Molten carbonate fuel cells (MCFCs) are a promising technology that could potentially replace traditional power generation methods. These fuel cells offer a unique advantage by utilizing a molten carbonate electrolyte, which enables them to operate at higher temperatures and efficiencies compared to other fuel cell types. With their ability to directly convert chemical energy from fuels like natural gas, hydrogen, or even biomass into electricity, MCFCs present a compelling alternative for power generation, especially in large-scale applications. This technology has the potential to revolutionize the energy sector by providing a clean, efficient, and sustainable power source, making it an exciting area of research and development.

What You'll Learn

- Cost-Effectiveness: Molten carbonate fuel cells offer competitive pricing compared to traditional power sources

- Efficiency: High efficiency in converting fuel to electricity, surpassing 60% in some models

- Environmental Impact: Zero emissions, reducing carbon footprint and air pollution

- Reliability: Robust and durable, ensuring consistent performance in various conditions

- Flexibility: Adaptable for diverse applications, from residential to industrial-scale power generation

Cost-Effectiveness: Molten carbonate fuel cells offer competitive pricing compared to traditional power sources

Molten carbonate fuel cells (MCFCs) have emerged as a promising alternative to traditional power generation methods, offering a unique set of advantages that make them a cost-effective solution for various applications. One of the key strengths of MCFCs lies in their ability to provide competitive pricing, challenging the dominance of conventional power sources.

The cost-effectiveness of MCFCs can be attributed to several factors. Firstly, these fuel cells operate at high temperatures, typically around 650-700°C, which allows for a more efficient combustion process. This efficiency is further enhanced by the use of a molten carbonate electrolyte, enabling the direct conversion of carbon fuel, such as coal or natural gas, into electricity. The high-temperature operation also reduces the need for additional heating systems, simplifying the overall design and reducing costs.

In comparison to traditional power generation technologies, MCFCs offer a more streamlined and cost-efficient process. For instance, when considering coal-fired power plants, MCFCs can eliminate the need for expensive and energy-intensive processes like coal cleaning and transportation. By directly utilizing coal as a fuel, MCFCs can reduce the overall cost of electricity generation, making it a more attractive option for power utilities.

Additionally, the modular design of MCFC systems allows for easy scalability, making them adaptable to various power requirements. This flexibility enables the technology to be deployed in a wide range of applications, from small-scale distributed power generation to large-scale central power plants. The ability to customize the system's size and configuration can further optimize costs, ensuring that MCFCs remain competitive in the market.

Furthermore, the long-term operational costs of MCFCs are expected to be lower due to their durability and reliability. These fuel cells have a longer lifespan compared to some traditional power generation methods, reducing the frequency of maintenance and replacement. The reduced downtime and lower maintenance requirements contribute to a more stable and cost-effective power supply over time.

In summary, molten carbonate fuel cells present a compelling case for cost-effectiveness in power generation. Their ability to provide competitive pricing, streamline processes, and offer long-term reliability makes them a viable alternative to traditional power sources. As the technology continues to advance and become more widely adopted, MCFCs are poised to play a significant role in shaping a more sustainable and economically viable energy landscape.

Replacing the Fuel Pump in Your 2002 BMW 325i: Step-by-Step Guide

You may want to see also

Efficiency: High efficiency in converting fuel to electricity, surpassing 60% in some models

Molten carbonate fuel cells (MCFCs) are a promising technology for efficient and sustainable power generation. These fuel cells offer a unique advantage in terms of efficiency, which is a critical factor in the energy sector. With an efficiency of over 60%, MCFCs surpass many traditional power generation methods, making them a highly attractive option for replacing conventional energy sources. This high efficiency is primarily due to the advanced design and operation of these fuel cells, which optimize energy conversion processes.

The key to MCFCs' superior efficiency lies in their ability to operate at higher temperatures compared to other fuel cell types. This higher temperature range allows for more complete combustion of the fuel, typically a mixture of hydrogen and carbon monoxide derived from natural gas or other feedstocks. By maximizing the energy extracted from the fuel, MCFCs minimize energy losses, resulting in a more efficient power generation process. This efficiency is further enhanced by the fuel cell's ability to directly convert chemical energy into electrical energy without the need for intermediate steps, such as those required in combustion-based power plants.

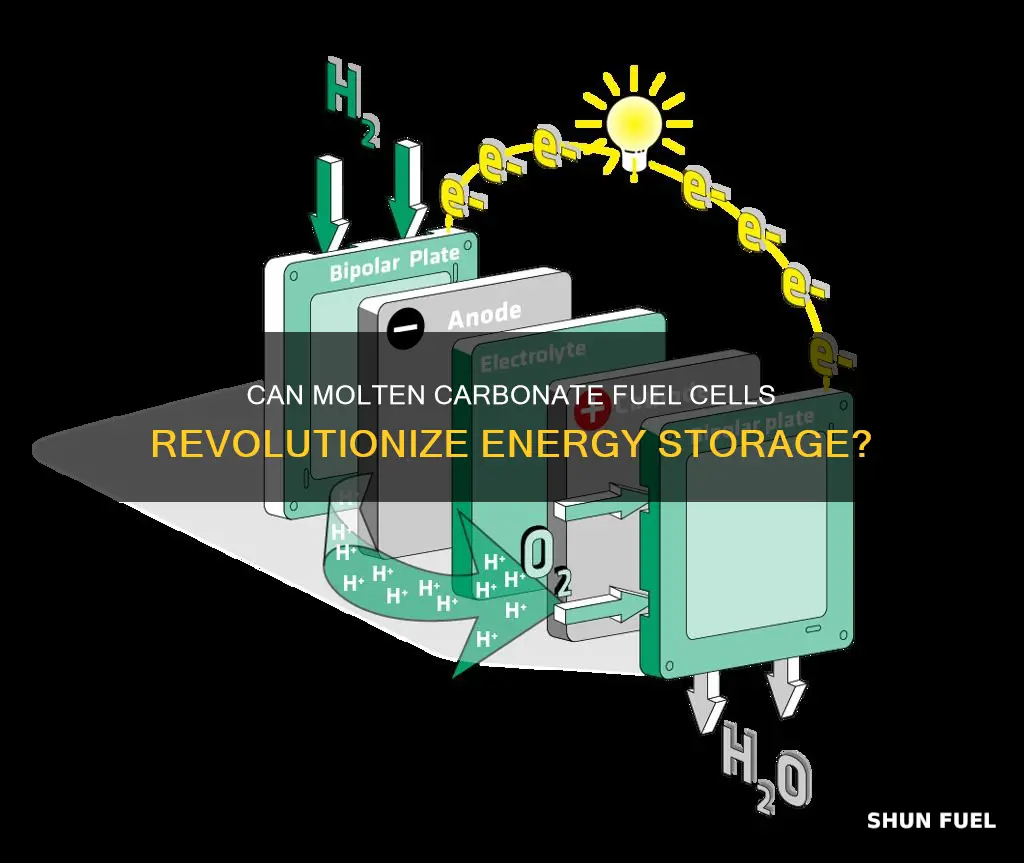

The design of MCFCs also contributes to their high efficiency. These fuel cells use a molten carbonate electrolyte, which enables the operation at elevated temperatures and facilitates the efficient transport of ions between the anode and cathode. This design feature, combined with the use of a solid oxide electrode, ensures a rapid and efficient electron transfer process, further enhancing the overall efficiency of the fuel cell. As a result, MCFCs can provide a consistent and reliable source of electricity with minimal energy waste.

In addition to their high efficiency, MCFCs offer other advantages that make them a viable replacement for traditional power generation methods. They have a longer lifespan and can operate continuously for extended periods without significant performance degradation. This longevity, coupled with their high efficiency, translates to reduced operational costs and a more sustainable energy solution. Furthermore, MCFCs can be integrated into various applications, including power generation for remote areas, backup power systems, and even transportation, making them a versatile and adaptable technology.

In summary, molten carbonate fuel cells' efficiency of over 60% in converting fuel to electricity is a significant advantage that sets them apart from conventional power generation methods. This high efficiency, coupled with their design features and operational advantages, makes MCFCs a compelling solution for replacing traditional energy sources. As the technology continues to advance, MCFCs are poised to play a crucial role in the transition towards a more sustainable and efficient energy landscape.

Replacing the Fuel Regulator in Your 2004 Nissan Frontier

You may want to see also

Environmental Impact: Zero emissions, reducing carbon footprint and air pollution

The environmental benefits of molten carbonate fuel cells (MCFCs) are significant and could play a crucial role in the transition to a cleaner energy future. One of the most notable advantages is their ability to produce electricity with zero direct emissions, making them an attractive alternative to traditional fossil fuel-based power generation. MCFCs operate by converting chemical energy from a fuel, typically a mixture of hydrogen and carbon monoxide, into electricity through an electrochemical process. This process does not involve the combustion of fossil fuels, which is a major source of greenhouse gas emissions and air pollution.

In urban areas, where air quality is a critical concern, MCFCs can significantly reduce the carbon footprint and improve air quality. These fuel cells can be deployed in various settings, including residential, commercial, and industrial complexes, providing a decentralized source of clean energy. By replacing conventional power generation methods, MCFCs can help lower the concentration of harmful pollutants such as nitrogen oxides (NOx), sulfur dioxide (SO2), and particulate matter, which are major contributors to smog and respiratory issues.

The environmental impact of MCFCs extends beyond local air quality. The reduction in greenhouse gas emissions is a global benefit, as it contributes to mitigating climate change. The combustion of fossil fuels releases vast amounts of carbon dioxide (CO2), a potent greenhouse gas, into the atmosphere. MCFCs, on the other hand, produce electricity with minimal CO2 emissions, making them an essential tool in the fight against global warming. This technology can be particularly valuable in sectors where emissions are challenging to eliminate, such as transportation and heavy industry.

Furthermore, the use of MCFCs can lead to a more sustainable and circular economy. The fuel for these cells can be derived from various sources, including renewable materials and waste streams. For instance, hydrogen can be produced through electrolysis using renewable energy, and carbon monoxide can be generated from biomass or waste gases. This approach not only reduces the reliance on finite resources but also provides a means to utilize and valorize waste materials, contributing to a more sustainable and environmentally friendly energy infrastructure.

In summary, molten carbonate fuel cells offer a promising solution to reduce environmental impact and combat climate change. Their zero-emission nature, ability to improve air quality, and potential for utilizing waste materials make them a valuable asset in the transition to a cleaner and more sustainable energy landscape. As the world seeks to reduce its carbon footprint, MCFCs could play a pivotal role in replacing conventional power generation methods and contributing to a healthier environment.

Upgrading Old Fuel Lines: Rubber Hose or Braided Steel?

You may want to see also

Reliability: Robust and durable, ensuring consistent performance in various conditions

Molten carbonate fuel cells (MCFCs) are renowned for their exceptional reliability and durability, making them a promising candidate to replace traditional power generation methods. This technology is designed to operate under a wide range of environmental conditions, ensuring consistent performance and minimal downtime. One of the key advantages of MCFCs is their ability to withstand harsh operating environments, including high temperatures and corrosive atmospheres. The fuel cell's molten carbonate electrolyte, typically composed of a mixture of lithium, potassium, and sodium carbonates, provides excellent thermal stability and chemical resistance. This unique characteristic allows MCFCs to maintain their performance even in extreme conditions, such as those found in industrial settings or remote locations.

The robust construction of MCFCs contributes to their reliability. These fuel cells are often designed with robust materials and components, ensuring they can endure the rigors of continuous operation. The cell stack, for instance, is typically composed of multiple layers of electrolyte, anode, and cathode, each carefully engineered to handle the chemical and thermal stresses during operation. The use of advanced manufacturing techniques and quality control processes further enhances the durability of MCFCs, ensuring that each component functions optimally over an extended lifespan.

In addition to their physical robustness, MCFCs exhibit excellent long-term stability. These fuel cells can operate continuously for thousands of hours without significant degradation in performance. This longevity is particularly advantageous for large-scale power generation applications, where consistent and reliable power supply is crucial. The ability of MCFCs to maintain their efficiency and output over extended periods reduces the need for frequent maintenance and replacement, making them a cost-effective and environmentally friendly energy solution.

The reliability of MCFCs is further enhanced by their ability to self-regulate and adapt to changing conditions. These fuel cells can automatically adjust their operating parameters to optimize performance and efficiency. For example, they can modulate the fuel and oxidant flow rates, as well as the operating temperature, to maintain a steady output even when faced with variations in input or environmental factors. This self-regulating capability ensures that MCFCs can consistently deliver power, making them a reliable choice for a wide range of applications.

Furthermore, the modular design of MCFC systems allows for easy maintenance and troubleshooting. Individual fuel cells or modules can be replaced or repaired without affecting the entire system, reducing the overall downtime. This modular approach also facilitates the integration of MCFCs into existing power infrastructure, making the transition to this technology more accessible and practical. In summary, the reliability and durability of molten carbonate fuel cells make them a strong contender to replace conventional power generation methods, offering a consistent and efficient energy solution for various industries.

Jeep YJ Fuel Filter Replacement: A Step-by-Step Guide

You may want to see also

Flexibility: Adaptable for diverse applications, from residential to industrial-scale power generation

Molten carbonate fuel cells (MCFCs) offer a unique advantage in terms of flexibility and adaptability, making them a promising technology for a wide range of power generation applications. This flexibility stems from their ability to operate with various fuels, including hydrogen, natural gas, and even renewable sources like biogas and landfill gas. This versatility is a significant advantage over other fuel cell technologies, which often require specific fuel inputs.

One of the key benefits of MCFCs is their scalability. These fuel cells can be easily adapted for both residential and industrial-scale power generation. For residential applications, MCFCs can provide efficient and clean electricity for homes, offering an alternative to traditional grid power. This is particularly valuable in remote areas or regions with unreliable power supplies, where MCFCs can provide a reliable and sustainable energy source.

In the industrial sector, MCFCs can play a crucial role in powering large-scale operations. They can be integrated into existing infrastructure, providing a clean and efficient power source for manufacturing processes, data centers, and other energy-intensive industries. The ability to use a variety of fuels allows MCFCs to be tailored to specific industrial needs, reducing the reliance on fossil fuels and contributing to a more sustainable energy model.

Furthermore, MCFCs can be designed as modular systems, allowing for easy installation and expansion. This modularity is especially advantageous for industrial applications, where power demands can vary significantly. By adding or removing modules, the system can be scaled up or down to meet changing energy requirements, ensuring optimal efficiency and cost-effectiveness.

The flexibility of MCFCs also extends to their integration with other renewable energy sources. They can be combined with solar panels or wind turbines to create hybrid power systems, providing a stable and consistent energy supply. This adaptability is essential for developing resilient and sustainable energy infrastructure, especially in the face of increasing energy demands and the need to reduce environmental impact.

Fuel Gauge Replacement: A Step-by-Step Guide for D17 Allis Chalmers Tractors

You may want to see also

Frequently asked questions

Yes, MCFCs have the potential to replace conventional power generation technologies due to their high efficiency and environmental benefits. These cells can directly convert chemical energy from fuels like natural gas, biogas, or hydrogen into electricity, offering a cleaner and more efficient alternative to burning fossil fuels.

MCFCs offer several advantages, including a higher thermal efficiency, the ability to operate at lower temperatures, and the use of readily available fuels. They can also produce both electricity and heat simultaneously, making them suitable for combined heat and power (CHP) applications.

MCFCs use a molten carbonate electrolyte, which allows for the transport of corrosive gases like carbon dioxide and water vapor. This unique feature enables the cells to operate in a high-temperature environment, facilitating the efficient conversion of chemical energy.

Absolutely. MCFCs can be integrated into power grids as distributed generation systems, providing electricity and heat to local areas or communities. Their modular design allows for easy scalability, making them adaptable to various grid requirements.

While MCFCs show great promise, there are challenges to be addressed. These include the need for improved durability and longevity, as well as the development of cost-effective and efficient methods for fuel preprocessing. Additionally, ensuring the safe handling and storage of molten carbonate electrolytes is crucial for widespread adoption.