Can I damage my car's fuel injectors? This is a common question among car owners, especially those who are new to vehicle maintenance. Fuel injectors are crucial components of a car's engine, responsible for delivering fuel to the engine's cylinders in precise amounts. However, they can be susceptible to damage from various factors, including improper maintenance, contamination, and mechanical issues. Understanding the potential risks and how to prevent damage is essential for ensuring your car's performance and longevity. This paragraph will explore the common causes of fuel injector damage and provide tips on how to keep them in optimal condition.

What You'll Learn

- Fuel Injector Design: Understanding the mechanics of fuel injectors and their impact on engine performance

- Fuel Pressure Regulation: How fuel pressure affects engine operation and potential damage

- Fuel Quality Impact: The role of fuel quality in preventing injector blockages and damage

- Over-fuelling Risks: Potential consequences of over-fuelling, including injector clogging and engine misfires

- Maintenance and Cleaning: Regular maintenance to prevent injector damage and ensure optimal engine performance

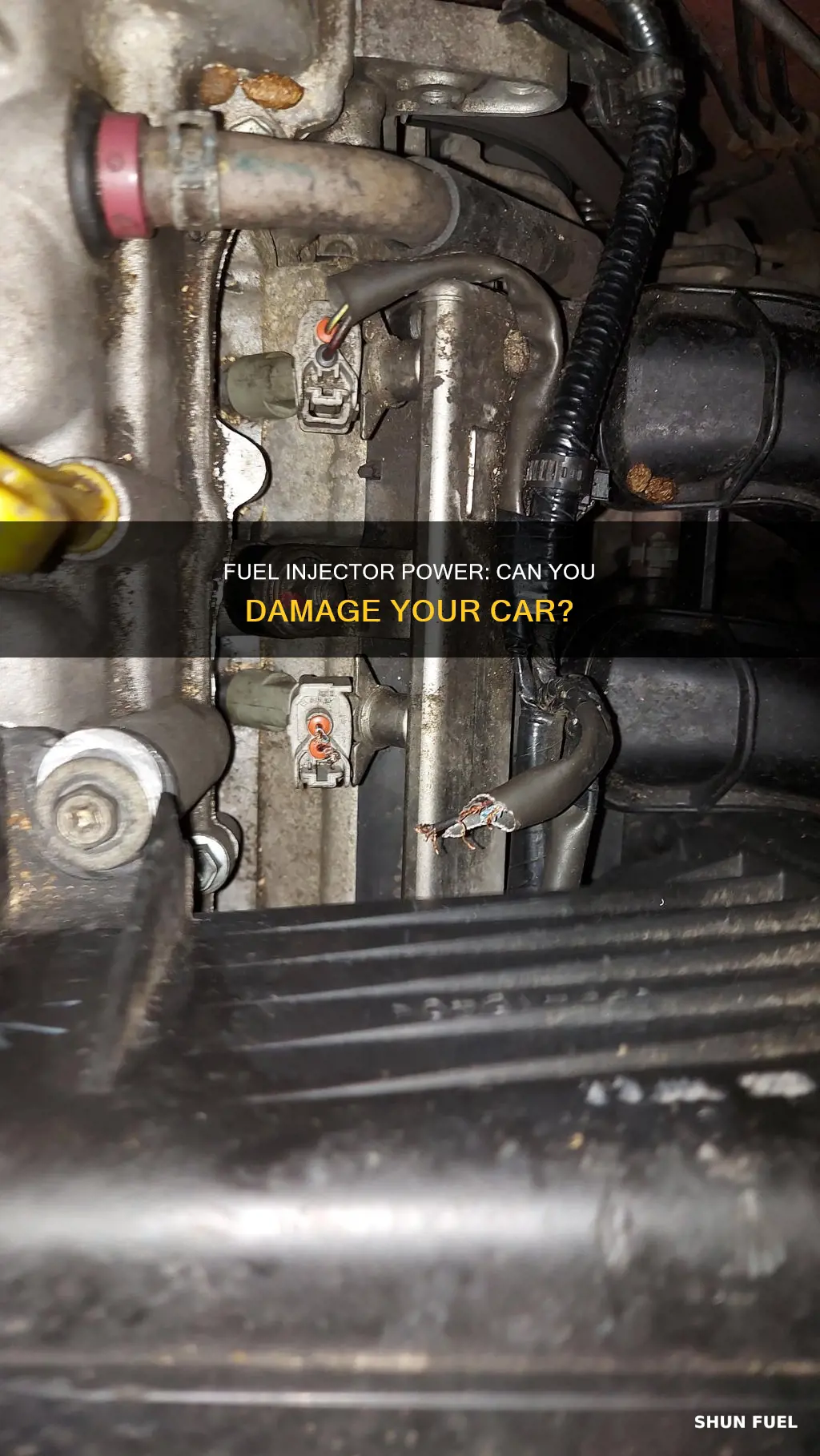

Fuel Injector Design: Understanding the mechanics of fuel injectors and their impact on engine performance

The fuel injector is a critical component in modern vehicle engines, responsible for delivering fuel to the combustion chamber with precision. Its design and functionality significantly influence engine performance, efficiency, and overall vehicle reliability. Understanding the mechanics of fuel injectors is essential for both automotive enthusiasts and professionals to appreciate the intricate relationship between fuel delivery and engine operation.

Fuel injectors operate based on the principle of precise fuel atomization and injection timing. Each injector is designed to deliver a specific volume of fuel at a predetermined rate, ensuring optimal combustion. The design of the injector includes several key elements. Firstly, the nozzle, which is the most visible part, is engineered to create a fine mist of fuel droplets. This mist formation is crucial as it allows for efficient mixing with air, promoting complete combustion. The nozzle's design also influences the spray pattern, ensuring it aligns with the engine's intake valves for effective fuel distribution.

Secondly, the injector's internal structure plays a vital role in its functionality. It consists of a solenoid valve, which is an electromagnetic actuator. When energized, the solenoid valve opens, allowing high-pressure fuel to pass through and exit through the nozzle. The design of this valve is critical, as it must respond rapidly to engine control unit (ECU) commands, ensuring fuel is injected at the right time and in the correct amount. The valve's responsiveness directly impacts the engine's ability to maintain optimal performance under various load conditions.

The impact of fuel injector design on engine performance is profound. Well-designed injectors can significantly improve engine efficiency, power output, and throttle response. They enable precise fuel control, allowing for better combustion quality and reduced emissions. Modern fuel injectors are often designed with multi-hole nozzles, which create multiple spray patterns, further enhancing fuel atomization. This design improvement results in more efficient combustion, especially in high-performance engines.

However, the design and installation of fuel injectors can also be a potential source of engine issues if not done correctly. Misaligned or poorly designed injectors may lead to fuel leaks, improper atomization, or uneven fuel distribution, all of which can cause engine misfires, reduced power, and increased emissions. Understanding the mechanics and design considerations of fuel injectors is, therefore, essential for mechanics and car enthusiasts to ensure optimal engine performance and longevity.

Fixing a Leaking Car Fuel Tank: A Step-by-Step Guide

You may want to see also

Fuel Pressure Regulation: How fuel pressure affects engine operation and potential damage

Fuel pressure is a critical aspect of engine operation, and its regulation is essential for optimal performance and longevity. The fuel pressure regulator ensures that the engine receives the correct amount of fuel at the right pressure, which is crucial for efficient combustion and power generation. When fuel pressure is too low, the engine may struggle to start, and if it does, it will likely run poorly, resulting in reduced performance and increased emissions. On the other hand, excessive fuel pressure can lead to engine damage, particularly in the fuel injectors and the engine's internal components.

The fuel pressure regulator is designed to maintain a precise balance between the fuel and air mixture. It monitors the pressure and adjusts it accordingly to ensure the engine operates within the optimal range. If the regulator fails or becomes faulty, it can lead to either too low or too high fuel pressure. Low fuel pressure might cause the engine to misfire, leading to poor acceleration and reduced power. In contrast, high fuel pressure can result in excessive fuel-air mixture, which can cause engine knocking, reduced engine life, and potential damage to the fuel injectors.

One of the primary concerns with fuel pressure regulation is the potential for fuel injector damage. Fuel injectors are responsible for delivering the precise amount of fuel required for each combustion cycle. If the fuel pressure is too high, the injectors may become overloaded, leading to potential damage. This can result in clogged or damaged injectors, which can cause the engine to run poorly or even fail to start. Over time, this can lead to increased maintenance costs and potential engine replacement.

To prevent such issues, it is essential to maintain the fuel pressure regulator and ensure it is functioning correctly. Regular maintenance, including fuel filter changes and system checks, can help identify and rectify any issues early on. Additionally, using high-quality fuel and additives can contribute to better fuel pressure regulation and overall engine health. It is also crucial to monitor the engine's performance and address any symptoms of fuel pressure issues promptly to avoid potential long-term damage.

In summary, fuel pressure regulation is vital for engine operation and longevity. Improper fuel pressure can lead to engine misfires, reduced performance, and potential damage to the fuel injectors and internal engine components. Regular maintenance and the use of high-quality fuel can help ensure optimal fuel pressure, contributing to a well-maintained and reliable vehicle. Understanding the impact of fuel pressure on engine operation is essential for drivers and mechanics alike to prevent costly repairs and ensure a smooth driving experience.

Car Fuel Tank Drain: A Step-by-Step Guide

You may want to see also

Fuel Quality Impact: The role of fuel quality in preventing injector blockages and damage

The quality of fuel plays a crucial role in maintaining the health and longevity of a vehicle's fuel injectors. Poor-quality fuel can lead to various issues, including blockages and damage to the injectors, which can have significant consequences for a car's performance and overall reliability. Understanding the impact of fuel quality is essential for vehicle owners and mechanics alike to ensure optimal engine operation.

When it comes to fuel injectors, the primary concern with low-quality fuel is the potential for clogging. Fuel injectors are responsible for delivering precise amounts of fuel to the engine's combustion chambers. Over time, if the fuel contains impurities or has a higher viscosity, it can lead to the formation of deposits and blockages within the injector passages. These blockages can restrict fuel flow, resulting in reduced power, poor engine performance, and even potential engine stall. For instance, if a fuel injector becomes clogged, it may spray fuel inefficiently or not at all, leading to misfires and reduced engine efficiency.

High-quality fuel, on the other hand, is carefully refined to meet specific standards and specifications. It undergoes processes to remove impurities and ensure a consistent viscosity, making it less prone to causing injector issues. Premium-grade fuels often have additives that help clean and protect the fuel system, including the injectors. These additives can help prevent the buildup of deposits and maintain the injector's performance over time. Using such fuel can lead to smoother engine operation, improved fuel efficiency, and reduced wear on engine components.

Furthermore, the impact of fuel quality extends beyond blockages. Poor-quality fuel may contain water or other contaminants that can cause corrosion within the fuel system, including the injectors. This corrosion can lead to injector damage, leaks, and even premature failure. In some cases, the presence of water in the fuel can cause electrical issues, as water can interfere with the electrical connections within the fuel injectors. This can result in erratic behavior or complete failure of the injector, requiring expensive repairs or replacements.

To minimize the risk of injector blockages and damage, it is recommended to use high-quality, premium-grade fuel whenever possible. Regular maintenance, such as fuel system cleaning and injector maintenance, can also help prevent issues. Additionally, keeping the fuel tank relatively full can minimize the exposure of the fuel to air, reducing the chances of water condensation and other contaminants. By understanding the relationship between fuel quality and injector health, vehicle owners can take proactive measures to ensure their cars' longevity and optimal performance.

Fuel Injector Issues: The Cause of Your Car's Shakes

You may want to see also

Over-fuelling Risks: Potential consequences of over-fuelling, including injector clogging and engine misfires

Over-fuelling, or adding too much fuel to a vehicle's engine, can have several detrimental effects on a car's performance and longevity. One of the primary risks associated with over-fuelling is injector clogging. Fuel injectors are responsible for precisely metering and delivering the correct amount of fuel to the engine's cylinders. When over-fuelling occurs, the excess fuel can lead to a buildup of deposits and carbon within the injectors. This buildup can cause the injectors to become clogged, resulting in a reduced or blocked fuel flow. Clogged injectors may lead to poor engine performance, reduced power, and even engine stall. In some cases, the engine may continue to run but will exhibit symptoms such as rough idling, misfires, and reduced fuel efficiency.

The consequences of injector clogging can be further exacerbated by the engine's inability to properly atomize the fuel. When the injectors are clogged, the fuel may not be sprayed with the required precision, leading to improper fuel-air mixture formation. This can result in engine misfires, where the engine fails to ignite the air-fuel mixture in one or more cylinders. Misfires can cause a loss of power, increased fuel consumption, and even potential engine damage over time. In severe cases, repeated misfires can lead to the premature wear and tear of engine components, such as spark plugs and the engine block.

Another consequence of over-fuelling is the potential for fuel system contamination. Excess fuel can mix with engine oil, leading to oil dilution and potential engine damage. This contamination can also affect the engine's performance and longevity, as it may result in increased engine wear, reduced lubrication, and the possibility of internal engine damage. Additionally, over-fuelling can cause the engine to run rich, meaning there is an excess of unburned fuel in the combustion chamber. This can lead to increased exhaust emissions, reduced fuel economy, and potential damage to the catalytic converter.

To mitigate these risks, it is crucial to follow the manufacturer's recommended fuel usage guidelines. Using the correct fuel type and ensuring that the fuel system is properly maintained can help prevent over-fuelling and its associated consequences. Regular fuel system inspections and cleanings can also help identify and address any issues related to fuel injector clogging or contamination. By being mindful of fuel usage and taking proactive measures, vehicle owners can ensure the longevity and optimal performance of their engines.

E85 Fuel Flexibility: Can Any Car Run on Ethanol?

You may want to see also

Maintenance and Cleaning: Regular maintenance to prevent injector damage and ensure optimal engine performance

Maintaining your fuel injectors is crucial for the longevity of your vehicle and its overall performance. Regular maintenance can help prevent damage to the injectors and ensure that your engine operates efficiently. Here are some key practices to keep in mind:

Routine Inspections: It is essential to inspect your fuel injectors periodically. Look for any signs of damage, such as cracks, blockages, or leaks. These issues can arise from contaminants in the fuel or debris entering the system. If you notice any problems, it's best to address them promptly to avoid further complications. Consider having a professional mechanic inspect the injectors during routine oil changes or at least once a year to ensure they are in good condition.

Fuel Quality: Using high-quality fuel is a simple yet effective way to maintain your fuel injectors. Contaminated or low-quality fuel can lead to injector damage and reduced engine performance. Always use the recommended fuel grade specified by your vehicle's manufacturer. Regularly check the fuel filter and replace it as needed to prevent contaminants from entering the system.

Engine Maintenance: Proper engine maintenance is closely tied to injector health. Regularly changing engine oil and oil filters helps keep the engine clean and ensures that any debris or contaminants are removed. Additionally, maintaining the correct engine temperature is vital. Extreme temperatures can cause fuel to vaporize or condense, leading to potential injector issues. Regularly check the engine's cooling system and ensure it operates efficiently.

Cleaning and Degreasing: Over time, fuel injectors can accumulate deposits and grease, especially in high-mileage vehicles. These deposits can restrict fuel flow and reduce performance. Consider using a fuel system cleaner as per the manufacturer's recommendations to flush out any built-up contaminants. For manual cleaning, you can use a fuel injector cleaner spray, which helps dissolve and remove deposits. However, always follow the instructions carefully to avoid any potential damage.

By implementing these maintenance practices, you can significantly reduce the risk of injector damage and ensure your engine operates at its best. Regular care and attention to the fuel injection system will contribute to a longer-lasting and more reliable vehicle. Remember, prevention is often more straightforward and cost-effective than dealing with injector damage and subsequent engine issues.

Why Turning Your Car Off While Filling Up Can Be a Bad Idea

You may want to see also

Frequently asked questions

Yes, using the wrong fuel can lead to significant issues. Different fuels have varying octane levels and additives, and using a lower-octane fuel than recommended can cause engine knock, which may result in engine damage over time. Always refer to your vehicle's manual or consult a mechanic to ensure you're using the correct fuel type.

A clogged fuel injector can cause a variety of problems. When an injector becomes blocked, it may not spray fuel correctly, leading to poor engine performance, reduced power, and even stalling. In some cases, a clogged injector can cause the engine to overheat due to improper fuel distribution. Regular maintenance and fuel system cleaning can help prevent this issue.

Absolutely. Some common indicators of fuel injector problems include rough idling, reduced power, and a noticeable decrease in fuel efficiency. You might also notice a 'check engine' light on your dashboard. If you experience any of these symptoms, it's advisable to have your fuel injectors inspected and tested by a professional to ensure timely repairs and prevent further damage.