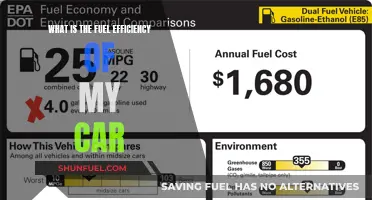

Flooding a fuel-injected car, which involves pouring excessive fuel into the engine, can cause significant damage and is generally not recommended. Fuel-injected engines rely on precise fuel delivery systems to ensure optimal combustion, and flooding can lead to engine misfires, reduced performance, and potential long-term issues. It's important to understand the proper fueling methods and maintenance practices to keep these vehicles running smoothly and avoid any unnecessary harm.

What You'll Learn

- Fuel Injection Basics: Understanding how fuel injection works in cars and its role in engine performance

- Flooding Risks: Potential consequences of flooding the fuel system, including engine damage and performance issues

- Fuel System Design: How fuel injectors and fuel rails are designed to prevent flooding

- Diagnosing Flooding: Methods to identify and diagnose fuel injection flooding in a car

- Prevention and Maintenance: Tips to prevent flooding, including regular maintenance and fuel system checks

Fuel Injection Basics: Understanding how fuel injection works in cars and its role in engine performance

Fuel injection is a critical component of modern automotive engineering, revolutionizing the way engines operate and perform. It involves the precise delivery of fuel to the engine's combustion chambers, ensuring optimal power output, fuel efficiency, and reduced emissions. This technology has become a standard feature in many vehicles, offering a significant improvement over traditional carburetor systems.

At its core, fuel injection works by injecting fuel into the engine's intake manifold or directly into the combustion chambers. This process is controlled by an electronic control unit (ECU), which monitors various engine parameters and adjusts the fuel-air mixture accordingly. The ECU receives input from sensors such as the mass airflow meter, oxygen sensors, and engine speed sensor, allowing it to make real-time adjustments to optimize performance.

One of the key advantages of fuel injection is its ability to deliver fuel at precise timings and quantities. Unlike carburetors, which mix air and fuel in a fixed ratio, fuel injectors spray fuel directly into the combustion chambers, ensuring a more accurate and consistent fuel-air mixture. This results in improved engine performance, as the engine can burn fuel more efficiently, leading to increased power output and better fuel economy.

The role of fuel injection in engine performance is multifaceted. Firstly, it enables a higher compression ratio, allowing for more efficient combustion and increased power. Secondly, it provides better low-end torque and improved throttle response, making the engine more responsive and easier to control. Additionally, fuel injection contributes to reduced emissions by optimizing the fuel-air mixture, ensuring complete combustion, and minimizing the release of harmful pollutants.

Understanding the basics of fuel injection is essential for car owners and enthusiasts. It empowers them to appreciate the technology behind their vehicles and make informed decisions regarding maintenance and performance upgrades. By recognizing the importance of fuel injection, drivers can ensure their cars operate at their full potential, delivering the desired performance while maintaining efficiency and environmental sustainability.

The Ultimate Guide to Using Racing Fuel in Any Car

You may want to see also

Flooding Risks: Potential consequences of flooding the fuel system, including engine damage and performance issues

Flooding a fuel-injected car, which involves pouring water or any liquid into the fuel system, can have severe and potentially catastrophic consequences for the vehicle's engine and overall performance. The primary risk lies in the intricate design of fuel-injected engines, where fuel and air are precisely mixed and injected into the cylinders for combustion. When water enters this system, it can lead to a series of detrimental effects.

One of the immediate consequences is the potential for engine misfire or complete failure. Water is an excellent conductor of electricity, and when it comes into contact with the fuel and electrical components, it can cause short circuits. This can result in the engine losing power or even shutting down completely, especially during operation. The electrical components, such as the fuel pump, injectors, and sensors, are particularly vulnerable to water damage, as it can corrode and short-circuit these delicate parts.

The fuel system itself is also at risk. Water can contaminate the fuel, leading to a condition known as 'water in fuel.' This contamination can cause the fuel to become less volatile, affecting its ability to vaporize and atomize properly. As a result, the engine may struggle to start, and even if it does, the performance will be significantly impacted. The water can also cause corrosion in the fuel tank, lines, and injectors, leading to rust and potential blockages, further exacerbating the engine's issues.

In addition to the immediate engine problems, flooding the fuel system can lead to long-term performance issues. Over time, the water can cause permanent damage to the engine's internal components, including the pistons, valves, and cylinder walls. This damage may result in increased engine wear, reduced power output, and even premature engine failure. Moreover, the water can attract and promote the growth of harmful microorganisms in the fuel, leading to the formation of sludge and deposits, which can further restrict fuel flow and performance.

To mitigate these risks, it is crucial to understand that flooding a fuel-injected car is extremely dangerous and should never be attempted. If a vehicle has been exposed to water, it is essential to seek professional assistance to drain and flush the fuel system thoroughly to prevent any potential damage. Regular maintenance and the use of fuel additives can also help maintain the health of the fuel system and engine, ensuring optimal performance and longevity.

Can a Car Start with a Bad Fuel Pump?

You may want to see also

Fuel System Design: How fuel injectors and fuel rails are designed to prevent flooding

The concept of flooding in a fuel-injected engine is a critical aspect of engine management and design, especially in modern vehicles. Flooding refers to the condition where the engine receives an excessive amount of fuel, leading to a rich mixture that can cause misfires, reduced performance, and potential damage over time. To prevent this, fuel injectors and fuel rails are meticulously designed to ensure precise fuel delivery and maintain optimal engine operation.

Fuel injectors are the heart of the fuel system, responsible for metering and injecting fuel into the engine's cylinders. These injectors are designed with precision to deliver the correct amount of fuel based on engine load and speed. Each injector has a unique nozzle design, often featuring multiple orifices, to control the fuel spray pattern and atomization. This ensures that the fuel is distributed evenly and efficiently, minimizing the chances of flooding. The injectors are also calibrated to open and close at specific times, allowing for precise fuel injection timing, which is crucial for maintaining the correct air-fuel ratio and preventing rich mixtures.

Fuel rails are another essential component in the design to prevent flooding. These rails are high-pressure lines that supply fuel from the fuel pump to the injectors. The design of the fuel rail includes precise fuel flow control, ensuring that the fuel pressure and volume delivered to the injectors are consistent and accurate. Fuel rails often incorporate pressure regulators to maintain the desired fuel pressure, which is critical for efficient fuel injection. This design ensures that the fuel is delivered at the right pressure and volume, allowing the injectors to function optimally and avoid flooding.

Additionally, the fuel system's design includes feedback mechanisms and sensors to monitor the engine's performance and adjust fuel delivery accordingly. Closed-loop feedback systems can detect and correct for any deviations in the air-fuel ratio, ensuring that the mixture remains optimal. This real-time adjustment capability is vital in preventing flooding and maintaining efficient combustion.

In summary, the design of fuel injectors and fuel rails is a complex process that aims to provide precise fuel delivery, control fuel pressure, and maintain the correct air-fuel ratio. By carefully engineering these components, engineers can ensure that fuel-injected engines operate efficiently, reliably, and without the risk of flooding, even under varying load conditions. This meticulous design approach is fundamental to the performance and longevity of modern vehicles.

Can You Mix Rec Fuel with Regular Gasoline?

You may want to see also

Diagnosing Flooding: Methods to identify and diagnose fuel injection flooding in a car

Fuel injection flooding, often referred to as 'flooding' in automotive terms, occurs when the engine receives an excessive amount of fuel, leading to poor performance, misfires, and potential damage. Identifying and diagnosing this issue is crucial for maintaining engine health and ensuring optimal performance. Here are several methods to help you pinpoint and address fuel injection flooding:

- Visual Inspection: Start by examining the engine and its components. Look for signs of excessive fuel accumulation, such as wet spots on the engine block, fuel leaks, or a strong fuel odor. Check the fuel injectors for any blockages or debris that might indicate a restriction in the fuel flow.

- Engine Performance Analysis: Pay close attention to the engine's behavior during operation. Flooding often manifests as a loss of power, hesitation, or stalling. Note any unusual noises, such as backfires or a roaring sound from the exhaust, which could be indicative of fuel-air mixture issues. Use a scan tool to monitor engine parameters like engine speed, load, and fuel injection timing. An excessive amount of fuel injection during high-load conditions might suggest flooding.

- Fuel Pressure and Flow Testing: Use a fuel pressure gauge to measure the pressure at the fuel rail or injectors. Low fuel pressure can lead to improper atomization and potential flooding. Additionally, consider using a fuel flow meter to measure the actual fuel flow rate. Compare these readings with the manufacturer's specifications to identify any deviations that might indicate flooding.

- Sensor Diagnostics: Modern vehicles are equipped with various sensors that provide critical data to the engine control unit (ECU). Use a scan tool to access and interpret sensor data, including the oxygen sensor readings, mass airflow sensor (MAF) values, and engine temperature. Flooding can cause a rich fuel-air mixture, leading to increased oxygen sensor voltage and altered MAF readings.

- Engine Compression Test: While not a direct method for diagnosing flooding, a compression test can help identify other potential issues that might contribute to or result from flooding. Low compression can indicate internal engine problems, which could be a symptom of previous flooding or other engine damage.

- Professional Diagnostic Tools: In some cases, specialized diagnostic equipment might be required. These tools can provide detailed insights into the engine's performance, fuel system behavior, and sensor data. Technicians can use these tools to identify specific issues related to fuel injection control, timing, and overall engine management.

When diagnosing fuel injection flooding, it's essential to consider the specific make and model of the vehicle, as well as the age and condition of the engine. Proper diagnosis often requires a systematic approach, combining visual inspections, performance analysis, and the use of diagnostic tools to pinpoint the exact cause of the flooding.

Understanding Car Fuel Pump Systems: More Than One?

You may want to see also

Prevention and Maintenance: Tips to prevent flooding, including regular maintenance and fuel system checks

Flooding a fuel-injected car is a common issue that can lead to expensive repairs and performance problems. It occurs when the engine's fuel system is overwhelmed, causing the engine to run rich and potentially damage vital components. To prevent this, regular maintenance and fuel system checks are essential. Here are some tips to ensure your fuel-injected car remains reliable and avoids flooding:

Regular Maintenance:

- Adhere to the manufacturer's recommended service schedule. This includes routine oil changes, filter replacements, and checking fluid levels. Regular maintenance ensures that all engine components, including the fuel system, are in optimal condition. Keep a record of your service history to ensure you don't miss any critical appointments.

- Inspect the engine for any signs of damage or wear. Look for leaks, particularly around the fuel lines and injectors. Even a small leak can lead to fuel accumulation and potential flooding. Address any issues promptly to prevent further complications.

Fuel System Checks:

- Check the fuel filter regularly. A clogged or dirty fuel filter can restrict fuel flow, leading to poor engine performance and potential flooding. Replace the filter at the recommended intervals to maintain a healthy fuel supply.

- Inspect the fuel injectors for blockages or malfunctions. Over time, debris or contaminants can accumulate in the injectors, causing them to spray fuel incorrectly. This can result in a rich fuel-air mixture and engine flooding. Consider using a fuel system cleaner to flush out any deposits, especially if you notice a decrease in engine performance.

- Ensure the fuel tank is clean and free from contaminants. Over time, water, dirt, and other impurities can enter the fuel tank, leading to potential issues. Regularly check for any signs of contamination and consider using a fuel stabilizer to maintain the quality of the fuel.

Driving Habits:

- Avoid rapid acceleration and aggressive driving, especially when the engine is cold. These actions can cause a sudden increase in fuel demand, overwhelming the fuel system and potentially leading to flooding. Allow the engine to warm up gradually to ensure optimal fuel-air mixture management.

- Be mindful of your driving style, especially during cold weather. Engines may struggle to maintain a balanced fuel-air mixture in colder temperatures, making flooding more likely. Adjust your driving habits accordingly to prevent unnecessary strain on the fuel system.

By following these preventive measures, you can significantly reduce the chances of flooding in your fuel-injected car. Regular maintenance, fuel system checks, and mindful driving habits are key to keeping your engine healthy and avoiding costly repairs. Remember, prevention is always better than cure when it comes to vehicle maintenance.

Fuel Filter Issues: Why Your Car Won't Start

You may want to see also

Frequently asked questions

No, flooding a fuel-injected car is not possible by over-accelerating it. Fuel injection systems are designed to precisely control the fuel-air mixture and inject the correct amount of fuel based on engine speed and load. While over-accelerating can lead to engine knock or pre-ignition, it does not result in an excessive fuel-air mixture that would cause flooding.

Flooding a fuel-injected engine can be detrimental. When too much fuel is introduced, it can cause the engine to misfire, lose power, and even stall. This often occurs due to a faulty fuel pump, clogged injectors, or a malfunctioning fuel pressure regulator. In such cases, it's essential to diagnose and fix the underlying issue to prevent further damage.

Yes, manually adding excessive fuel to a fuel-injected car can lead to flooding. Modern fuel injection systems are designed to maintain a precise fuel-air ratio, and adding extra fuel can disrupt this balance. This can result in engine performance issues, such as reduced power, poor fuel economy, and potential long-term engine damage. It's always recommended to use the correct fuel and follow the manufacturer's guidelines.