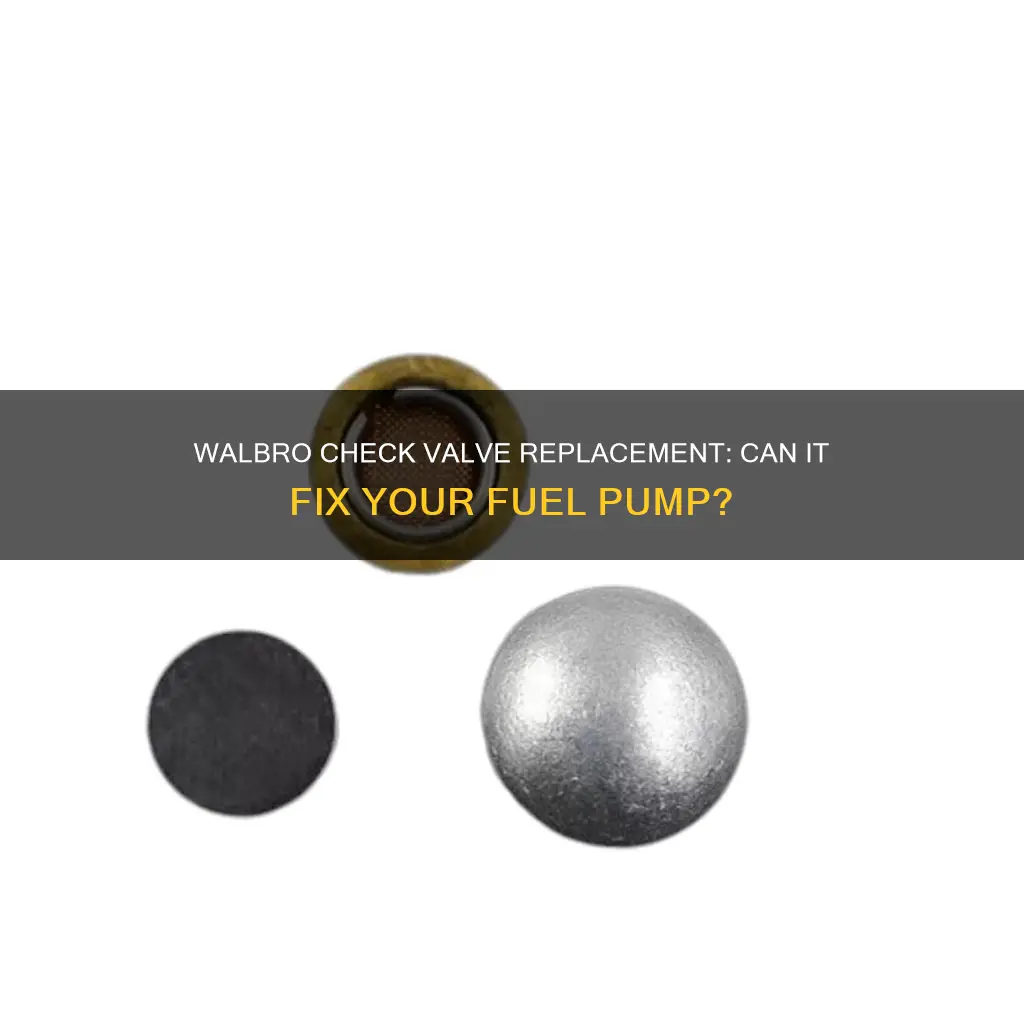

The Walbro check valve is a crucial component in fuel pumps, ensuring that fuel flows in one direction while preventing backflow. Over time, this valve can wear out or become damaged, leading to fuel pump issues. This paragraph introduces the topic of whether it is possible to replace the Walbro check valve in a fuel pump, providing an overview of the potential solutions and considerations for maintaining or repairing fuel pump systems.

| Characteristics | Values |

|---|---|

| Part Number Compatibility | Walbro 145-140, 145-141, 145-142, 145-143, 145-144, 145-145, 145-146, 145-147, 145-148, 145-149 |

| Material | Brass |

| Design | Check valve design prevents fuel from flowing back into the tank when the pump is off |

| Function | Allows fuel to flow from the tank to the pump when the engine is running |

| Durability | Built to last and withstand the pressure and temperature changes in the fuel system |

| Installation | Can be replaced without removing the fuel pump, making it a convenient repair option |

| Performance | Ensures optimal fuel flow and pressure to the engine |

| Compatibility | Designed for use with Walbro fuel pumps |

| Warranty | May vary depending on the retailer or manufacturer |

| Maintenance | Regular cleaning and inspection can extend the life of the check valve |

What You'll Learn

- Design and Function: Walbro check valves are integral components of fuel pumps, directing fuel flow

- Replacement Process: Replacing a Walbro check valve involves removing the old valve and installing a new one

- Compatibility: Ensure the replacement valve is compatible with the specific Walbro fuel pump model

- Troubleshooting: Common issues with Walbro check valves include leaks or blockages, requiring replacement

- Maintenance: Regular maintenance can prevent valve failure, ensuring optimal fuel pump performance

Design and Function: Walbro check valves are integral components of fuel pumps, directing fuel flow

Walbro check valves are an essential part of the intricate design of fuel pumps, playing a critical role in ensuring the efficient and safe operation of fuel-injected engines. These valves are specifically engineered to be a component of the Walbro fuel pump assembly, a popular choice for automotive applications. The primary function of the check valve is to regulate the flow of fuel, allowing it to pass in one direction while preventing backflow, which is crucial for maintaining the engine's performance and reliability.

In the context of fuel pumps, the check valve is strategically positioned within the pump's mechanism. Its design incorporates a unique structure with an opening that is only active when the fuel pressure is higher in the input side compared to the output side. This pressure differential triggers the valve to open, enabling fuel to flow through the pump and into the engine. Once the pressure equalizes, the valve closes, preventing any backflow and ensuring that the fuel remains in the correct direction.

The construction of Walbro check valves is meticulous, often featuring a durable material such as brass or a similar alloy. This material choice ensures longevity and resistance to corrosion, which is vital given the harsh operating conditions within an engine. The valve's design also includes a sealing mechanism, typically a rubber or similar elastic material, which provides a tight seal when the valve is closed, preventing any unwanted fuel leakage.

When designing fuel pump systems, engineers must consider the placement and orientation of the check valve. It is often positioned near the pump's outlet, ensuring that the fuel flows in the correct direction and minimizing any potential issues with fuel pressure regulation. This strategic placement is a key factor in the overall performance and efficiency of the fuel pump system.

In summary, Walbro check valves are integral to the functionality of fuel pumps, providing a critical layer of protection against backflow and ensuring the engine receives the precise fuel delivery it requires. Their design, construction, and placement are all carefully considered to meet the demanding requirements of automotive applications. Understanding the role and importance of these valves is essential for anyone working with fuel pump systems, as it highlights the need for proper maintenance and the potential for replacement when necessary.

Replacing a Corolla Fuel Strainer: A DIY Guide

You may want to see also

Replacement Process: Replacing a Walbro check valve involves removing the old valve and installing a new one

The Walbro check valve is a crucial component in the fuel pump system of many vehicles, ensuring that fuel flows in one direction and prevents backflow. Over time, this valve can wear out or become damaged, leading to fuel pump issues. Replacing the Walbro check valve is a task that can be accomplished by skilled mechanics or enthusiasts with the right tools and knowledge. Here's a step-by-step guide to help you through the replacement process:

Step 1: Preparation and Safety

Before you begin, ensure you have the necessary tools, including a wrench or socket set, a new Walbro check valve, and a fuel pump primer (if required). It is essential to work on a clean, well-lit surface and wear appropriate safety gear, such as gloves and eye protection, to avoid any potential hazards. Additionally, drain the fuel tank and disconnect the fuel lines to prevent fuel spillage and ensure a safe working environment.

Step 2: Accessing the Check Valve

Locate the Walbro check valve in your vehicle's fuel pump assembly. This valve is typically positioned near the fuel pump and may require removing certain panels or access panels to gain visibility. Carefully inspect the valve and take note of its position and any unique features or mounting methods. This information will be crucial for a successful replacement.

Step 3: Removing the Old Valve

Start by disconnecting any electrical connections or sensors attached to the valve. Carefully loosen the mounting bolts or screws holding the valve in place. Be gentle to avoid damaging the surrounding components. Once the fasteners are removed, carefully lift the old Walbro check valve out of its housing, ensuring you do not damage the fuel pump or other nearby parts.

Step 4: Installing the New Valve

Now, take the new Walbro check valve and align it with the housing, ensuring it fits perfectly. Secure the valve in place using the appropriate fasteners, tightening them by hand first and then with a wrench to avoid over-tightening. Double-check that the valve is seated correctly and securely fastened.

Step 5: Final Checks and Reassembly

With the new valve installed, reconnect any disconnected components, such as sensors and electrical wiring. Ensure all connections are secure and properly seated. Reattach the fuel lines and allow the fuel pump to prime to ensure all components are functioning correctly. Finally, refill the fuel tank and test the vehicle to ensure the fuel pump operates efficiently without any issues related to the check valve.

Remember, if you are unsure about any step or encounter complex issues, it is best to consult a professional mechanic who can provide guidance and ensure the job is done safely and correctly.

Replacing Fuel Lines in Your 1994 Kawasaki Vulcan 1500: A Step-by-Step Guide

You may want to see also

Compatibility: Ensure the replacement valve is compatible with the specific Walbro fuel pump model

When dealing with Walbro fuel pumps, ensuring compatibility is crucial for a successful repair or upgrade. The check valve, an essential component in the fuel pump assembly, can sometimes require replacement due to wear and tear or damage. However, it's important to approach this task with caution and a thorough understanding of the specific model you're working with.

The first step is to identify the exact Walbro fuel pump model you have. Walbro offers a wide range of fuel pumps, each with unique specifications and component requirements. Different models may have varying valve designs, sizes, and mounting styles. For instance, a Walbro 280 series pump might use a different check valve than a 500 series pump. Obtaining the correct part number and understanding the model's unique characteristics are essential.

Compatibility ensures that the replacement valve fits perfectly within the fuel pump's assembly. A mismatch can lead to improper function, reduced performance, or even damage to the pump. When sourcing a replacement, always refer to the manufacturer's specifications and diagrams specific to your Walbro model. These resources will provide detailed information on the valve's dimensions, material, and any unique features that must be matched.

Online forums and communities dedicated to automotive repairs can also be valuable resources. Experienced mechanics and enthusiasts often share their knowledge and experiences, providing insights into compatible replacement valves for various Walbro models. Their input can help you avoid common pitfalls and ensure a proper fit.

In summary, when replacing a check valve in a Walbro fuel pump, compatibility is key. Take the time to identify your specific model, consult manufacturer resources, and seek additional guidance if needed. By doing so, you'll ensure a successful repair, maintaining the optimal performance of your fuel pump system.

Replacing Fuel Tube in 2010 Ford Escape: Step-by-Step Guide

You may want to see also

Troubleshooting: Common issues with Walbro check valves include leaks or blockages, requiring replacement

When it comes to troubleshooting Walbro check valves, two common issues that often arise are leaks and blockages. These problems can significantly impact the performance of your fuel pump and should be addressed promptly to ensure optimal operation.

Leakage is a critical concern as it can lead to fuel loss, reduced engine performance, and potential damage to the fuel system. If you suspect a leak, start by checking the connections and seals around the check valve. Over time, gaskets and O-rings can deteriorate, allowing fuel to escape. Carefully inspect these components for any signs of damage or wear. If you find any leaks, the solution is often a simple replacement of the affected parts. Ensure you use high-quality seals and gaskets to prevent future issues.

Blockages in the check valve can also occur due to various reasons, such as debris, contaminants, or mineral deposits. These blockages restrict the flow of fuel, leading to engine performance problems. To address this, start by removing the check valve and inspecting it for any visible blockages. Use a fine brush or compressed air to gently clean the valve, removing any debris. If the issue persists, consider using a fuel system cleaner to dissolve and flush out any contaminants. However, if the blockage is severe or persistent, it may indicate a more serious issue, and professional assistance might be required.

In both cases, regular maintenance and inspection of the Walbro check valve are essential. This includes checking for any signs of wear, corrosion, or damage during routine fuel system maintenance. By promptly addressing leaks and blockages, you can ensure the longevity and efficient operation of your fuel pump. Remember, proper maintenance can often prevent costly repairs and downtime.

Replacing Your 2005 F150 Fuel Pump: Step-by-Step Guide

You may want to see also

Maintenance: Regular maintenance can prevent valve failure, ensuring optimal fuel pump performance

Regular maintenance is a crucial aspect of vehicle care, especially when it comes to preventing potential issues with the fuel system, such as valve failure in a Walbro check valve. This type of valve is a critical component in the fuel pump assembly, responsible for ensuring that the fuel flows in the correct direction and at the right pressure. Over time, these valves can wear out or become damaged, leading to potential fuel pump failure. By implementing a consistent maintenance routine, you can significantly reduce the risk of such failures and ensure the long-term performance of your fuel pump.

One of the primary methods to maintain the Walbro check valve is to regularly inspect it for any signs of wear or damage. Visual inspections can help identify common issues such as cracks, corrosion, or debris buildup. If any issues are detected, it is essential to address them promptly. For instance, if you notice corrosion, cleaning the valve with a suitable solvent can help restore its functionality. Additionally, checking the fuel pump's overall condition is vital. Inspect the pump for leaks, worn-out seals, or any unusual noises, as these could indicate potential problems that may affect the valve's performance.

Another critical aspect of maintenance is the use of high-quality fuel. Contaminated or low-quality fuel can accelerate the degradation of the check valve and the fuel pump. Over time, fuel can become contaminated with water, dirt, or other impurities, leading to valve clogs and pump failures. Using a fuel filter and regularly replacing it can help prevent this. Furthermore, ensuring that your vehicle's fuel system is properly vented and that the fuel tank is kept clean can also contribute to the overall health of the fuel pump and its associated valves.

In addition to visual inspections and fuel quality, it is beneficial to follow the manufacturer's recommended maintenance schedule. This often includes regular fuel pump testing and replacement of specific components, such as the check valve, at specified mileage intervals. Adhering to these guidelines can help identify and rectify potential issues before they cause significant problems. For example, some manufacturers suggest replacing the fuel pump and its components every 50,000 to 100,000 miles to ensure optimal performance and longevity.

By incorporating these maintenance practices, you can significantly extend the life of your fuel pump and its associated components, including the Walbro check valve. Regular maintenance not only prevents unexpected failures but also ensures that your vehicle's fuel system operates efficiently, providing reliable performance on the road. Remember, proper care and attention to the fuel system can save you from potential breakdowns and costly repairs in the long run.

Replacing Fuel Injectors in a 2007 Ford Edge: Step-by-Step Guide

You may want to see also

Frequently asked questions

Yes, replacing the Walbro check valve is a task that can be accomplished by a DIY enthusiast with some mechanical knowledge and the right tools. It involves disassembling the fuel pump and carefully replacing the valve, so it's important to follow detailed instructions and have some experience with engine mechanics.

A faulty check valve can lead to fuel leaks, reduced fuel pressure, or even engine misfires. Common symptoms include fuel pump noise, hard starting, stalling, or a strong fuel odor inside the car. If you notice any of these issues, it's advisable to inspect the valve and consider replacement if necessary.

The frequency of replacement depends on various factors, including the fuel pump's usage, environmental conditions, and maintenance history. Generally, it is recommended to inspect the valve periodically and replace it if it shows signs of wear or damage. Regular maintenance can help ensure optimal fuel delivery and prevent potential issues.

Yes, you will need a few specialized tools to replace the valve. These may include a fuel pump removal tool, a torque wrench, and various sizes of sockets or wrenches. It's essential to have the correct tools to ensure proper installation and avoid any damage to the fuel pump during the replacement process.

It is not recommended to use a different brand's check valve as a replacement. Walbro valves are specifically designed to work with their fuel pumps, and using an incompatible valve can lead to performance issues and potential damage to the fuel system. Always source the replacement parts from reputable suppliers to ensure compatibility.