An in-tank fuel pump can be replaced with an external fuel pump, but there are several factors to consider. Firstly, an external pump may not work properly if the stock fuel pickup in the tank is not covered with fuel, causing the fuel pressure to drop and the engine to sag. Secondly, the location of the external pump is important for safety reasons, as placing it too close to the passenger compartment or firewall may pose a risk in the event of an accident. Additionally, the type of pump and fuel system must be compatible, and the use of a return-style system or surge tank may be necessary to maintain fuel pressure and flow. Furthermore, an external pump may require additional electrical wiring and relays, and it is important to ensure proper isolation to minimize noise. While an external pump can be a viable option, it is essential to carefully plan and execute the installation to avoid potential issues and ensure safety.

What You'll Learn

An in-tank pump may be more efficient and quieter

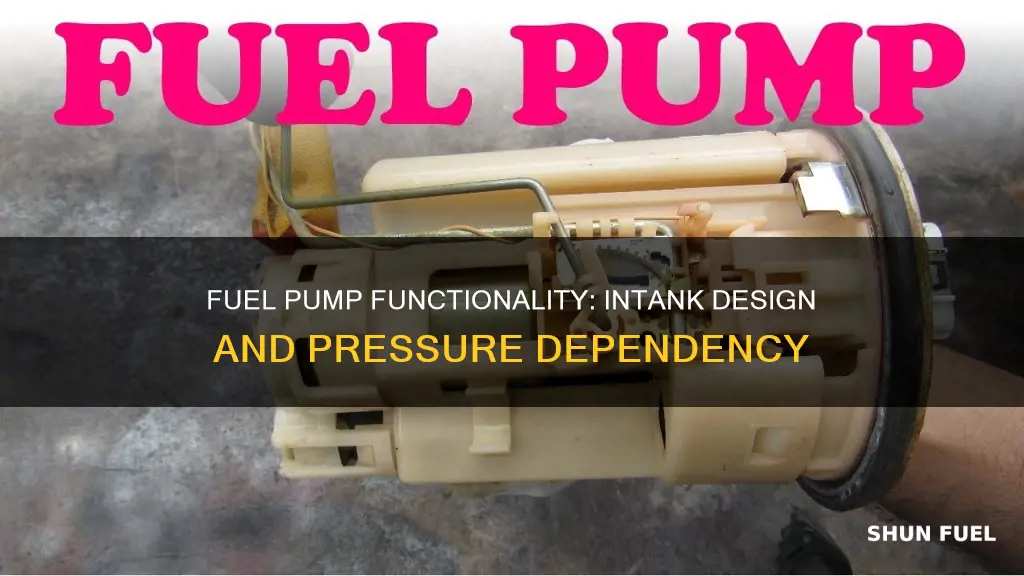

An in-tank fuel pump is a fuel pump that is located inside the fuel tank. It is typically mounted on the fuel tank’s top or side and is connected to the fuel lines that run from the tank to the engine. In-tank fuel pumps offer a range of benefits, and one of the most significant advantages is that they are generally more efficient and quieter than inline fuel pumps.

In-tank fuel pumps are designed to deliver the precise amount of fuel required by the engine, leading to better fuel efficiency. They are also known for their quieter operation, making for a more comfortable driving experience. The location of the in-tank pump inside the fuel tank also contributes to its quieter performance as it is less prone to vibration.

In addition to improved efficiency and reduced noise, in-tank fuel pumps also operate at a cooler temperature. Being immersed in the fuel helps keep the pump cool, reducing the likelihood of overheating. This is in contrast to inline fuel pumps, which are more susceptible to heat-related issues as they are mounted outside the fuel tank.

While in-tank fuel pumps offer these advantages, there are also some drawbacks to consider. They tend to be more expensive than inline fuel pumps due to their complex design and installation process. Accessing and replacing an in-tank fuel pump can be more challenging since it is located inside the fuel tank. Additionally, in-tank fuel pumps are typically designed for specific vehicle types, which can limit their versatility.

In summary, in-tank fuel pumps offer enhanced efficiency, quieter operation, and cooler performance compared to inline fuel pumps. However, they may come with a higher price tag and require more effort for maintenance and replacement. The decision between choosing an in-tank or inline fuel pump ultimately depends on factors such as vehicle type, performance requirements, and budget.

Ideal Fuel Pressure for Jeep Cherokee Idling

You may want to see also

External pumps are used for racing and high-performance cars

External fuel pumps are commonly used for racing and high-performance cars. They can be installed inline when converting from a carburetor to fuel injection, using the original fuel tank and much of the existing fuel system. External pumps can also be used as lift pumps to get fuel from the tank to the engine.

One of the main advantages of external pumps for racing applications is their ability to deliver fuel at higher pressures and flow rates, which can support increased horsepower. They can also be larger than internal pumps and, consequently, can be built to support more horsepower. By moving the pumps inside the fuel cell, the chances of vapour-lock or cavitation are reduced, ensuring consistent fuel delivery at high altitudes or with hotter fuel. This makes external pumps a popular choice in off-road and rally-style racing.

Additionally, external electric pumps can supply huge quantities of fuel in racing applications and feed a dedicated nitrous oxide fuel system. They are also easier to service than internal pumps.

When it comes to choosing between external and internal fuel pumps, it depends on the specific application and the horsepower and fuel consumption requirements of the vehicle. While internal pumps are generally more reliable, external pumps are often preferred for high-performance and racing cars due to their ability to deliver higher flow rates and pressures.

Ford's Fuel Pressure Regulator: What's in a Name?

You may want to see also

In-tank pumps may be a pain to access and more costly

In-tank fuel pumps are a pain to access and more costly than external pumps. While it is possible to install an external fuel pump without removing the in-tank pump, it is not recommended as it may lead to future issues and headaches.

In-tank fuel pumps are more efficient and quieter than external pumps. They also run cooler as they are sitting in a body of fluid. Additionally, in-tank pumps have the potential to use a bucket setup, where a venturi feature sucks gas out of the bottom of the tank, keeping the bucket full even when the gas tank is almost empty. This is especially beneficial for cars that corner well, as it prevents the engine from stalling when the pickup is uncovered during turns.

However, one of the main drawbacks of in-tank fuel pumps is the difficulty of access. If the pump fails or needs to be replaced, it requires dropping the fuel tank or cutting a hole in the trunk floor for access. This can be a time-consuming and costly process. In contrast, external fuel pumps can be unbolted and replaced in half the time, without the need to remove the fuel tank.

Furthermore, in-tank fuel pumps can be more expensive, especially if a new tank is required for the installation. The cost of the internals/tank may not be competitive with just purchasing an external pump. Additionally, there may be extra costs involved in building an in-tank pump and return fuel system.

While in-tank fuel pumps offer some advantages in terms of efficiency and quietness, they come with the trade-off of being more challenging and costly to access and maintain. It is important to consider the potential issues and expenses associated with in-tank pumps before making a decision.

Fuel Pressure Sweet Spot for Elderbrook Carburetors

You may want to see also

An in-line pump may be more cost-effective and easier to install

An in-line fuel pump may be more cost-effective and easier to install than an in-tank fuel pump. This is especially true if you are a racer or are using your vehicle for high-performance applications. In these cases, having an external pump can save you time and money if your fuel pump fails. With an in-line pump, you can simply unbolt the external pump in half the time it would take to drop the fuel tank to remove an in-tank pump. Additionally, the cost of the internal tank and the labour required to install it is not competitive with just buying an external pump.

Furthermore, if you are unable to remove a faulty in-tank pump, you may be able to leave it in the tank, unplugged, and install an in-line pump without any issues. However, some people have reported that this setup may not work optimally, as the new pump may have to work harder, potentially leading to a shorter life. Therefore, it is recommended to do it right the first time and remove the faulty in-tank pump if possible.

When installing an in-line pump, it is important to mount the pump as low as possible in relation to the tank to create a gravity feed and reduce the workload on the pump. Additionally, using a return regulator and a relay to prevent burning up switches and wiring can enhance the performance and longevity of the in-line pump.

In terms of noise, in-tank pumps are generally quieter, but with proper isolation, in-line pumps can also be very quiet. Some people even prefer the louder noise of an in-line pump to know that it is on and functioning.

In conclusion, an in-line fuel pump can be a more cost-effective and easier-to-install option, especially for high-performance applications. However, it is important to consider the potential drawbacks, such as increased noise and the need for proper installation and accessories to ensure optimal performance and longevity.

Troubleshooting No Fuel Pressure in Vehicles

You may want to see also

An in-line pump may not work if the fuel tank is less than half-full

An in-line fuel pump may not work if the fuel tank is less than half-full. This is because the pump needs to be submerged in fuel to work effectively. If the tank is less than half-full, the pump may not be able to draw enough fuel, causing the engine to stall. Additionally, a low fuel level can increase the risk of debris being sucked into the pump, which can lead to clogging and damage.

There are several other reasons why it is advisable to maintain at least a half-full fuel tank. Firstly, a higher fuel level can help to cool the pump, extending its lifespan. Secondly, a fuller tank reduces the risk of water accumulation, which can freeze and cause issues in colder climates. Finally, keeping the tank at least half-full can improve fuel efficiency and reduce the weight of the vehicle, resulting in better mileage and reduced wear on tires and brakes.

While there are advantages to maintaining a higher fuel level, it is not necessary to keep the tank constantly full. Doing so can increase the weight of the vehicle, impacting fuel efficiency and handling. It is generally recommended to keep the tank at least a quarter to half-full to balance these factors.

In conclusion, an in-line fuel pump may not function properly if the fuel tank is less than half-full due to insufficient fuel for the pump to draw from. Additionally, maintaining a higher fuel level offers several benefits, including improved pump cooling, reduced risk of water accumulation, and enhanced fuel efficiency. However, it is not necessary to keep the tank constantly full, and a balance between fuel level and vehicle weight should be considered.

Fuel Pressure Fundamentals for Chevy Carb Enthusiasts

You may want to see also

Frequently asked questions

Yes, it is possible to leave the old pump in the tank and install a new in-tank fuel pump. However, doing so may cause issues with fuel pressure and fuel delivery, and it is generally recommended to remove the old pump to avoid future headaches and potential performance issues.

An in-line fuel pump can be used without removing the in-tank pump, but it may not work optimally. The in-tank pump will act as a restriction, and the in-line pump will have to work harder, which may lead to decreased performance and a shorter lifespan.

An in-tank fuel pump is generally more efficient and quieter than an in-line fuel pump. It can also stay cooler as it is submerged in the fuel. Additionally, it is easier to access for maintenance or replacement if a dedicated access hole is cut in the trunk.

Yes, it is possible to use an in-line fuel pump with an electronic fuel injection (EFI) system. However, you will need to install a fuel pressure regulator and ensure that the stock fuel pickup in the tank is covered with fuel to maintain stable fuel pressure.

External fuel pumps can work, but they may cause issues with fuel pressure and delivery, especially when the fuel level in the tank is low. Additionally, placing a small reservoir of fuel under the hood, as is the case with some external pump setups, can be a safety concern in the event of an accident.