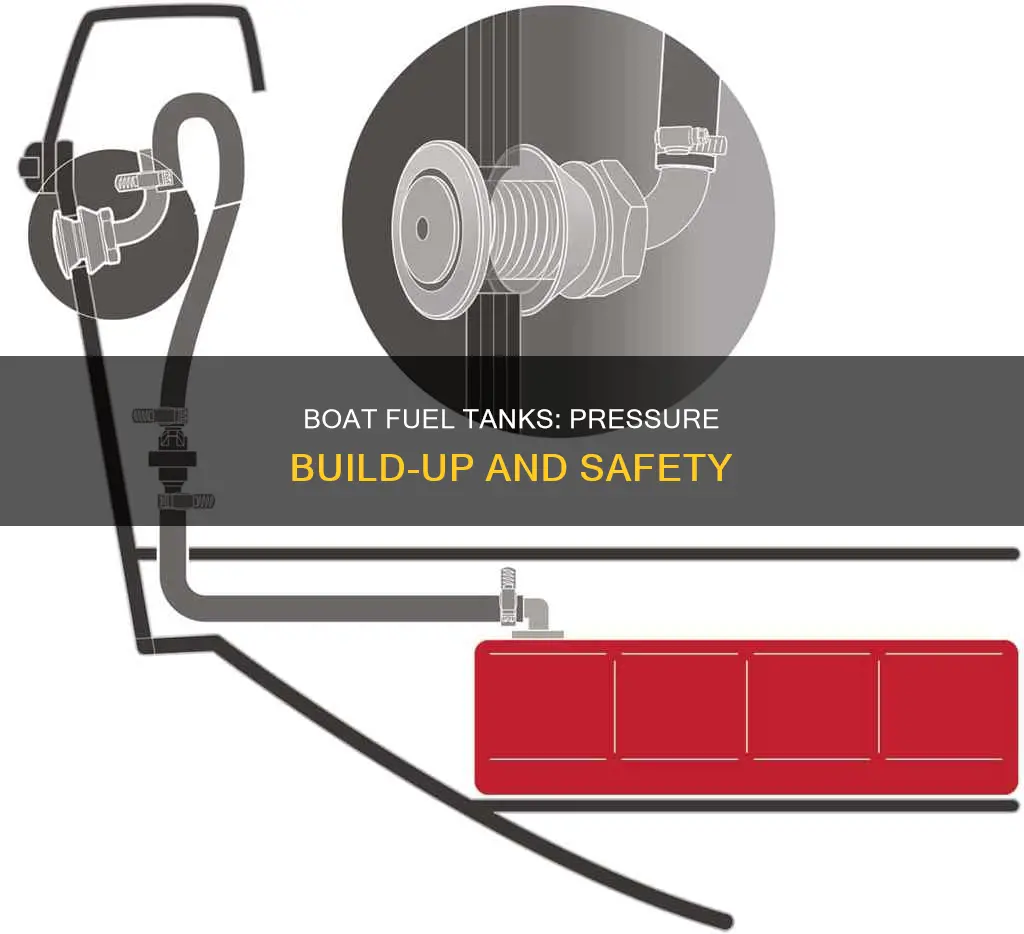

Boat fuel tanks are not pressurised like car fuel tanks, and instead have an air vent to relieve pressure that builds while filling a tank. This means that fuel tanks on boats can build up internal pressure, which can cause the tank to swell and, in some cases, force fuel into the engine. This can be a fire hazard and cause environmental damage. To prevent this, fuel-line valves and fuel-tank caps can be installed to prevent gas from reaching the engine and to vent gas fumes when pressure reaches a certain level.

| Characteristics | Values |

|---|---|

| Fuel tank pressure | Positive pressure (>1PSI) |

| Fuel tank capacity | Varies from the label or published capacity by no less than 5% and up to 10% |

| Diurnal Fuel Systems | Produce a clean refueling shut-off event, create a 5% vapour space, reduce spit-back events, and allow for appropriate venting when the vessel is stored or on a trailer |

| Fuel cap | Contains valves designed to retain fuel vapour (up to 1PSIG) and to allow makeup air during engine operation |

| Boat fuel tanks | Not pressurised like car fuel tanks |

| Boat fuel tank vents | Relieve the pressure that builds while filling a tank |

| Mercury Marine Inc. fuel-tank cap | Under a certain pressure, will vent gas fumes to lower the pressure to a safe level |

What You'll Learn

- Boat fuel tanks are not pressurised like car tanks

- EPA-approved Diurnal Fuel Systems require boat fuel tanks to have positive pressure (>1PSI)

- Fuel tanks swell in the sun, and without a vent, fuel can be forced into the engine

- Mercury Marine Inc. has developed a fuel-tank cap that vents gas at high pressure, but not when jostled

- Fuel tanks should not be topped off

Boat fuel tanks are not pressurised like car tanks

Boat fuel tanks are vented to prevent them from collapsing or bulging as the inside pressure varies with temperature changes. If a boat's fuel tank was sealed, the tank would collapse or bulge, and the fuel starvation would cause the engine to die. If a leak developed in a pressurised boat fuel tank, the fuel would go into the boat.

Boat fuel tanks are also vented because diurnal expansion and contraction pull moisture-laden air into the tank, where it precipitates into the fuel because the ethanol is hygroscopic. This is why water can get into boat fuel through the venting system.

Boat fuel tanks can be pressure tested at home without expensive tools. To do this, you will need to close off all the locations where air could get out and have a way to put air into the tank. You will need a pair of hose pinch pliers, an inflatable pipe plug, and a low-pressure air pressure gauge.

Testing PT6 Fuel Nozzles: Managing Optimal Performance

You may want to see also

EPA-approved Diurnal Fuel Systems require boat fuel tanks to have positive pressure (>1PSI)

Will a Boat Fuel Tank Build Up Pressure?

Yes, boat fuel tanks can and do build up pressure. This is a common issue that boat owners face, and it can be frustrating when you're unable to fill your boat's gas tank completely. This issue has become more prevalent due to the recent implementation of environmental regulations for marine fuel tanks, which aim to reduce atmospheric emissions. As a result, boat fuel tanks now have positive pressure (>1 PSI) to comply with EPA-approved Diurnal Fuel Systems requirements.

EPA-Approved Diurnal Fuel Systems and Positive Pressure Requirements:

The US Environmental Protection Agency (EPA) has introduced regulations for marine fuel tanks, known as Diurnal Fuel Systems, to reduce their environmental impact. These regulations mandate that boat fuel tanks maintain positive pressure (>1 PSI) to address the expansion of fuel as the sun heats the vessel. The installed valves inside these tanks are designed to manage this pressure and vapour buildup while also ensuring a clean refuelling process and reducing the risk of spit-back events.

Understanding the Pressure Buildup:

The positive pressure requirement in boat fuel tanks is a result of the sun's heat causing the fuel to expand. This expansion creates vapours, and the tank's valves are designed to manage this vapour buildup. By maintaining positive pressure, the valves can effectively regulate the vapours and ensure a safe and efficient refuelling process.

Safety Precautions:

It is important to note that boat owners should only open the fuel cap for refuelling. Pressure may be present when opening the deck fill, and the initial introduction of cold raw fuel vapours can occasionally lead to spit-back anomalies. Therefore, it is crucial to be cautious and follow the recommended procedures to avoid any potential hazards.

Troubleshooting and Maintenance:

If you experience significant variances in fuel capacity or other issues, it is advisable to consult a dealer or a professional to check the fuel gauge and sender for proper functioning. Additionally, regular maintenance and inspections of the fuel tank and related components can help identify and address any potential problems early on.

Understanding Base Fuel Pressure: Defining Optimal Performance

You may want to see also

Fuel tanks swell in the sun, and without a vent, fuel can be forced into the engine

Fuel tanks are an integral part of any vehicle, including boats, and they serve as a storage container for the fuel that powers the engine. However, fuel tanks, especially those without vents, can pose safety risks. One of the main dangers of unvented tanks is the risk of deformity or tank rupture. As the temperature rises, fuel tanks can swell up like balloons, and without a vent, the internal pressure can increase to a dangerous level.

A vent allows the tank to breathe by relieving both vacuum and pressure. Fuel, such as gasoline, expands in volume as it warms up and shrinks as it cools down. This means that the fuel level in a tank changes throughout the day, even without the vehicle being driven. A vent allows air to escape when fuel is added and enter when fuel is withdrawn.

Up until the 1960s, most vehicles used vented gas caps, which were simply gas caps with a hole in them. However, this design had the drawback of allowing fuel to splash out when accelerating or turning a corner. Modern fuel tanks may not have a traditional vent, but instead, a small screw-type fixture on the tank's cap or top. These newer-style portable tanks are designed to prevent smog-causing gas fumes from escaping into the atmosphere.

However, without a vent, a portable gas container can swell up in the hot sun, and the increasing pressure can force fuel into the engine. This can create a dangerous situation, as the pressurized fuel may spray out through the engine or fuel line, potentially causing a fire or polluting the environment. Therefore, it is crucial to have a venting system in place to release pressure and prevent the risk of explosion, rupture, or fuel spills.

Bluedriver's Real-Time Fuel Pressure Monitoring: What You Need to Know

You may want to see also

Mercury Marine Inc. has developed a fuel-tank cap that vents gas at high pressure, but not when jostled

Boaters will be all too familiar with the smell of fuel. But why does this happen? Well, a boat's fuel tank can build up pressure, and this can cause the tank to be damaged. This is why it is important to pressure test a boat's fuel tank.

One company has developed a solution to this problem. Mercury Marine Inc. has created a fuel-tank cap that vents gas at high pressure, preventing a build-up of pressure that could damage the tank. This innovative cap also has another important feature: it doesn't vent gas when jostled. This is crucial, as it prevents fuel from being accidentally released into the environment, which could be harmful to both the boat and the surrounding ecosystem.

The Mercury Marine fuel-tank cap is a simple yet effective solution to a common problem faced by boaters. It is a replacement cap that can be purchased for a reasonable price, and it fits a range of 4-stroke outboard models. This product is a great example of how innovative solutions can be created to address specific issues within a community.

By investing in this fuel-tank cap, boaters can not only improve the performance and longevity of their boats but also contribute to a healthier marine environment. This product demonstrates how Mercury Marine Inc. is committed to creating practical and eco-friendly solutions for the boating community.

Fuel Pressure and RPM: Understanding the Relationship

You may want to see also

Fuel tanks should not be topped off

Firstly, it is important to understand that gasoline is highly flammable and evaporates quickly when exposed to heat. Even inside your gas tank, there is always a pocket of vaporized fuel that the vehicle's Onboard Refueling Vapor Recovery (ORVR) system helps manage and harness. The ORVR system consists of a charcoal-lined canister that collects fuel vapors and absorbs them using activated carbon. This system reduces hydrocarbon emissions during refueling by about 95%.

When you top off your tank, you run the risk of saturating the charcoal filters in the ORVR system with liquid fuel, ruining their capacity to filter vapors. This can lead to an increase in hazardous emissions from your vehicle, impacting air quality. Additionally, topping off your tank can affect engine performance and reduce your vehicle's mileage per gallon.

Secondly, topping off your tank can also be detrimental to your wallet. When you override the automatic shut-off, the excess gasoline is fed back into the gas station's storage tanks through the pump's vapor-recovery system. This means you are paying for gas that is not actually going into your vehicle.

Furthermore, the spillage and evaporation of gasoline from overfilling contribute to air pollution and the formation of toxic sewage runoff. Gasoline contains toxic pollutants such as benzene, which are harmful to breathe and have negative environmental impacts.

In summary, topping off your fuel tank can lead to permanent damage to your vehicle's vapor recovery system, increased emissions, and unnecessary costs. It is also an environmental and safety hazard due to the flammable and toxic nature of gasoline. Therefore, it is recommended to stop pumping when the fuel pump clicks off to avoid these potential issues.

Understanding Ideal Fuel Pressure for Your Vehicle's Performance

You may want to see also

Frequently asked questions

Boat fuel tanks build up pressure due to the sun heating the vessel and the fuel in the tank expanding.

A boat fuel tank can build up to 3 PSI of pressure.

If there is too much pressure in a boat fuel tank, it can split the welds and destroy the tank.

To relieve pressure in a boat fuel tank, you can open the fuel cap. However, this may not always be practical, and it defeats the EPA's zero-emissions plan.

Yes, there are products such as inline fuel/air separators, combination deck fills and vents, and fuel computers that can help prevent fuel spills and relieve pressure. These products can be purchased from stores like West Marine and BoatUS.