged, it is essential to act promptly and seek professional help to avoid potential hazards.

Is the Milwaukee Fuel Line Worth the Investment?

You may want to see also

Fuel Line Material Compatibility: Choose the right tape material to avoid fuel leaks

When it comes to repairing fuel lines, choosing the right tape material is crucial to ensure the integrity of the fuel system and prevent leaks. The primary concern is compatibility with the fuel type and the material of the fuel line itself. Different fuels, such as gasoline, diesel, or aviation fuel, have varying properties that can affect the performance of the tape. For instance, gasoline is more volatile and can cause certain adhesives to swell or dissolve, leading to potential failure. Therefore, it's essential to select a tape that is specifically designed for the fuel in question.

For gasoline applications, rubber-based tapes are often recommended. Natural rubber or synthetic rubber compounds can provide excellent adhesion and flexibility, allowing the tape to conform to the fuel line's shape and withstand the dynamic nature of the fuel flow. These tapes are also resistant to gasoline's corrosive effects, ensuring long-term reliability. On the other hand, for diesel fuel, which is generally less volatile, a wider range of tape materials can be considered. Silicone-based tapes are a popular choice due to their ability to maintain adhesion in high-temperature environments and their resistance to fuel degradation.

In the case of aviation fuels, which can be more aggressive and contain additives, specialized tapes are often required. These tapes might include materials like fluoropolymers or specialized adhesives that can withstand the unique challenges posed by aviation fuels. It's crucial to consult manufacturer guidelines or seek expert advice to ensure compatibility. Additionally, the fuel line material itself plays a significant role in tape selection. For example, if the fuel line is made of rubber, a tape with similar rubber compounds can create a strong bond, ensuring a leak-free repair.

When applying the tape, ensure proper surface preparation by cleaning the fuel line to remove any contaminants. Follow the manufacturer's instructions for the correct application technique, including any specific requirements for primers or adhesives. Additionally, consider the environmental conditions the fuel line will be exposed to and choose a tape that can withstand those factors, such as temperature extremes or UV radiation.

In summary, selecting the appropriate tape material for fuel line repairs is a critical step to guarantee the safety and efficiency of the fuel system. By considering the fuel type, fuel line material, and environmental factors, you can make an informed decision and choose a tape that provides reliable and long-lasting performance, minimizing the risk of fuel leaks and potential engine damage. Always refer to the specific requirements of your fuel system and consult experts when needed.

Motorcycle Fuel Line Sizes: A Comprehensive Guide to Diameter

You may want to see also

Fuel Line Inspection Before Taping: Check for damage, cracks, and leaks before applying any tape

Before you consider taping a fuel line, it is crucial to conduct a thorough inspection to ensure the process is safe and effective. The primary goal is to prevent any potential hazards associated with fuel lines, such as leaks or fires. Here's a step-by-step guide to inspecting the fuel line before applying any tape:

- Visual Inspection: Start by visually examining the fuel line for any visible signs of damage, cracks, or deterioration. Look for any bends, kinks, or areas where the line might be pinched or compressed. Over time, fuel lines can develop wear and tear, especially in areas where they are exposed to heat, vibration, or chemical contaminants. Check for any signs of corrosion or rust, particularly if the fuel line is made of metal. These issues can compromise the integrity of the line and should be addressed before taping.

- Leaks and Moisture: Fuel lines can develop leaks, which may not always be visible. If you suspect a leak, it is essential to address it immediately. Look for any signs of moisture or wet spots around the fuel line, as this could indicate a hidden leak. You can use a soapy water solution to test for leaks. Apply the solution along the length of the fuel line and observe if any bubbles form, indicating the presence of a leak. If a leak is found, it should be repaired or replaced before proceeding with taping.

- Pressure Test: Conducting a pressure test is another critical step in fuel line inspection. This test helps identify any potential weaknesses or leaks in the line. You can use a fuel line pressure tester for this purpose. Attach the tester to the fuel line and gradually increase the pressure. Listen for any hissing sounds or observe any changes in the fuel level to detect leaks. If any issues are found, the fuel line may require repair or replacement before taping.

- Check Connections: Pay close attention to any connections or fittings along the fuel line. Ensure they are tight and secure. Loose connections can lead to fuel leaks and should be tightened or replaced. Check for any signs of corrosion or damage around the connections, as this could affect the sealing mechanism. It is essential to ensure that all components are in good condition before applying any tape.

- Document and Repair: After the inspection, create a detailed report of any issues found. If any damage, cracks, or leaks are identified, address them promptly. This may involve repairing the fuel line, replacing damaged sections, or seeking professional assistance. Ensuring that the fuel line is in optimal condition before taping is vital for safety and the longevity of the fuel system.

By following these inspection steps, you can ensure that the fuel line is safe and ready for any necessary taping or reinforcement. Remember, proper inspection and maintenance are key to preventing potential hazards associated with fuel lines.

Silverado 1998 Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Fuel Line Taping for Emergency Use: Temporary solutions for sudden fuel line issues

In emergency situations where a fuel line is damaged or leaking, temporary solutions can be employed to prevent further loss of fuel and potential engine damage. Taping the fuel line is a common practice, but it should be approached with caution and a clear understanding of the risks involved. Here's a detailed guide on how to tape a fuel line for emergency use:

Assess the Situation: Before attempting any repair, ensure that the vehicle is parked safely and securely. Turn off the engine and allow it to cool down to avoid any potential hazards. Identify the damaged section of the fuel line and assess the severity of the issue. Small punctures or leaks might be manageable with temporary fixes, but severe damage may require professional assistance.

Gather Materials: For emergency taping, you'll need a few essential items. Get a roll of heavy-duty electrical tape or duct tape specifically designed for automotive use. Ensure it is compatible with the fuel line material to avoid any chemical reactions. Additionally, have a small amount of fuel-resistant adhesive or a temporary sealant, if available, to provide extra security.

Prepare the Fuel Line: Clean the affected area of the fuel line to remove any debris or contaminants. Use a clean cloth or a small brush to ensure a smooth surface for the tape. If the leak is minor, you might be able to use the fuel-resistant adhesive to seal it temporarily. However, for more significant damage, the tape will be the primary solution.

Apply the Tape: Start by wrapping the electrical tape or duct tape around the fuel line, ensuring complete coverage of the damaged area. Apply firm pressure as you wrap to create a secure bond. Use a minimum of three layers of tape for added strength and security. Ensure the tape is tight and smooth, without any wrinkles or gaps, as these can compromise the seal. Consider using a small amount of fuel-resistant adhesive on the tape's edges for an extra layer of protection.

Test and Monitor: After taping the fuel line, start the engine and monitor it closely. Listen for any unusual noises and check for any signs of further leaks. The temporary fix should hold the fuel line in place, but it might not be as effective as a professional repair. If the engine runs smoothly and there are no leaks, you can consider this a successful temporary solution. However, it is crucial to have the fuel line repaired or replaced as soon as possible to avoid long-term issues.

Remember, this method is intended for emergency use only and should not be considered a permanent fix. Professional automotive repair services should be sought for a more durable and safe resolution. Always prioritize safety and consult experts for any fuel-related emergencies.

Understanding the Perfect Fuel Line Size for Snapper Lawb Mowers

You may want to see also

Fuel Line Taping Best Practices: Proper methods to ensure safety and effectiveness of the repair

Taping a fuel line is a temporary fix that should be approached with caution and a thorough understanding of the process. While it might seem like a quick solution to a fuel leak, improper taping can lead to more serious issues and potential safety hazards. Here are some best practices to ensure the safety and effectiveness of your fuel line repair:

- Identify the Cause: Before you start taping, it's crucial to identify the reason for the fuel line leak. Fuel lines can leak due to various reasons, such as damage from rust, corrosion, or physical impact. Addressing the root cause is essential to ensure a long-lasting solution. If the leak is due to a small puncture or a minor crack, taping might provide a temporary fix. However, if the damage is extensive or the line is severely corroded, professional repair or replacement is necessary.

- Prepare the Materials: Use the right type of tape specifically designed for fuel line repairs. Rubber-based or silicone-based tapes are commonly used for this purpose. Ensure you have a tape with good adhesive strength and flexibility to withstand the pressure and movement within the fuel system. Additionally, consider using a fuel line repair kit, which often includes the necessary tape, primer, and tools for a more comprehensive repair.

- Clean and Prepare the Surface: Proper surface preparation is critical for a successful tape job. Clean the fuel line where the tape will be applied to remove any dirt, grease, or debris. Use a mild detergent or a specialized fuel line cleaner to ensure the tape adheres properly. Ensure the surface is dry before applying the tape to avoid any moisture-related issues.

- Apply the Tape Correctly: Start by wrapping the tape around the fuel line, ensuring complete coverage of the damaged area. Use a smooth, even motion to avoid any air bubbles or uneven pressure. Overlap the tape slightly, following the manufacturer's instructions for the specific tape you are using. Apply enough tape to provide a secure and tight seal, but be careful not to overtighten, as this can restrict fuel flow.

- Consider Additional Support: For longer fuel lines or those with significant movement, consider using a fuel line protector or a temporary clamp to provide additional support. This extra measure ensures that the taped area remains secure and doesn't come loose over time.

- Test and Monitor: After taping the fuel line, test the vehicle's fuel system to ensure the leak has been stopped. Monitor the vehicle's performance and fuel levels regularly to detect any further issues. While taping can provide a temporary solution, it is essential to have the fuel line repaired or replaced by a professional mechanic for a more permanent fix.

Remember, while taping a fuel line might seem like a quick fix, it should be considered a temporary measure. Always prioritize safety and consult a professional for any significant vehicle repairs.

Mastering Chainsaw Maintenance: The Ultimate Guide to Using a Fuel Line Tool

You may want to see also

Frequently asked questions

No, it is not safe to tape a fuel line. Taping a fuel line is a temporary fix and can lead to serious issues. Fuel lines are designed to withstand pressure and temperature changes, and any damage or compromise to the line can result in fuel leaks, which pose a fire hazard and can cause engine damage.

Using tape on a fuel line can have several risks. Firstly, the tape may not adhere properly to the fuel line material, leading to potential slippage and further damage. Secondly, the tape might not be compatible with the fuel type, causing corrosion or degradation over time. Lastly, if the fuel line is under pressure, the tape could fail, leading to a sudden and potentially dangerous fuel leak.

Yes, there are several alternative solutions to repair a damaged fuel line. The best approach is to replace the entire fuel line with a new one, ensuring it is compatible with your vehicle's specifications. If the damage is minor, such as a small hole, a professional mechanic can use specialized adhesives or sealing compounds designed for fuel lines. It is crucial to seek professional help to ensure the repair is done safely and effectively.