The concept of modifying a fuel-injected car to become naturally aspirated is an intriguing one, as it involves altering the car's engine to rely solely on atmospheric pressure to draw air into the cylinders, rather than using forced induction. While fuel-injected cars are typically equipped with electronic fuel injection systems that precisely manage the fuel-air mixture, the idea of removing this system and replacing it with a naturally aspirated setup presents both challenges and opportunities. This transformation requires careful consideration of engine design, performance, and the trade-offs between power, efficiency, and drivability.

| Characteristics | Values |

|---|---|

| Engine Type | Fuel-Injected, Naturally Aspirated |

| Fuel Delivery System | Fuel Injection |

| Aspiration Method | Natural (atmospheric pressure) |

| Performance Impact | May result in reduced power and efficiency |

| Common Practice | Not typically, as fuel injection and forced induction are more common |

| Engine Design | Requires modifications to the intake system |

| Efficiency | Potentially less efficient due to the lack of forced induction |

| Cost | Additional modifications may increase expenses |

| Maintenance | Regular maintenance of the intake system is required |

| Reliability | Potential reliability concerns due to the complexity of the setup |

| Performance Tuning | Requires careful tuning to optimize performance |

What You'll Learn

- Engine Design: Modifying the engine to accept naturally aspirated intake and exhaust systems

- Fuel Injection: Retaining the fuel injection system while using a naturally aspirated engine

- Performance Trade-offs: Weighing the benefits of natural aspiration against fuel injection efficiency

- Engine Management: Adapting the engine control unit to handle naturally aspirated performance

- Air Intake Systems: Exploring different air intake methods for naturally aspirated fuel-injected engines

Engine Design: Modifying the engine to accept naturally aspirated intake and exhaust systems

The concept of modifying a fuel-injected engine to accommodate naturally aspirated intake and exhaust systems is an intriguing one, and it involves a series of intricate engine design changes. This process requires a deep understanding of engine mechanics and careful planning to ensure optimal performance and efficiency. Here's an overview of the key considerations and steps involved:

Intake System Modification:

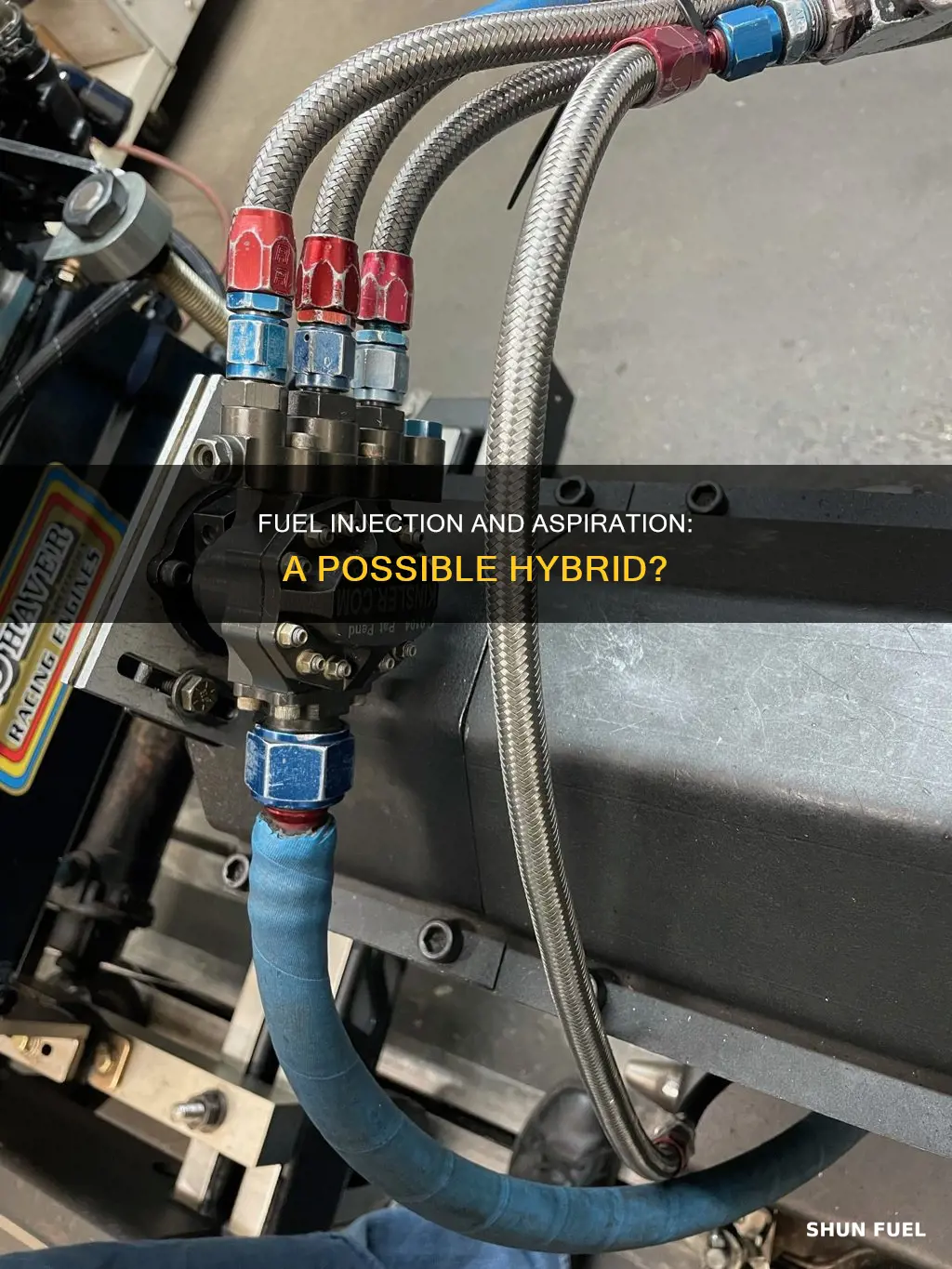

When transitioning from a fuel-injected setup to a naturally aspirated one, the intake system undergoes significant alterations. The primary goal is to optimize air intake and ensure efficient combustion. The stock intake manifold of a fuel-injected engine is typically designed for precise fuel metering and distribution. However, for naturally aspirated engines, a different approach is necessary. The intake manifold needs to be modified to accommodate larger air filters, which can handle the increased airflow associated with naturally aspirated setups. This often involves redesigning the manifold to have a larger plenum volume, allowing for better air accumulation and improved performance.

Engine Block and Head Changes:

Modifying the engine block and head is a crucial aspect of this conversion. The engine block may require modifications to accommodate the new intake and exhaust systems. This could include altering the cylinder head design, porting the combustion chamber, and adjusting the valve train to optimize airflow. The goal is to create a more open and efficient combustion process, which is essential for naturally aspirated engines. The engine block might also need modifications to the piston geometry, valve sizes, and valve timing to suit the naturally aspirated configuration.

Exhaust System Integration:

The exhaust system plays a vital role in expelling spent gases and maintaining engine efficiency. When converting to a naturally aspirated setup, the exhaust system must be designed to handle the modified engine's output. This often involves using larger diameter exhaust pipes to facilitate better gas flow and reduce back pressure. The exhaust manifold may also need to be redesigned to efficiently route gases to the exhaust ports. Proper exhaust system design is critical to ensuring optimal engine performance and minimizing unwanted noise.

Engine Control Unit (ECU) Calibration:

One of the most critical aspects of this modification is ECU calibration. The ECU is responsible for managing the engine's performance, and its programming needs to be adjusted to accommodate the changes made. Calibration involves fine-tuning the fuel injection settings, air-fuel mixture ratios, and ignition timing to match the naturally aspirated engine's characteristics. This process ensures that the engine operates efficiently and delivers the desired power output.

This engine design modification process requires a meticulous approach, considering various factors such as engine size, power output requirements, and the specific characteristics of the vehicle. It is a challenging but rewarding endeavor for enthusiasts and engineers alike, offering a unique blend of performance and customization.

Electric Revolution: Unveiling the Green vs. Fuel Debate

You may want to see also

Fuel Injection: Retaining the fuel injection system while using a naturally aspirated engine

The concept of combining fuel injection with a naturally aspirated engine setup is an intriguing one, and it's a topic that often sparks curiosity among car enthusiasts. While naturally aspirated engines are known for their simplicity and reliability, the idea of retaining fuel injection can seem contradictory. However, with the right modifications and careful tuning, it is indeed possible to achieve a harmonious blend of these two seemingly disparate systems.

Retaining the fuel injection system in a naturally aspirated engine primarily involves understanding the unique characteristics of each component. Fuel injection, as we know, is a sophisticated process that delivers precise amounts of fuel to the engine's cylinders, ensuring optimal combustion. On the other hand, naturally aspirated engines rely on the natural vacuum created by the piston movement to draw air into the engine, without the assistance of forced induction. The challenge lies in finding a balance between these two systems to maximize performance and efficiency.

One approach to achieving this is by utilizing a variable-flow fuel pump. Unlike the traditional fixed-flow pump, a variable-flow pump can adjust its output based on engine speed and load. This adaptability allows for more precise fuel delivery, mimicking the behavior of a naturally aspirated engine's intake process. By programming the fuel pump to respond to the engine's needs, you can retain the benefits of fuel injection while still allowing the engine to breathe naturally.

Additionally, the use of a high-flow intake manifold and a free-flowing air filter is crucial. These components ensure that the engine receives an ample supply of fresh air, which is essential for efficient combustion. The intake manifold should be designed to direct air smoothly and evenly across the cylinders, promoting optimal fuel-air mixing. Furthermore, a high-performance air filter will prevent dust and debris from entering the engine, maintaining the cleanliness of the combustion chamber.

When implementing these modifications, it is imperative to fine-tune the engine's electronics. The engine control unit (ECU) plays a pivotal role in managing fuel injection. By recalibrating the ECU to account for the changes in airflow and fuel delivery, you can optimize performance and maintain the desired power output. This process may require extensive testing and adjustments to ensure the engine operates smoothly and efficiently under various driving conditions.

In summary, retaining fuel injection in a naturally aspirated engine is a feasible endeavor with the right approach. By employing variable-flow fuel pumps, high-flow intake manifolds, and carefully calibrated engine electronics, it is possible to strike a balance between the precision of fuel injection and the simplicity of a naturally aspirated setup. This combination can result in a powerful and responsive engine, offering the best of both worlds to enthusiasts seeking a unique driving experience.

Powering the Future: Fuel Cells, Batteries, or Engines? Unlocking the Mystery

You may want to see also

Performance Trade-offs: Weighing the benefits of natural aspiration against fuel injection efficiency

The concept of combining natural aspiration with fuel injection in an internal combustion engine presents an intriguing performance trade-off. While fuel injection systems offer precise control over fuel delivery, allowing for improved efficiency and power, natural aspiration, or the use of a naturally aspirated engine, provides a different set of advantages. This exploration aims to delve into the performance implications of this unique engine configuration.

Natural aspiration, a simpler and more traditional approach, relies on atmospheric pressure to draw air into the engine. This method offers a more straightforward design, often associated with classic, high-revving engines. The simplicity of natural aspiration can lead to a lighter and more compact engine package, which can be beneficial for certain vehicle applications. However, the efficiency of fuel injection, which precisely meters and injects fuel into the engine's cylinders, is a significant consideration. Fuel injection ensures optimal fuel-air mixture formation, resulting in improved combustion and power output. It also allows for better control over emissions, making it a popular choice for modern vehicles.

When considering performance, the trade-off lies in the balance between power delivery and efficiency. Natural aspiration can provide a unique power characteristic, often delivering a high-revving, rev-happy engine that responds well to aggressive driving styles. This is particularly appealing in sports cars or high-performance vehicles where the thrill of rapid acceleration and high engine speeds is desired. On the other hand, fuel injection's precision can lead to more consistent and efficient power delivery, ensuring a smooth and responsive drive, especially in everyday driving conditions.

The key performance consideration is the engine's ability to breathe and deliver power effectively. Natural aspiration's simplicity may result in a more responsive engine, but it can also lead to reduced power output due to the limitations of atmospheric pressure. Fuel injection, with its ability to optimize fuel-air mixture, can overcome some of these limitations, potentially providing a more powerful and efficient engine. However, the complexity of fuel injection systems and their calibration requirements should not be overlooked, as they can introduce additional challenges in certain performance scenarios.

In summary, the performance trade-offs between natural aspiration and fuel injection efficiency are complex. While natural aspiration offers a simpler, rev-happy engine, fuel injection provides precision and efficiency. The decision to combine these technologies depends on the specific vehicle's requirements, the desired performance characteristics, and the trade-offs between simplicity, power, and efficiency. This unique engine configuration showcases the ongoing evolution of internal combustion engine design and the pursuit of optimal performance in various automotive applications.

The Dangers of Fueling a Running Car: What You Need to Know

You may want to see also

Engine Management: Adapting the engine control unit to handle naturally aspirated performance

The concept of adapting a fuel-injected engine to naturally aspirated performance is an intriguing challenge for automotive enthusiasts and engineers. While fuel injection is designed to optimize fuel delivery and combustion in an engine, naturally aspirated engines rely on atmospheric pressure to draw air into the cylinders, offering a different set of characteristics and requirements. The task at hand is to modify the engine control unit (ECU) to accommodate these changes and maintain optimal performance.

One of the primary considerations is the air-fuel ratio. In a naturally aspirated engine, the intake of air is directly influenced by the engine's RPM and the throttle position. The ECU must be programmed to adjust the fuel injection accordingly. For instance, at higher RPMs, the ECU should increase the fuel injection to maintain the desired power output. Conversely, during low-speed cruising, a leaner air-fuel mixture can be employed to improve fuel efficiency. This adjustment is crucial to ensure the engine operates efficiently across various driving conditions.

Another critical aspect is the timing of the fuel injection. In a naturally aspirated setup, the intake and compression strokes are more pronounced, requiring precise timing to maximize power and efficiency. The ECU should be calibrated to advance the fuel injection timing slightly, especially during high-load conditions, to ensure proper combustion. This adjustment compensates for the lack of forced induction and helps maintain the engine's performance characteristics.

Additionally, the ECU needs to account for the different airflow dynamics. Naturally aspirated engines often experience a more significant drop in intake manifold pressure, especially at high RPMs. To address this, the ECU can be programmed to adjust the fuel injection based on manifold pressure sensors. By monitoring these sensors, the ECU can make real-time adjustments to the fuel-air mixture, ensuring optimal performance even under varying atmospheric conditions.

Furthermore, the ECU's ability to learn and adapt is essential. With the introduction of naturally aspirated performance, the ECU should be capable of learning the new engine characteristics and making adjustments accordingly. This includes learning the engine's response to different throttle positions, RPM ranges, and ambient conditions. Over time, the ECU can optimize the fuel injection and engine management, providing a seamless and responsive driving experience.

Fuel Savings: Is a New Car Worth the Investment?

You may want to see also

Air Intake Systems: Exploring different air intake methods for naturally aspirated fuel-injected engines

The concept of combining fuel injection with natural aspiration might seem contradictory, as fuel injection typically requires a precise and controlled air-fuel mixture, while natural aspiration relies on atmospheric pressure to draw air into the engine. However, with the right modifications, it is indeed possible to achieve a naturally aspirated fuel-injected engine, and understanding the role of air intake systems is crucial to this process.

In a naturally aspirated engine, the air intake system's primary goal is to maximize the amount of fresh air entering the engine while minimizing turbulence and restriction. This is typically achieved through a simple air filter and a smooth, straight intake manifold. However, when fuel injection is introduced, the system becomes more complex. Fuel-injected engines require a precise and consistent air-fuel mixture, and the air intake system must be designed to provide this while still allowing for natural aspiration.

One approach to achieving this is by utilizing a high-flow air filter that can handle the increased air volume required by the fuel injection system. This filter should be designed to minimize restriction, ensuring that the air flows freely into the engine. Additionally, the intake manifold should be carefully designed to promote smooth air flow and efficient fuel injection. A straight, smooth manifold with carefully positioned throttle bodies can help optimize the air-fuel mixture and ensure proper atomization of the fuel.

Another method to consider is the use of a ram air intake system, which utilizes the engine's compression to draw air into the system. This method can provide a significant boost in air density, especially at higher engine speeds. Ram air intakes often feature a large, open design with a filter positioned to capture as much cool, dense air as possible. This approach can be particularly effective for naturally aspirated fuel-injected engines, as it helps maintain a consistent air-fuel mixture even under high-performance conditions.

In summary, creating a naturally aspirated fuel-injected engine requires a thoughtful approach to the air intake system. By using high-flow filters, carefully designed intake manifolds, and potentially ram air systems, it is possible to optimize the air-fuel mixture while still allowing for natural aspiration. These modifications ensure that the engine can breathe efficiently, providing the necessary air for the fuel-injected system while maintaining the benefits of a naturally aspirated engine's simplicity and responsiveness.

F1's Fuel Efficiency: A Race Against Time

You may want to see also

Frequently asked questions

Yes, it is possible to convert a fuel-injected engine to a naturally aspirated one, but it requires significant modifications. The process involves removing the fuel injectors, intake manifold, and associated wiring, and replacing them with a carburetor or a manual fuel pump system. This conversion can be challenging and may require expert knowledge and mechanical skills.

Converting a fuel-injected car to a naturally aspirated setup can offer several benefits. Firstly, it can improve low-end torque and drivability, especially in older engines where fuel injection might not be as precise. Secondly, it can provide a more engaging driving experience with a more responsive throttle response. Additionally, naturally aspirated engines often have a unique sound and character, which can be appealing to enthusiasts.

The impact on fuel efficiency will depend on various factors, including the specific engine, modifications made, and driving conditions. Generally, naturally aspirated engines tend to be more fuel-efficient at lower RPMs due to the simpler induction system. However, they may lose some efficiency at higher speeds or when demanding more power. Proper tuning and calibration are crucial to optimize fuel efficiency in the converted setup.

Yes, there are a few considerations. Firstly, the engine may lose some power and performance, especially if the fuel injection system was optimized for specific engine requirements. Secondly, the conversion process can be complex and time-consuming, requiring careful planning and execution. Additionally, maintaining the engine's health and longevity might require more attention, as the modified setup may have different operating characteristics.