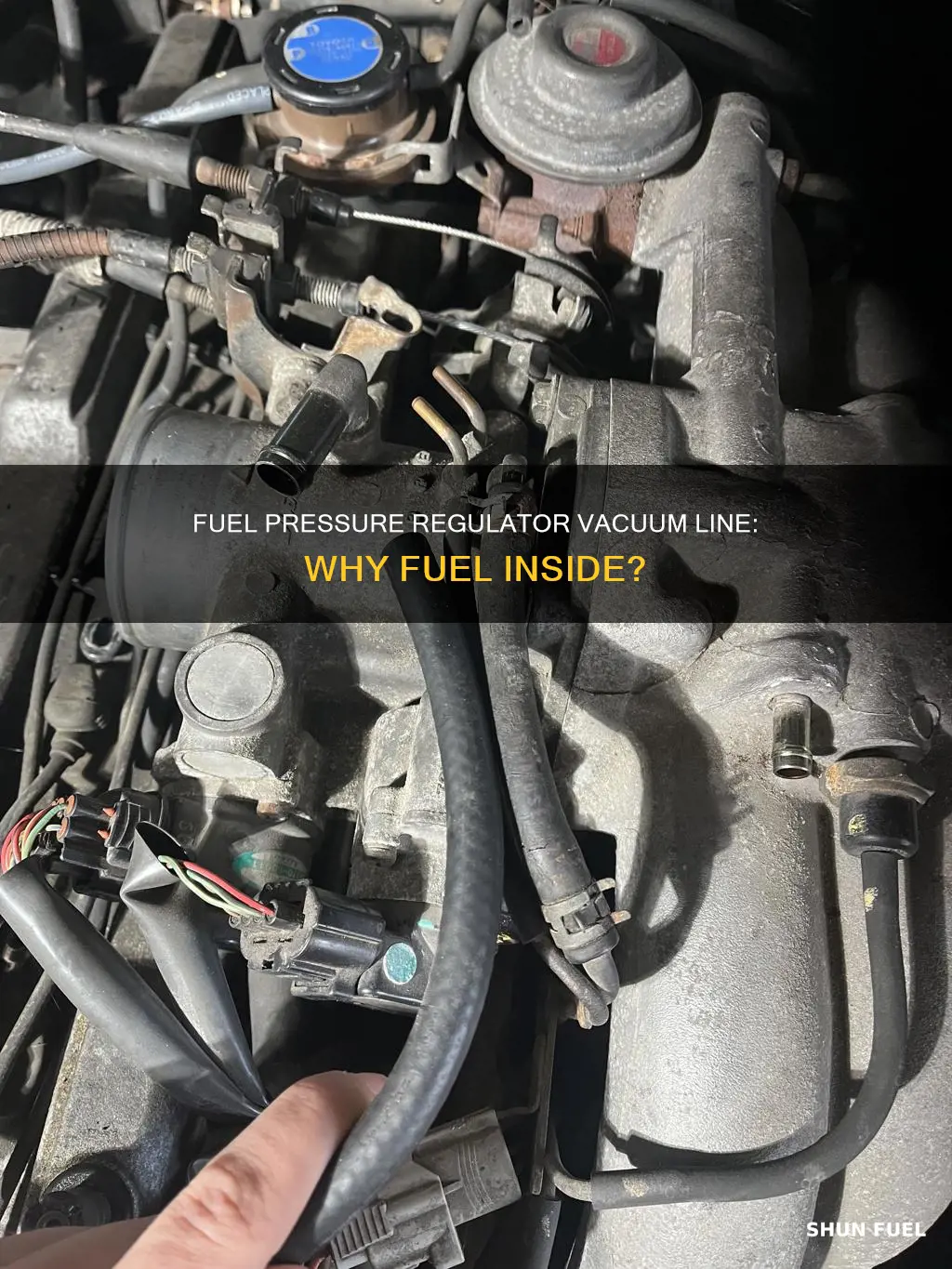

A vacuum line is attached to a fuel-pressure regulator in port-fuel-injected engines to maintain consistent fuel delivery and pressure regulation across the fuel injectors. The vacuum line helps to create an equal pressure drop across the injectors, ensuring that each injector delivers fuel consistently, regardless of the engine load. This is achieved by adjusting the fuel pressure based on the manifold vacuum. The vacuum line draws from the intake manifold, and as the engine runs, the manifold creates varying levels of vacuum depending on the throttle position and engine load. This dynamic adjustment helps ensure that the air-fuel mixture remains optimal for effective combustion, enhancing power output and improving fuel economy.

What You'll Learn

Vacuum line issues can cause flooding and vapor lock

A vacuum line issue can cause flooding in your engine. A mechanic has suggested that a vacuum line can cause a vehicle to flood, and a vacuum leak could be the culprit. A vacuum line issue can also cause vapor lock.

Vapor lock is a problem that is more common in older vehicles, especially those with carbureted engines. It occurs when fuel changes from a liquid to a gas before it is meant to, preventing the fuel system from delivering the correct amount of fuel to the engine. This can be caused by heat, which boils the fuel, preventing it from being pumped into the carburetor or fuel injectors.

Vapor lock can be caused by a variety of factors, including high ambient temperatures, extreme engine temperatures, fuel lines that are too close to hot components, using winter fuel in warm weather, and driving at high altitudes. It is more likely to occur in carbureted engines because the fuel is sucked over a long distance from the gas tank, rather than being pushed through the fuel line by a tank-mounted pump as in modern fuel-injected engines.

Vapor lock can cause a range of issues, including stalling, hard starting, misfiring, rough running, poor acceleration, and hesitation. To fix vapor lock, you may need to address other problems in the vehicle, such as overheating or misrouted fuel lines.

Supercharger Pressure Secrets of Top Fuel Engines

You may want to see also

A leaking regulator can cause fuel pressure to drop

A leaking fuel pressure regulator can cause fuel pressure to drop, leading to a range of engine problems. The fuel pressure regulator controls the upper limit of fuel pressure to ensure that fuel injectors receive and dispense fuel at a known rate. When this regulator leaks, it can cause a drop in fuel pressure, affecting the engine's performance.

In a continuous return fuel system, commonly found in older vehicles, the regulator is externally mounted and can leak if the diaphragm ruptures or if one of its seals fails. This can lead to fuel leaks, resulting in decreased engine performance and increased fuel consumption. The engine may also run rich, using more fuel than necessary to produce the required power, and emitting black smoke from the exhaust.

A leaking regulator can also cause issues with acceleration and deceleration. When the engine does not receive the required fuel pressure, it may struggle to accelerate smoothly, and excessive gasoline can build up during deceleration, leading to potential backfires.

Furthermore, a leaking fuel pressure regulator can cause the engine to misfire or stall completely. The air-fuel ratio and tune may be affected, impacting the overall performance of the vehicle. In some cases, the engine may fail to start, causing significant frustration for drivers.

To diagnose a faulty fuel pressure regulator, it should be tested by checking the fuel pressure downstream with a mechanical gauge or a scan tool. If a leak is detected, the regulator should be replaced to restore normal fuel pressure and engine performance.

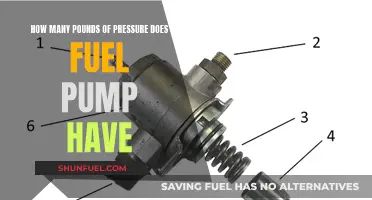

Understanding Fuel Pump Pressure: Performance and Efficiency

You may want to see also

The vacuum line helps maintain consistent fuel pressure

The vacuum line plays a crucial role in maintaining consistent fuel pressure, which is essential for optimal engine performance. By attaching a vacuum hose to the mechanical regulator, the vacuum or pressure acting on the regulator's diaphragm works in tandem with the mechanical spring. This interplay ensures that fuel pressure changes at a 1:1 ratio with manifold pressure. As a result, the fuel injector pressure delta, or the change across the injector, remains constant throughout the engine's operational range.

Additionally, the vacuum line aids in managing fuel pressure during engine acceleration. When the engine accelerates, fuel demand increases, and the intake manifold's vacuum decreases. The vacuum line, connected to the fuel pressure regulator, detects these conditions and responds accordingly. It closes the regulator, restricting fuel flow through the return line and increasing fuel pressure at the fuel rail. This, in turn, ensures that the injectors receive the necessary fuel supply to meet the engine's demands.

The vacuum line also comes into play when dealing with fuel injectors of different sizes. By utilising the vacuum line, smaller injectors can benefit from increased fuel pressure, enhancing their performance. Conversely, larger injectors may not require the vacuum line if their base pressure is sufficient to cover acceleration demands and sustained high-rpm operation.

In conclusion, the vacuum line is an essential component in maintaining consistent fuel pressure. It helps manage fuel flow, compensates for intake manifold vacuum, and ensures that the fuel injectors receive the required fuel supply under various engine conditions. By working in conjunction with the mechanical regulator, the vacuum line plays a vital role in optimising engine performance and ensuring a smooth and efficient fuel delivery system.

Who Manufactures AC Delco Fuel Pressure Regulators?

You may want to see also

The vacuum line is not always necessary

Another benefit of a non-manifold-referenced system is that it provides a relatively constant fuel pressure. While the fuel pressure does drop as fuel flow increases, this may not be detrimental to the overall performance of the engine. This type of system can be tuned to accommodate a near-constant change in fuel pressure, ensuring that the engine receives the necessary fuel supply without the need for a vacuum line.

Additionally, non-manifold-referenced systems allow for the use of in-tank pressure regulators. This is particularly useful for fuel pressure regulators that are mounted inside the fuel tank, as it is not possible to attach a vacuum line to these regulators due to their location. By eliminating the need for a vacuum line, this setup provides more flexibility in terms of regulator placement and design.

It is important to note that while a vacuum line is not always necessary, there are certain scenarios where it may be beneficial. For example, in forced induction applications, a fuel pressure increase may be required to maintain sufficient fuel flow. In such cases, a manifold-referenced system with a vacuum line can help ensure that the fuel injector receives the required fuel pressure.

Outlander Fuel Pressure Regulator: Performance and Efficiency

You may want to see also

The vacuum line is important for maintaining fuel efficiency

A fuel pressure regulator controls the upper limit of fuel pressure, ensuring that fuel injectors receive and dispense fuel at a known rate. The vacuum line attached to the fuel pressure regulator allows the vacuum or pressure acting on the regulator diaphragm and the mechanical spring to work together to change the fuel pressure. This, in turn, maintains a constant pressure across the outlet of the fuel injector.

When the engine is idling, the vacuum is high, and the fuel demand is low. The vacuum line assists in opening the valve, which lowers the fuel pressure at the rail by allowing more fuel to circulate back to the tank through the return line. This ensures that the engine doesn't receive too much fuel, which would be inefficient and could lead to issues such as flooding or vapor lock.

When the engine accelerates, fuel demand increases, and the intake manifold's vacuum is low. In this situation, the vacuum line is crucial for closing the fuel pressure regulator, which restricts the flow through the return line and increases fuel pressure at the fuel rail. This provides more fuel to the injectors, ensuring that the engine receives the necessary amount of fuel to meet the increased demand.

By maintaining the correct fuel pressure and ensuring the efficient delivery of fuel to the engine, the vacuum line plays a vital role in optimising fuel efficiency. It helps to prevent issues such as flooding and vapor lock, which can impact the engine's performance and fuel economy.

The Right Place for Your Fuel Pressure Regulator

You may want to see also

Frequently asked questions

This is an indication that your fuel pressure regulator is defective. The regulator is responsible for maintaining a steady fuel pressure within the fuel rail, but when it malfunctions, fuel can escape through the vacuum line.

If the fuel pressure regulator is not replaced, it can cause a momentary flooding condition and even vapor lock. This is because the leaking regulator causes a drop in fuel pressure, leading to fuel boiling into vapour instead of remaining liquid. As a result, your engine may experience extended crank times or refuse to start altogether.

The vacuum line helps maintain an equal pressure drop across the injectors, ensuring consistent fuel delivery. It connects the fuel pressure regulator to the intake manifold, allowing the vacuum to counterbalance the fuel pressure. As engine load and throttle position change, the intake manifold's vacuum also varies, which in turn adjusts the fuel pressure delivered to the injectors.

Removing the vacuum line may impact the performance and efficiency of your engine. Without the vacuum line, the fuel pressure may not adjust properly in response to changes in manifold vacuum. This can result in higher fuel pressure at idle and lower fuel pressure during acceleration, affecting the air-fuel mixture and engine combustion.