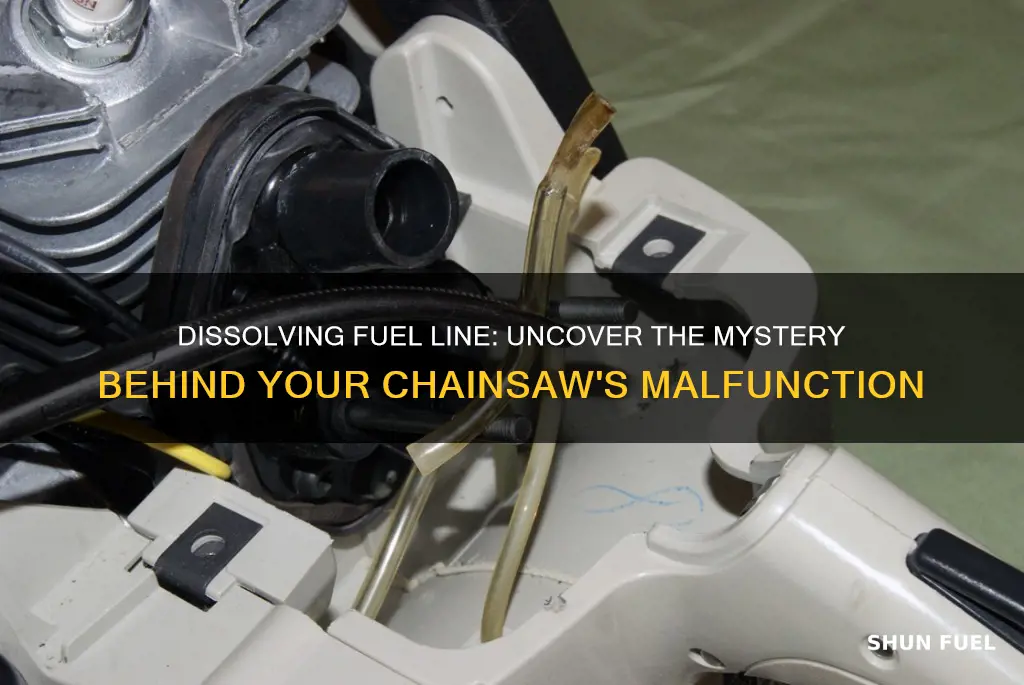

The fuel line on a chainsaw dissolving can be a concerning issue for any homeowner or professional. This problem often arises due to several factors, including the type of fuel used, the age of the chainsaw, and the maintenance routine. Understanding the causes and potential solutions to this problem is essential to ensure the longevity and safe operation of your chainsaw. In this article, we will explore the reasons behind fuel line dissolution and provide practical tips to prevent and address this issue.

What You'll Learn

- Material Degradation: Chainsaw fuel lines may dissolve due to material degradation over time

- Chemical Composition: The chemical composition of the fuel line material can affect its durability

- Temperature Effects: Extreme temperatures can cause fuel lines to dissolve or degrade

- Fuel Contaminants: Contaminated fuel can lead to fuel line dissolution

- Maintenance Neglect: Regular maintenance is crucial to prevent fuel line dissolution

Material Degradation: Chainsaw fuel lines may dissolve due to material degradation over time

The dissolution of fuel lines in chainsaws is a critical issue that can lead to significant performance problems and even safety hazards. One of the primary causes of this phenomenon is material degradation, which occurs over time due to various factors. Understanding these factors is essential for maintaining the longevity and reliability of your chainsaw.

Fuel lines are typically made from materials such as rubber, vinyl, or synthetic compounds, which are chosen for their flexibility and durability. However, these materials are susceptible to degradation when exposed to certain environmental conditions. One of the main culprits is the presence of ethanol in gasoline. Modern gasoline blends often contain ethanol, which can cause the plastic components of the fuel line to swell and weaken over time. This process is accelerated by the high temperatures and constant movement within the engine, leading to a gradual breakdown of the material.

Another contributing factor is the exposure to fuel itself. Chainsaw fuel lines are in constant contact with the fuel, which can cause the rubber or synthetic material to degrade. This is particularly true if the fuel contains impurities or is not of high quality. Impure fuel can contain water or other contaminants that can corrode the fuel line material, leading to its deterioration. Additionally, the constant vibration and movement of the chainsaw can further stress the fuel line, making it more prone to dissolving.

To prevent material degradation, it is crucial to use high-quality, ethanol-free gasoline in your chainsaw. Look for gasoline blends specifically designed for chainsaws or outdoor power equipment, as they are formulated to minimize the risk of fuel line damage. Regularly inspecting the fuel line for any signs of wear or damage is also essential. If you notice any cracks, brittleness, or discolouration, it may be an indication of material degradation, and you should consider replacing the fuel line promptly.

In summary, material degradation is a significant factor in the dissolution of fuel lines in chainsaws. The presence of ethanol in gasoline, exposure to fuel impurities, and the constant vibration of the chainsaw contribute to the breakdown of the fuel line material. By using appropriate fuel and regularly maintaining your chainsaw, you can minimize the risk of fuel line dissolution and ensure the optimal performance of your equipment.

Understanding Touareg Fuel Filter: Input vs. Output Lines

You may want to see also

Chemical Composition: The chemical composition of the fuel line material can affect its durability

The dissolution of fuel lines in chainsaws is a critical issue that can lead to equipment failure and potential safety hazards. One of the primary factors contributing to this problem is the chemical composition of the fuel line material. Different materials used in the construction of fuel lines have varying levels of resistance to the chemicals present in the fuel, which can significantly impact their durability over time.

The fuel used in chainsaws often contains a blend of gasoline and oil, which can include additives and impurities. These additives, such as detergents and corrosion inhibitors, are designed to enhance the fuel's performance and protect the engine. However, some of these additives can also react with the fuel line material, especially if it is not compatible with the fuel's chemical properties. For instance, certain types of rubber or plastic used in fuel lines may not withstand the presence of ethanol, a common additive in modern gasoline, which can cause the material to degrade and dissolve over time.

The chemical composition of the fuel line material is crucial because it determines its ability to resist the corrosive effects of the fuel. Materials like natural rubber and some synthetic rubbers are susceptible to dissolution when exposed to gasoline and its additives. This is because the hydrocarbons in gasoline can penetrate the material, leading to swelling and eventual disintegration. On the other hand, materials such as neoprene or butyl rubber, which are known for their resistance to hydrocarbons, can provide better durability in fuel lines.

In addition to the type of rubber, the additives and fillers used in the fuel line material can also play a significant role. Some manufacturers use plasticizers, stabilizers, or antioxidants to enhance the material's properties. However, if these additives are not compatible with the fuel, they may accelerate the dissolution process. For example, certain plasticizers can make the material more flexible but may also increase its susceptibility to fuel-related degradation.

To ensure the longevity of your chainsaw's fuel lines, it is essential to choose materials that are specifically designed to withstand the chemicals present in the fuel. Manufacturers often provide recommendations or specifications regarding the compatibility of their fuel line materials with different types of fuel. By selecting the right material, you can minimize the risk of dissolution and ensure the reliable operation of your chainsaw.

Clamping Fuel Lines: A Guide to 1994 Chevy Astro

You may want to see also

Temperature Effects: Extreme temperatures can cause fuel lines to dissolve or degrade

Extreme temperatures, whether hot or cold, can have detrimental effects on the components of a chainsaw, including the fuel lines. These lines are crucial for delivering fuel from the tank to the engine, and their integrity is essential for the chainsaw's performance and longevity. When exposed to extreme temperatures, fuel lines can undergo significant changes that may lead to their dissolution or degradation.

In high-temperature environments, the fuel lines can experience accelerated degradation. This is primarily due to the increased molecular motion within the fuel line material. As the temperature rises, the fuel line's plastic components become more pliable, and the fuel itself can vaporize, leading to a loss of pressure and potential engine performance issues. Over time, this can result in the fuel line softening, becoming brittle, and eventually dissolving, especially if the fuel contains volatile organic compounds (VOCs) that are sensitive to heat.

Conversely, cold temperatures can also pose a significant threat to fuel lines. In freezing conditions, the fuel can turn into a gel-like substance or even solidify, causing blockages in the fuel lines. This phenomenon, known as 'fuel gelling,' can occur in fuels that contain ethanol or other additives that are susceptible to freezing. As the fuel line narrows due to the solidification, it can restrict fuel flow, leading to engine starvation and potential damage.

The impact of temperature extremes is particularly critical for chainsaws, which are often used in outdoor environments with varying weather conditions. During hot summer days, the fuel lines may expand and become more susceptible to damage, especially if they are made of lower-quality materials. Conversely, in cold climates, the fuel lines could contract and become more rigid, potentially cracking or splitting due to the stress.

To mitigate these issues, it is recommended to use fuel lines made from high-quality, temperature-resistant materials. Additionally, maintaining the chainsaw's fuel system by using the correct type of fuel and adding stabilizers can help prevent issues related to temperature extremes. Regularly inspecting the fuel lines for any signs of damage or degradation is also essential to ensure the chainsaw's optimal performance and longevity.

Understanding the 3/8 Fuel Line: A Comprehensive Guide

You may want to see also

Fuel Contaminants: Contaminated fuel can lead to fuel line dissolution

The dissolution of the fuel line on a chainsaw is a serious issue that can be caused by contaminated fuel. When fuel becomes contaminated, it can lead to a variety of problems, including the degradation of the fuel line material. This is a critical component of the chainsaw's fuel system, and its failure can result in a complete breakdown of the machine.

Contaminants in fuel can originate from several sources. One common issue is the presence of water in the fuel. Water can enter the fuel tank through various means, such as condensation from the air or improper fuel storage. When water is present in the fuel, it can cause the fuel to become unstable and lead to the formation of harmful byproducts. These byproducts can then corrode the fuel line, causing it to dissolve over time.

Another significant contaminant is ethanol, which is often added to gasoline as a blend to meet environmental regulations. While ethanol is less harmful to the environment, it can be detrimental to the fuel system of a chainsaw. Ethanol has a higher octane rating, which means it can cause the fuel to ignite more rapidly. This increased combustion can lead to the formation of corrosive byproducts that attack the fuel line material, causing it to dissolve.

Additionally, the presence of other organic compounds in the fuel can contribute to fuel line dissolution. These compounds, often referred to as 'fuel system contaminants,' can be introduced through the use of low-quality fuel or improper fuel storage conditions. Over time, these contaminants can accumulate in the fuel and cause the fuel line to deteriorate, leading to potential fuel delivery issues and, ultimately, the dissolution of the fuel line.

To prevent fuel line dissolution, it is crucial to ensure that the fuel used in the chainsaw is clean and free from contaminants. Regularly checking the fuel for water and ethanol content, as well as using high-quality fuel, can help maintain the integrity of the fuel system. Additionally, proper fuel storage and handling practices should be followed to minimize the risk of contamination. By taking these precautions, chainsaw users can ensure the longevity of their fuel lines and avoid costly repairs or replacements.

Understanding Fuel Crossovers: A Comprehensive Guide to Efficient Systems

You may want to see also

Maintenance Neglect: Regular maintenance is crucial to prevent fuel line dissolution

Neglecting regular maintenance of your chainsaw can have serious consequences, especially when it comes to the fuel line. The fuel line is a critical component that delivers gasoline from the tank to the engine, and its deterioration can lead to a range of issues, including the dissolution of the fuel line itself. This problem is often caused by a lack of proper care and attention, which can be easily prevented.

Over time, the fuel line can become susceptible to wear and tear due to various factors. One primary cause is the accumulation of fuel contaminants. Gasoline contains volatile organic compounds (VOCs) that can evaporate and leave behind residue. This residue, combined with moisture from the air, can create a corrosive environment within the fuel line. If left unattended, this corrosion can lead to the dissolution of the fuel line's inner walls, resulting in a loss of fuel flow and potential engine damage.

Regular maintenance is essential to combat this issue. It involves cleaning and replacing the fuel filter, which acts as a barrier against contaminants. By regularly replacing the fuel filter, you remove the source of corrosion and ensure that the fuel line remains free from harmful substances. Additionally, checking and replacing the fuel line itself is vital, especially if you notice any signs of damage or wear. This proactive approach helps prevent the fuel line from dissolving and maintains the overall health of your chainsaw.

Another critical aspect of maintenance is the use of the correct fuel and additives. Using low-quality gasoline or failing to add stabilizers can accelerate the dissolution process. Stabilizers are designed to prevent fuel degradation and maintain its quality over time. By using the right fuel and additives, you ensure that the fuel line remains intact and that your chainsaw operates efficiently.

In summary, neglecting regular maintenance can have detrimental effects on your chainsaw's fuel line. The accumulation of contaminants, corrosion, and improper fuel usage can all contribute to the dissolution of the fuel line. By implementing a consistent maintenance routine, including fuel filter replacement, fuel line inspection, and the use of appropriate fuel, you can prevent this issue and ensure the longevity of your chainsaw's performance. Remember, regular care is key to avoiding costly repairs and maintaining a reliable power tool.

Fuel Line Cut: Understanding Gas Flow and Pressure

You may want to see also

Frequently asked questions

The dissolution of the fuel line in a chainsaw can be attributed to several factors. Firstly, the fuel line is typically made of a rubber or synthetic material that is susceptible to degradation over time, especially when exposed to certain chemicals in gasoline. This can be accelerated by factors such as age, prolonged exposure to fuel, and the presence of contaminants like water or ethanol in the fuel mixture. Regular maintenance and the use of high-quality, ethanol-free gasoline can help prevent this issue.

To prevent the fuel line from dissolving, it is essential to use the correct type of fuel for your chainsaw. Always refer to the manufacturer's guidelines and use gasoline that is free from ethanol, as ethanol can cause rubber components to deteriorate. Additionally, ensure that the fuel mixture is properly balanced, and consider using a fuel stabilizer to maintain the fuel's quality. Regularly inspect and replace the fuel line if you notice any signs of wear or damage.

Yes, there are a few other potential causes for fuel line problems. Clogged or restricted fuel lines can lead to pressure buildup, causing the rubber to expand and potentially dissolve. This can be a result of dirt, debris, or old fuel that has thickened over time. Another cause could be the use of low-quality or contaminated oil, which can affect the fuel's performance and potentially damage the fuel line. It is crucial to use the recommended oil and maintain regular oil changes to ensure optimal chainsaw performance.