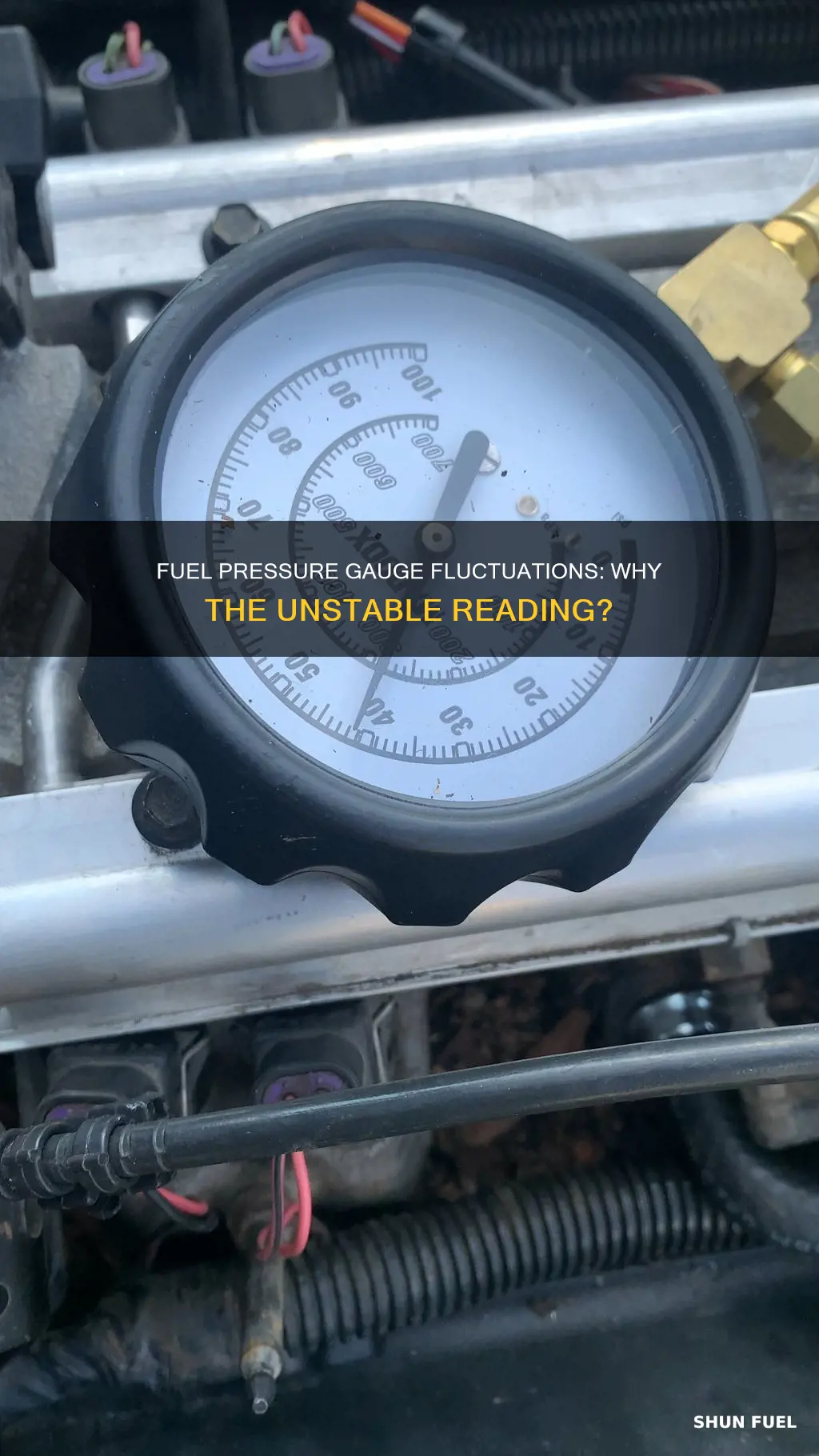

A bouncing fuel pressure gauge can be caused by a number of issues, including a faulty gauge, a faulty fuel pump, or a vacuum leak. In some cases, the issue may be with the vehicle's fuel system, such as a blockage or a leak. Other potential causes include problems with the regulator or the fuel filter. It is also possible that the gauge is not liquid-filled, which can lead to discrepancies in the readings. Checking for leaks, verifying the fuel pump's voltage, and ensuring proper grounding are some initial steps that can be taken to diagnose the issue. Consulting with automotive experts or seeking professional assistance may be necessary to identify and resolve the specific problem causing the fuel pressure gauge to bounce.

What You'll Learn

A faulty gauge

The sending unit, located inside the fuel tank, plays a crucial role in measuring fuel levels. It consists of a floating block attached to a potentiometer, which changes the electrical circuit's resistance based on its position relative to the fuel level. This, in turn, sends a signal to the fuel gauge, determining where the needle should be. Over time, the sending unit can wear out, causing the gauge to bounce as the angle of the car changes or the fuel sloshes around.

In some cases, the issue may lie with the fuel gauge itself, which can develop problems that result in inaccurate readings. Replacing either the sending unit or the fuel gauge, or both, is often the solution to erratic fuel level readings. However, these repairs can be costly, leading many people to postpone them until the gauge becomes completely unreliable.

It is worth noting that fuel gauge issues may also arise from problems with the fuel pump, regulator, or other components in the fuel system. Therefore, it is essential to conduct a thorough diagnosis to identify the root cause of the issue and take appropriate remedial measures.

Understanding Fuel Pressure in the 2000 Toyota RAV4

You may want to see also

A faulty fuel pump

In some cases, the fuel pump may be delivering fuel in a pulsing manner, which can be normal for certain mechanical pumps. However, if the pulsing is causing the needle on the fuel pressure gauge to bounce excessively, it may indicate an issue with the pump's performance.

One possible cause of a faulty fuel pump is cavitation, which can occur when there is excessive pump capacity relative to the system's requirements. This can be addressed by using a pump controller to reduce the voltage to the pump, thereby decreasing its capacity and reducing cavitation.

Another potential issue could be a blockage or restriction in the fuel line, causing the pump to work harder to deliver the required fuel pressure. This can result in pulsating fuel flow and, consequently, an erratic fuel pressure gauge reading.

Additionally, a faulty fuel pump may be due to internal damage or wear, which can affect its performance and cause fluctuations in fuel delivery. This could be caused by various factors, such as contamination, excessive heat, or simply the age of the pump.

To diagnose a faulty fuel pump accurately, it is essential to perform a thorough inspection of the entire fuel system, including the fuel lines, filters, and the pump itself. Consulting with a professional mechanic who specializes in fuel systems can also provide valuable insights and guidance in identifying and rectifying the issue.

Fuel Pressure Requirements for a 1998 Chevy 2500

You may want to see also

Vacuum leaks

A fuel pressure gauge that bounces around could be indicative of a vacuum leak. Vacuum gauges are valuable tools for mechanics, and a bouncing needle could indicate several issues.

One potential cause of a bouncing fuel pressure gauge is an uneven mixture of air and fuel. This can be caused by a vacuum leak, which can affect the air pressure in the engine. Other potential causes of a bouncing fuel pressure gauge include irregular ignition timing, improperly set valves, or a manifold leak close to one or two cylinders.

If you suspect a vacuum leak, there are several steps you can take to diagnose and address the issue:

- Connect your vacuum gauge to a manifold vacuum tap, not a ported vacuum.

- Run the engine at low cruise (1800-2200 rpm), high cruise, and idle (2500-3000 rpm). Keep track of the vacuum readings and any changes for each speed.

- Read the gauge while maintaining an engine speed of approximately 2500 rpm for 15 seconds.

- Release the throttle and observe the gauge as the speed decreases.

- As the throttle shuts, the vacuum meter should increase before falling to its typical idle value.

- Compare your readings to the normal vacuum gauge readings for your specific engine and altitude.

- If you suspect a vacuum leak, you can perform a smoke test to check for leaks in the intake manifold or other vacuum lines.

- If you identify any leaks, repair or replace the affected components.

By following these steps, you can diagnose and address vacuum leaks that may be causing your fuel pressure gauge to bounce.

Fuel Pressure Test: What Your Car Needs to Tell You

You may want to see also

A loose rocker nut

- Identify the source: Start by locating the loose rocker nut. It is usually found on the valve train, specifically the #1 exhaust valve. In some cases, it may be necessary to remove custom valve covers to access the area.

- Access the rocker nut: Before attempting any adjustments, ensure the engine is cool. This will make it safer to work on and prevent any potential damage caused by high temperatures.

- Tighten the rocker nut: Once you have accessed the rocker nut, use the appropriate tool to tighten it securely. It is important to torque it to the specified standard to ensure it doesn't come loose again.

- Check for other issues: In some cases, a loose rocker nut may indicate underlying issues with the valve train or engine. It is recommended to inspect the area for any signs of damage or wear. If any problems are identified, address them accordingly.

- Test the fuel pressure: After tightening the rocker nut, start the engine and observe the fuel pressure gauge. Ensure that the needle is steady and no longer bouncing. If the issue persists, there may be other factors contributing to the problem.

- Regular maintenance: To prevent future issues, regular maintenance is key. This includes checking the torque on all rocker nuts and ensuring that they are secure. Additionally, keep an eye out for any unusual noises or performance issues that may indicate a loose rocker nut or other engine problems.

By following these steps, you can address a loose rocker nut and potentially resolve the issue of a bouncing fuel pressure gauge. It is important to be methodical and thorough when working on engine components to ensure the issue is properly diagnosed and resolved.

Fuel Pressure Requirements for 1996 Jeep Cherokee

You may want to see also

A faulty regulator diaphragm

To diagnose a faulty regulator diaphragm, you can perform a visual inspection of the vacuum line and regulator for any signs of wear or deterioration. You can also check for any gasoline drip coming from the regulator or vacuum line. If you observe any gasoline in the regulator or vacuum line, it is likely that the diaphragm is faulty and the regulator needs to be replaced.

Another way to test for a faulty regulator diaphragm is to use a manual vacuum pump and a fuel pressure gauge. Connect the vacuum pump and fuel pressure gauge to the regulator and start the engine. Apply vacuum pressure and watch the fuel gauge while increasing the vacuum. The fuel pressure should drop as you increase the vacuum. Release the vacuum and observe if the pressure goes up and stays up. Compare all fuel pressure readings with the OEM literature. If the regulator is faulty, you will need to replace it.

It is important to note that a faulty regulator diaphragm is just one potential cause of a bouncing fuel pressure gauge. Other factors, such as pump cavitation or incorrect plumbing of the regulator return, may also be contributing to the issue.

Finding the Fuel Pressure Regulator in a 2010 Cadillac SRX

You may want to see also

Frequently asked questions

The fuel pressure gauge could be bouncing around due to a faulty gauge, a pump cavitation, or a regulator issue. It is recommended to check the ground-side resistance and voltage drop from the battery to the pump.

The issue could be due to a faulty gauge, a problem with the regulator, or a leak in the fuel system. It is also important to ensure that the fuel lines are properly routed and secured, as loose or damaged fuel lines can cause fluctuations in pressure.

To stabilise the fuel pressure gauge, one can consider using a liquid-filled gauge, which tends to provide more stable readings. Additionally, ensuring that the fuel lines are securely fastened and routed away from the exhaust can help mitigate the issue. In some cases, it may be necessary to replace the fuel pump, regulator, or the entire fuel system.