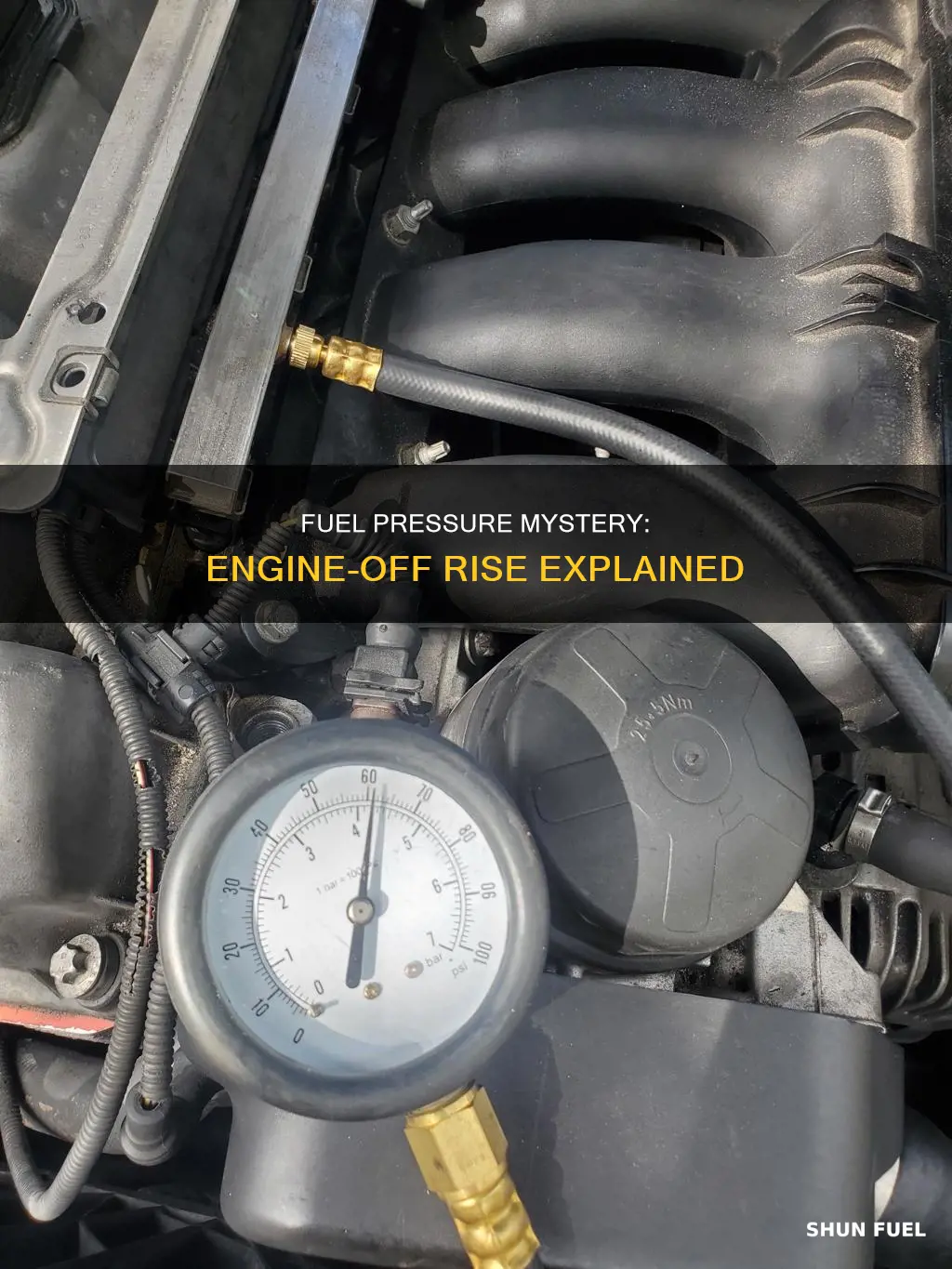

Fuel pressure can rise when the engine is off due to a variety of factors, including the design of the fuel system, the condition of the fuel pump, and potential leaks or blockages in the fuel lines.

In a returnless fuel system, for example, fuel pressure may drop when the engine is turned off as the pressure reverses against the pump and back into the fuel tank. This can be influenced by the strength of the check valves in the fuel pump, with weaker valves potentially leading to a greater drop in pressure.

Additionally, the fuel pressure regulator, which is responsible for maintaining the correct fuel pressure, may develop faults or leaks, leading to fluctuations in fuel pressure. A faulty fuel pump or restrictions in the fuel lines can also contribute to inconsistent fuel pressure, particularly under high engine load or speeds.

It is important to note that fuel pressure should remain within a specific range, typically between 34-57 psi, depending on the engine type. Deviations from this range may indicate issues with the fuel system that require further investigation and potential repairs.

What You'll Learn

Fuel pressure regulator malfunction

A fuel pressure regulator malfunction can lead to a host of issues, including:

- Engine performance problems: A faulty regulator can cause a loss of fuel pressure, resulting in hard-starting, rough running, stalling, and a lack of power.

- Check Engine Light: The engine computer detects issues, including those caused by a faulty regulator, which triggers the check engine light and stores a corresponding diagnostic trouble code.

- Black smoke from the tailpipe: A faulty regulator can cause the engine to run rich, leading to black smoke emissions from the tailpipe.

- Fuel in the vacuum line: A ruptured diaphragm in the regulator can cause fuel to be drawn into the vacuum line and the engine's intake manifold, resulting in a rich running condition.

- Engine won't start: A faulty regulator can prevent the engine from receiving proper fuel pressure, resulting in a vehicle that cranks but doesn't start.

- Excessive fuel pump noise: While the fuel pump normally makes a humming sound, a faulty regulator can make the noise irritating and excessive, especially during traffic jams or when the engine is under stress.

- Fuel leaks: A faulty regulator can cause fuel leaks from the tailpipe or vacuum hose, leading to reduced engine performance and potential safety hazards.

- Engine misfires and poor acceleration: A faulty regulator can interrupt the vehicle's fuel pressure, causing the air-fuel ratio to be thrown off, resulting in engine misfires and decreased power, acceleration, and fuel efficiency.

- Fuel smell: Leaking fuel from a faulty regulator can result in a noticeable fuel smell.

- Increased fuel costs: A malfunctioning regulator can lead to inefficient fuel usage, resulting in more frequent fill-ups and higher fuel expenses.

- Safety hazards: In addition to fuel leaks, a faulty regulator can cause engine backfires and sudden loss of power, creating dangerous driving conditions.

Understanding Fuel Pressure Regulator Control Limits Exceeded

You may want to see also

Fuel pump malfunction

A fuel pump malfunction can cause a rise in fuel pressure when the engine is off. This can be due to several factors, including wear and tear, electrical issues, or lack of maintenance.

Wear and Tear

Fuel pumps have a lifespan and can wear out over time with continuous use. This can lead to decreased efficiency and eventual failure. The average fuel pump is built to last between 100,000 and 200,000 miles, but regular maintenance and the use of quality fuel can prolong its life.

Electrical Issues

Faulty wiring, corroded connections, or blown fuses can disrupt the power supply to the pump, causing it to malfunction or stop working. It is important to check the pump's electrical connections and relay if other issues are ruled out.

Lack of Maintenance

Lack of oil changes and using engine oil that does not meet OE specifications can lead to premature wear between the camshaft lobes and the high-pressure pump follower. This prevents the pump from generating enough piston movement, resulting in lower fuel pressure.

Contaminated Fuel

Dirt, debris, or water in the fuel can damage the pump over time by increasing friction and causing premature wear of the pump components. Regular fuel filter changes can prevent contaminants from entering the pump and preserve its efficiency.

Overheating

Running a vehicle on low fuel can cause the pump to overheat as the fuel acts as a coolant for the pump. Consistently low fuel levels can lead to increased temperatures and reduce the pump's lifespan.

It is important to address fuel pump issues promptly to ensure vehicle safety and performance. A malfunctioning pump can cause the engine to sputter or stall, especially at high speeds, and may lead to broader engine damage if left unattended.

Fuel Injector Pressure: 2003 Dodge Dakota's Stock Performance

You may want to see also

Fuel injector issues

Fuel injectors are an essential part of a car's fuel system. They spray fuel into the engine as a fine mist, which mixes with air and then enters the cylinder. When fuel injectors are not working properly, it can cause a range of issues with the car's performance and fuel efficiency. Here are some common problems caused by faulty fuel injectors:

- Engine Misfires: Dirty or faulty fuel injectors can cause the engine to misfire, making the motor feel like it is sputtering and sending vibrations through the car. This happens when the delicate balance between fuel and air entering the engine is disrupted.

- Rough Idling: If your vehicle sputters and shakes when you're at a stop or in traffic, it may be due to issues with the fuel injectors. Rough idling is often characterised by varying RPMs even when your foot is off the accelerator.

- Poor Fuel Economy: Well-functioning fuel injectors help your vehicle achieve optimal fuel efficiency. If your car is consuming more fuel than usual, it could be a sign of fuel injector problems.

- Unstable RPM Needle: Dirty fuel injectors can cause the needle on the tachometer to move erratically, indicating changes in RPM when the car is not switching gears.

- Engine Won't Start: In rare cases, fuel injector issues can lead to engine failure and prevent your car from starting. This is usually due to a lack of fuel reaching the engine, disrupting the air-fuel ratio required for combustion.

- Check Engine Light: The check engine light on your dashboard could be illuminated for various reasons, one of which is a problem with the fuel injector. This warning light indicates that the injector may be dirty or malfunctioning, leading to an insufficient or excessive supply of fuel to the engine.

- Fuel Leak: Over time, fuel injectors may develop cracks in their rubber seals or the injector itself, resulting in a fuel leak. If you notice any traces of fuel on the injector or fuel rail, it's important to address the issue promptly.

- Failed Emissions Test: Fuel injector problems can lead to increased emissions if the air-fuel mixture is too rich or burns irregularly. This can damage the catalytic converter and cause your car to fail emissions tests.

To prevent and resolve these issues, regular cleaning and maintenance of fuel injectors are crucial. It is recommended to clean your fuel injectors every 30,000 miles or as needed. Additionally, keep an eye out for any signs of fuel leaks or unusual odours, as these could be indicators of fuel injector problems.

Understanding High-Pressure Fuel Systems: Performance and Safety

You may want to see also

Vacuum line issues

A vacuum line issue can cause a rise in fuel pressure when the engine is off. The vacuum line is connected to the fuel pressure regulator, which is responsible for maintaining the correct fuel pressure in the engine. If the vacuum line is disconnected or damaged, it can affect the performance of the fuel pressure regulator and cause an increase in fuel pressure.

In some cases, a broken vacuum line may not cause any noticeable difference in the performance of the vehicle. However, it is important to address any vacuum line issues to ensure the fuel pressure regulator can function correctly.

One way to diagnose a vacuum line issue is to observe the engine's behaviour when the vacuum line is disconnected or plugged. If there is no change in engine performance, it may indicate an issue with the vacuum line or the fuel pressure regulator itself. It is also possible to use a vacuum gauge to test for vacuum at the fuel pressure regulator port. If there is no vacuum present, it could be due to a blockage or leak in the vacuum line.

It is important to note that vacuum lines are typically made of rubber or silicone and can become perished or damaged over time. Regular inspection and maintenance of vacuum lines are essential to ensure the proper functioning of the fuel system and engine.

Fuel Pressure Maintenance for a 2001 Dakota

You may want to see also

Fuel filter issues

Fuel filters are a critical component of a vehicle's fuel supply system. They trap dirt, rust, scale, and other impurities to prevent them from entering the fuel pump, fuel injectors, and engine. However, when fuel filters become clogged, they can cause a range of issues, including:

Poor Engine Performance

A clogged fuel filter may cause the engine to hesitate, surge, or sputter, especially under heavy loads or when accelerating up a steep incline. This is because the obstructed flow of fuel through the filter is insufficient to meet the engine's demands. The engine may also shake or stutter at different speeds due to erratic fuel flow caused by a partially clogged filter.

Engine Hesitation and Hard Starting

A clogged fuel filter can make it difficult to start the engine, requiring extended cranking. Once started, the engine may hesitate or stumble, also known as "bucking," which can be dangerous when making quick driving decisions.

Engine Stalling

A clogged fuel filter may allow just enough fuel to start the engine but not enough for acceleration and cruising, leading to stalling while driving. As the clog worsens, stalling becomes more frequent and severe, indicating the filter is close to becoming completely blocked.

Random Misfire or Rough Idle

Low fuel pressure caused by a clogged fuel filter can result in a lean fuel condition, leading to engine misfires, poor fuel mileage, and rough idling. The check engine light may also illuminate due to various trouble codes related to a lean running condition or mass air flow sensor fault.

Fuel System Part Failures

A restricted fuel filter increases the load on the fuel pump as it tries to compensate for the reduced fuel flow. This can lead to premature fuel pump failure, noisy operation, or damage. Additionally, contaminants that bypass a dirty fuel filter can damage, clog, or cause fuel injectors to leak, resulting in further engine drivability problems.

Fuel Pressure Maintenance for Nissan Frontier Owners

You may want to see also

Frequently asked questions

Fuel pressure rises when the engine is off because the heat that was being dissipated by the coolant circulation suddenly stops. The remaining heat is left standing and any closed system's pressure will rise until convection and radiation and gravity flow cooling takes place.

You can check your fuel pressure using a fuel pressure gauge. Turn the ignition key to "run" (engine off). The pressure should rise to about 34 psi to 38 psi for 1984-1985 N/A engines, 13.5 psi to 15.5 psi for 1986 and up N/A engines, or 53 psi to 57 psi for turbo engines.

If your fuel pressure is rising when the engine is off, there may be a leaking fuel injector, a bad fuel pressure regulator, or a bad check valve on the fuel pump.